Patents

Literature

91results about How to "Extended fall time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

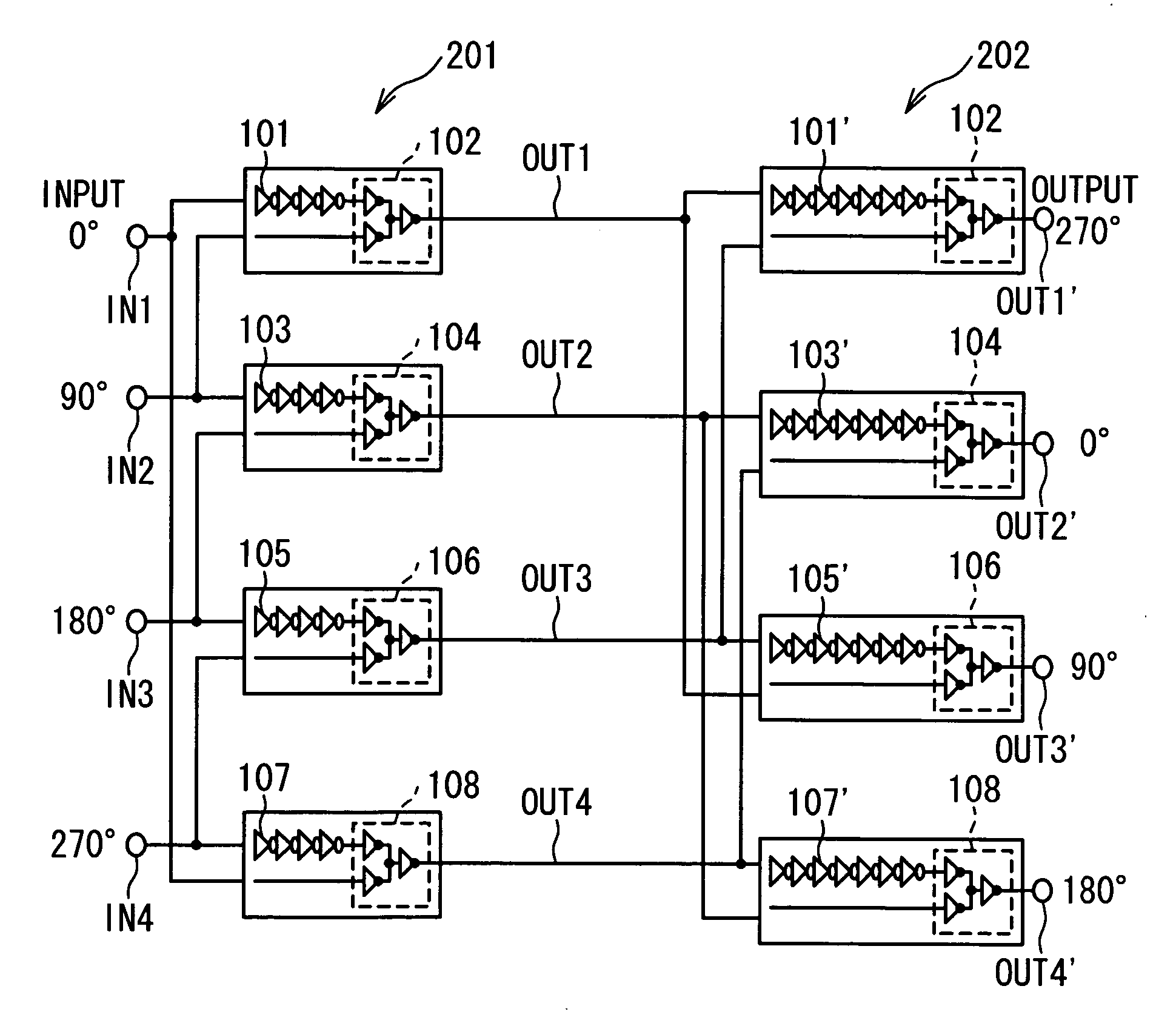

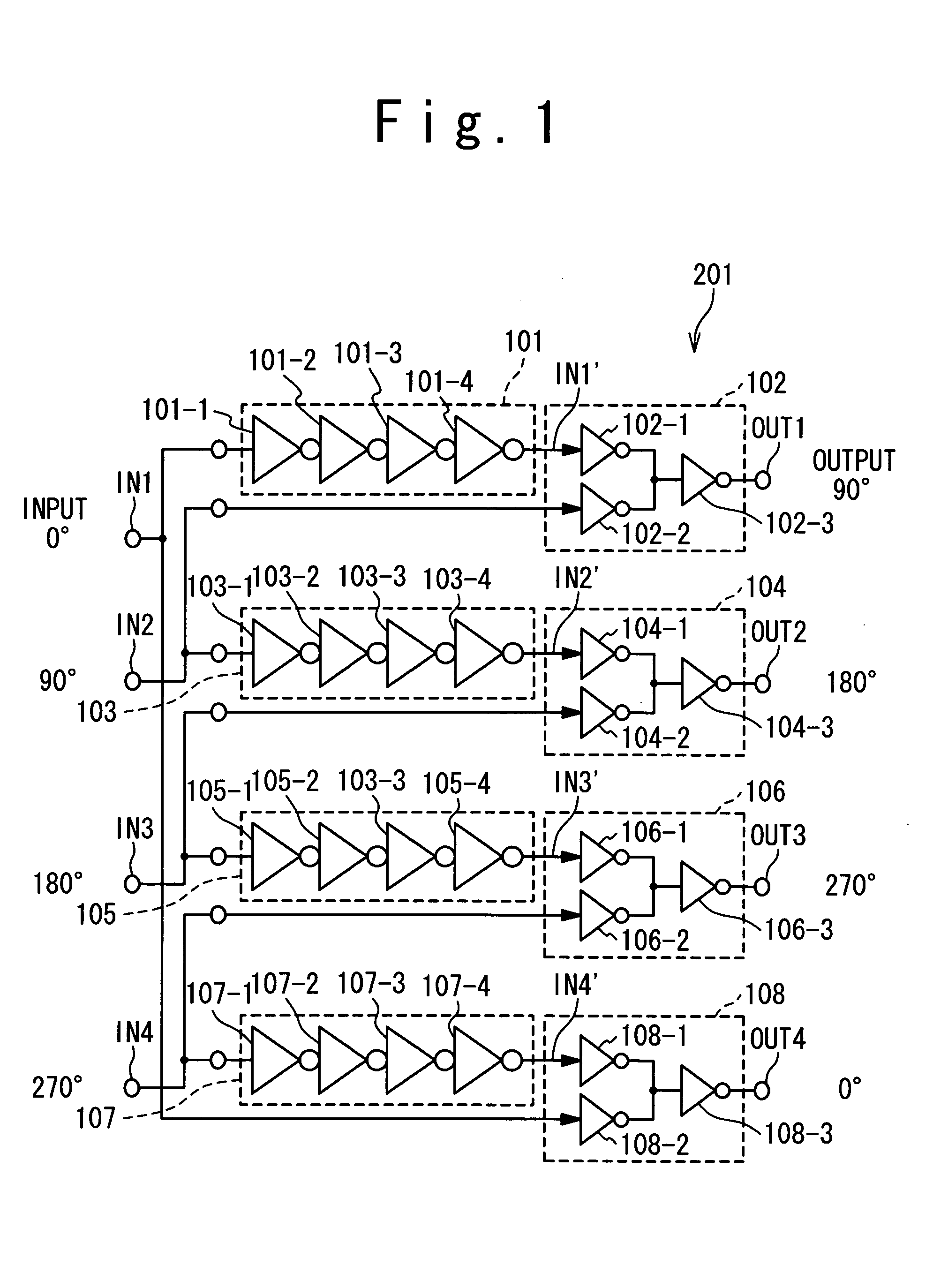

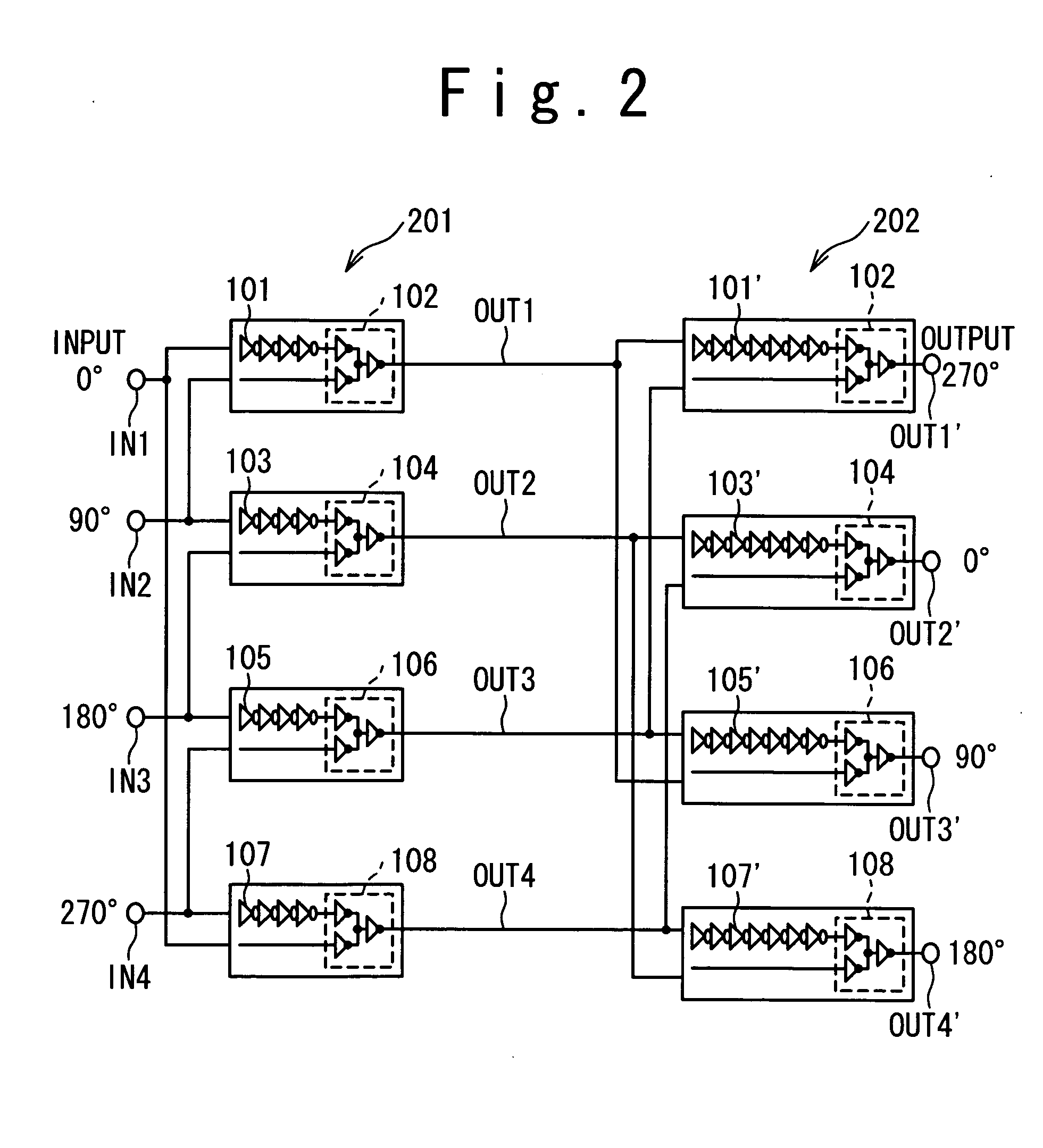

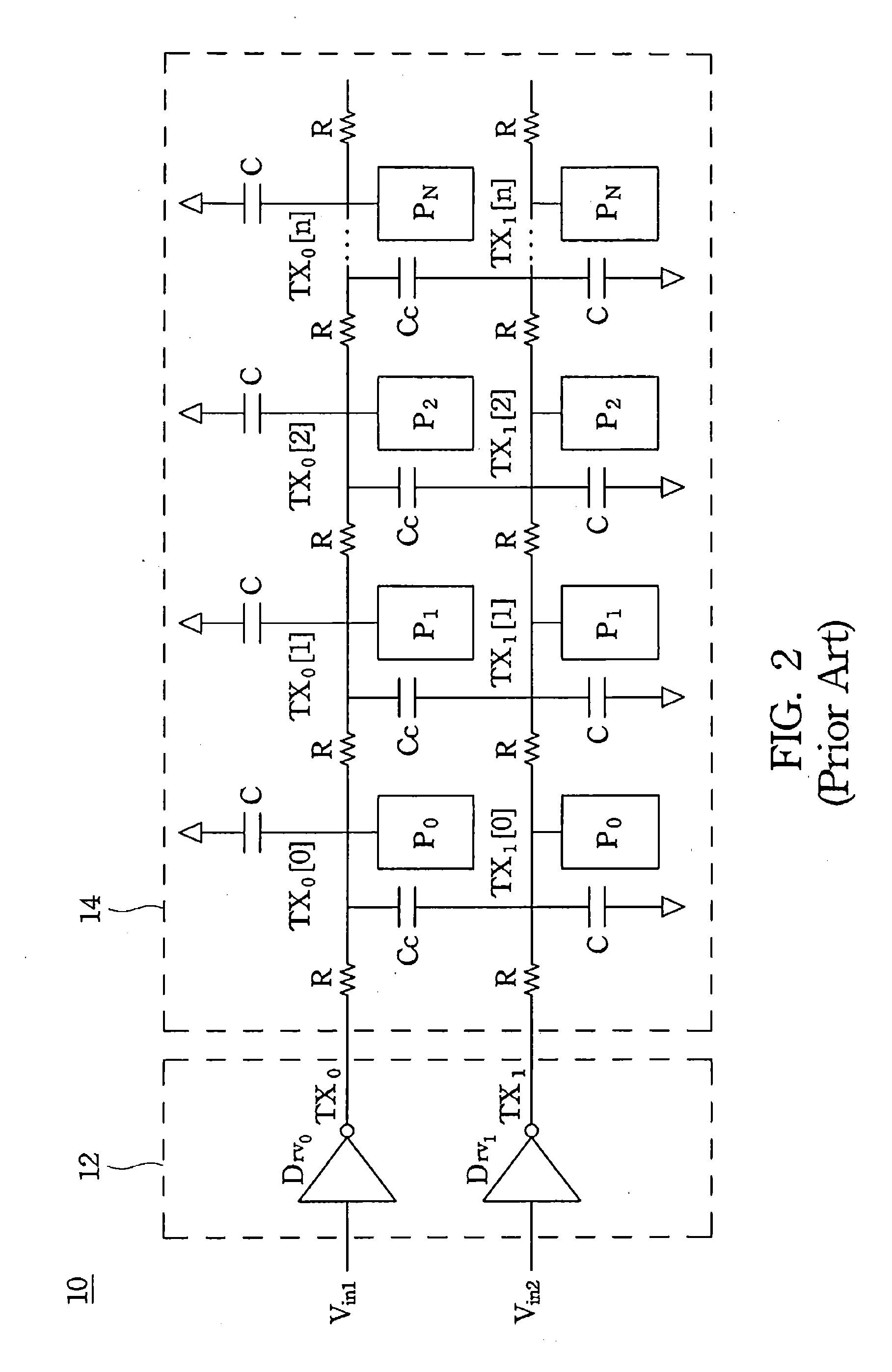

Phase interpolator circuitry for reducing clock skew

InactiveUS20050024117A1Reduced clock skewsImprove smoothnessChannel dividing arrangementsSingle output arrangementsConstant current sourceEngineering

A phase interpolator circuitry is composed of a delay line, and a phase blender circuit. The delay line delays a first input clock signal to develop a delayed clock signal. The phase blender circuit includes a first inverter receiving the delayed clock signal, and a second inverter receiving a second input clock signal phased away from the first input clock signal. The outputs of the first and second inverters are commonly coupled together. The phase interpolator circuitry additionally includes at least one of constant current sources: first one connected between a power terminal of the first inverter and a power supply, second one connected between a ground terminal of the first inverter and ground, third one connected between a power terminal of the second inverter and a power supply, and fourth one connected between a ground terminal of the second inverter and ground.

