Smelting degassing method of aluminum-silicon alloy liquid

An aluminum-silicon alloy and smelting furnace technology, which is applied in the field of smelting and degassing of aluminum-silicon alloy liquid, can solve the problems of affecting the quality of castings and insufficient degassing rate, and achieve the improvement of product performance, no shrinkage cavity, and improved tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with accompanying drawing:

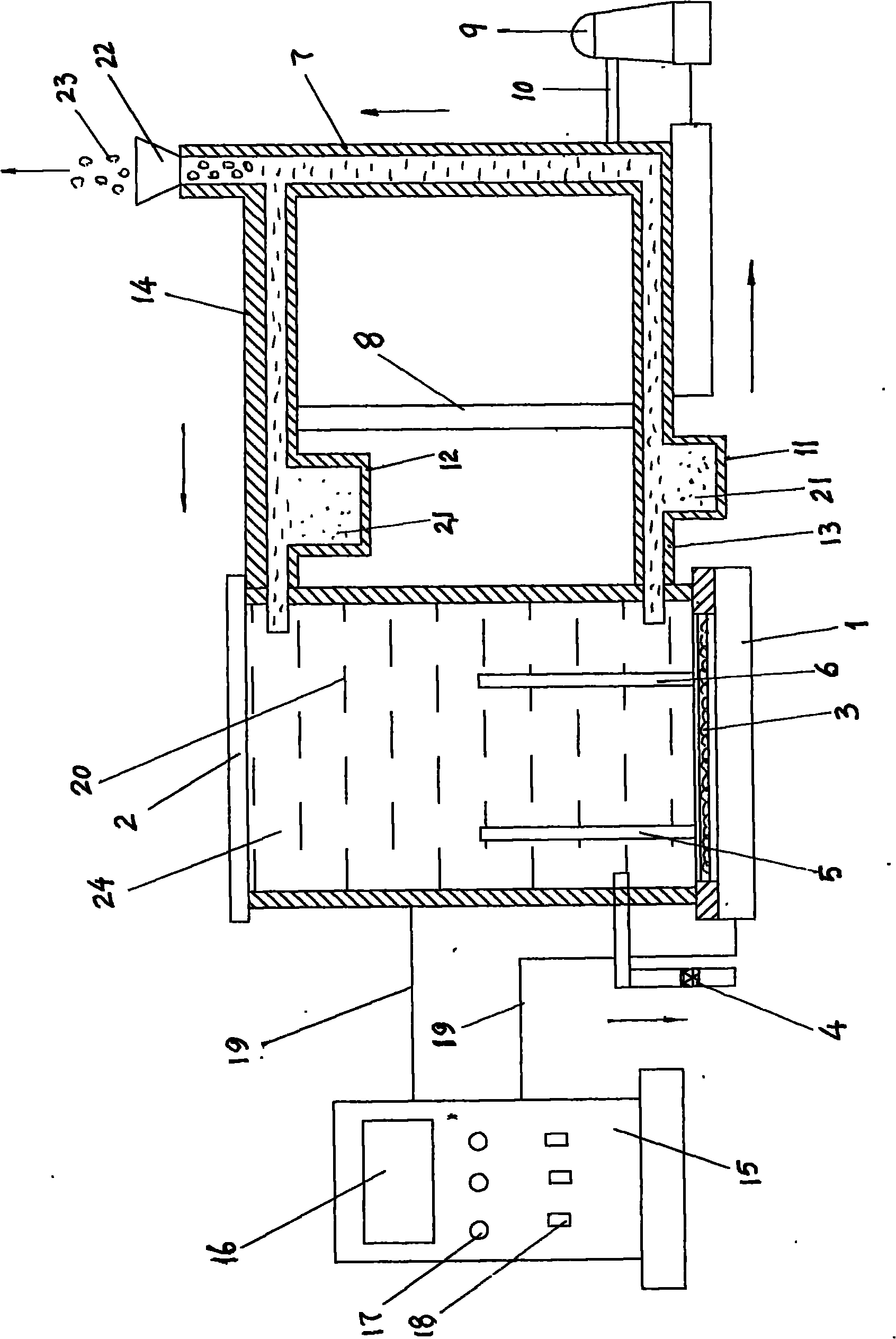

[0067] figure 1 As shown, it is the degassing state diagram of aluminum-silicon alloy smelting, the position and connection relationship of each part must be correct, and the sequence operation should be performed.

[0068] The melting furnace 1 is in the shape of a rectangular groove, the upper part is a furnace cover 2, and a resistance heater 3 is installed in the base of the melting furnace 1; inside the melting furnace 1 is a furnace chamber 24, and a DC positive electrode 5 and a DC negative electrode are vertically placed in the furnace chamber 24 left and right. Electrode 6; the lower left part of the furnace chamber 24 is provided with a casting pipe valve 4, the lower right part is provided with a liquid outlet pipe 13, and the upper right part is provided with a liquid return pipe 14, and the furnace chamber 24 is filled with an aluminum-silicon alloy liquid 20; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com