Beneficiation method of micro-fine particle graphite ores for producing high-carbon graphite

A beneficiation method and graphite ore technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems such as difficulty in producing high-carbon graphite concentrates, achieve good collection and selectivity, eliminate The effect of improving the recovery rate of inclusions and graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

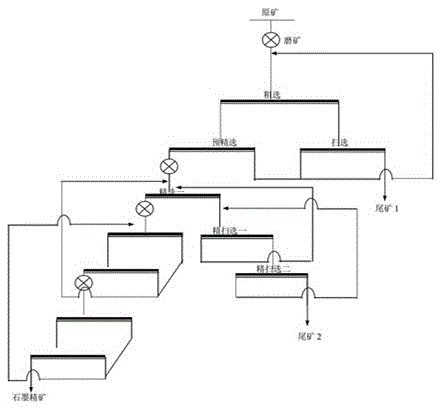

Image

Examples

Embodiment 1

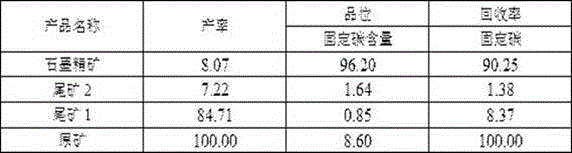

[0030] A certain domestic fine-grained flake graphite mine, according to the test data, shows that the fixed carbon content in the raw ore is 8.50%, which is a low-grade fine flake graphite mine. The graphite in the ore is mainly produced in the form of flakes and small plates, with 90% graphite The particle size of the mineral intercalation is below 10μm, and it is difficult for graphite to dissociate completely. Because the particle size of the graphite intercalation is very fine, and the gangue mineral feldspar is strongly altered, fine hematite, mica and graphite flakes are intertwined. At the same time, it makes the beneficiation of the graphite ore very difficult, and the conventional beneficiation process cannot produce high-purity graphite concentrate products.

[0031] The raw ore is first crushed and ground to -0.074mm accounting for 72%, and the slurry is stirred until the slurry concentration is 35% and the pH is 7.2. After re-adjusting the slurry, the slurry enters t...

Embodiment 2

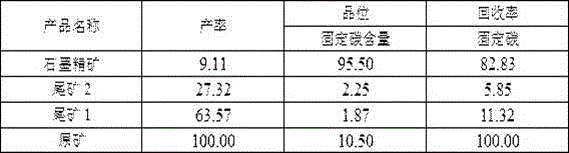

[0036] A fine-scale cryptocrystalline graphite mine in Henan Province, according to analysis, the fixed carbon content in the ore is 10.5%, which belongs to the fine-scale cryptocrystalline graphite ore. The graphite embedded in the raw ore has a very fine particle size, graphite flakes, quartz, mica and other veins Stone minerals are intertwined and grow together, making the graphite ore beneficiation very difficult. The ore can only produce graphite concentrate with a fixed carbon content of about 85% using conventional beneficiation technology.

[0037] The raw ore is first crushed and ground to -0.074mm accounting for 80%, stirred and adjusted to a slurry concentration of 32%, pH is 7.5, and the slurry enters the flotation operation after re-adjustment. The flotation operation is a roughing, a sweeping and a pre-finishing selected. For rough separation operation, first add 500g / t collector, stir for 2min, and flotation time is 8min; add 150g / t collector for the first sweepin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com