Wire rod for steel cord and its Al2O3 inclusion control method

A steel wire rod and cord technology, applied in the field of high-carbon steel wire rod and its refining process, can solve the problems of wire rod breakage, micro-cracks, unfavorable drawing performance of high-carbon steel wire rod, etc., and reduce the broken wire rate , Eliminate the effect of inclusion

Active Publication Date: 2013-03-06

ANGANG STEEL CO LTD

View PDF7 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Such inclusions are not deformed at the same time as the matrix during the processing of the wire rod, and microcracks are likely to occur between the inclusions and the matrix, resulting in wire rod breakage, which is extremely unfavorable to the drawability of high carbon steel wire rods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

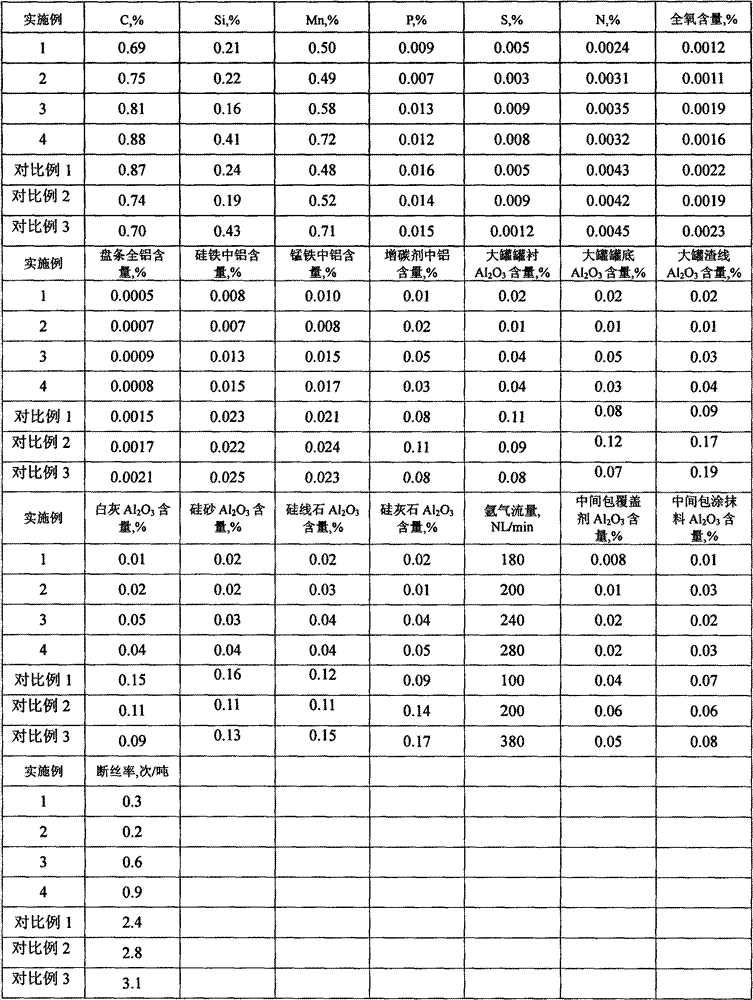

[0011] Several specific embodiments of the present invention are introduced below: the composition and inclusion composition of the high-carbon steel wire rod involved in the present invention are shown in the following table.

[0012]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wire rod for steel cord and its Al2O3 inclusion control method. The wire rod for steel cord comprises 0.68-0.89wt% of C, 0.1-1.0wt% of Si, 0.35-0.80wt% of Mn, 0.015wt% or less of P, 0.010wt% or less of S, 0.004wt% or less of N, 0.002% or less of total oxygen, 0.0010wt% or less of total aluminum, and the balance Fe and inevitable impurities. The Al2O3 inclusion control method comprises the following steps: allowing the content of Si-Fe and Mn-Fe-Al used after converting to be not greater than 0.02% and the content of Al in a carburant to be not greater than 0.05%; allowing the content of Al2O3 in a refractory material at the pot liner, the pot bottom and the slag line of a large pot to be not greater than 0.05% in the refining process and the content of Al2O3 in lime, silica sand, sillimanite and wollastonite slagging materials to be not greater than 0.05%; allowing the large pot used in the molten steel refining to be special; completing the final deoxidation and component micro-adjustment of the wire rod for steel cord within 15min before the ending of an LF furnace refining; carrying out argon stirring treatment of the molten steel, wherein the argon flow is 150-350NL / min; and allowing the content of Al2O3 in a tundish covering agent to be not greater than 0.03% and the content of Al2O3 in a tundish coating to be not greater than 0.04% in the continuous casting process. The Al content in the wire rod for steel cord is not greater than 0.001% in the invention, so the Al2O3 inclusion in the wire rod is eliminated, and the fracture rate of the wire rod in the drawing process is reduced.

Description

technical field [0001] The invention relates to a high carbon steel wire rod and its refining process, especially a cord steel wire rod and its Al 2 o 3 inclusion control methods, Background technique [0002] With the development of the automobile industry, the demand for high-carbon steel wire rods for steel cords continues to increase. In 2010, the demand for such high-carbon steel wire rods reached 1 million tons. In order to reduce costs and obtain more profits in the fierce market competition, users have higher and higher requirements for the processing performance of wire rods in the production process. [0003] The patent No. CA2058470 provides a chemical composition of a high-strength wire rod for silk production. The weight percentage of the chemical composition of the wire rod is C 0.85%-1.2%, Si<0.45%, Mn0.3%-1.0%, Ni 0.1%-4%, Co 0.05%-4%, Al≤0.005%, N≤0.005% , P≤0.02%, S≤0.015%. [0004] The Japanese patent No. JP60152659 provides a wire rod with excelle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/06C21C7/00C21C7/06

Inventor 郭大勇任玉辉臧绍双王长顺王秉喜薛军高航

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com