Micro heating device

A technology of micro-heating and heating structure, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of unusable, inaccurate control of temperature, inability to accurately determine the magnitude of the current that generates heat, etc., to achieve uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

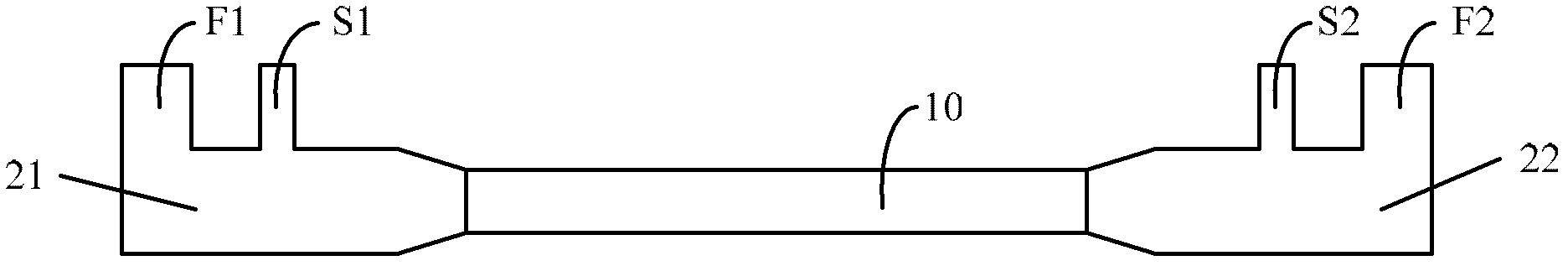

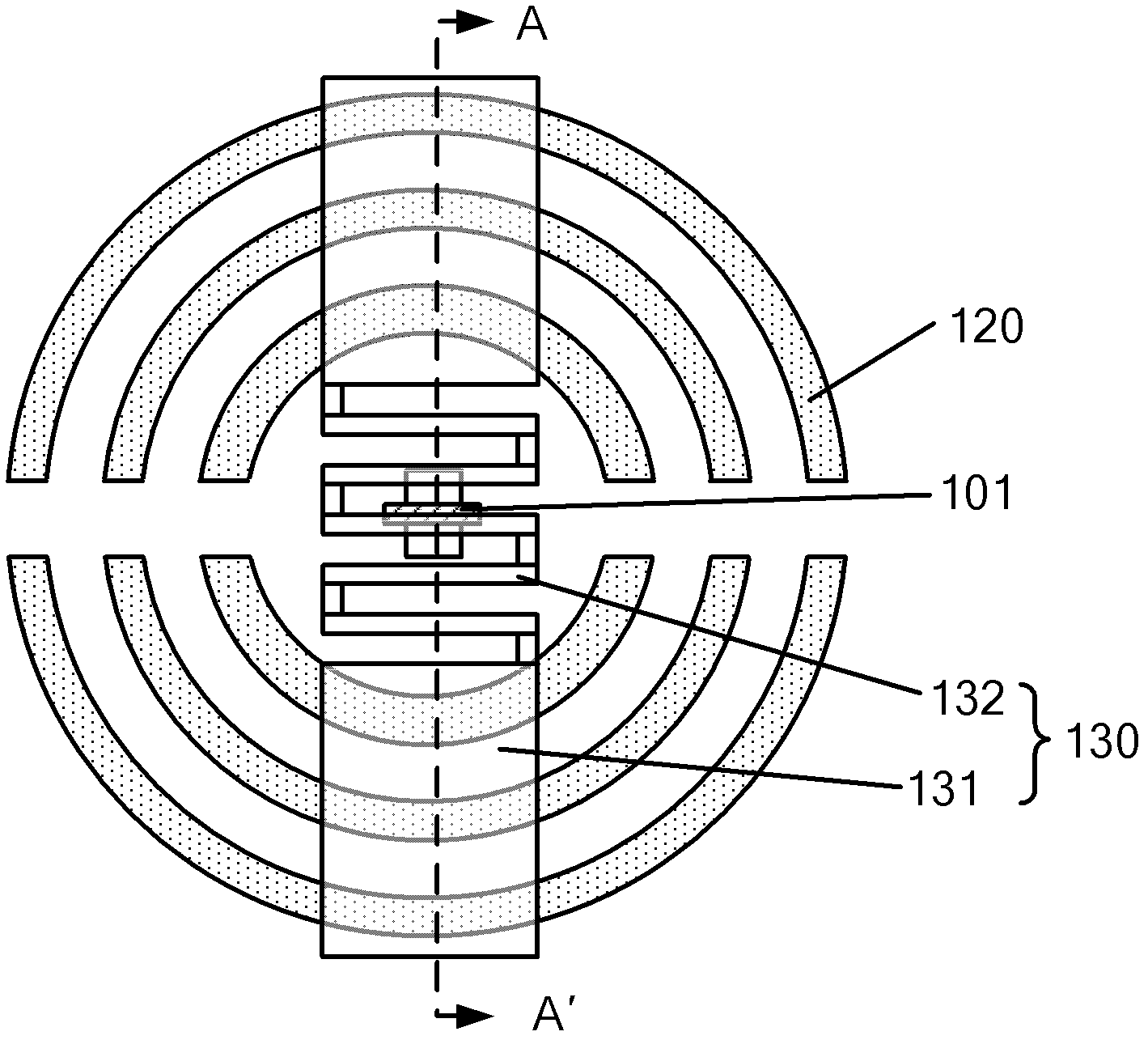

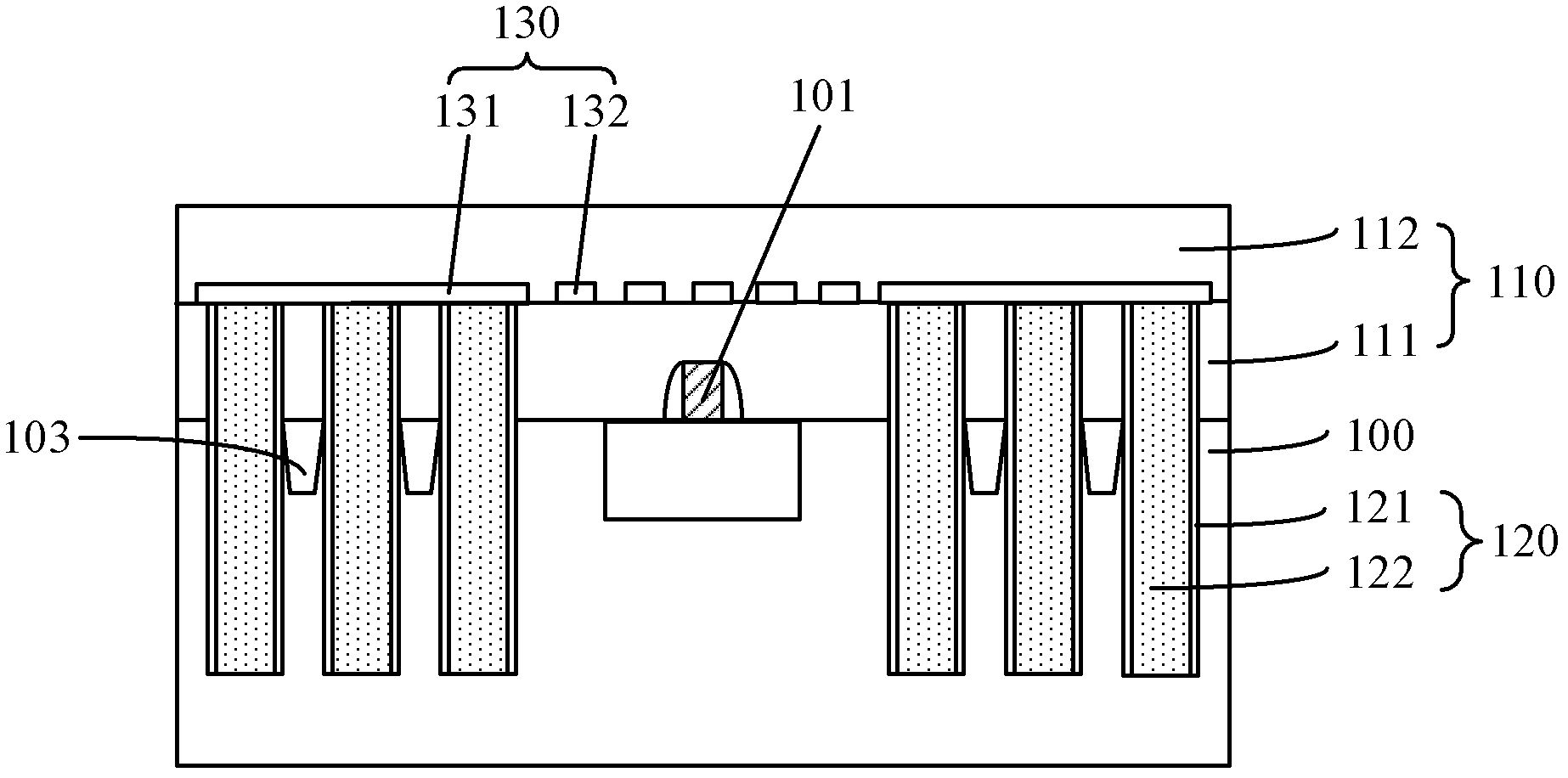

[0034] The first embodiment of the present invention provides a micro heating device, please refer to figure 2 with image 3 , figure 2 It is a structural schematic diagram of a micro-heating device according to an embodiment of the present invention in a top view, image 3 for figure 2 The cross-sectional schematic diagram of the micro-heating device on the line AA' in the middle, specifically including: a semiconductor substrate 100, a device to be tested 101 located on the semiconductor substrate 100; a first interlayer dielectric layer located on the surface of the semiconductor substrate 100 111, a thermal conduction trench 120 located in the semiconductor substrate 100 and the first interlayer