Copper-nickel 19 metal wire and preparation method thereof

A metal wire, copper-nickel technology, which is applied in the field of copper-nickel 19 metal wire and its preparation, can solve the problems such as unsatisfactory various properties, achieve the effect of reducing burrs, reducing wire breakage rate, and meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

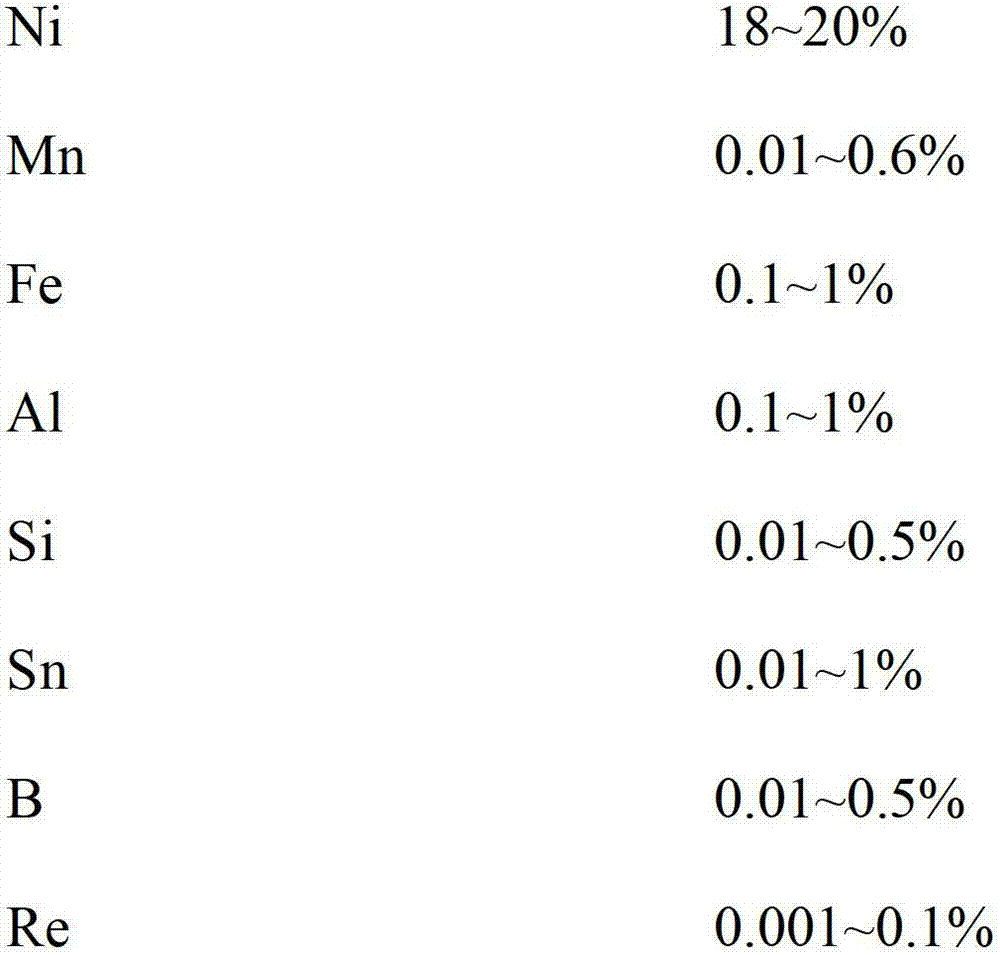

[0045] Copper nickel 19 wire consists of 18% Ni, 0.6% Mn, 1% Fe, 0.1% Al, 0.5% Si, 0.01% Sn, 0.01% B, 0.001% Re, and 79.779% Copper composition.

[0046] Copper Nickel 19 wire was prepared by the following method:

[0047] (1) Mix and melt the raw materials, peel and forge the obtained ingot;

[0048] (2) After drawing the forged billet to obtain a filament with a diameter of 4.0mm, draw it again to obtain a filament with a diameter of 1.0mm, then anneal it, draw it again to obtain a filament with a diameter of 0.3mm, anneal it, and draw it again The filaments with a diameter of 0.15 mm are pulled out and then annealed to finally obtain filaments with a diameter of 0.15 mm.

Embodiment 2

[0050] Copper nickel 19 wire is made of 20% Ni, 0.01% Mn, 0.1% Fe, 1% Al, 0.01% Si, 1% Sn, 0.5% B, 0.1% Re, and 77.28% Copper composition.

