High-abrasion-resistant sizing agent formula of ultrathin electronic-grade glass fiber cloth and method of high-abrasion-resistant sizing agent formula

A technology of glass fiber cloth and high wear resistance, which is applied in fiber processing, textiles and papermaking, etc. It can solve the problems of poor wear resistance, many broken yarns, and poor sizing uniformity of ultra-fine electronic yarn, so as to improve wear resistance, Helps in processing and reduces the rate of broken wires and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

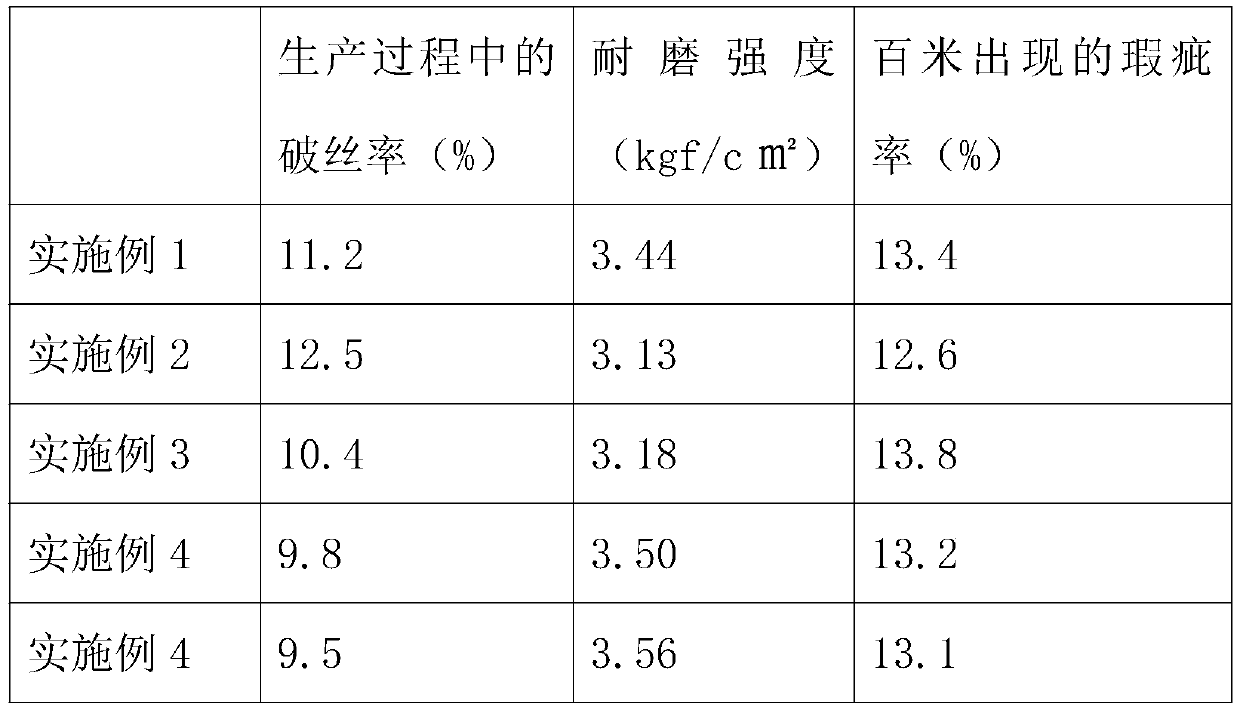

Examples

Embodiment 1

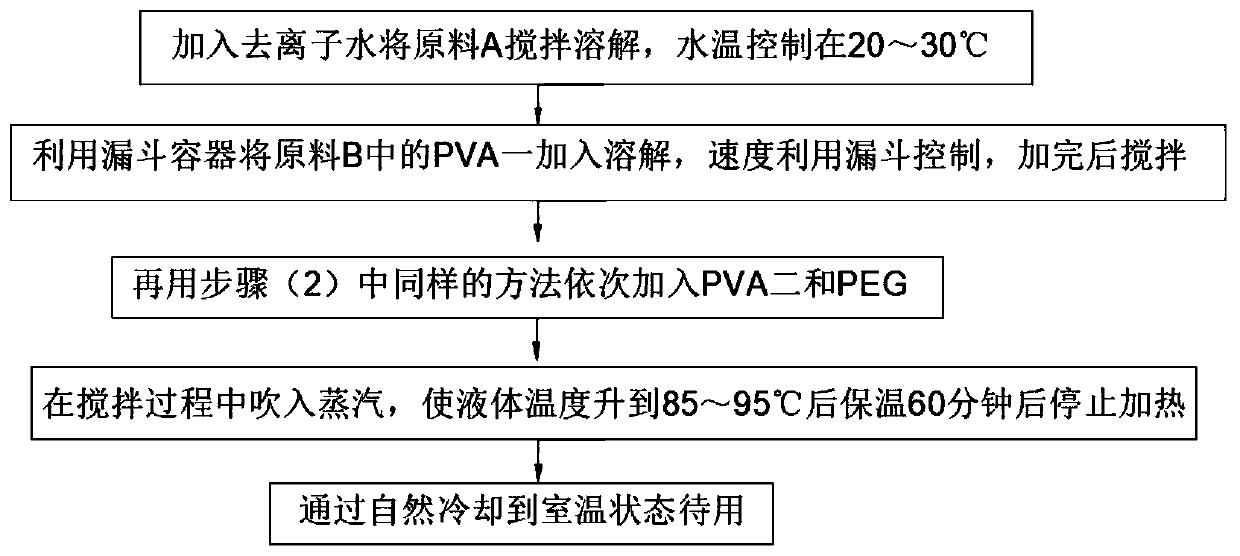

[0027] Such as figure 1 As shown, a formula and method of an ultra-thin electronic grade glass fiber cloth high wear resistance slurry is prepared from the following raw materials in parts by weight: raw material A: 2 parts of polyoxymethylene, 1 part of graphite, defoamer 1 part, 15 parts of main slurry starch, 2 parts of binder, 1 part of surfactant; raw material B: 3 parts of PVA-1, 4 parts of PVA-2, 2 parts of PEG and 50 parts of deionized water.

[0028] In the raw material B, PVA 1 is polyvinyl alcohol with a content of 4%, PVA 2 is polyvinyl alcohol with a content of 1%, and PEG is polyethylene glycol with a content of 1%.

[0029] A preparation method of ultra-thin electronic grade glass fiber cloth high wear resistance slurry formula,

[0030] The specific steps are as follows:

[0031] (1) Add deionized water to stir and dissolve raw material A, and control the water temperature at 25°C;

[0032] (2), use the funnel container to add and dissolve the PVA in the raw...

Embodiment 2