dielectric layer 111, the thermal conduction trench 120 is arranged around the device to be tested 101; located on the surface of the first interlayer dielectric layer 111 The heating structure 130, the heating structure 130 includes a heat conduction portion 131 located on t...

no. 2 example

[0045] In the second embodiment of the present invention, please refer to Figure 4 , the structure of the micro-heating device is substantially the same as that of the micro-heating device in the first embodiment, the only difference is that the pattern of the heat conduction groove 120' is a disconnected spiral, and the disconnected spiral A heat conduction groove 120 ′ is arranged around the structure to be inspected 101 , and the structure to be inspected 101 is located at the center of the disconnected spiral heat conduction groove 120 ′, so that the device to be inspected 101 is evenly heated. The spiral shape is a circular spiral or a rectangular spiral, wherein, Figure 4 The pattern of the heat conduction groove 120 ′ is a circular spiral. Since the entire spiral heat conduction groove 120' is divided into two electrically isolated parts, each part is connected to a heat conduction part 131, so that the heating part 132 between the two heat conduction parts 131 gener...

no. 3 example

[0047] Please also refer to Figure 5 with Image 6 , Figure 5 It is a structural schematic diagram of the micro-heating device according to the third embodiment of the present invention in a top view, Image 6 for Figure 5 Schematic diagram of the cross-sectional structure of the micro-heating device on the line BB', specifically including: a semiconductor substrate 100, a device to be tested 101 located on the semiconductor substrate 100; a first interlayer dielectric layer located on the surface of the semiconductor substrate 100 111, a concentric annular thermal conduction trench 120″ located in the semiconductor substrate 100 and the first interlayer dielectric layer 111, the concentric annular thermal conduction trench 120″ is arranged around the device to be tested 101, and The concentric annular heat conduction groove 120" is divided into four electrically isolated parts, and the surface of each part of the heat conduction groove 120" is connected to a different h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com