Owner:NEC ELECTRONICS CORP

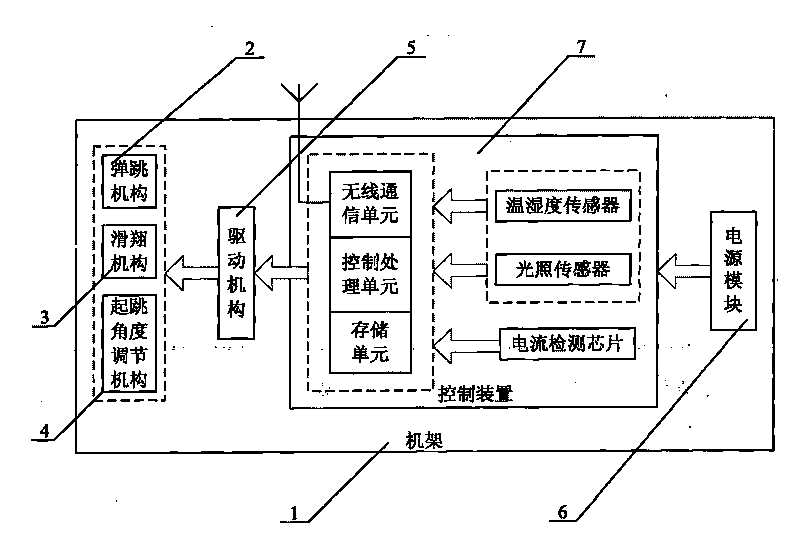

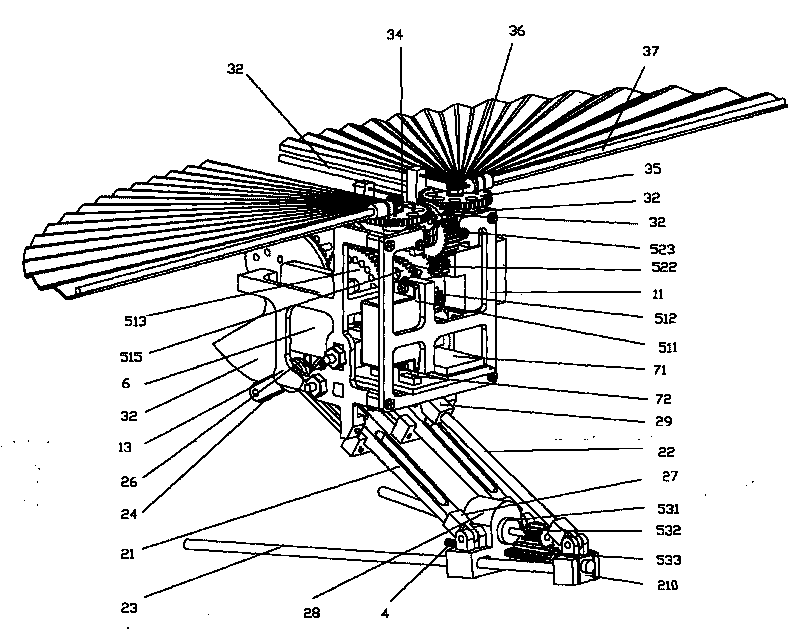

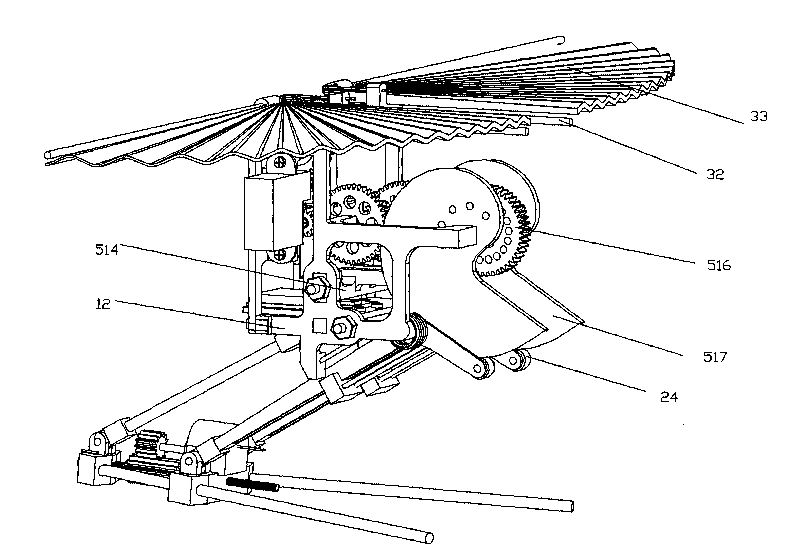

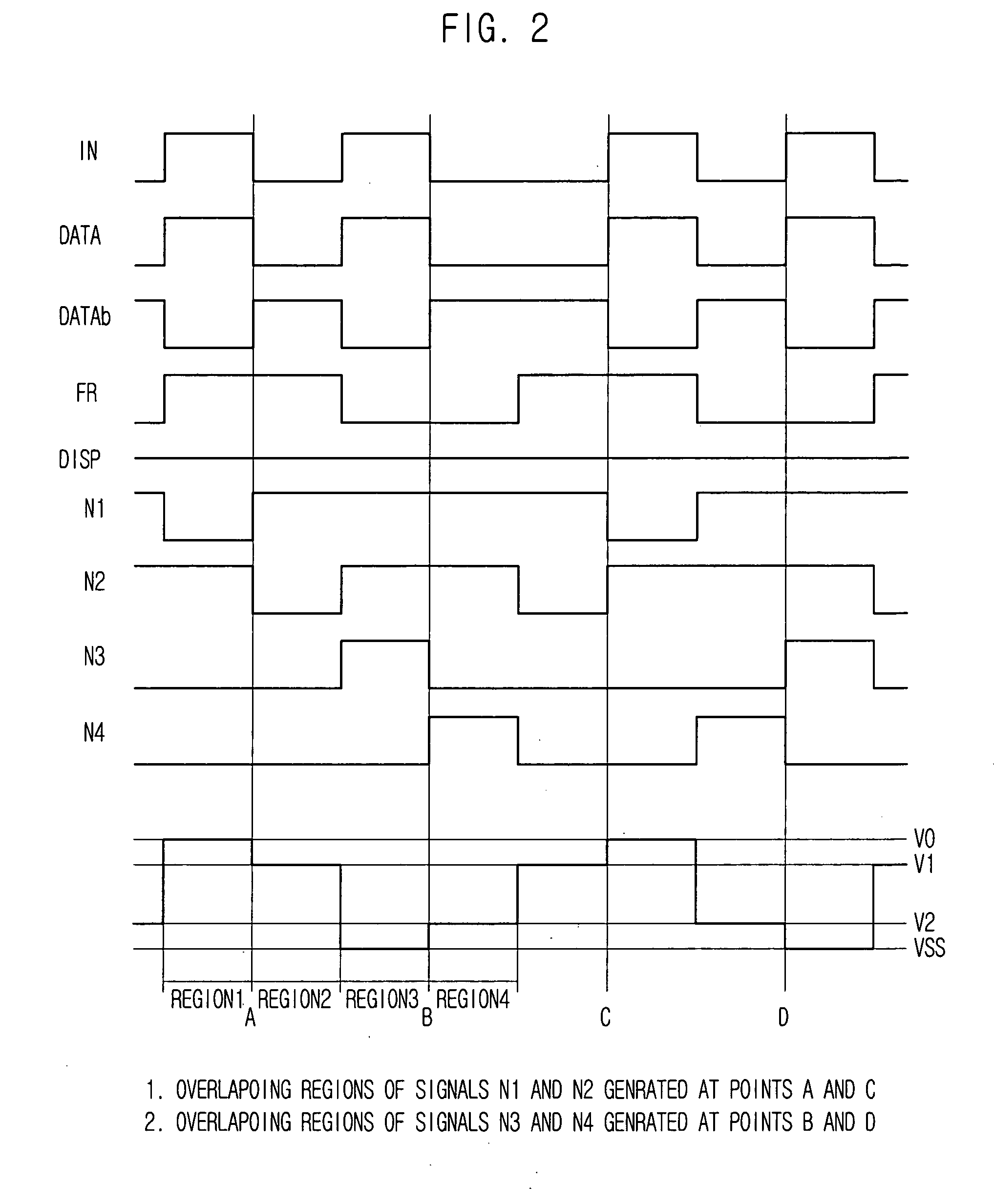

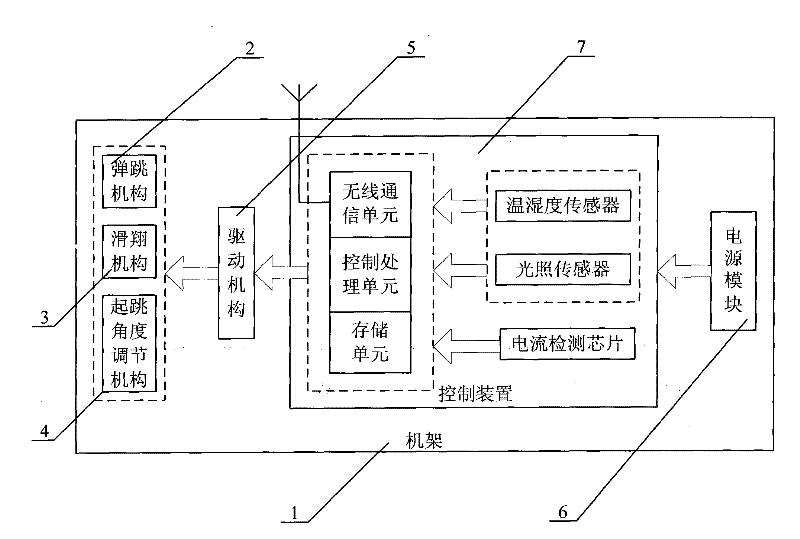

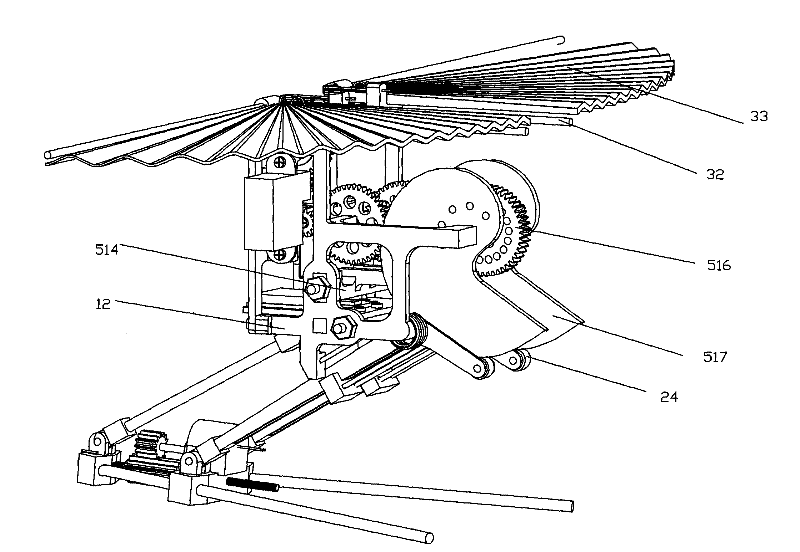

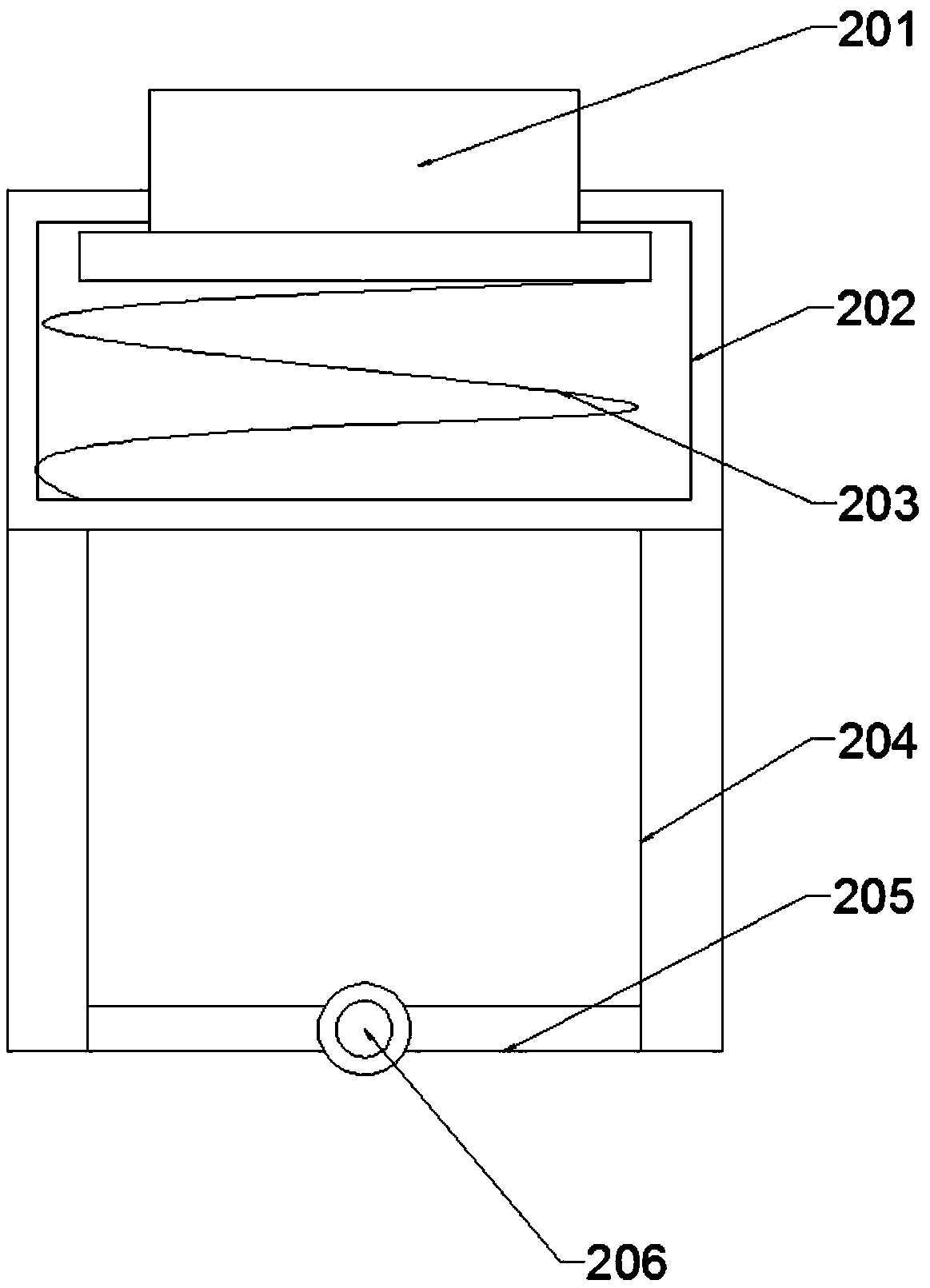

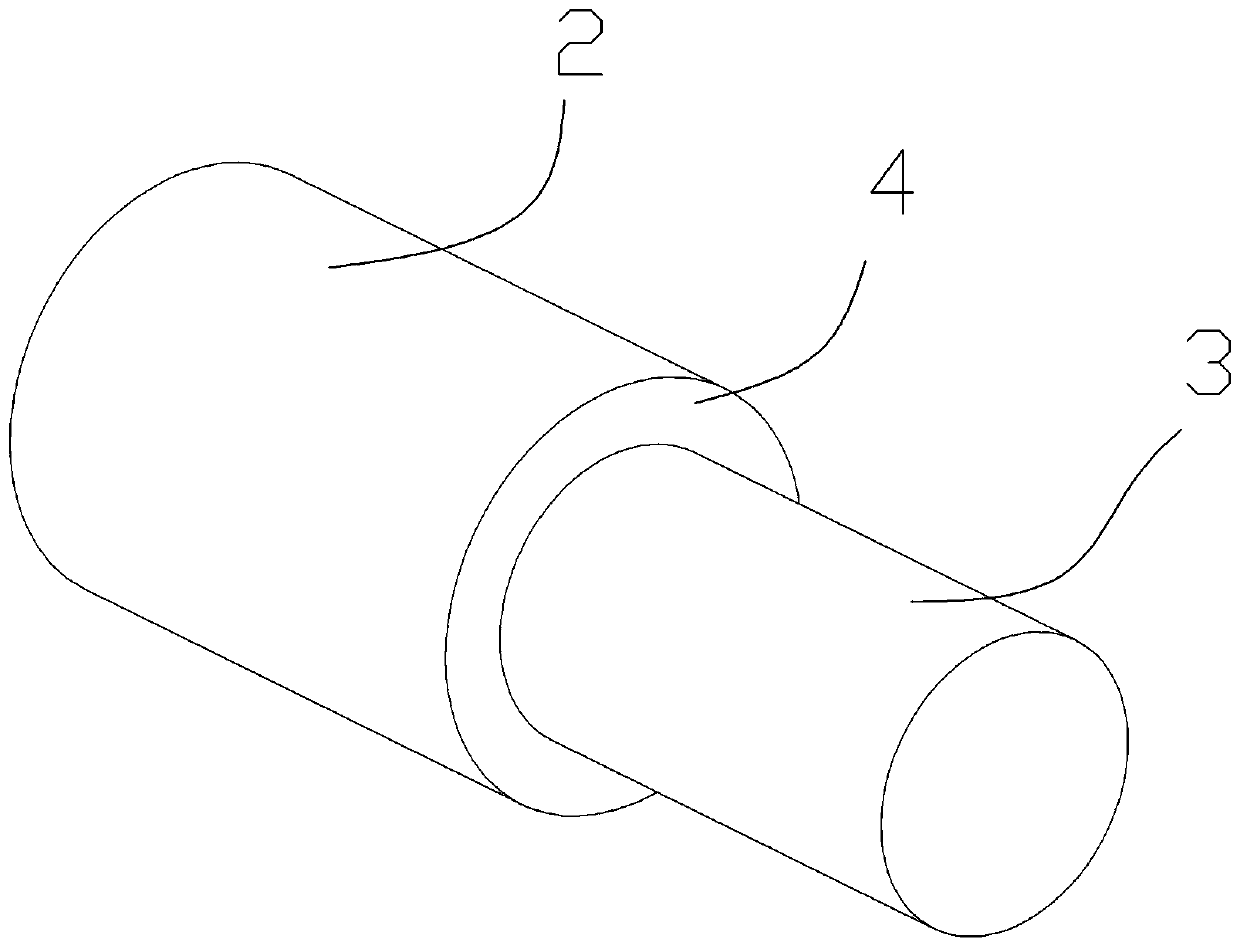

Gliding robot capable of autonomously flying in salutatory mode

InactiveCN101734299AIncrease elastic potential energyHigh snapback characteristicsVehiclesEngineeringRobot

The invention discloses a gliding robot capable of autonomously flying in a salutatory mode, which comprises a frame, a bouncing device arranged on the frame and a bouncing drive device used for driving the bouncing device. A pair of gliding devices and a gliding drive device for driving the gliding devices are also arranged on the frame; each gliding device comprises a front framework, a rear framework, a wing and a folding mechanism; the wings are fixed between the front framework and the rear framework; the front framework and the rear framework are connected with the folding mechanism; and the folding mechanism is connected with the gliding drive device for unfolding the wings. A take-off angle adjustment mechanism of the invention enables the robot to adjust take-off angles autonomously so as to adjust bouncing heights, bouncing distances and achieve stable landing; and therefore, the flexibility of actions of the robot is improved.

