Method for constructing refractory materials at pellet rotary kiln bellow port

A refractory material and construction method technology, applied in the direction of rotary drum furnace, furnace, lining repair, etc., can solve the problems of reducing the service life of the bellows port, losing the sealing effect of the bellows port, affecting the thermal balance of the system, etc. Good effect and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

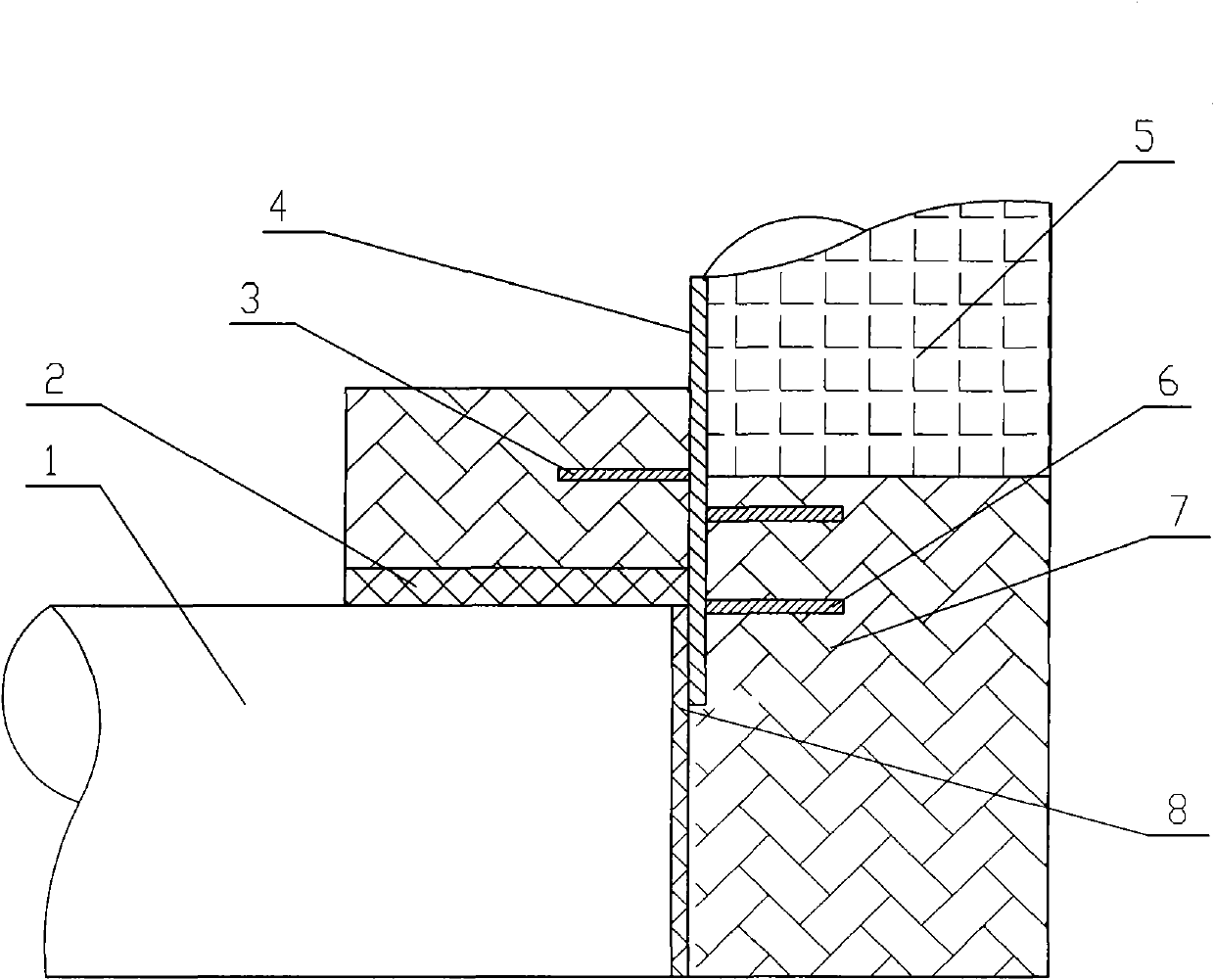

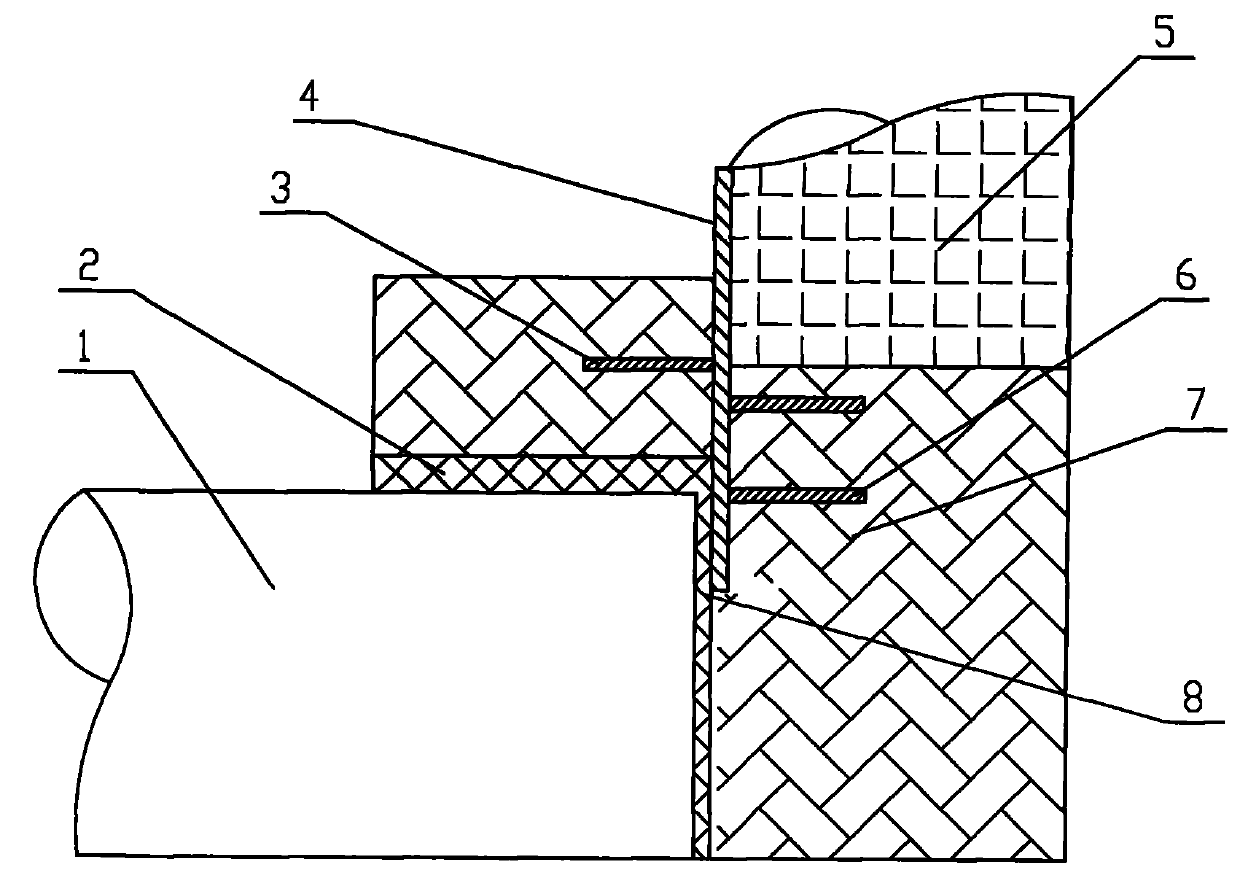

[0024] The layer thickness of the cast refractory material is 90-100mm, and the length of the staple is 40-50mm. This process parameter is suitable for smaller rotary kiln bellows.

[0025] The layer thickness of the cast refractory material is 100-120mm, and the length of the staple is 50-60mm. This process parameter is suitable for the bellows port of medium rotary kiln.

[0026] The layer thickness of the cast refractory material is 120-160mm, and the length of the staple is 60-80mm. This process parameter is suitable for larger rotary kiln air box mouth.

[0027] The construction method of the refractory material at the bellows mouth of the pelletizing rotary kiln of the invention prolongs the service life of the refractory material at the bellows mouth of the pelletizing rotary kiln, meets the needs of production, reduces the maintenance workload, and reduces the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com