Heat-emitting graphite material comprising amorphous carbon particles and a production method therefor

A technology of amorphous carbon and heat dissipation materials, applied in heat exchange materials, chemical instruments and methods, thin material processing, etc., can solve the problems of reducing economy, high production costs, and generating toxic gases, etc., to improve thermal diffusion and thermal conductivity, improve the effect of vertical heat conduction, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

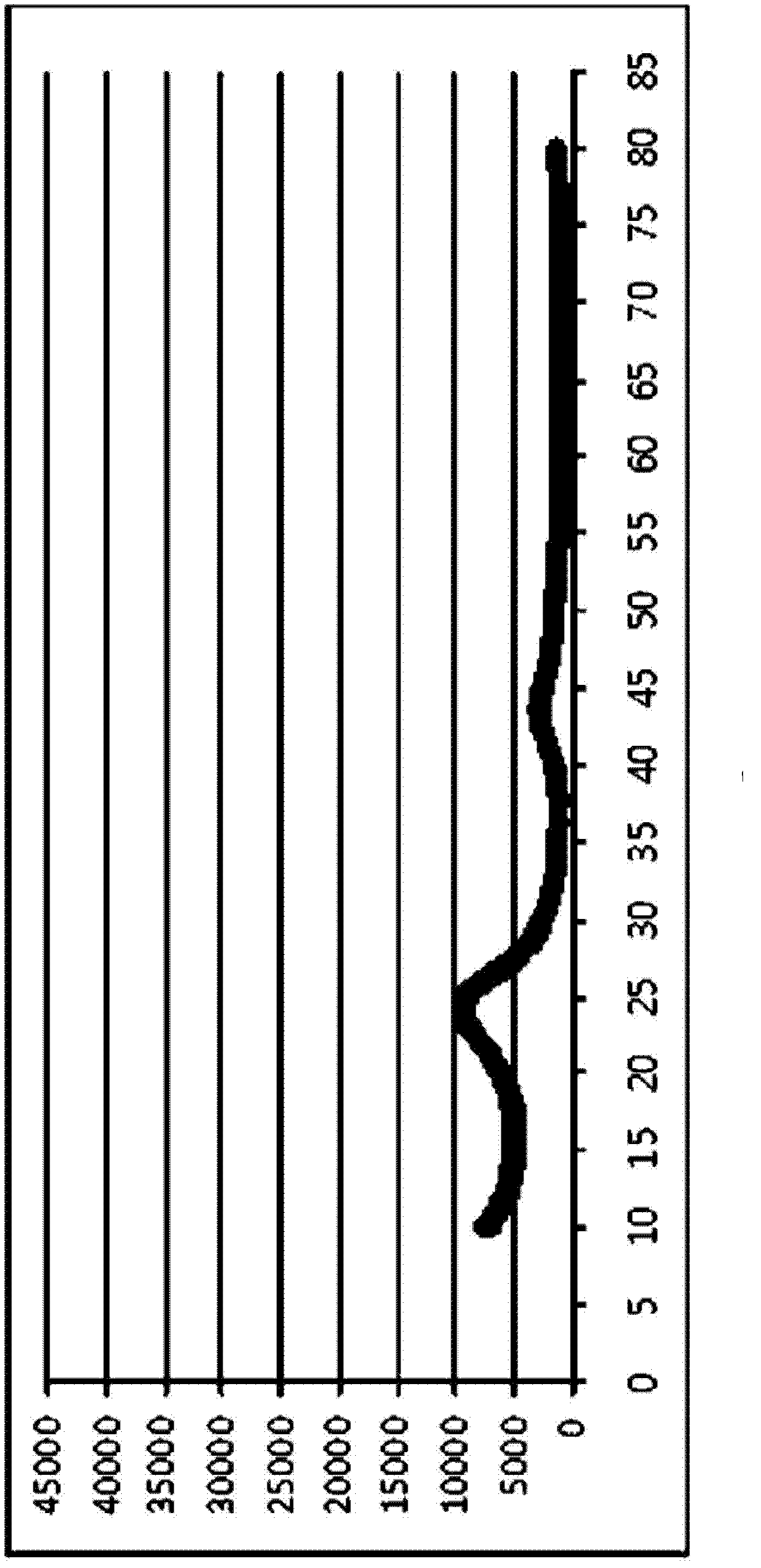

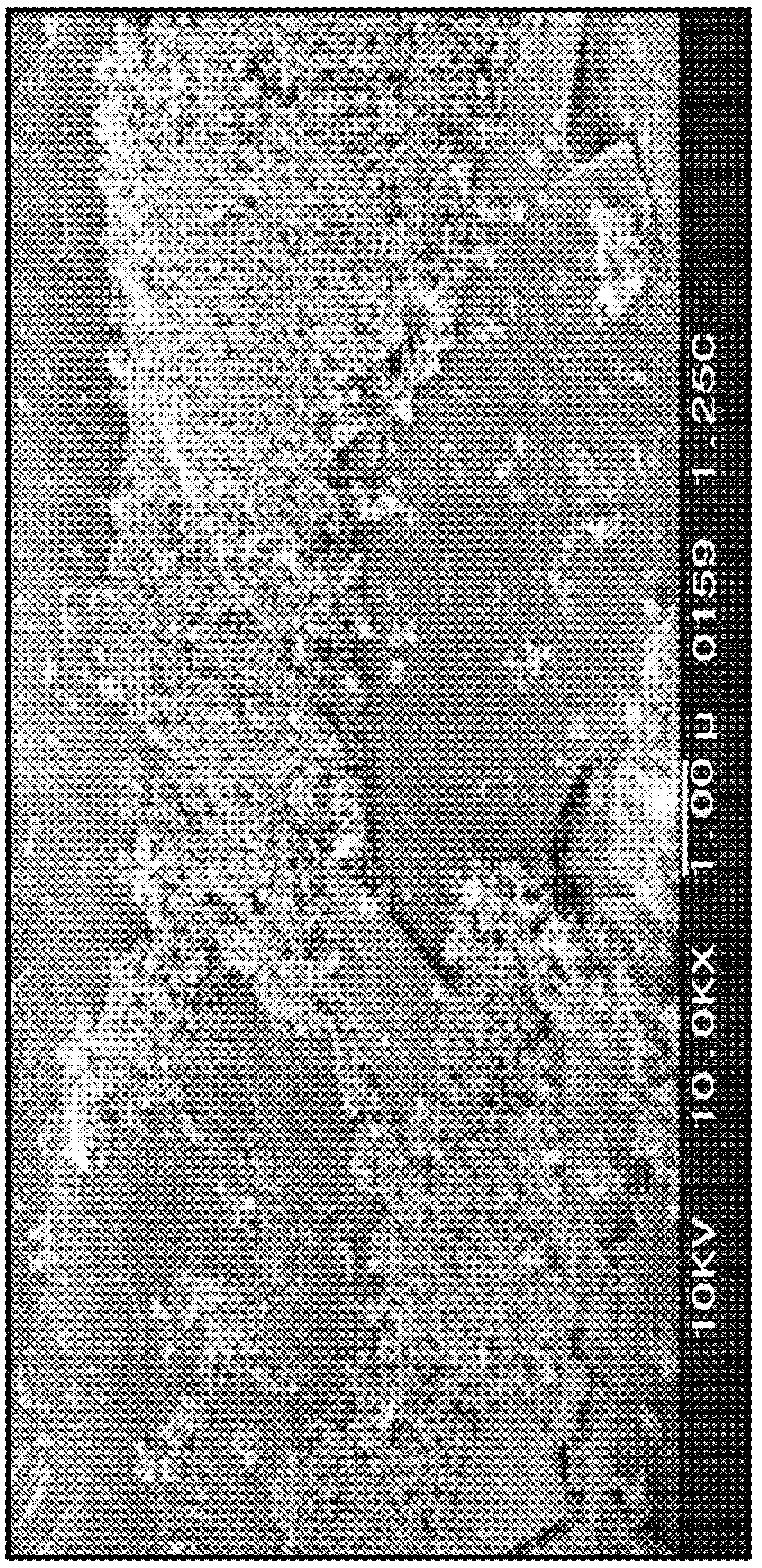

[0050] The graphite used in the present invention is expanded graphite with a high expansion volume of 380ml / g, which can prevent the decline in thermal properties caused by unexpanded graphite, mix a certain amount of 60nm amorphous carbon particles, and utilize roller (roller) compression molding The process carries out compression molding with a compression rate of more than 30% to make a tablet with a density of 1-2g / cm 3 slices.

[0051] As shown in Table 1 below, amorphous carbon fine particles were mixed with expanded graphite. Then respectively with a thickness of 1mm, a compression rate of more than 30%, and a pressure of 500-700kg / cm 2 Make into flakes.

[0052] Table 1

[0053] sample number

Graphite (wt%)

Amorphous carbon particles (wt%)

1

100

0

2

95

5

3

90

10

4

85

15

5

80

20

6

70

30

[0054] The thermal conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com