[0040] Such as figure 1 As shown, an ultra-thin electronic grade glass fiber cloth high wear resistance slurry formula and method thereof are prepared from the following raw materials in parts by weight: 5 parts of polyoxymethylene, 3 parts of graphite, 3 parts of defoaming agent, 20 parts of main slurry starch, 4 parts of binder, 3 parts of surfactant; raw material B: 6 parts of PVA-1, 7 parts of PVA-2, 5 parts of PEG and 60 parts of deionized water.

[0041] In the raw material B, PVA 1 is polyvinyl alcohol with a content of 4%, PVA 2 is polyvinyl alcohol with a content of 1%, and PEG is polyethylene glycol with a content of 1%.

[0042] A preparation method of ultra-thin electronic grade glass fiber cloth high wear resistance slurry formula,

[0043] The specific steps are as follows:

[0044] (1) Add deionized water to stir and dissolve raw material A, and control the water temperature at 25°C;

[0045] (2), use the funnel container to add and dissolve the PVA in the ra...

Embodiment 3

[0053] Such as figure 1 As shown, a formula and method of an ultra-thin electronic grade glass fiber cloth high wear resistance slurry is prepared from the following raw materials in parts by weight: raw material A: 3 parts of polyoxymethylene, 2 parts of graphite, defoamer 2 parts, 18 parts of main slurry starch, 2 parts of binder, 3 parts of surfactant; raw material B: 4 parts of PVA-1, 6 parts of PVA-2, 3 parts of PEG and 57 parts of deionized water.

[0054] In the raw material B, PVA 1 is polyvinyl alcohol with a content of 4%, PVA 2 is polyvinyl alcohol with a content of 1%, and PEG is polyethylene glycol with a content of 1%.

[0055] A preparation method of ultra-thin electronic grade glass fiber cloth high wear resistance slurry formula,

[0056] The specific steps are as follows:

[0057] (1) Add deionized water to stir and dissolve raw material A, and control the water temperature at 25°C;

[0058] (2), use the funnel container to add and dissolve the PVA in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com