Dual-pressure back-pressure turbine heat supply system

A technology of back pressure steam turbine and heating system, which is applied in the direction of steam engine device, steam application, mechanical equipment, etc. It can solve the problems of high back pressure, complex system structure, energy loss, etc., and achieve good economy, simple system and obvious The effect of technological advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

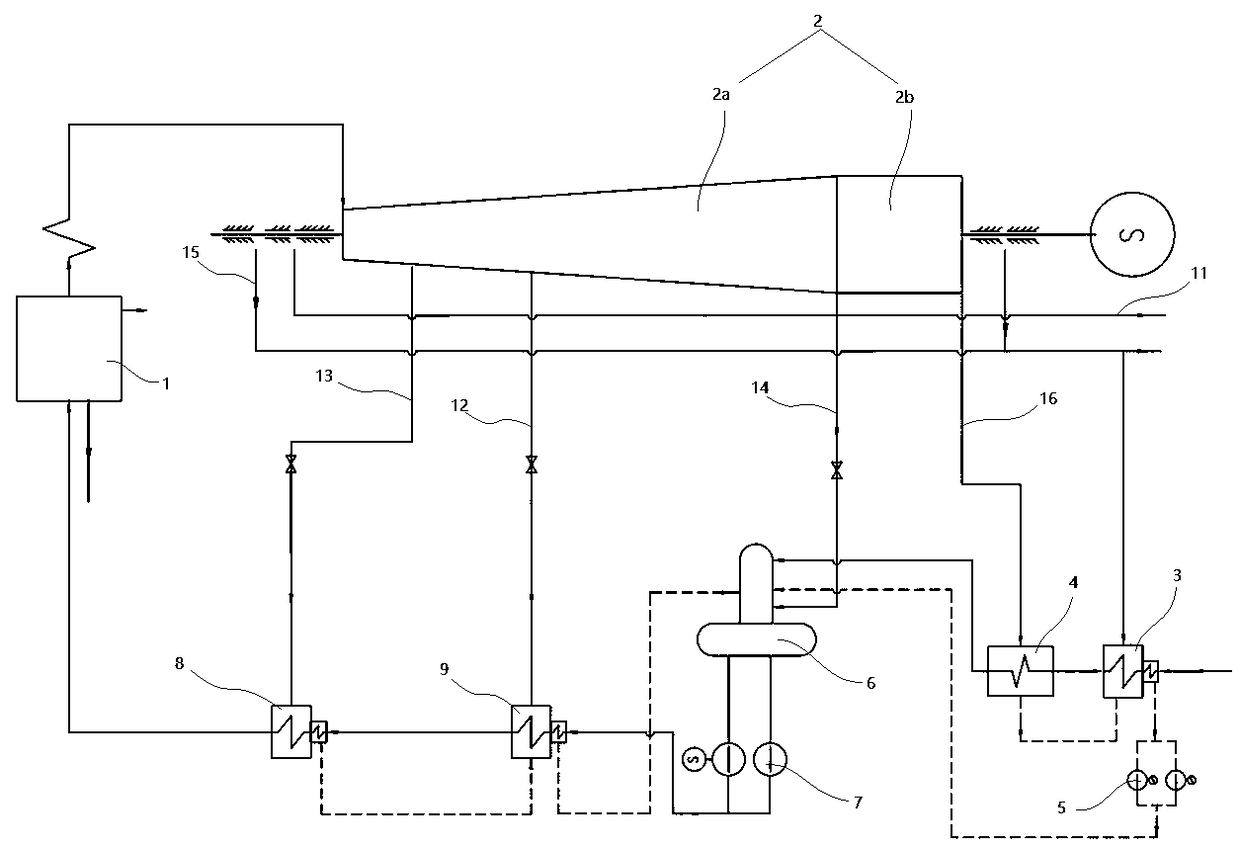

[0015] Please combine figure 1 As shown, the dual-pressure back-pressure steam turbine heating system includes boiler 1, double-pressure back-pressure steam turbine 2, shaft seal heater 3, low-pressure heater 4, drain pump 5, deaerator 6, electric feed water pump 7, first High pressure heater 8 and second high pressure heater 9. Among them, the double-pressure back-pressure steam turbine 2 is a steam turbine composed of a high-pressure back-pressure machine part 2a and a low-pressure back-pressure machine part 2b, that is, there is a space behind the exhaust cylinder of the original back-pressure machine, which is convenient for adding a low-pressure back-pressure machine The impeller, blade and its supporting parts. The low pressure back pressure machine part 2b and the high pressure back pressure machine part 2a are connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com