Special hot air nonwoven fabric for face masks and manufacturing method of special hot air nonwoven fabric for face masks

A technology of nonwoven fabrics and manufacturing methods, which is applied in the field of nonwoven fabrics, can solve the problems of non-woven fabrics without improving the air permeability, comfort, no, single components, etc., achieve little impact on the environment and human body, prevent fiber overheating, Reasonable and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

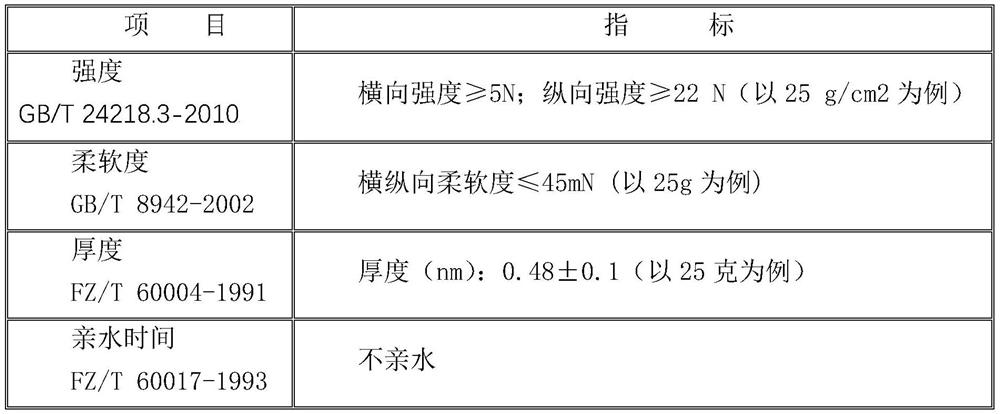

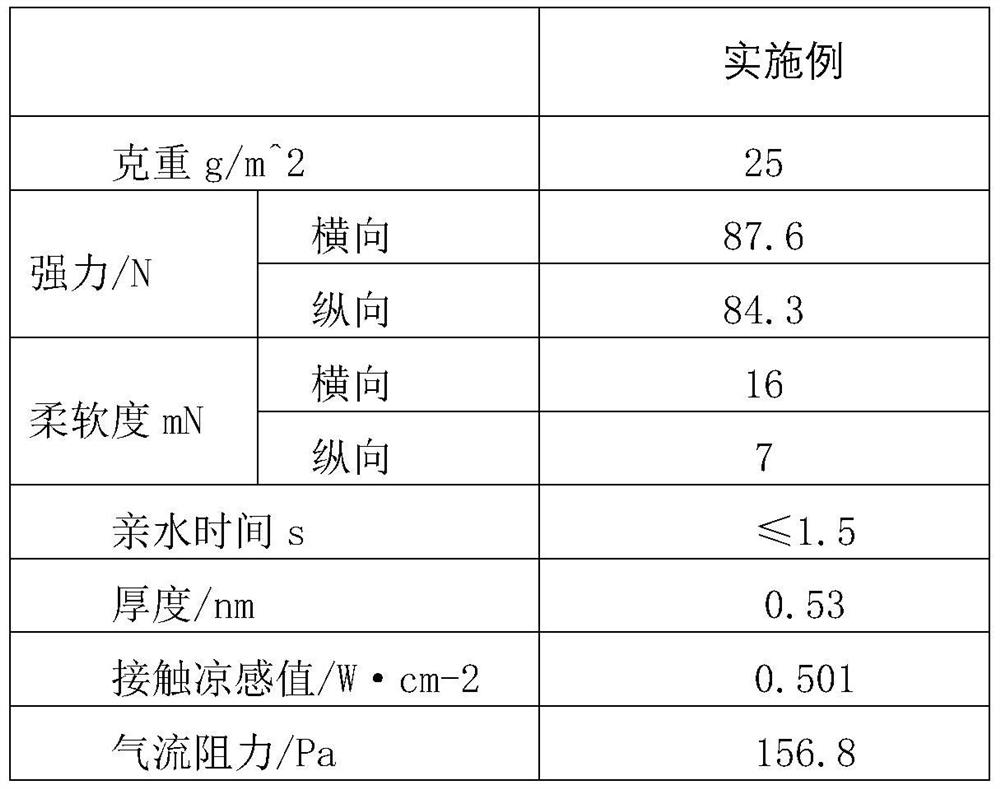

Examples

Embodiment

[0044] The manufacturing method of the hot-air nonwoven fabric for masks includes the following steps:

[0045] (1) Feeding: Put the first component and the second component of the opened cotton bale into No. 1 and No. 2 bale openers respectively, and use the electronic scale of the bale opener to separate the first and second components. The fiber is put into the opener according to the proportion stated in the formula;

[0046] (2) Opening and blending: The opening machine loosens the above-mentioned fibers in the agglomerate, and then sends the opened fibers into the blending box to fully mix the fibers;

[0047] (3) Carding: the mixed fibers are sent to a carding machine for full carding, and the fibers are carded into monofilaments and spread into a uniform web;

[0048] (4) Primary thermal consolidation: The above-mentioned fiber web is sent into a hot air oven, and the hot air flows through the hot air oven to heat the fibers. Self-adhesive reinforcement is generated between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com