Owner:SOUTHEAST UNIV

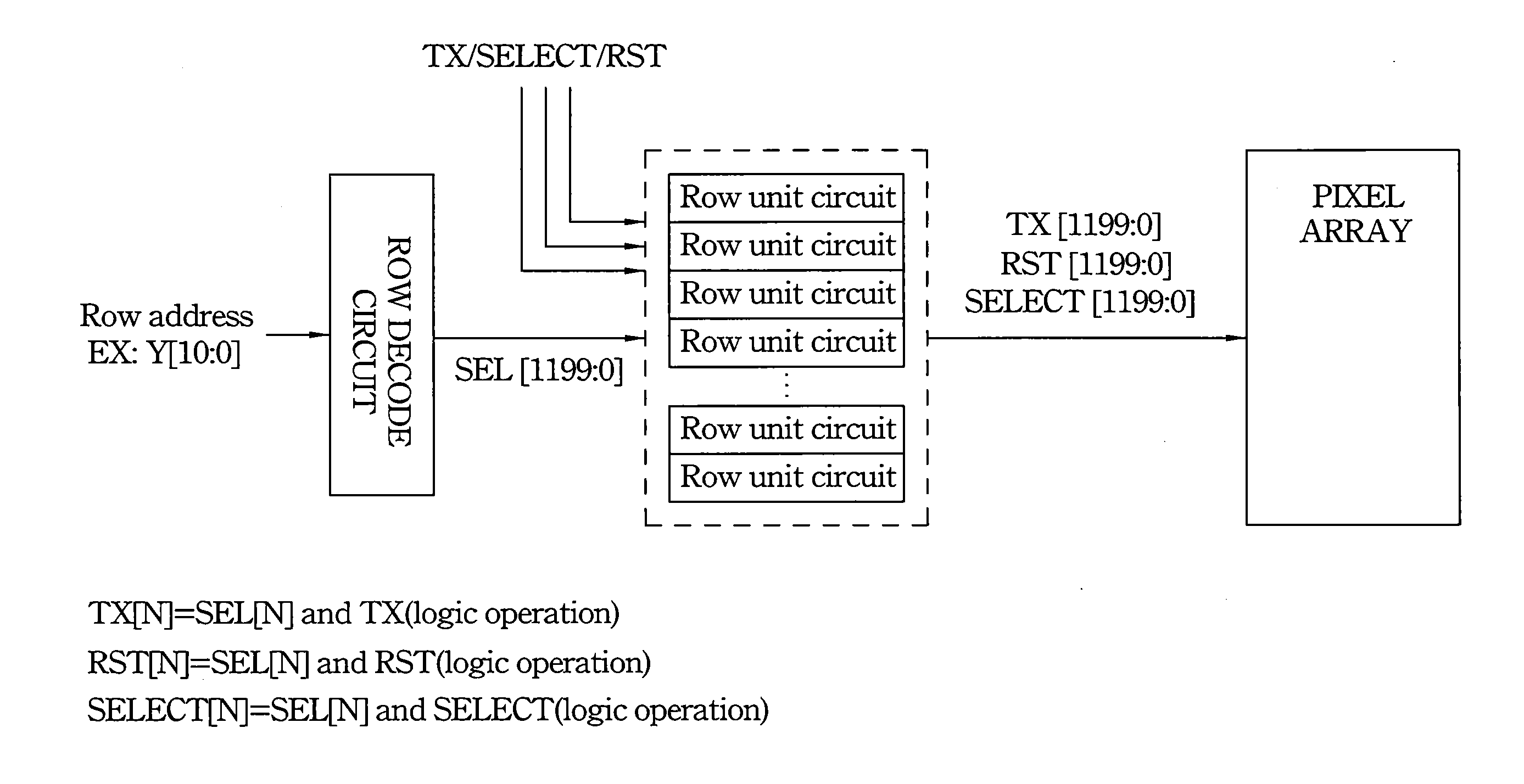

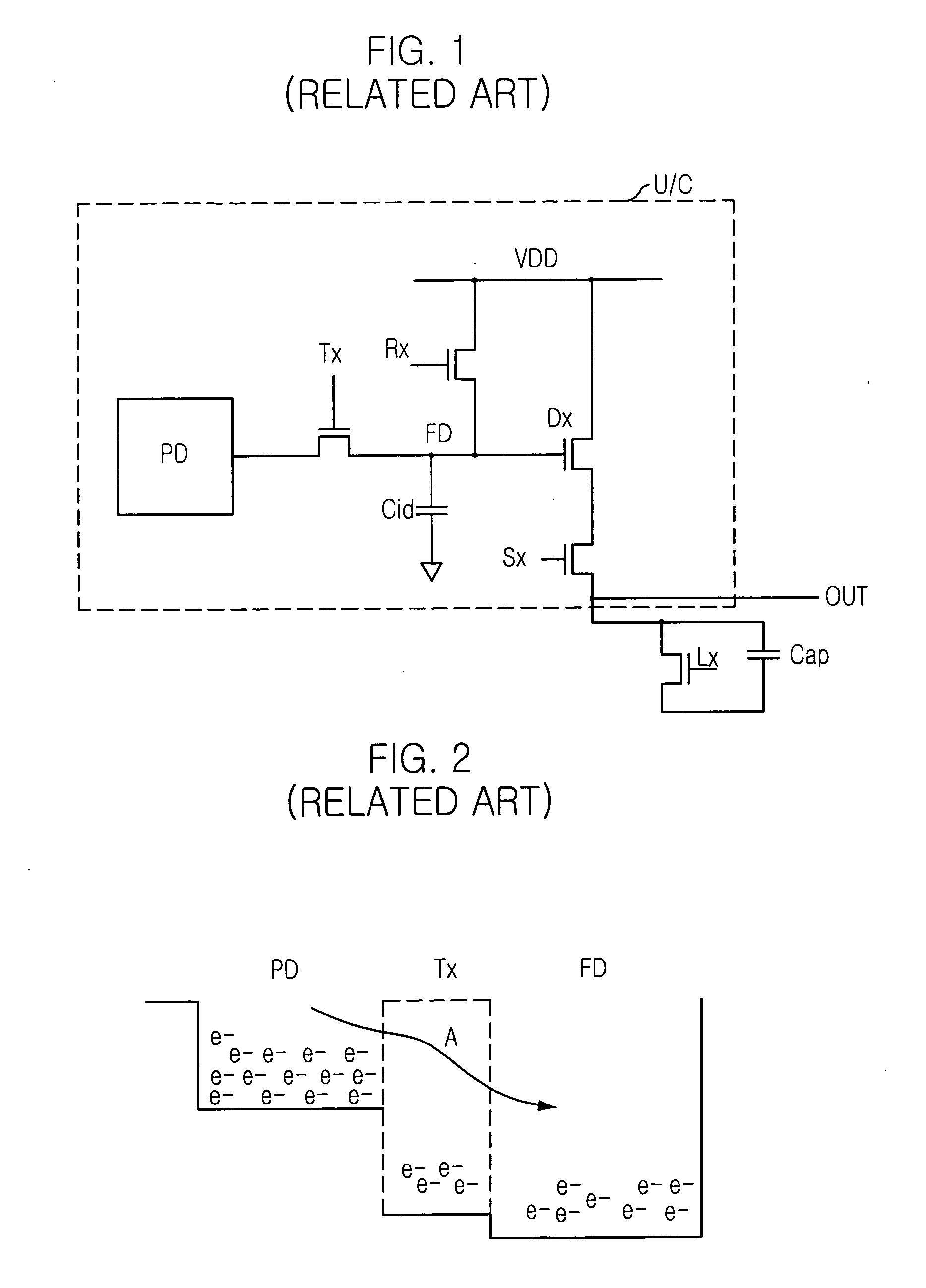

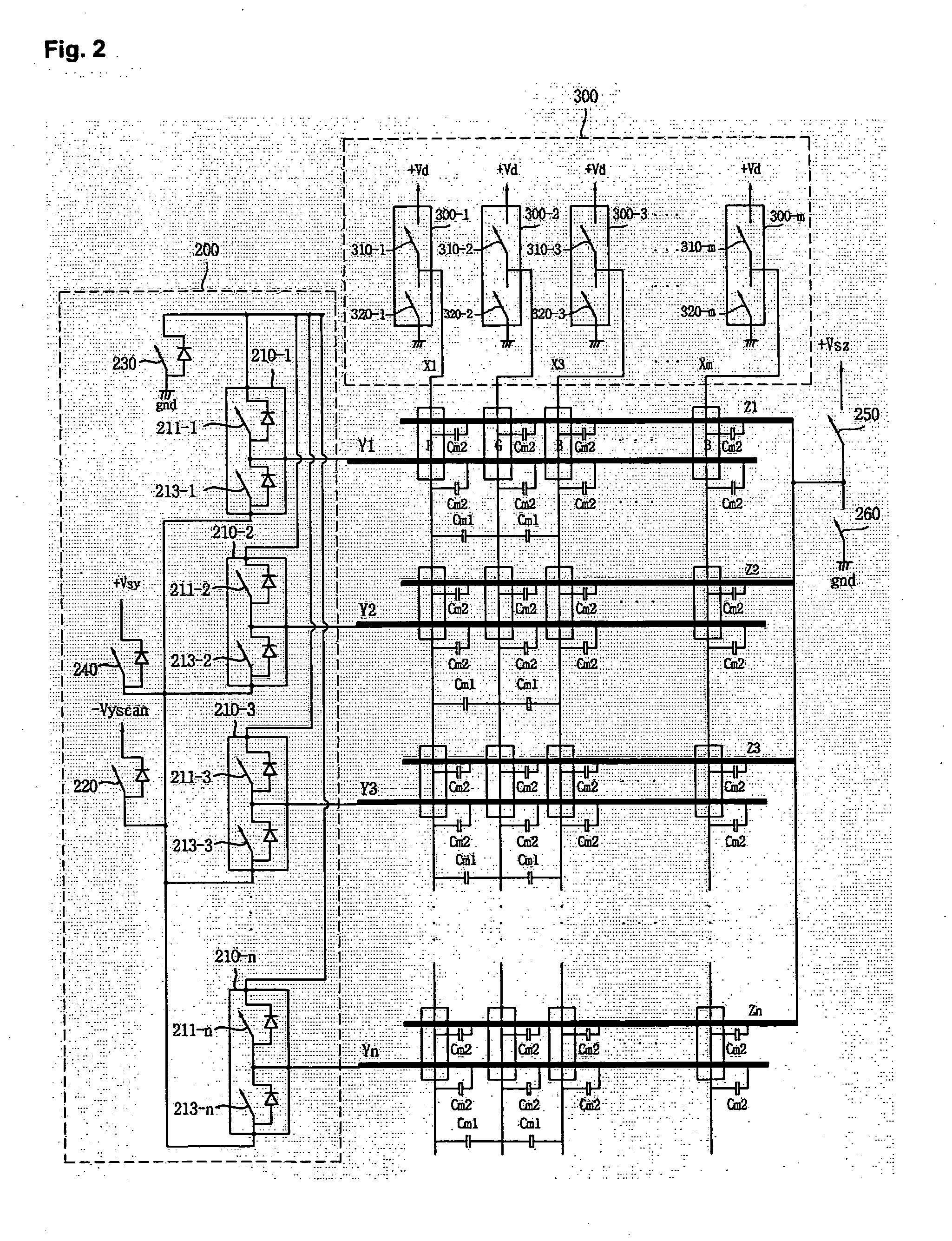

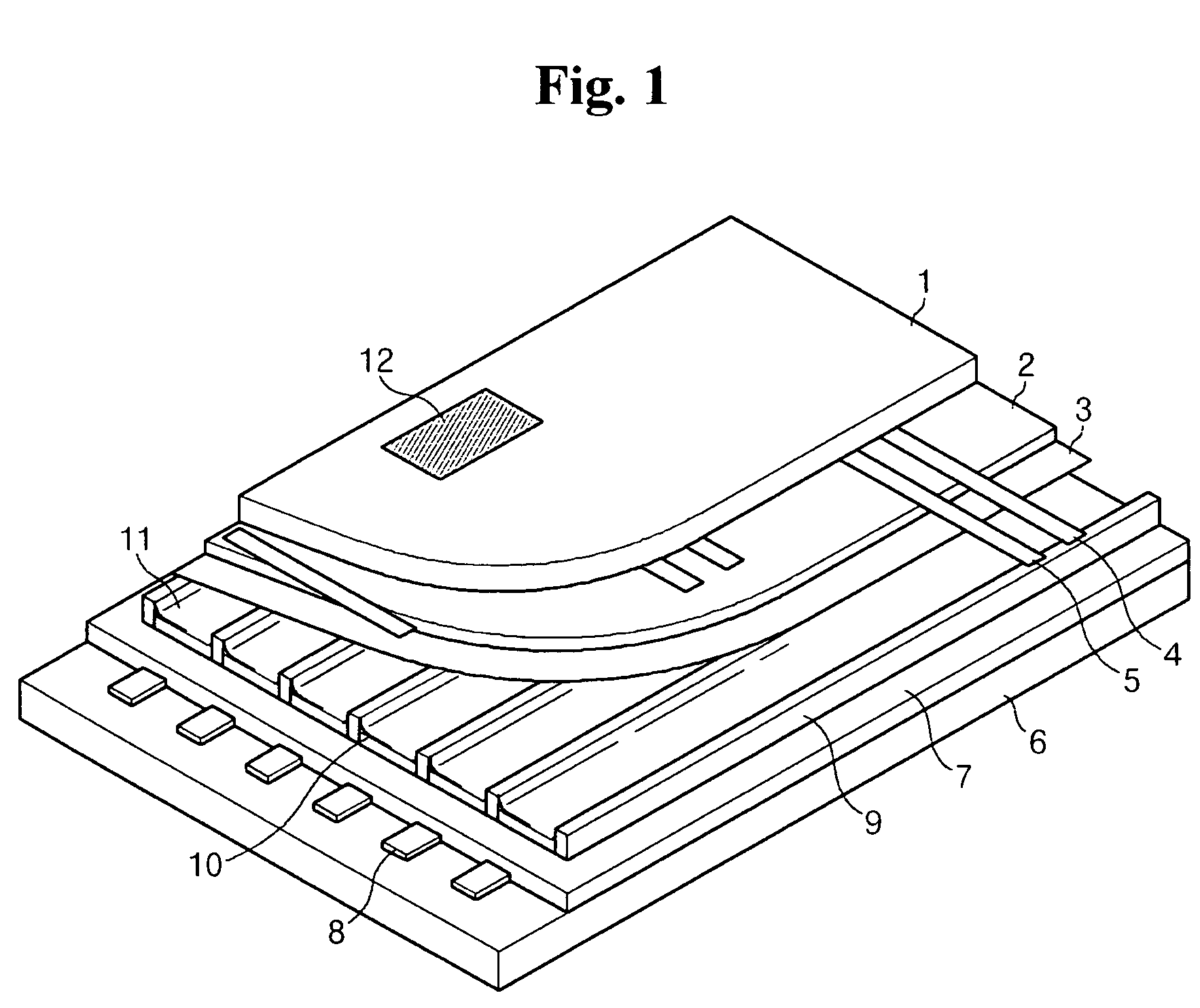

CMOS sensor with low partition noise and low disturbance between adjacent row control signals in a pixel array

ActiveUS20120044398A1Improve partition noiseExtended fall timeTelevision system detailsTelevision system scanning detailsCMOS sensorControl signal

A CMOS image sensor includes a pixel array including a plurality of unit pixels with individual rows of unit pixels being coupled to respective row control signal lines, and a buffer including plural row control signal drivers. Each driver is coupled to a respective one of the row control signal lines and is configured to provide a row control signal pulse to a respective row control signal line in response to an input pulse when the row control signal line is in an active state and to bias the row control signal line at a ground voltage when the respective row control signal line is in an inactive state. Each driver has a first drive capability when the row control signal line is in the active state and a second drive capability greater than the first drive capability when the row control signal line is in an inactive state.

