Preparation method for resin for improving wet skid resistance of rubber and application of resin

A wet skid resistance and resin technology, applied in the rubber industry, can solve the problems of affecting the mechanical properties of rubber, waste of non-renewable resources, and shortening the service life of tires, and achieve the advantages of improving contact efficiency, high wet grip, and reducing rolling resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

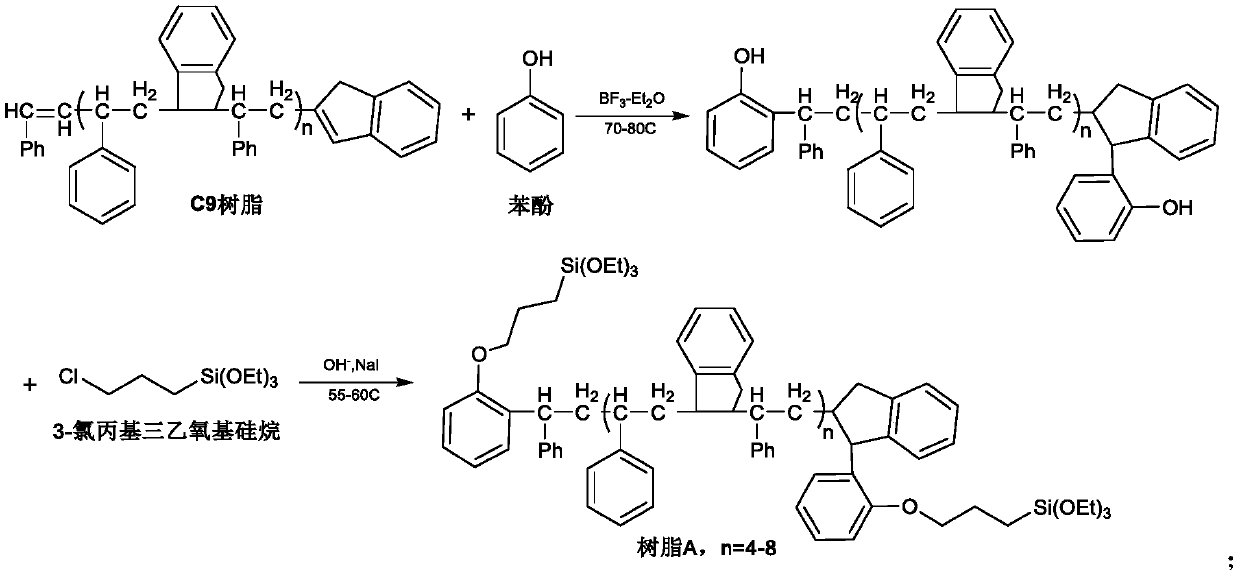

[0062] Embodiment 1 (resin A: C9-phenol-silane preparation)

[0063] The preparation reaction formula of functionalized resin A is as follows:

[0064]

[0065] Specific steps:

[0066] 1. In a four-neck flask, dissolve 80g of C9 resin in xylene solvent and keep it at 70-80°C;

[0067] 2. Add a boron trifluoride catalyst of 0.8% by weight of C9 petroleum resin into the reaction system, and stir for half an hour;

[0068] 3. Add 20g of phenol and xylene mixture dropwise, keep the system temperature at 70-80°C, and stir continuously for 2-3h; the weight ratio of C9 petroleum resin to phenol is 4:1;

[0069] 4. Add water to the reaction solution for extraction, take the upper organic phase and distill under reduced pressure to obtain 90 g of the first step yellow resin product;

[0070] 5. 90g resin product is dissolved in xylene, adds the 3-chloropropyl triethoxysilane of resin product weight simultaneously, adds the NaI of the sodium ethylate of resin product weight 0.4% ...

Embodiment 2

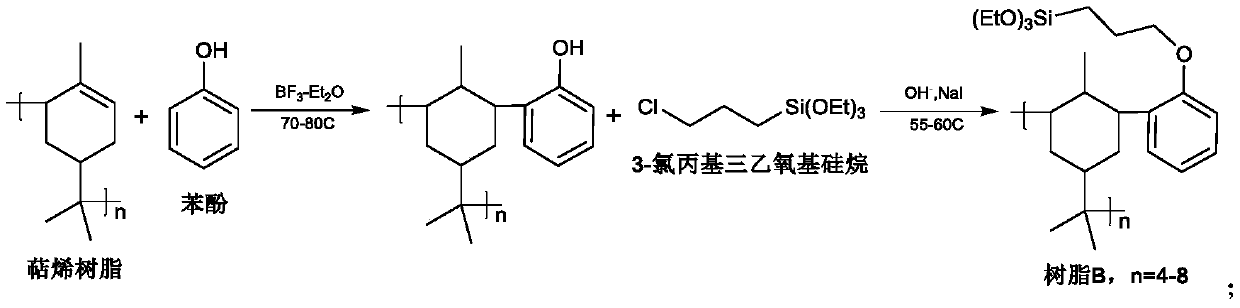

[0072] Embodiment 2 (resin B: preparation of terpene-phenol-silane)

[0073] Replace the C9 resin in Example 1 with a terpene resin, and the rest of the steps are the same, the preparation reaction formula of resin B is as follows, and resin B is obtained.

