Method for improving performance of heat-treatable reinforced aluminum alloy friction stir welding joint

A technology of friction stirring and welding joints, applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., to achieve the effect of inhibiting dissolution and coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

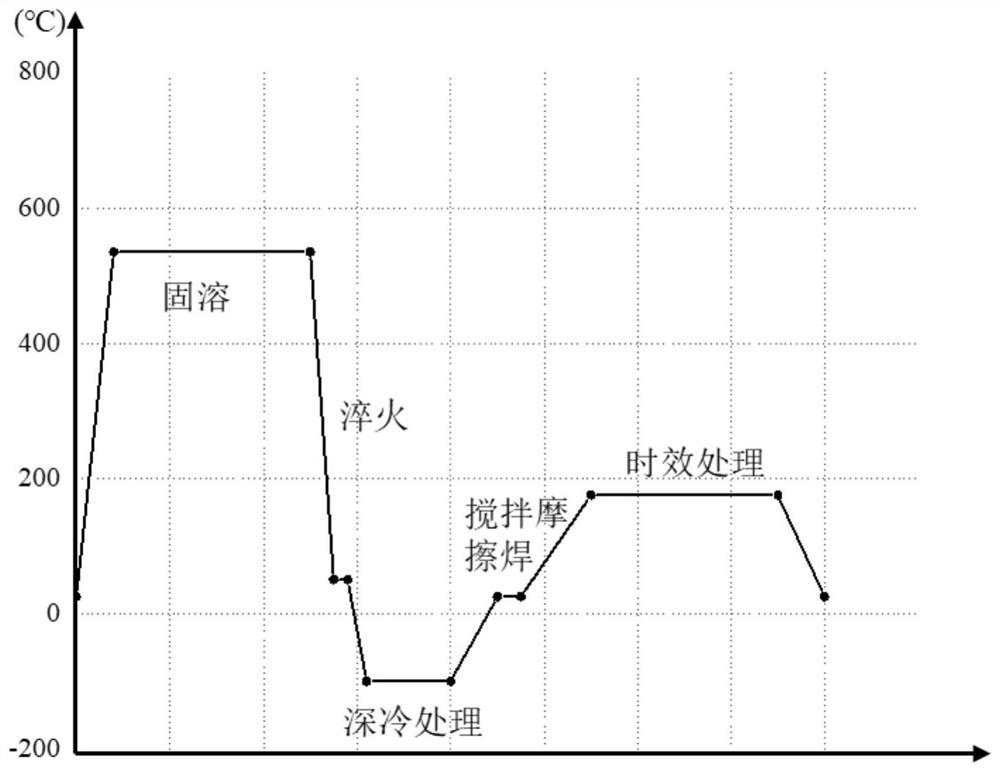

Method used

Image

Examples

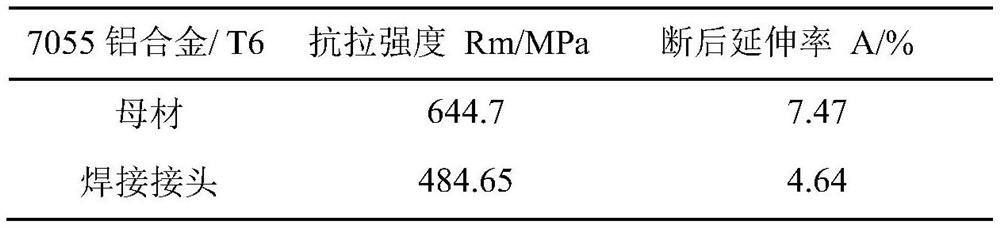

Embodiment 1

[0022] The first step is to select a 4mm thick spray-formed 7055 aluminum alloy plate, the solution heat treatment temperature is 490±5°C, the holding time is 1h, and it is quickly transferred to the quenching device. The quenching medium is 50±5°C warm water, and the aluminum alloy is supersaturated. state;

[0023] Transfer the solid-solution aluminum alloy to a low-temperature storage device for storage, and the temperature of the device is always controlled below zero;

[0024] Take out the aluminum alloy sheet from the storage device, place it on a friction stir welding machine for welding after reaching room temperature, wherein the rotation speed of the stirring head is 100r / min, and the welding speed is 100mm / min;

[0025] During the welding process, spray liquid nitrogen on the rear side of the shoulder to cool the joint;

[0026] After the welding of 7055 aluminum alloy is completed, put the welded parts into the aging heat treatment furnace for aging treatment, the...

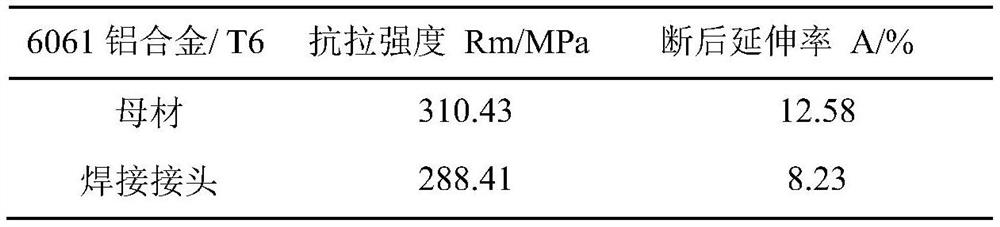

Embodiment 2

[0031] The first step is to select 6061 aluminum alloy plate with a thickness of 3mm, the solution heat treatment temperature is 530±5°C, and the holding time is 1h, and it is quickly transferred to the quenching device. The quenching medium is warm water at 50±5°C, and the aluminum alloy is in a supersaturated state;

[0032] Transfer the solid-solution aluminum alloy to a low-temperature storage device for storage, and the temperature of the device is always controlled below zero;

[0033] The aluminum alloy plate is taken out from the storage device and placed on a friction stir welding machine for welding, wherein the rotation speed of the stirring head is 1200r / min, and the welding speed is 200mm / min;

[0034] During the welding process, spray liquid nitrogen on the rear side of the shoulder to cool the joint;

[0035] After the welding of 6061 aluminum alloy is completed, put the weldment into the aging heat treatment furnace for aging treatment, the aging temperature is...

Embodiment 3

[0040] The first step is to select 4.5mm thick 2024 aluminum alloy plate, the solution heat treatment temperature is 490±5℃, the holding time is 1h, and it is quickly transferred to the quenching device. The quenching medium is 50±5℃ warm water, and the aluminum alloy is in a supersaturated state ;

[0041] Transfer the solid-solution aluminum alloy to a low-temperature storage device for storage, and the temperature of the device is always controlled below zero;

[0042] The aluminum alloy plate is taken out from the storage device and placed on a friction stir welding machine for welding, wherein the rotation speed of the stirring head is 1600r / min, and the welding speed is 120mm / min;

[0043] During the welding process, spray liquid nitrogen on the rear side of the shoulder to cool the joint;

[0044] After the welding of 2024 aluminum alloy is completed, put the weldment into the aging heat treatment furnace for aging treatment, the aging temperature is 170 ° C, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com