Vertically-movable furnace at short temperature zone and method for growing CdTe crystal by using same

A vertical movement, vertical direction technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficult to guarantee the stability of the temperature field, difficult to control the interface morphology, slow crystal growth rate, etc. Purification effect, elimination of Te precipitation, effect of low crystal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

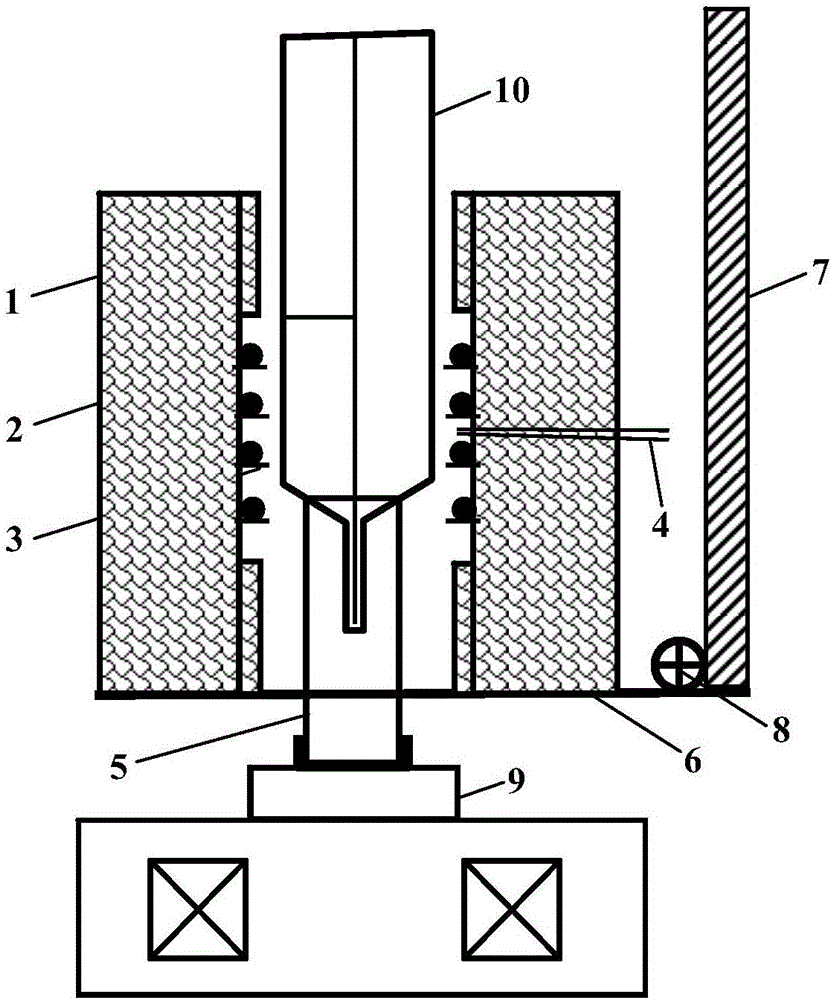

[0043] In this embodiment, the structure of the vertical moving furnace device in the short temperature zone is as follows: figure 1 shown, see figure 1 , the device for growing CdTe crystals in a vertical moving furnace in a short temperature zone in this embodiment, the main functional parts

[0044] Including furnace body 1, iron-chromium-aluminum heating wire 2, alumina ceramic sheet 3, platinum / platinum-rhodium alloy thermocouple 4, silicon carbide heat conduction support 5, furnace body support platform 6, moving guide rail 7, servo rotating motor 8, servo Rotary motor 9, quartz crucible 10.

[0045] The furnace body 1 is installed and fixed on the furnace body support platform 6 . The inner wall of the furnace is surrounded by the FeCrAl electric heating wire 2, and the FeCrAl electric heating wire 2 is supported by the alumina ceramic sheet 3 and clings to the inner wall of the furnace to form a heating zone. Both ends of the furnace body 1 are insulated with alumin...

Embodiment 2

[0056] In this embodiment, the structure of the vertically moving furnace device in the short-temperature zone is basically the same as that in Embodiment 1, except that in this embodiment, the height h of the heating zone in the vertical direction is 35 mm, and the diameter d of the furnace is 30 mm.

[0057] The method for growing CdTe crystals using this short-temperature zone vertical moving furnace is basically the same as the method in Example 1, the difference is that in this example, in step (1), small pieces of Te and CdTe polycrystalline The rods were loaded into a high-purity boron nitride crucible (PBN) with a conical bottom in sequence, and then the loaded boron nitride crucible was placed in a quartz tube and vacuumed to 1.0×10 -3 Pa and sealed with an acetylene flame.

Embodiment 3

[0059] In this embodiment, the structure of the vertically movable furnace device in the short temperature zone is basically the same as that in Embodiment 2, except that in this embodiment, the height h of the heating zone in the vertical direction is 70 mm, and the diameter d of the furnace is 60 mm.

[0060] The method for growing CdTe crystals using the short temperature zone vertical moving furnace is basically the same as the method in Example 2, the difference is: in the step (1) of this example, the bottom of the high-purity boron nitride crucible has a seed crystal well, In the implementation process, the preprocessed CdTe seed crystal can be firstly loaded into the seed crystal well at the bottom of the boron nitride crucible, and then small pieces of Te and CdTe polycrystalline rods are sequentially loaded into the boron nitride crucible, and finally the quartz crucible is sealed. , that is, crystal growth through seed seeding and shouldering can obtain high-quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com