Water pipe joint and water pipe mounting structure

A technology for water pipe joints and tubular structures is applied in the field of water pipe joints and water pipe installation structures realized by using the water pipe joints, which can solve the problems that the sealing performance cannot be guaranteed, the water pipe installation is prevented from falling off, the production life of the mold is damaged, and the mold structure is complex, etc. Tight installation, prevention of falling off, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

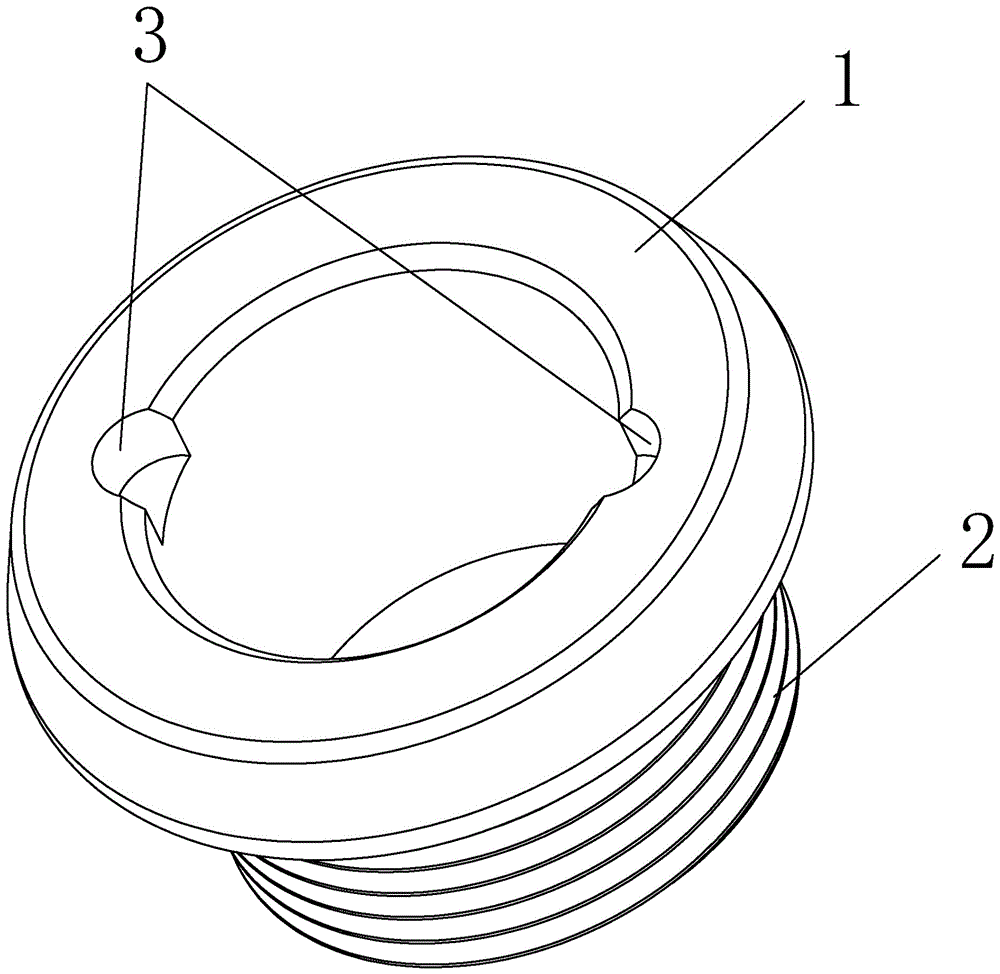

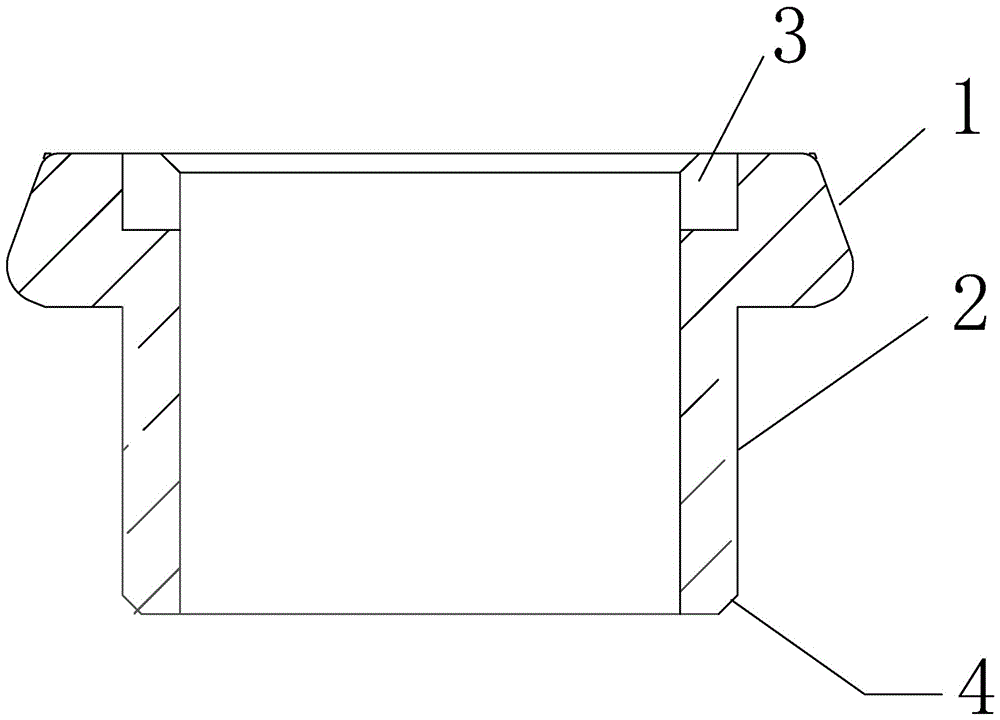

[0014] Such as figure 1 , figure 2 As shown, the water pipe joint provided by the present invention is similar to a screw shape, including a stud 2 and a screw head 1, but the center of the stud 2 and the screw head 1 is a hollow tubular structure, so that a passage will be formed between the two connected pipes .

[0015] The outer surface of the stud 2 is provided with external threads to be threadedly connected with one of the pipes, and the bottom of the outer surface of the stud is a chamfered structure 4 toward the center thereof. The top surface of the screw head 1 is provided with a pair of slots 3 with opposite openings, and the top surface of the slots 3 is also open, so that the water pipe joint can be easily tightened or unscrewed by a flat knife tool to realize quick installation.

[0016] In this embodiment, the included angle between two adjacent cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com