Manufacturing method and device for resin in-situ coated fiber precursor and application of manufacturing method and device

A manufacturing method and in-situ coating technology, applied in the direction of coating, etc., can solve the problem that the original wire cannot solve the problem of broken wire, increase the traction force of the original wire, and cannot be uncoiled for use, so as to maintain the strength and various properties, Reduce fiber production cost and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

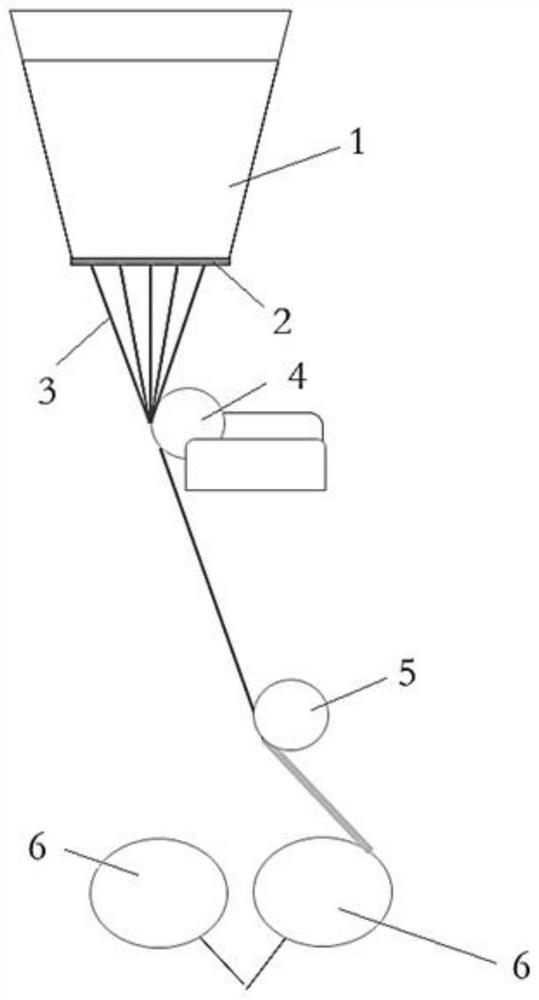

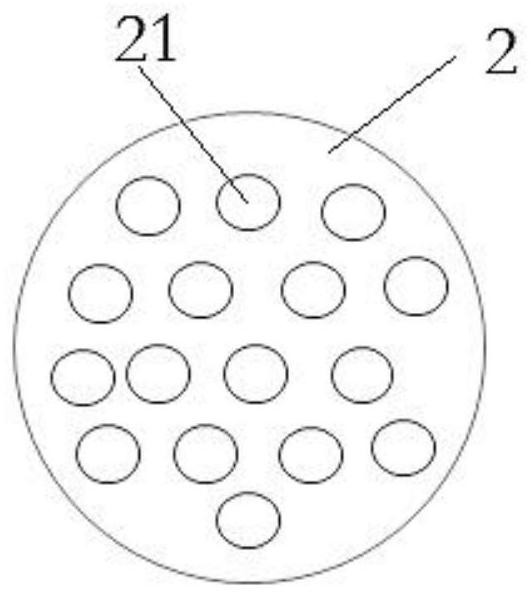

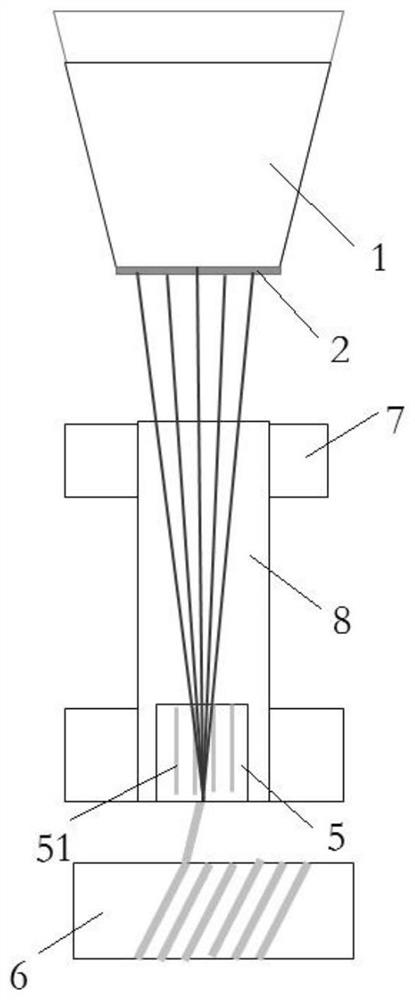

[0170] Embodiment one: if image 3 and 4 As shown, the prepreg compounding device includes a conveying roller 7, the bundling device includes a bundling roller 5, and the winding device includes a winding roller 6, and the state of the resin is fiber bundles, fabrics or films made of resin. Taking the resin film 8 as an example below, the glass fiber filaments are pulled into the precursor 3, and then the resin film 8 conveyed by the conveying roller 7 is combined to form the prepreg filament 9, and then they are bundled together by the bundle roller 5 to form a prepreg bundle. After 10, it is wound on the winding roller 6 to become a prepreg roll, and the resin content in the prepreg bundle 10 can be controlled by controlling the thickness of the resin film 8 .

[0171] Preferably, in order to improve the adhesion between the resin and the precursor, the resin is charged or a charged cationic coupling agent is added to the resin. Preferably, the raw silk 3 is compounded wit...

Embodiment 2

[0175] Embodiment two, such as Figure 5 and 6 , Embodiment 2 is a modification of Embodiment 1, which can further prevent the transverse disturbance of the traction force of the precursor when the resin coats the precursor.

[0176] Others are the same as in Embodiment 1, the difference is that the raw silk 3 is not compounded with the resin film 8 on the conveying roller 7, but is compounded with the resin film 8 in the air before the raw silk 3 enters the bundle roller, so that the resin melting and adhesion are completely avoided. Risk of lateral disturbances to the strand traction on the delivery rollers 7.

[0177] The specific embodiment is: use one or a pair of rotating conveying rollers 7 to convey the resin film 8 so that it enters one side or the opposite side of the path of the converging roller 5 with the precursor 3, and sandwiches the precursor 3 and passes through the converging roller 5 for melting and compounding It becomes the prepreg yarn bundle 10. Pref...

Embodiment 3

[0179] Embodiment three, such as Figure 7 and 8 , Embodiment 3 is a modification of the process shown in Embodiment 1, which can further prevent the transverse disturbance of the traction force of the precursor when the resin coats the precursor.

[0180] Others are the same as in Embodiment 1, the difference is that a pair of oppositely rotating conveying rollers 7 are used to convey the resin film 8 to sandwich the raw yarn 3 into the converging roller 5 to be bundled into a prepreg bundle 10 and then wound on the winding roller to become Rolls of prepreg yarn.

[0181] During the specific operation, the conveying roller 7 is separated first, and the raw silk 3 and the resin film 8 are twisted together and then wound on the winding roller 6 by the bundle roller 5, and the conveying roller 7 is closed, so that the resin film 8 is heated at a temperature higher than that of the raw silk 3 When the melting point of the resin is 0-40°C, it is fused with the raw silk and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com