Method for producing ammonium sulfate in S-NPK device by using refined phosphoric acid byproduct tail liquid

A technology of ammonium phosphate and tail liquid, applied in the direction of phosphate, phosphorus oxyacids, etc., to reduce investment costs, increase economic benefits, and improve equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

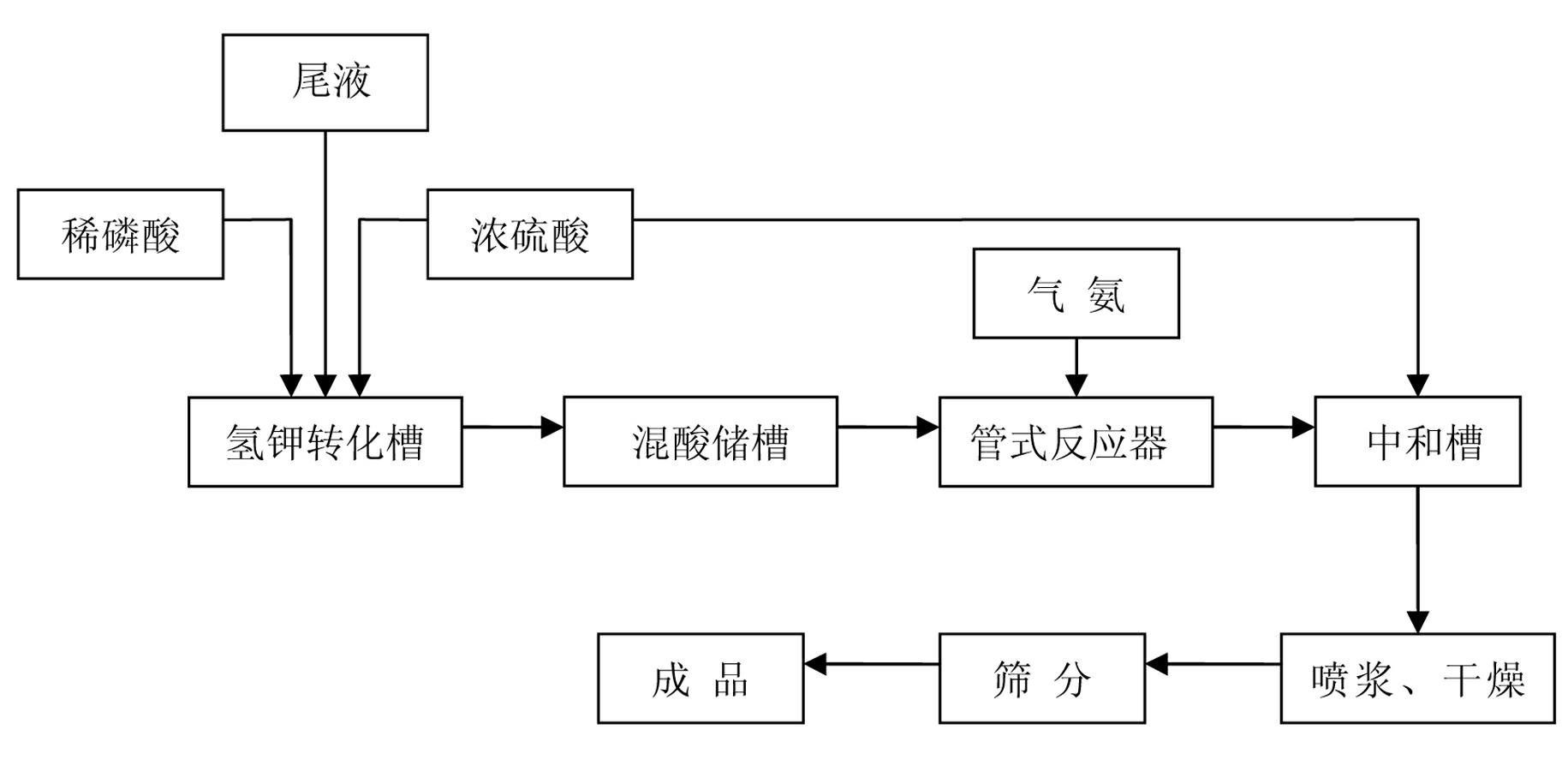

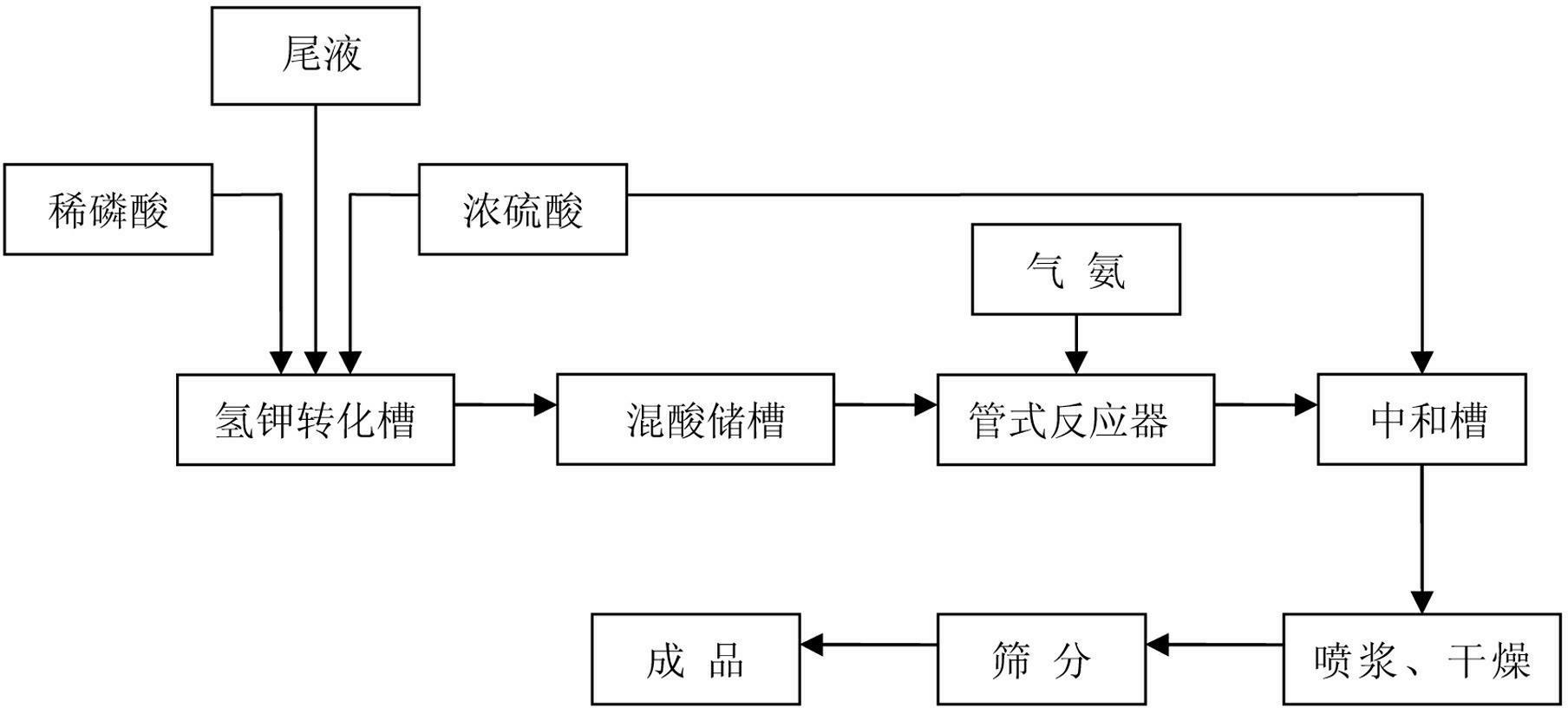

[0022] Using the sulfur-based compound fertilizer (S-NPK) production plant, the tail liquid (containing w(P 2 o 5 ) 有效 13-22%, including w (H 2 SO 4 ) is 25 to 33%), concentrated sulfuric acid (w (H 2 SO 4 ) is 98%) and dilute phosphoric acid (w (P 2 o 5 ) 有效 20%-22%) into the potassium hydrogen conversion tank and mix thoroughly, control the temperature in the conversion tank to 95-100°C, the mixed acid material enters the mixed acid storage tank and then pumps to the tubular reactor, where it is mixed with gas ammonia in the tubular reactor React in the reactor, control the temperature in the tubular reactor to 105-115°C, control the degree of neutralization at 1.1-1.2, and neutralize the slurry generated from the tubular reactor with concentrated sulfuric acid in the neutralization tank. After spraying, drying and sieving, the finished ammonium phosphate compound fertilizer can be obtained. Concentrated sulfuric acid is added to the potassium hydrogen conversion ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com