Submersed nozzle lining material lowering wire fracture rate in silicon killed steel processing process

A technology of processing and silicon deoxidized steel, applied in the field of refractory materials, can solve the problems of reducing the broken wire rate, achieve the effects of reducing the broken wire rate, good thermal shock resistance, and reducing high alumina inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

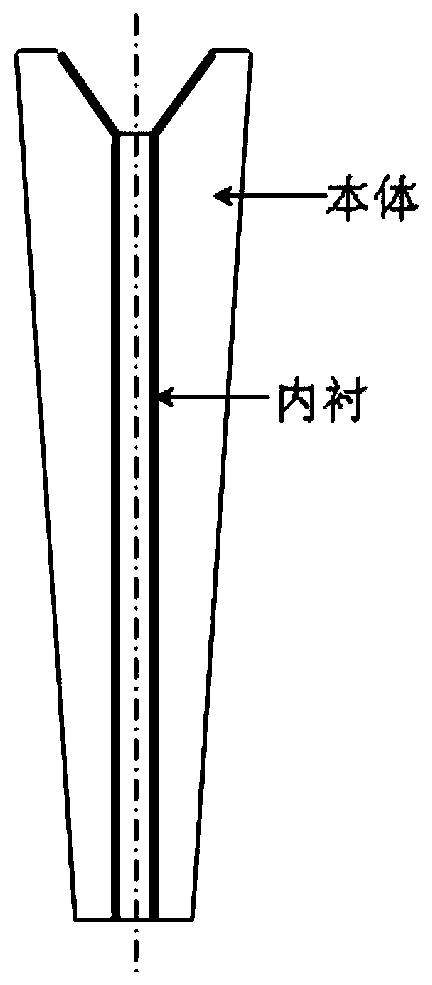

[0018] A submerged nozzle lining material for reducing wire breakage rate in silicon-deoxidized steel processing, which is made by mixing raw materials according to the following weight percentages: 55% magnesium oxide, 30% quartz sand, 5% graphite, and 10% phenolic resin as a binding agent. The particle size of magnesium oxide is 0.1mm-1.0mm, the particle size of quartz sand is 0.5-2.0mm, and the lining thickness is 8mm.

Embodiment 2

[0020] A submerged nozzle lining material for reducing wire breakage rate in silicon-deoxidized steel processing, which is made by mixing raw materials in the following percentages by weight: magnesia 60%, quartz sand 25%, graphite 10%, plus 5% phenolic resin as a binding agent. The particle size of magnesium oxide is 0.1mm-1.0mm, the particle size of quartz sand is 0.5-2.0mm, and the lining thickness is 5mm.

Embodiment 3

[0022] A submerged nozzle lining material that reduces the wire breakage rate during the processing of silicon-deoxidized steel. It is made by mixing the following raw materials in weight percentages: 58% magnesium oxide, 28% quartz sand, 8% graphite, and 6% phenolic resin as a binding agent. The particle size of magnesium oxide is 0.1mm-1.0mm, the particle size of quartz sand is 0.5-2.0mm, and the lining thickness is 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com