Zero-drive chain digital control gear hobbing machine

A gear hobbing machine and zero transmission technology, which is applied in the field of zero transmission CNC gear hobbing machines, can solve problems such as limitations, affecting machining accuracy, and affecting machine tool accuracy retention, and achieve the effects of improving rigidity, improving machining accuracy, and good quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

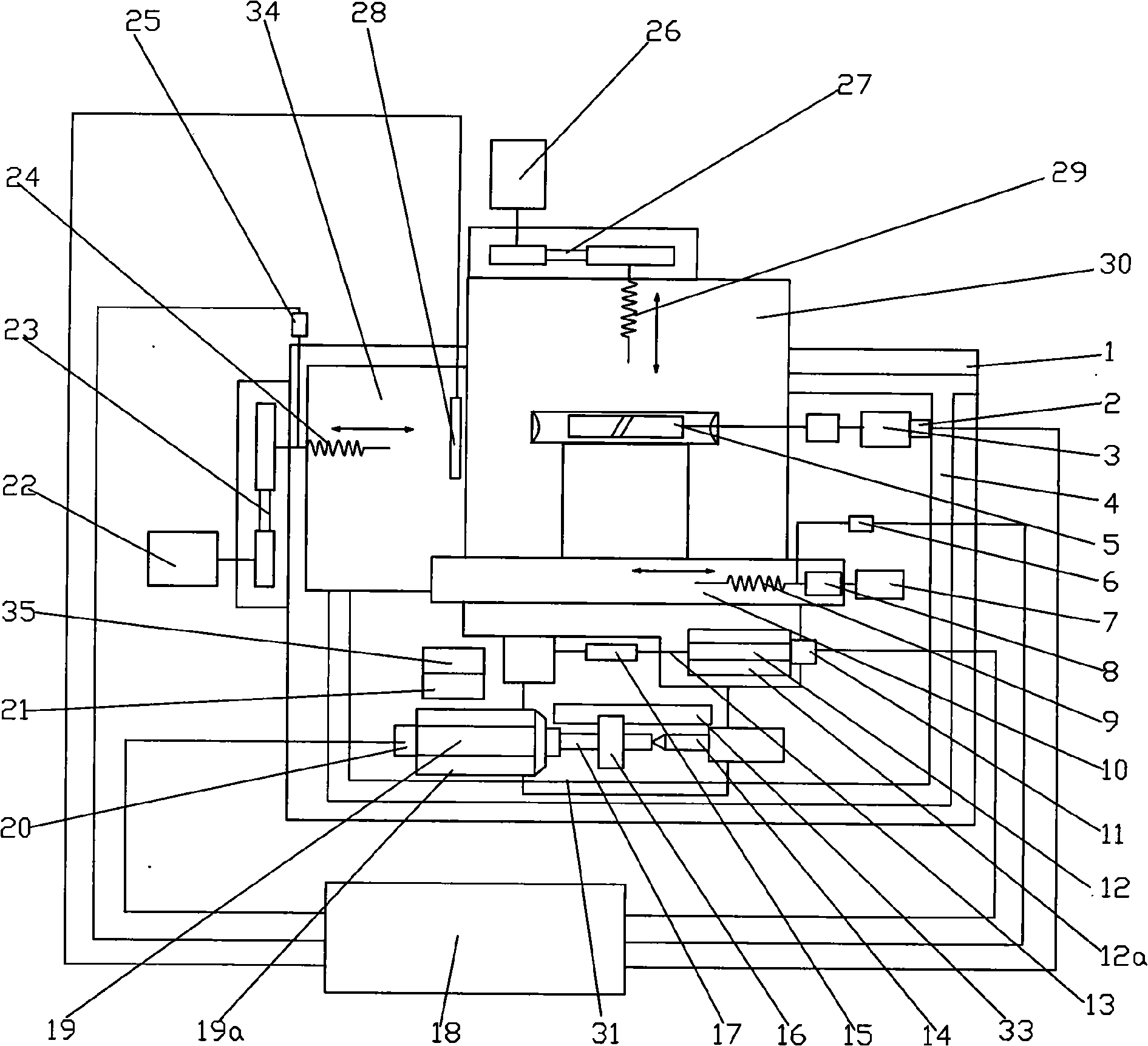

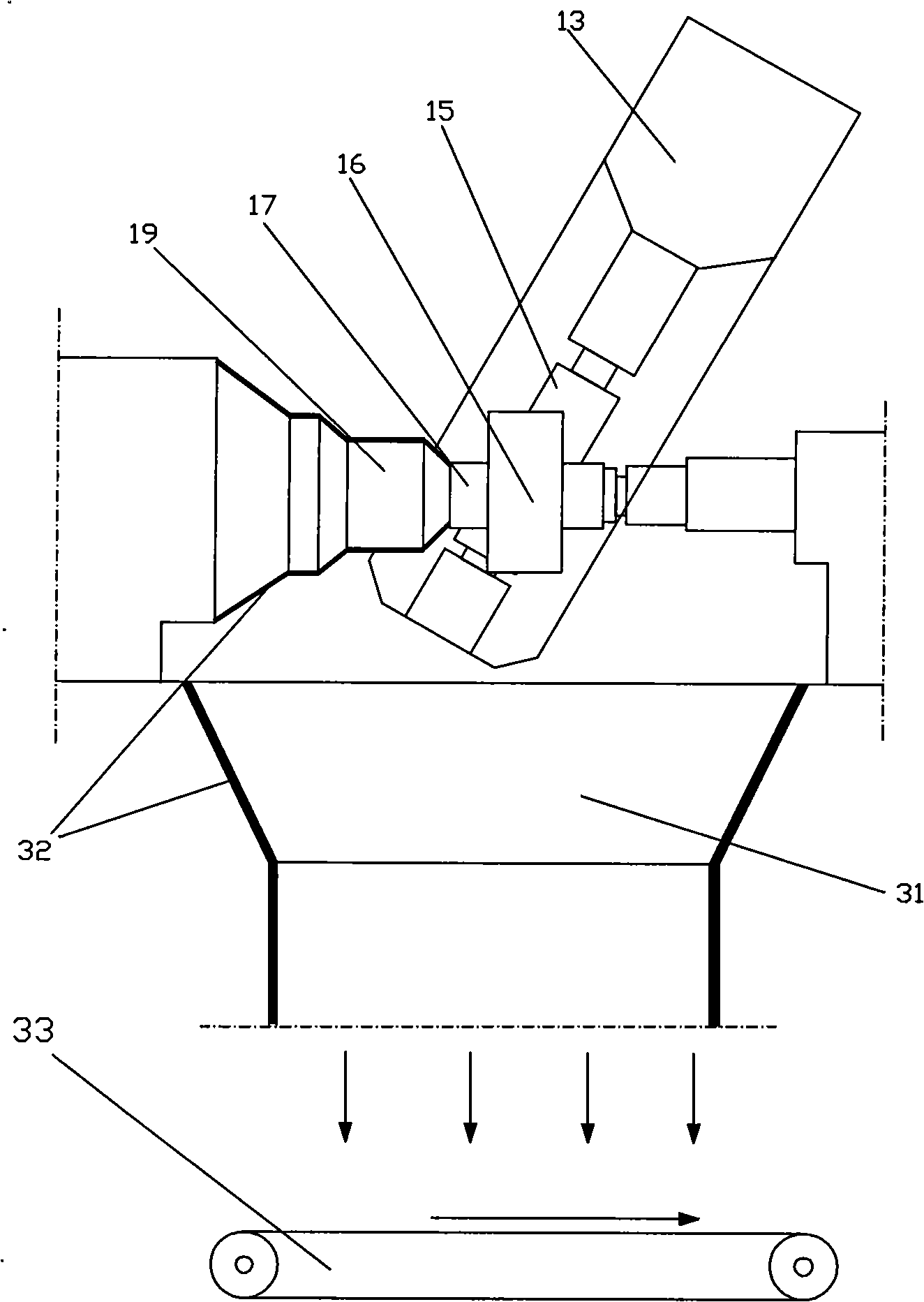

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the chip removal port and the workpiece spindle of the present invention, as shown in the figure: the zero-transmission CNC gear hobbing machine of this embodiment adopts a horizontal layout, including a bed 1, a spindle system, a hob feed system, and a hob installation angle adjustment device and CNC control system 18;

[0022] The spindle system includes a hob spindle functional part 12 and a workpiece spindle functional part 19. The hob spindle functional part 12 is the rotor of the servo motor I 12a integrated with the hob spindle, and the workpiece spindle functional part 19 is the servomotor II 19a. The rotor is integrated with the workpiece spindle to achieve zero transmission; the end of the workpiece spindle functional part 19 is connected to the workpiece mandrel 17, and the end of the workpiece mandrel 17 is provided with a relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com