Processing method of rose aromatized wine

A fragrant wine and processing method technology, which is applied in the processing field of rose scented wine, can solve the problem of low added value of the product, and achieve the effects of full body, clear and transparent wine body, simple production process and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

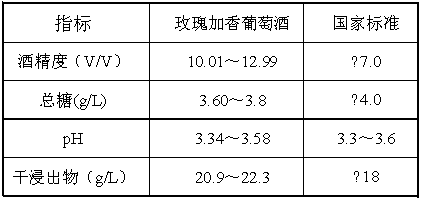

[0034] Example 1 A method for processing rose scented wine, comprising the following steps:

[0035] ⑴Sort Merlot grape fruits, remove branches, leaves, stiff fruits, raw green fruits and other sundries, wash fully with water, wash away the attached sediment, impurities and residual pesticides, crush and press them, and then add 90mg sodium metabisulfite to make SO 2 50ppm to get grape must.

[0036] (2) Add bitter water roses with the calyx removed in 2.5% of the mass of the grape mash, mix and remove stems and crush to obtain grape juice.

[0037] (3) Add 25 mg of activated pectinase to 1 L of grape juice for impregnation, add 180 mg of activated yeast to 1 L of grape juice after 36 hours, and ferment at 22°C according to the conventional method; after 10 days, the main fermentation ends , separated self-flowing new wine, stored in a closed fermenter, the filling rate of the fermenter is 95%, and the post-fermentation is carried out without skin marc; after 60 days, ...

Embodiment 2

[0042] Example 2 A method for processing rose scented wine, comprising the following steps:

[0043] ⑴Sort Merlot grape fruits, remove branches, leaves, stiff fruits, raw green fruits and other sundries, wash fully with water, wash away the attached sediment, impurities and residual pesticides, crush and press them, and then add 180mg sodium metabisulfite to make it SO 2 100ppm to get grape must.

[0044] (2) Add bitter water roses with the calyx removed in 2.5% of the mass of the grape mash, mix and remove stems and crush to obtain grape juice.

[0045] (3) Add 25 mg of activated pectinase to 1 L of grape juice for impregnation. After 48 hours, add 200 mg of activated yeast to 1 L of grape juice, and ferment at 27°C according to a conventional method; 12 days later, the main fermentation At the end, the free-flowing new wine is stored in a closed fermenter with a filling rate of 95%, and post-fermentation is carried out without pomace; after 90 days, the post-fermenta...

Embodiment 3

[0050] Example 3 A method for processing rose scented wine, comprising the following steps:

[0051] ⑴Sort Merlot grape fruits, remove branches, leaves, stiff fruits, raw green fruits and other sundries, wash fully with water, wash away the attached sediment, impurities and residual pesticides, crush and press them, and then add 130mg sodium metabisulfite to make it SO 2 80ppm to get grape must.

[0052] (2) Add bitter water roses with the calyx removed in 2.5% of the mass of the grape mash, mix and remove stems and crush to obtain grape juice.

[0053] (3) Add 25 mg of activated pectinase to 1 L of grape juice for impregnation. After 40 hours, add 190 mg of activated yeast to 1 L of grape juice, and ferment at 25°C according to a conventional method; after 11 days, the main fermentation At the end, the free-flowing new wine is stored in closed fermenters with a filling rate of 95%, and post-fermentation is carried out without pomace; after 75 days, the post-fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com