Production method of high-magnetic-induction-orientated silicon steel with low inclusion defect rate

A technology of high magnetic induction orientation and production method, applied in the direction of manufacturing converters, etc., can solve the problems of waste, high viscosity of molten steel, low material rate, etc., and achieve the effects of saving cost, reducing waste and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for producing grain-oriented silicon steel with low inclusion defect rate and high magnetic induction, comprising the following steps:

[0050] 1) Smelting

[0051] a) Smelting a can of SL type HGO, the chemical composition is calculated by weight percentage:

[0052] C 0.05%, Si 3.3%, Mn 0.12%, S 0.005%, Als 0.028%, N 0.007%, Cu 0.2%, Sn 0.06%;

[0053] b) Argon blowing in the whole process of converter smelting, control end point after converter furnace: C 0.035%, P 0.008%, S 0.004%;

[0054] c) The basicity of the slag in the blowing process is 3.2; the thickness of the slag is 70 mm, and the slag is blocked after tapping, and no converter slag is lowered into the ladle;

[0055] d) fine-tuning the composition in the RH refining furnace to obtain the chemical composition of the SL-type HGO described in the above step a;

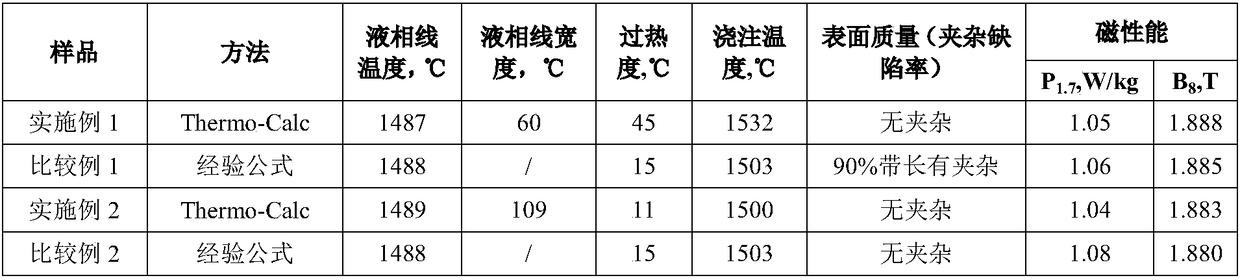

[0056] e) Using Thermo-Cal software to calculate the liquidus width of the SL-type HGO described in step a is 60°C, from 1487°C to 1427°C...

Embodiment 2

[0068] A method for producing grain-oriented silicon steel with low inclusion defect rate and high magnetic induction, comprising the following steps:

[0069] 1) Smelting

[0070] a) Smelting a can of HiB type HGO, the chemical composition is calculated by weight percentage:

[0071] C 0.055%, Si 3.2%, Mn 0.08%, P 0.010%, S 0.023%, Als 0.022%, N0.008%;

[0072] b) Argon blowing in the whole process of converter smelting, control end point after converter furnace: C 0.03%, P 0.01%, S 0.005%;

[0073] c) The basicity of the slag in the blowing process is 3.2; the thickness of the slag is 60 mm, and the slag is blocked at the end of tapping, and no converter slag is lowered into the ladle;

[0074] d) fine-tuning the composition in the RH refining furnace to obtain the HiB-type HGO chemical composition described in the above step a;

[0075] e) Using Thermo-Cal software to calculate the liquidus width of the HiB-type HGO described in step a is 109°C, from 1489°C to 1380°C.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com