Technique for manufacturing high-carbon steel thrust sliding bearing of high-power low speed diesel engine

A technology for thrust sliding bearings and manufacturing processes, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as low bond strength, edge defects, loose defects, etc., to reduce loose defects, reduce edge defects, reduce The effect of small machining allowances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

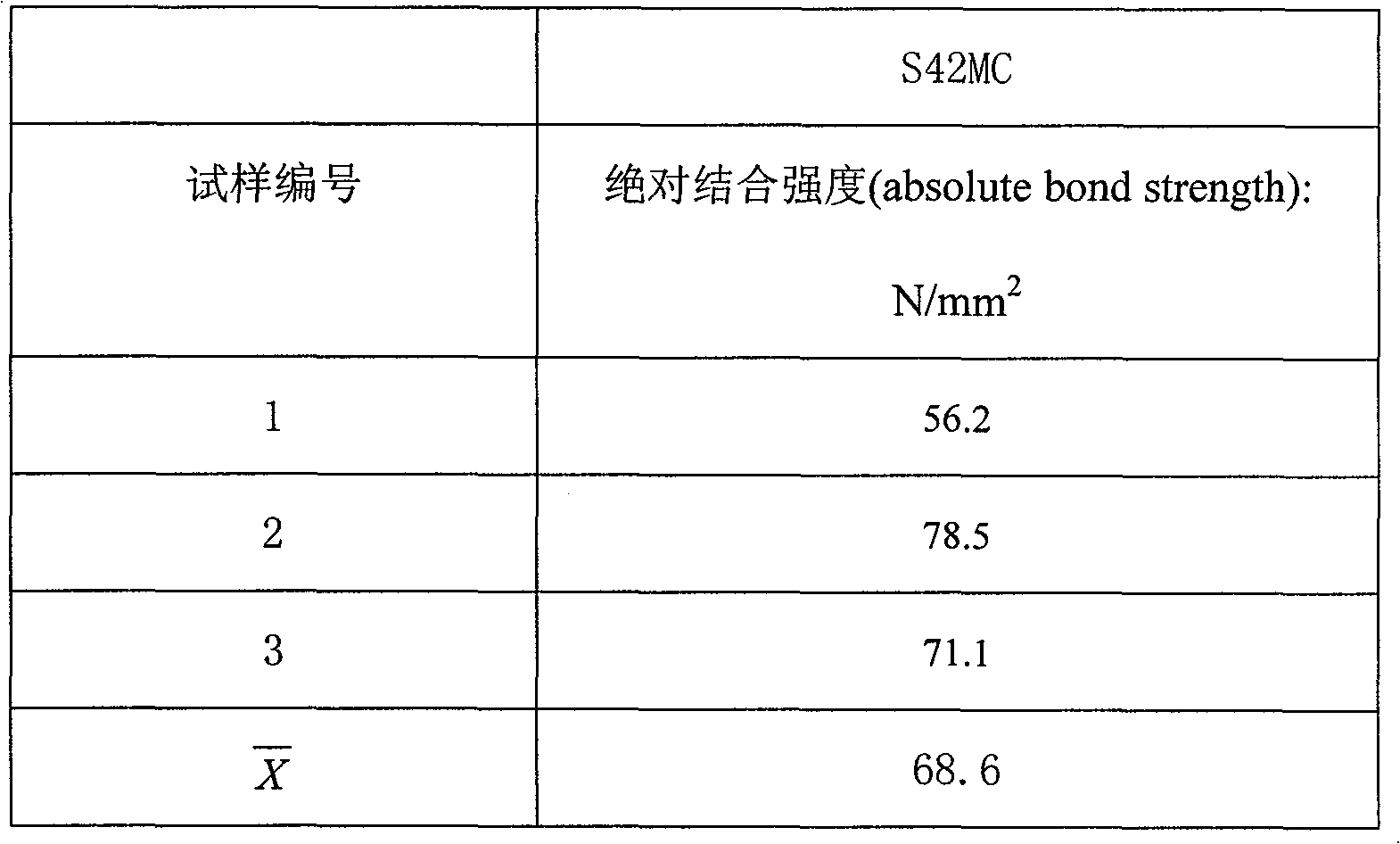

Examples

Embodiment 1

[0049]A kind of concrete method step of the manufacturing process of high-carbon steel thrust sliding bearing of high-power low-speed diesel engine is as follows:

[0050] (1) Rough manufacturing

[0051] ① Rough casting

[0052] Cast high-carbon steel into a rough thrust sliding bearing of the required size through a mold, and cool it naturally in the air after demoulding, and reserve it for later use.

[0053] ② rough machining

[0054] After step (1)-① is completed, the thrust sliding bearing blank cast in step (1)-① is passed through a lathe, and the upper and lower planes are first turned and the center line and outline line are drawn. The two outer arc surfaces are milled with a milling machine on both sides, pouring surface and back.

[0055] ③Feeding groove processing

[0056] After the completion of steps (1)-②, around the pouring surface of the blank, through a lathe, first car the feeding groove, the width and depth of the feeding groove are both 5mm, and then t...

Embodiment 2

[0084] The specific method steps of a high-power low-speed diesel engine thrust high-carbon steel sliding bearing manufacturing process are as follows:

[0085] (1) Rough manufacturing

[0086] With embodiment 1. The feature is that the width and depth of the feeding groove are both 6mm, and the width and thickness of the stopper are both 6mm.

[0087] (2) Treatment of blank pouring surface

[0088] With embodiment 1. The characteristics are: the decarburization treatment temperature in the holding furnace is 930 DEG C, the holding time is 1.5 hours, the 9% NaOH solution prepared by industrial alkali is used for cleaning, and the 10% industrial hydrochloric acid is soaked for 4 minutes.

[0089] (3) The pouring surface is tinned

[0090] With embodiment 1. The characteristics are: the preheating temperature is 170°C, and the preheating time is 30 minutes. When tinning, soak in the tin pot for 3 minutes.

[0091] (4) Pouring Babbitt alloy

[0092] With embodiment 1.

[...

Embodiment 3

[0096] A kind of concrete method step of the manufacturing process of high-carbon steel thrust sliding bearing of high-power low-speed diesel engine is as follows:

[0097] (1) Rough manufacturing

[0098] With embodiment 1. The feature is that the width and depth of the feeding groove are both 4mm, and the width and thickness of the stopper are both 4mm.

[0099] (2) Treatment of blank pouring surface

[0100] With embodiment 1. The characteristics are: the decarburization treatment temperature in the holding furnace is 900 DEG C, the holding time is 2 hours, the 8% NaOH solution prepared by industrial alkali is used for cleaning, and the 10% industrial hydrochloric acid is soaked for 5 minutes.

[0101] (3) The pouring surface is tinned

[0102] With embodiment 1. The characteristics are: the preheating temperature is 150°C, the preheating time is 40 minutes, and when tinning, soak in the tin pot for 8 minutes.

[0103] (4) Pouring Babbitt alloy

[0104] With embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com