Planting method of wild grapes

A technology of wild grapes and planting methods, applied in the field of grape planting, can solve problems such as the influence of light intensity, lack of effective means for maintenance, and inability to fully exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

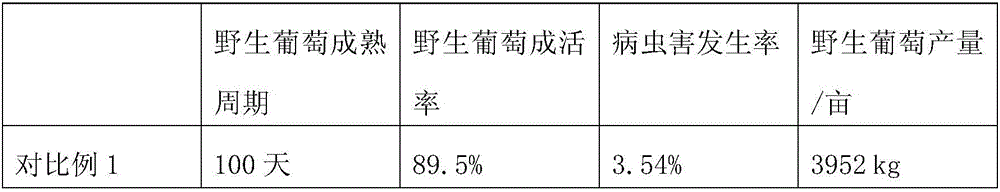

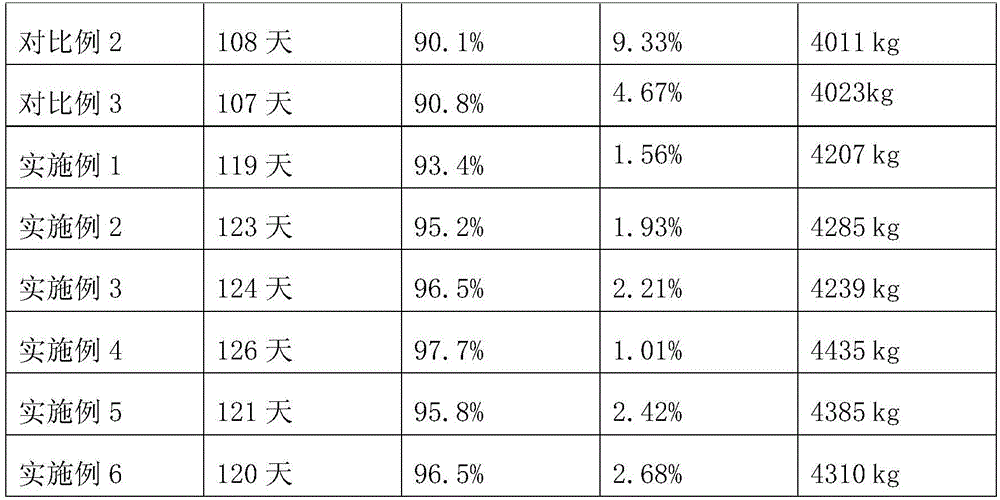

Examples

Embodiment 1

[0048] 1. Early preparation

[0049] Preparation of polyethylene composite film: in parts by weight, 100 parts of polyethylene, 5 parts of starch microspheres, 3 parts of activated carbon, 2 parts of 2,4,6-tri-tert-butylphenol, 3 parts of ethylene glycol, 1 1 part of glycerol and 2 parts of macroporous molecular sieve are mixed evenly, put into a twin-screw melt extruder, and the barrel temperature is 160°C, the head temperature is 200°C, extruded at a speed of 20r / min, cut into granules, and then Then, it is blown into a film by a blow molding machine to obtain a polyethylene composite film.

[0050] Preparation of polyethylene terephthalate composite film: by weight parts, 85 parts of polyethylene terephthalate, 5 parts of lignin, 2 parts of nano titanium dioxide, 2 parts of nano silicon dioxide, Mix 2 parts of 2,6-di-tert-butyl-p-cresol, 2 parts of glycerol and 1 part of benzotriazole evenly, put them into a twin-screw melt extruder, the barrel temperature is 175°C, and th...

Embodiment 2

[0058] 1. Early preparation

[0059] Preparation of polyethylene composite film: in parts by weight, 105 parts of polyethylene, 6 parts of starch microspheres, 3.5 parts of activated carbon, 2.5 parts of 2,4,6-tri-tert-butylphenol, 4 parts of ethylene glycol, 2 1 part of glycerol and 3.5 parts of macroporous molecular sieve are mixed uniformly, put into a twin-screw melting extruder, and the barrel temperature is 165°C, the head temperature is 220°C, extruded at a speed of 45r / min, cut into granules, and then Then, it is blown into a film by a blow molding machine to obtain a polyethylene composite film.

[0060] Preparation of polyethylene terephthalate composite film: by weight parts, 90 parts of polyethylene terephthalate, 8 parts of lignin, 2.5 parts of nano titanium dioxide, 2.2 parts of nano silicon dioxide, Mix 3 parts of 2,6-di-tert-butyl-p-cresol, 3 parts of glycerol and 1.5 parts of benzotriazole evenly, put them into a twin-screw melt extruder, the barrel temperatu...

Embodiment 3

[0068] 1. Early preparation

[0069] Preparation of polyethylene composite film: in parts by weight, 115 parts of polyethylene, 7 parts of starch microspheres, 4 parts of activated carbon, 3.5 parts of 2,4,6-tri-tert-butylphenol, 4 parts of ethylene glycol, 2.5 1 part of glycerol and 2.5 parts of macroporous molecular sieve are mixed evenly, put into a twin-screw melt extruder, and the barrel temperature is 175°C, the head temperature is 210°C, extruded at a speed of 45r / min, cut into granules, and then Then, it is blown into a film by a blow molding machine to obtain a polyethylene composite film.

[0070] Preparation of polyethylene terephthalate composite film: by weight parts, 90 parts of polyethylene terephthalate, 10 parts of lignin, 2.8 parts of nano titanium dioxide, 3 parts of nano silicon dioxide, Mix 3.5 parts of 2,6-di-tert-butyl-p-cresol, 3.5 parts of glycerol and 1.5 parts of benzotriazole evenly, put them into a twin-screw melt extruder, the barrel temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com