Owner:TAIWAN SEMICON MFG CO LTD

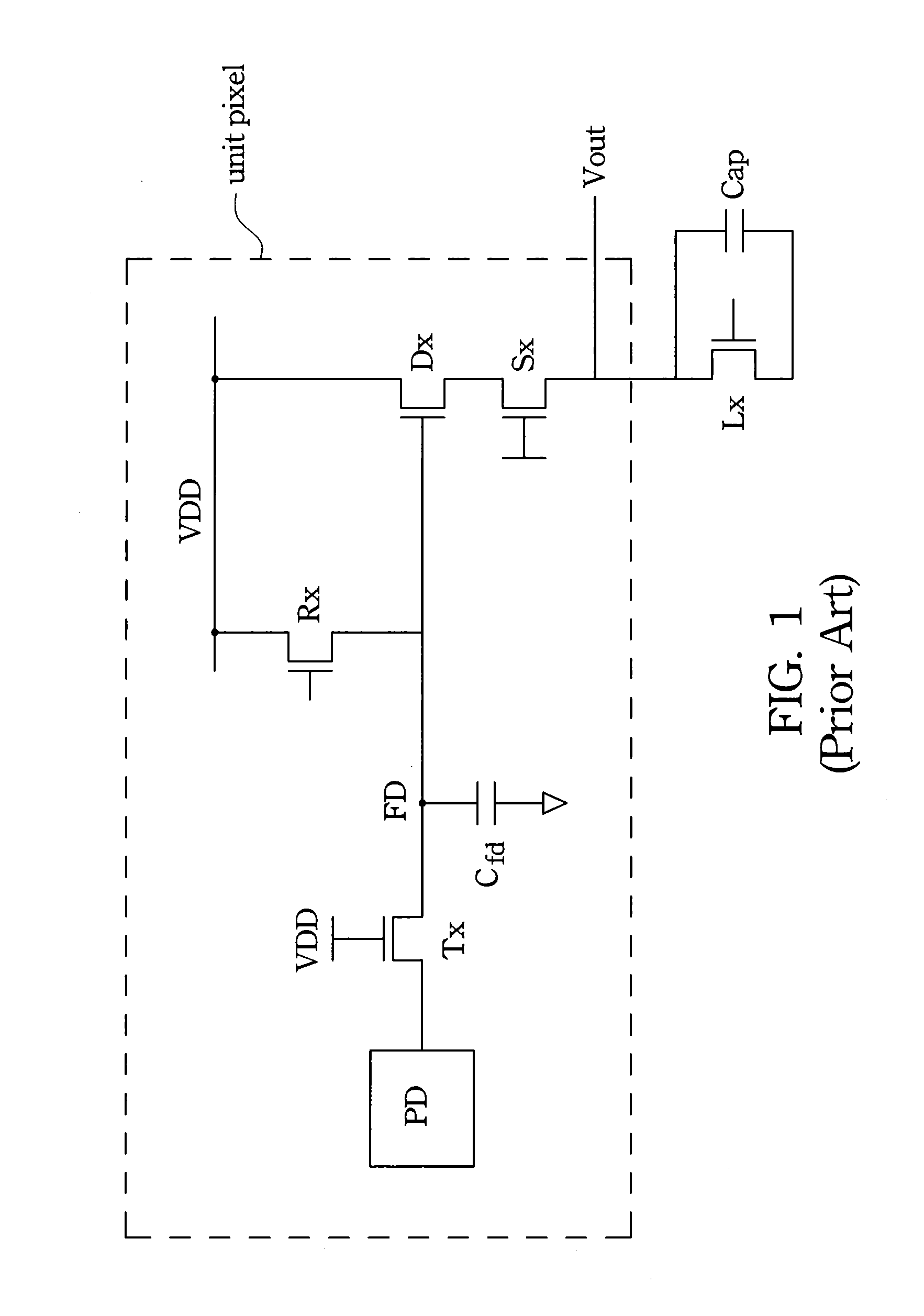

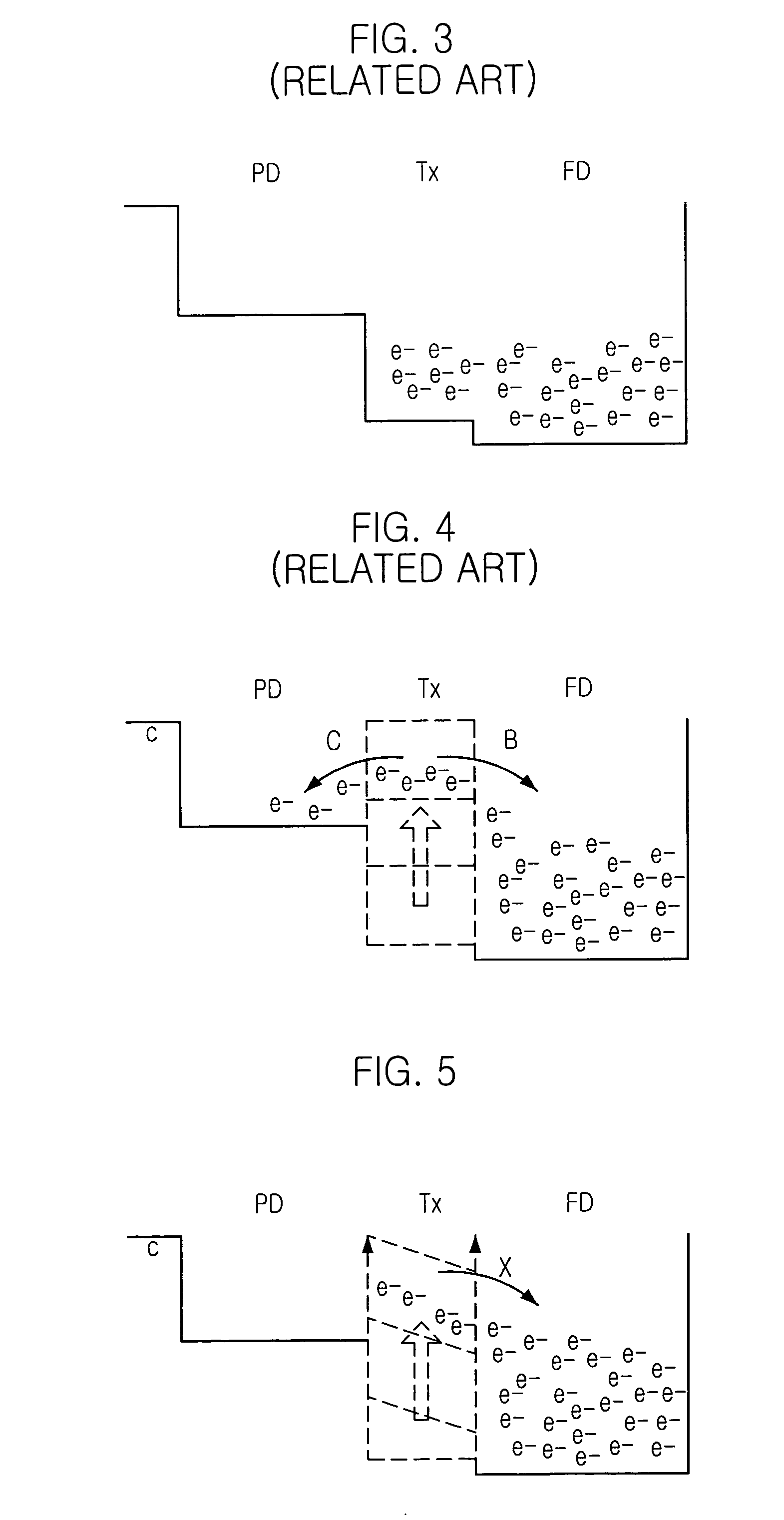

CMOS image sensor for reducing partition noise

InactiveUS20060186504A1Reduce noiseExtended fall timeTelevision system detailsSolid-state devicesCMOSFall time

A CMOS image sensor according to an embodiment of the present invention includes a unit pixel, including a transfer transistor controlled by a transfer control signal; and a transfer control signal controller for controlling a rising and a falling times of the transfer control signal, wherein the falling time of the transfer control signal is sufficiently increased to reduce a partition noise.

