Intermittent cooling water supplying system for die casting mold

A technology of cooling water system and die-casting mold, which is applied in the field of cooling system, can solve problems such as mold overcooling, mold continuous water supply, uncontrollable cooling water supply time, etc., and achieve the effect of ensuring heat balance and improving cooling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

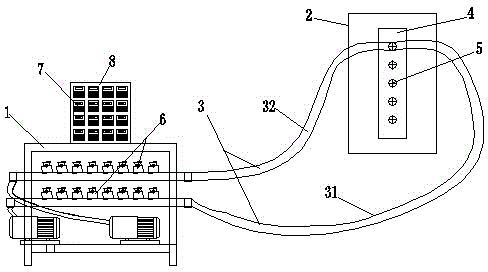

[0011] The present invention comprises a body 1, the body 1 is provided with a cooling pipe 3 connected to the mold 2; the mold 2 is provided with a cooling connection block 4 corresponding to the cooling pipe 3, and the cooling connection block 4 is provided with several cooling The cooling joint 5 corresponding to the pipe 3;

[0012] The cooling pipe 3 is provided with a valve 6 , and is provided with a time relay 7 and a control box 8 for controlling the action of the valve 6 .

[0013] The cooling pipe 3 is separated into two parts, one is the water inlet pipe 31, and the other is the air inlet pipe 32. The ports of the water inlet pipe 31 and the air inlet pipe 32 are connected with the cooling joint 5 respectively, and are provided with a control water inlet pipe 31, The valve 6 that connects the intake pipe 21 and the cooling joint 5 .

[0014] The steps of the present invention are: first set the time for water supply and air supply at the time relay 7, after the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com