[0074]

Embodiment 3

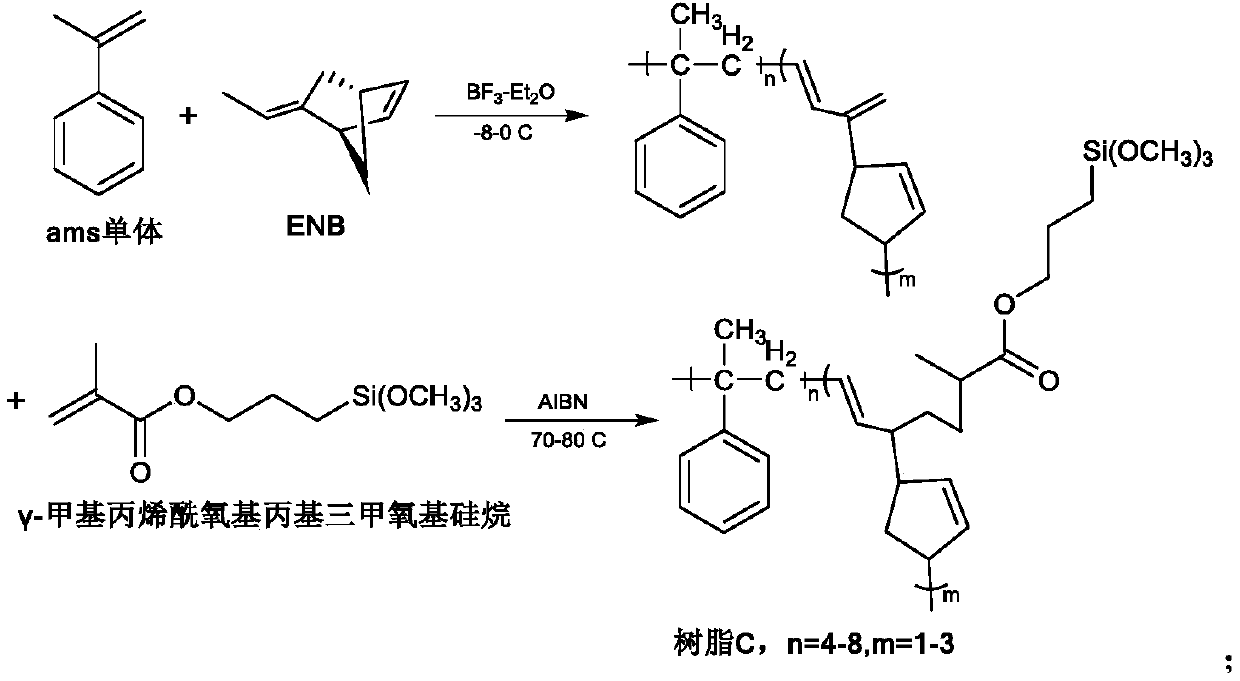

[0075] Embodiment 3 (resin C: ams-ENB-silane preparation)

[0076] The preparation method of functionalized resin C is as follows:

[0077]

[0078] Specific steps:

[0079] 1. In a four-necked flask, cool 50g of xylene solvent to -10°C, add 1% boron trifluoride catalyst based on the weight of xylene solvent, and stir for 0.5h;

[0080] 2. Add 100g ams monomer (a-methylstyrene) dropwise to the reaction system, and control the drop rate to control the system temperature at -8-0°C;

[0081] 3. After adding ams dropwise, continue to add 20g of ENB (5-ethylidene-2-norbornene) and xylene mixture dropwise, keep the system temperature at -8-0°C, and react for 3h; the ams monomer and ENB The weight ratio of (5-ethylidene-2-norbornene) is 4:1;

[0082] 4. Raise the temperature of the system to 70-80°C, and at the same time add 0.3% of the free radical initiator AIBN of the ams monomer weight and 3% of the ams monomer weight of γ-methacryloxypropyltrimethoxysilane ;

[0083] 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com