Owner:INTELLECTUAL VENTURES II

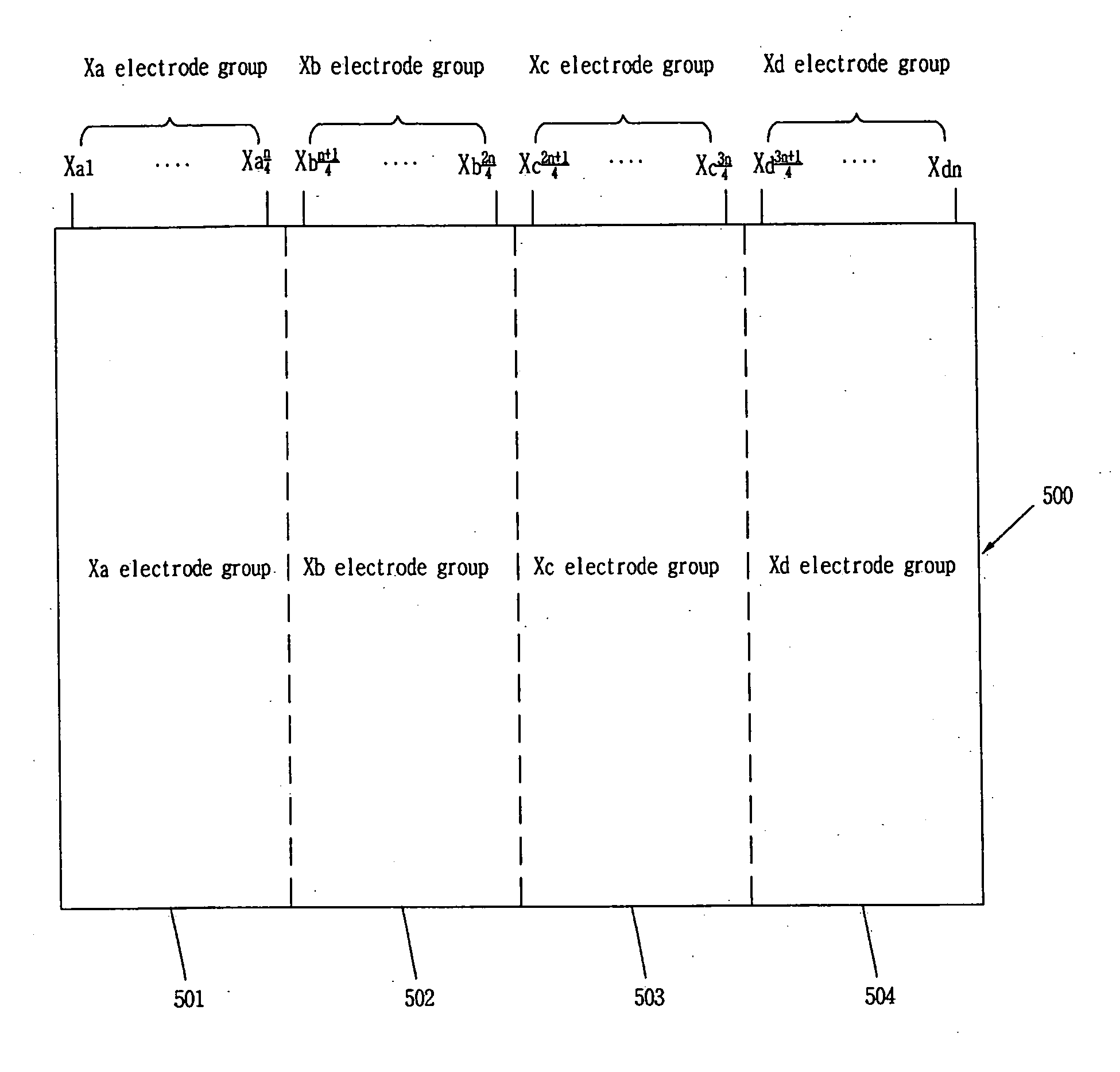

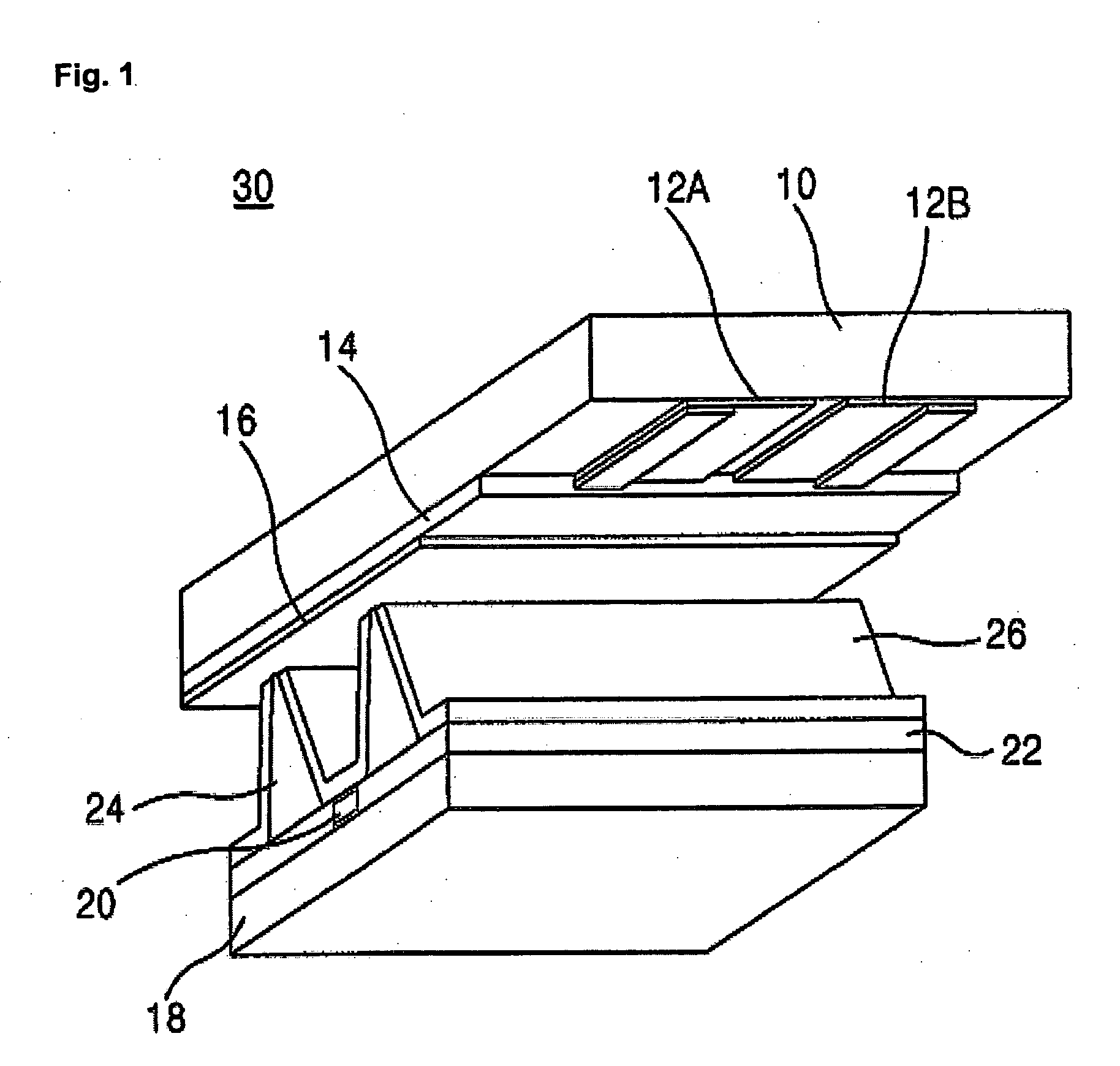

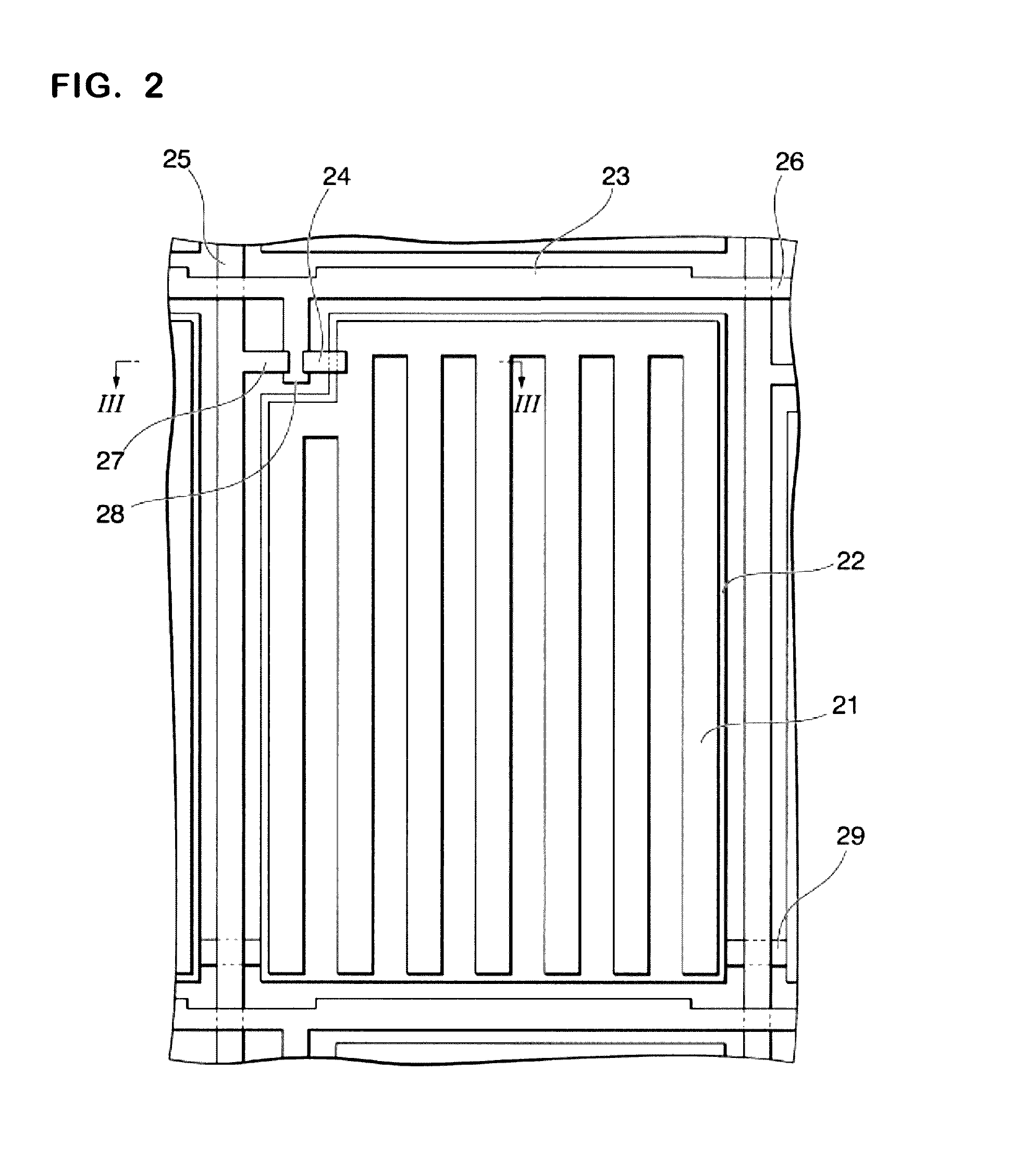