[0051] Copper Nickel 19 wire was prepared by the following method:

[0052] (1) Mix and melt the raw materials, peel and forge the obtained ingot;

[0053] (2) After drawing the forged billet to obtain a filament with a diameter of 8.0mm, draw it again to obtain a filament with a diameter of 6.0mm, then anneal, repeat drawing and annealing 6 times, and finally obtain a filament with a diameter of 0.05mm .

Embodiment 3

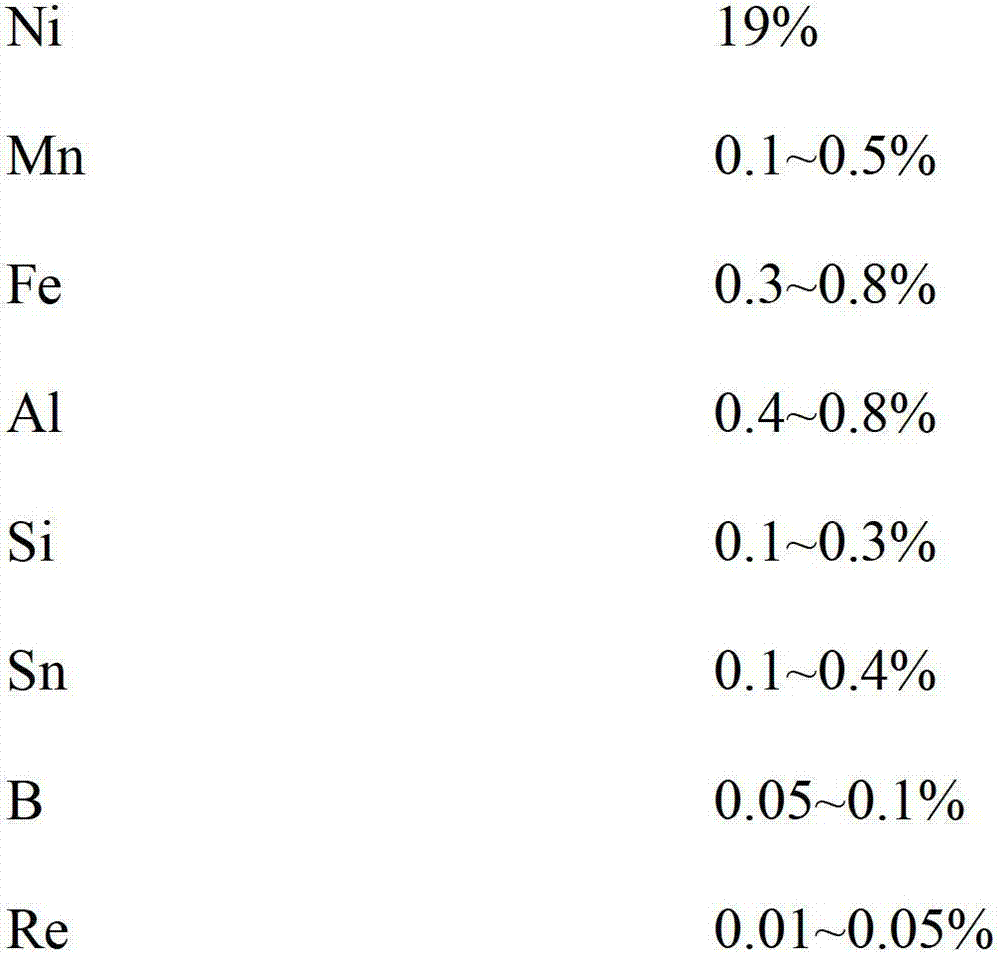

[0055] Copper nickel 19 wire is made of 19% Ni, 0.1% Mn, 0.6% Fe, 0.2% Al, 0.01% Si, 0.08% Sn, 0.06% B, 0.003% Re, 0.02% Ce , and 79.927% copper composition.

[0056] Copper Nickel 19 wire was prepared by the following method:

[0057] (1) Mix and melt the raw materials, peel and forge the obtained ingot;

[0058] (2) After drawing the forged billet to obtain a filament with a diameter of 6.0mm, draw it again to obtain a filament with a diameter of 4.0mm, then anneal, repeat drawing and annealing 3 times, and finally obtain a filament with a diameter of 0.1mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com