High-vertical-rack grape cultivation method

A cultivation method and high-hanging frame technology, applied in the field of viticulture, can solve the problems of inconvenient mechanized pruning, large amount of manual input, and control of growth potential, so as to reduce manual management and maintenance links and costs, reduce the cost of erecting wires, and reduce production. and the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

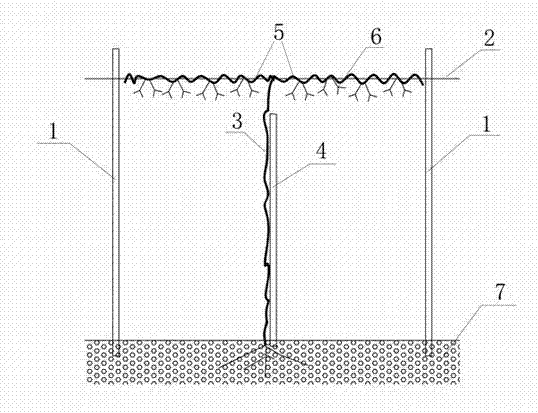

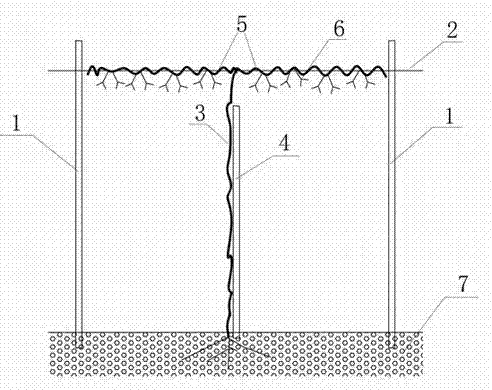

[0028] Figure 1 It is an embodiment of the high-hanging viticulture method, which is realized by means of the support column 1 set in the vineyard and the load line 2 provided between the support column 1, and is carried out according to the following steps:

[0029] 1) After the new shoots of the grape seedlings grow, select a new shoot and tie it to the upright pole, and cultivate it as the trunk 3, so that the trunk 3 can grow upright, and the trunk 3 can be tied to the upright pole 4 every 30 centimeters and tied once every 30 cm. 3 When the growth exceeds the bearing line 2, the main trunk 3 is topped off, and the auxiliary shoot at the top of the topping mouth is selected as the main vine 5 to be cultivated along the direction of the bearing line 2. The main vine 5 is bound on the bearing line 2, and the bearing line is set at a distance from the ground. 1.5 meters, the main vine 5 is 1.5 meters from the ground,

[0030] 2) On both sides of the main vine 5, according t...

Embodiment 2

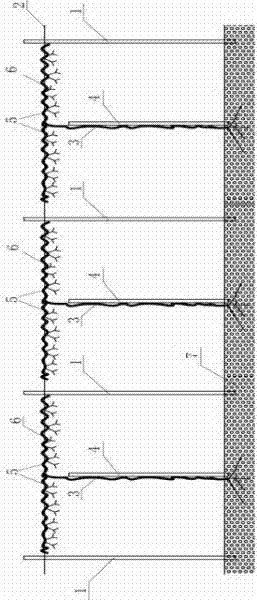

[0035] Another embodiment of a high-hanging type viticulture method is realized by means of a supporting column 1 arranged in a vineyard and a carrying line 2 provided between the supporting column 1, and is carried out according to the following steps:

[0036] 1) After the new shoots of the grape seedlings grow, select a new shoot and bind it to the upright pole, and cultivate it as the trunk 3, so that the trunk 3 can grow upright, and the trunk 3 can be tied to the upright pole 4 every 40 cm. 3. When growing beyond the bearing line 2, the trunk 3 will be pinched after the end, and the auxiliary tip at the top of the pinching mouth will be selected as the main vine 5 to cultivate along the bearing line 2 direction. The bearing line is set to 2 meters away from the ground, and the main vine 5 is 2 meters away from the ground.

[0037] 2) On both sides of the main vine 5, according to the characteristics of the grape variety, the medium and short shoot group 6 is interleaved, ...

Embodiment 3

[0041] Realize by means of the supporting column 1 provided in the vineyard and the carrying line 2 provided between the supporting column 1, and proceed according to the following steps:

[0042] 1) After the new shoots of the grape seedlings grow, select a new shoot and tie it to the upright pole, and cultivate it as the trunk 3, so that the trunk 3 can grow upright, and the trunk 3 can be tied to the upright pole 4 every 35 cm. 3. When growing beyond the bearing line 2, the trunk 3 will be pinched after the end, and the auxiliary shoot at the top of the pinching mouth will be selected as the main vine 5 to cultivate along the bearing line 2 direction. The bearing line is set to 1.75 meters away from the ground, and the main vine 5 is 1.75 meters away from the ground.

[0043] 2) On both sides of the main vine 5, according to the characteristics of the grape variety, the medium and short shoot group 6 is interleaved, and the distance between the medium and short shoot groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com