Superconductive magnetic separating device

A separation device and superconducting magnet technology, which are applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low processing capacity of the separator, easy blockage, and inability to use solenoid superconducting magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples, so as to help to understand the content of the present invention.

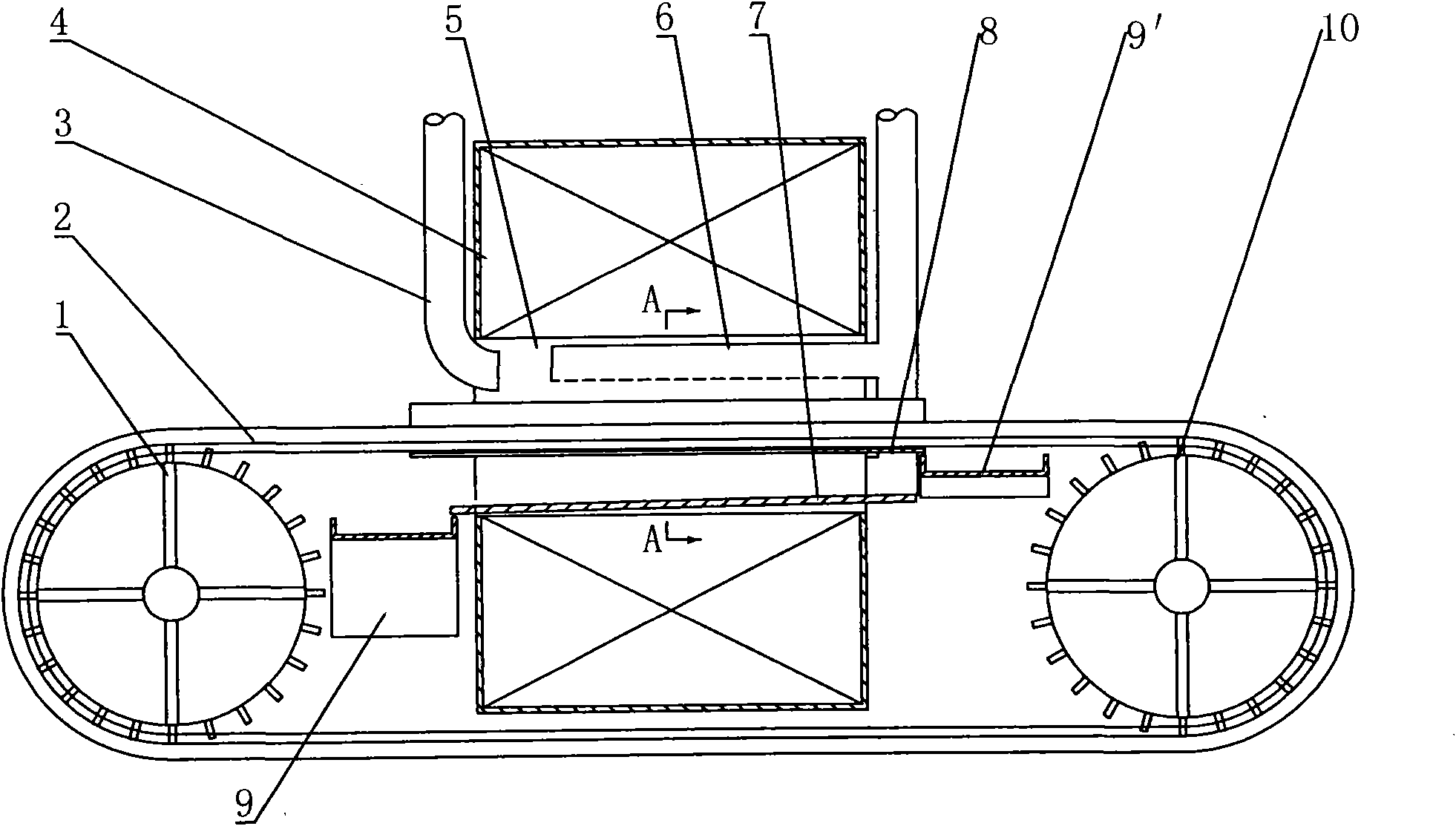

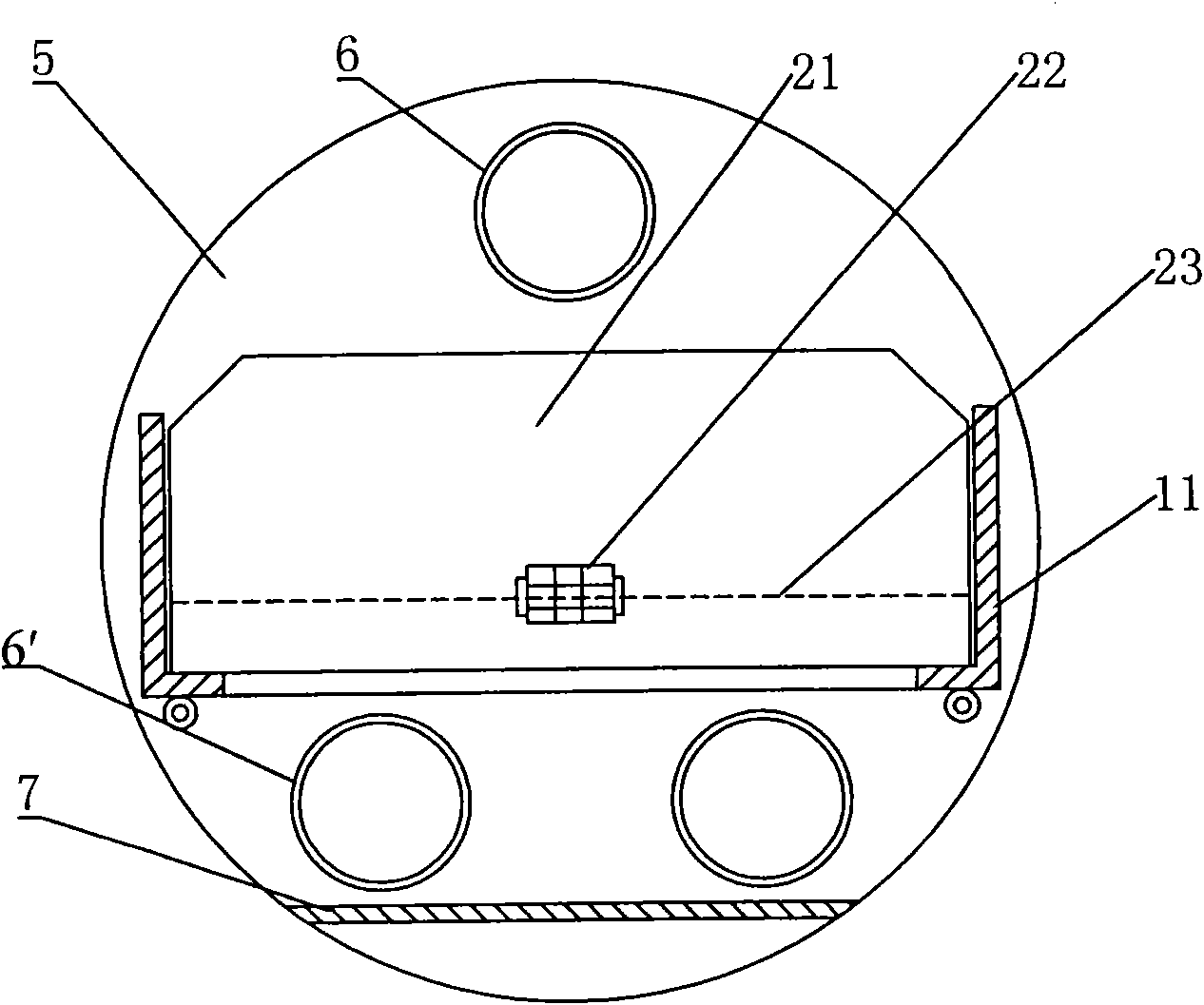

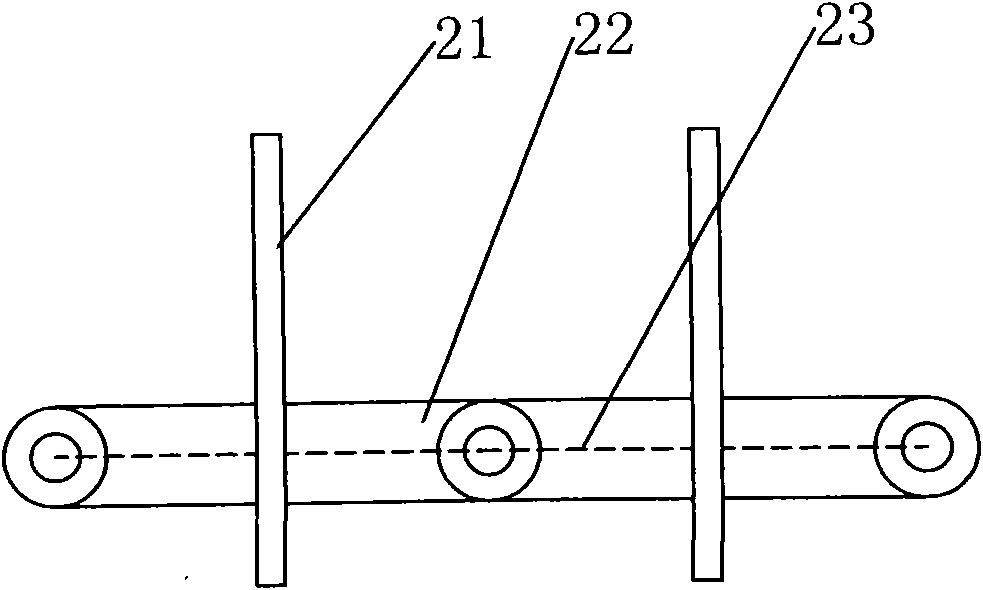

[0033] Such as figure 1 Shown is a superconducting magnetic separation device, including:

[0034] Solenoid-type superconducting magnet 4 The present invention adopts a solenoid-type superconducting magnet. In its aperture at room temperature, the magnetic field intensity is basically uniform on the axis, and the magnetic field in some selected areas is generally 4-6T. The wire tube winding is cooled by liquid helium (temperature is 4.2K), and the periphery of the superconducting winding is surrounded by a high vacuum layer, a 40K thermal barrier layer and 1 to 2 sets of multilayer insulation layers, and a 4K refrigerator is used to maintain the liquid helium. This kind of superconducting magnet has a magnetic field of 4-6T in the separation area in the hole at room temperature, and the magnetic susceptibility c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com