Preparation method and application method of composite anticorrosive coating for stay cable of cable-stayed bridge

A technology for anti-corrosion coatings and cable-stayed bridges, which can be used in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., and can solve problems such as harm to humans and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The above-mentioned content of the present invention will be described in further detail below by the form of the embodiment, but this should not be interpreted as the scope of the above-mentioned theme of the present invention being limited to the following embodiments, all technologies realized based on the above-mentioned content of the present invention belong to scope of the invention.

[0029] Specific embodiments of the present invention are further described below:

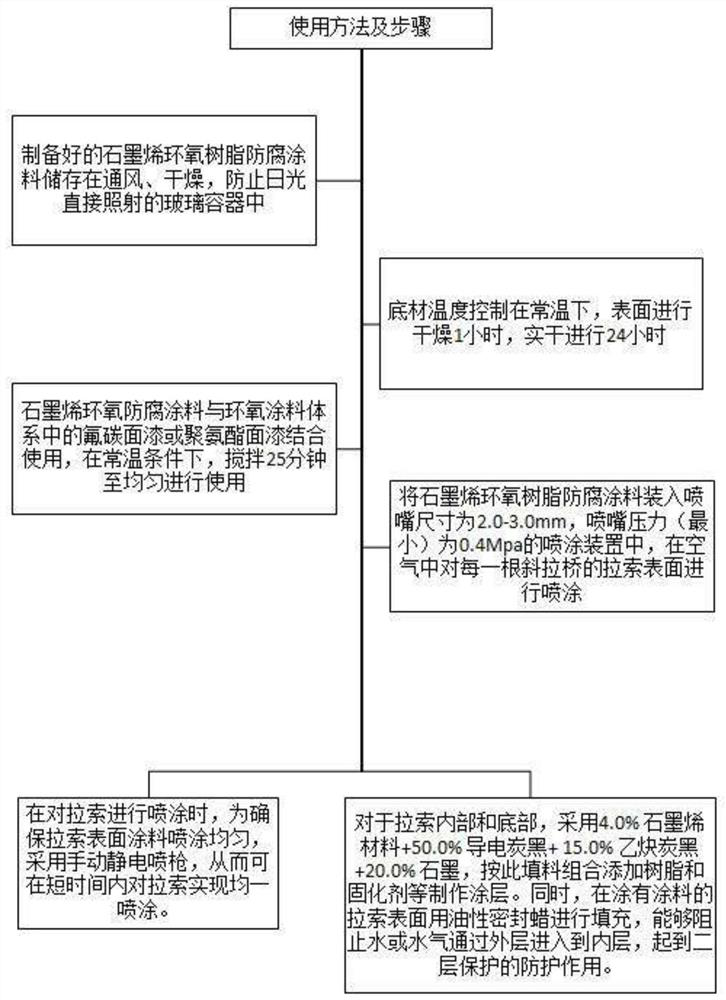

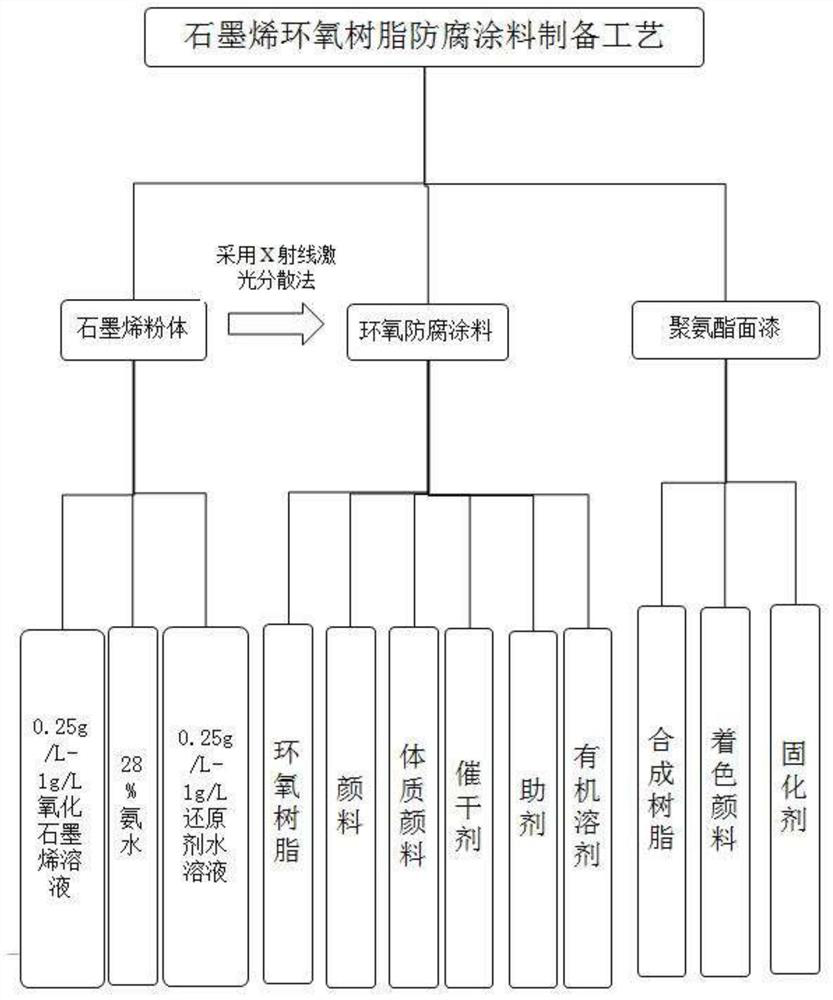

[0030] A preparation and application method of a composite anticorrosion coating for cables of cable-stayed bridges, characterized in that graphene is dispersed in ammonia solvent by X-ray laser dispersion method, thereby preparing graphene dispersion liquid, and adding Anti-sedimentation agent, mixed with water-based epoxy resin by magnetic stirring to prepare composite anti-corrosion materials, and can also be used in combination with fluorocarbon topcoat or polyurethane topcoat in epoxy coating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com