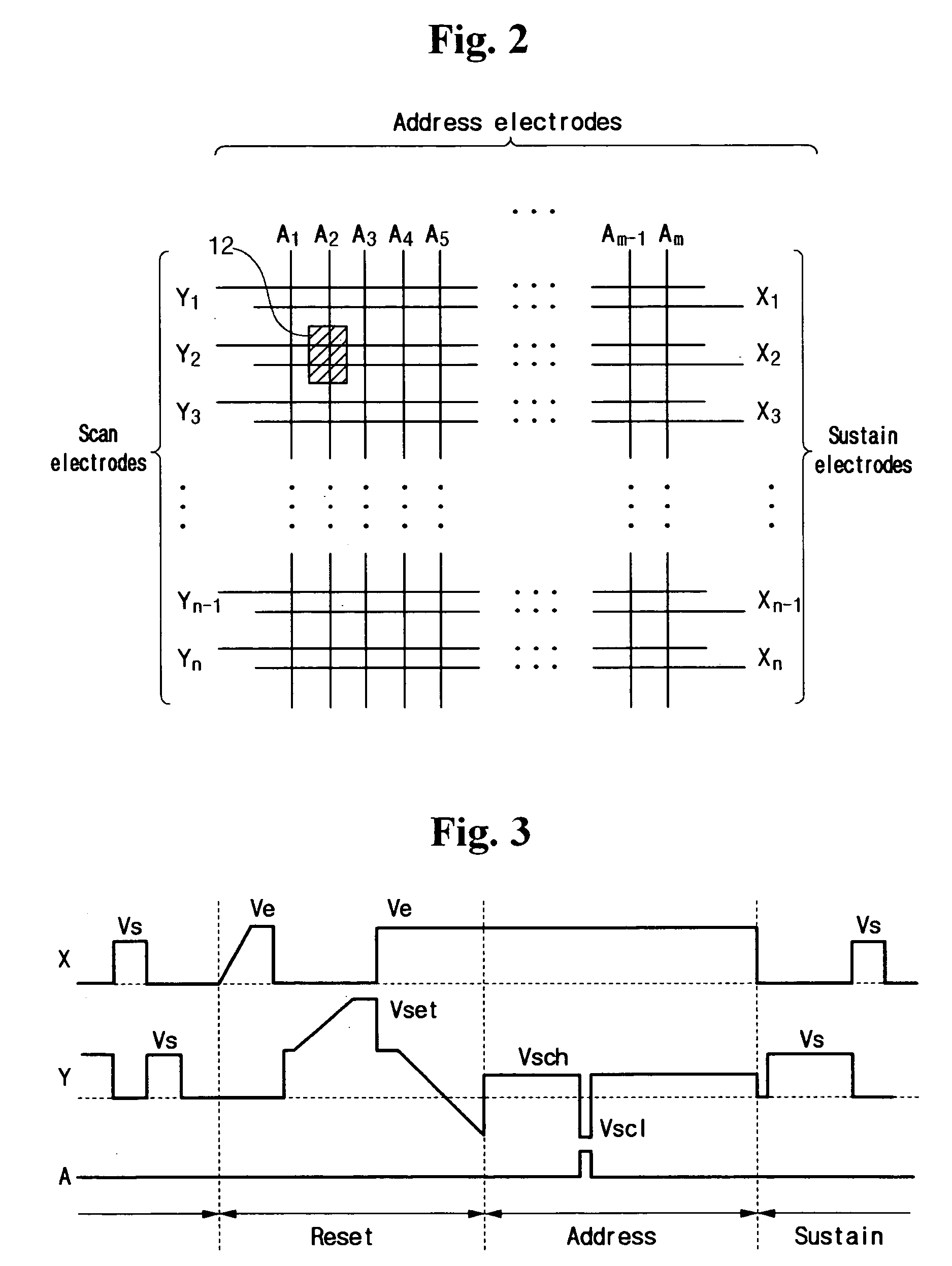

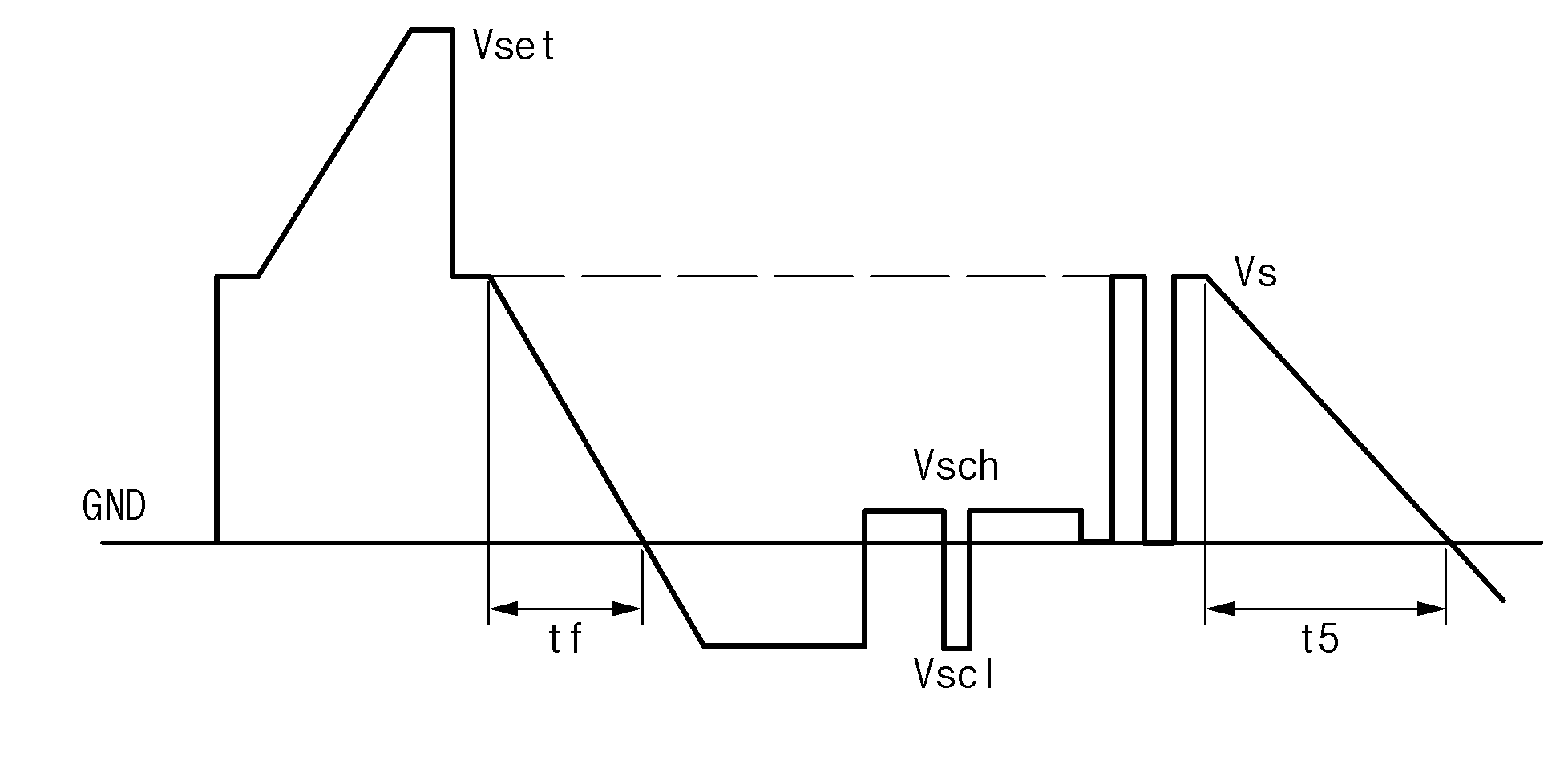

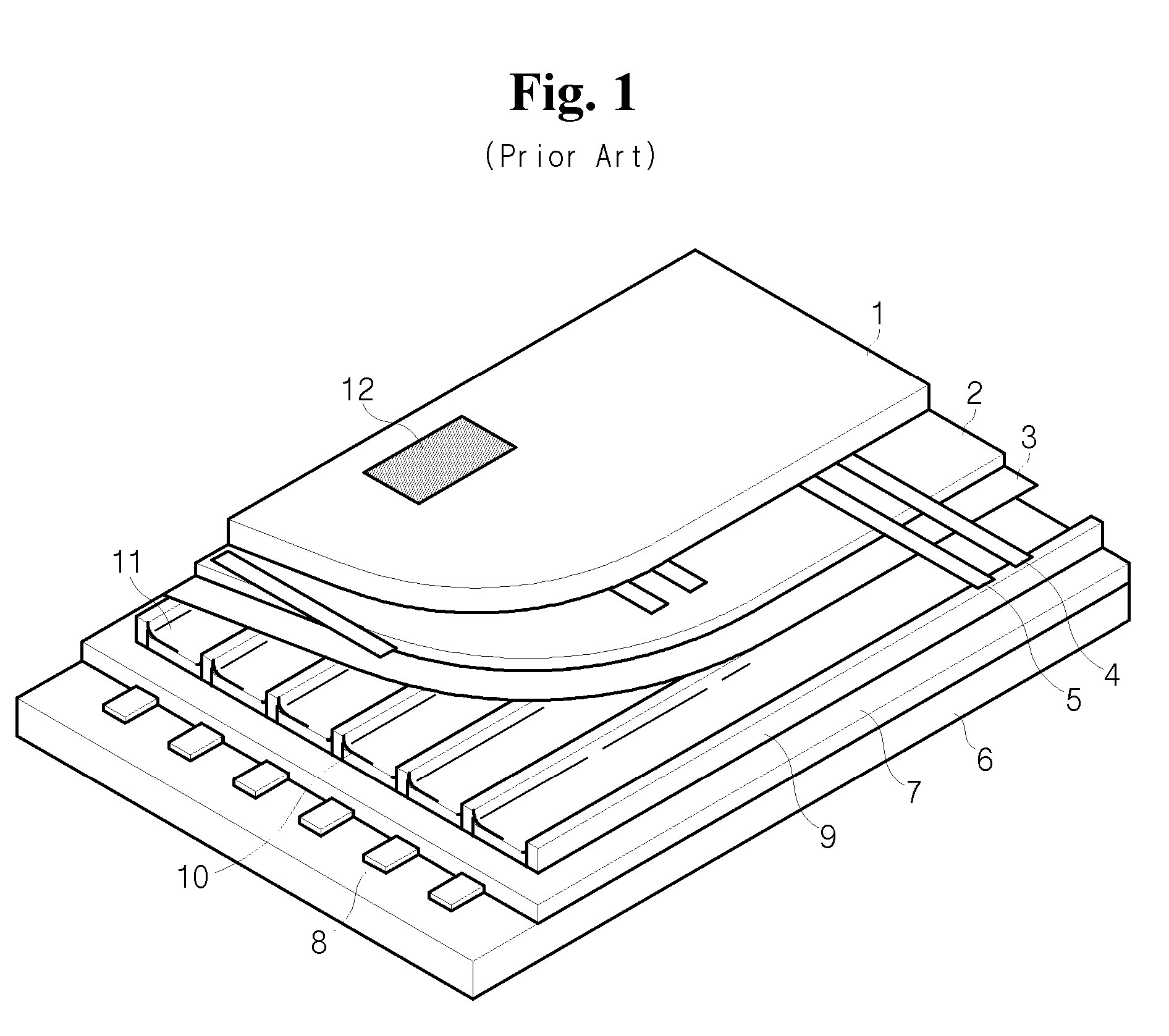

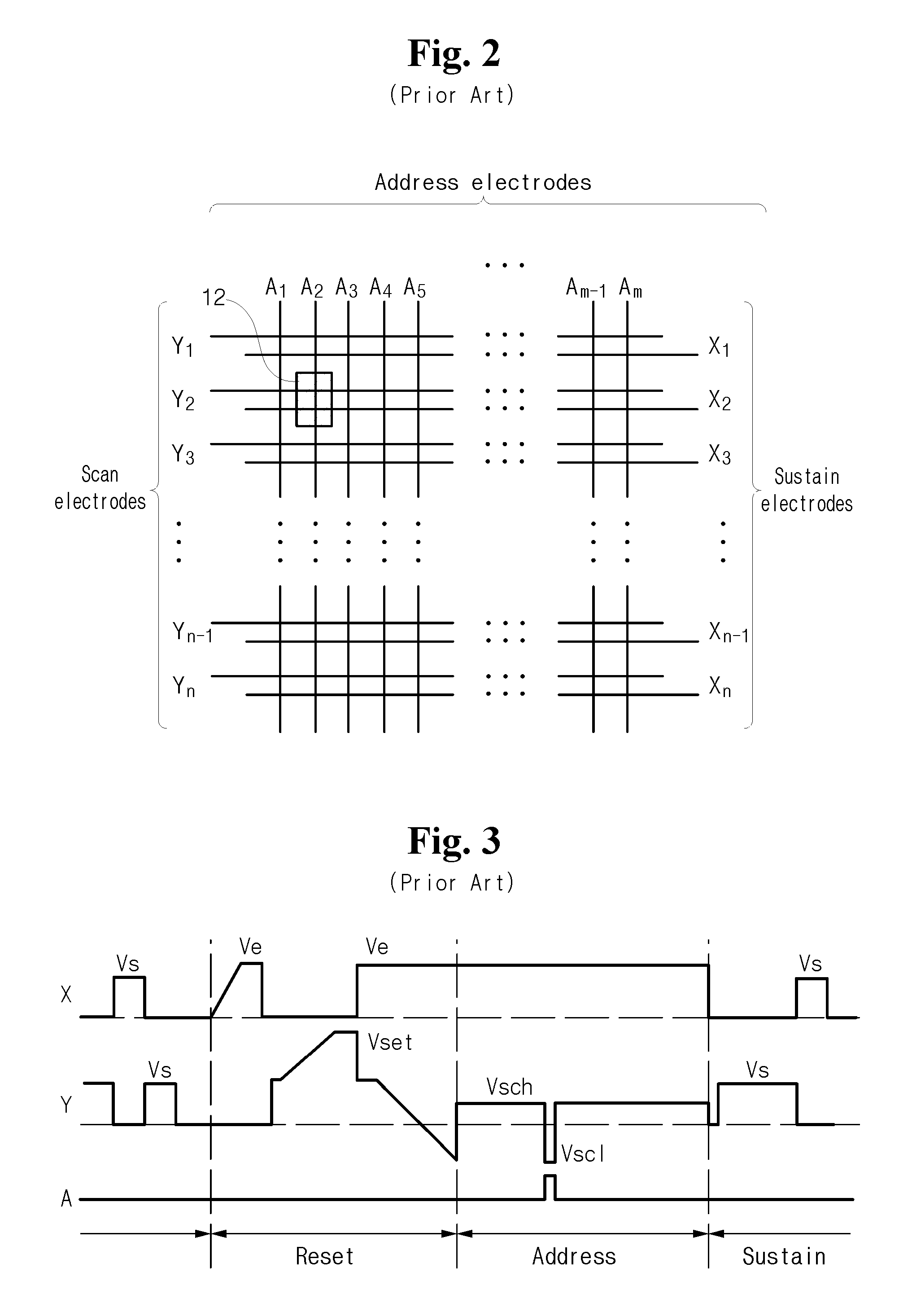

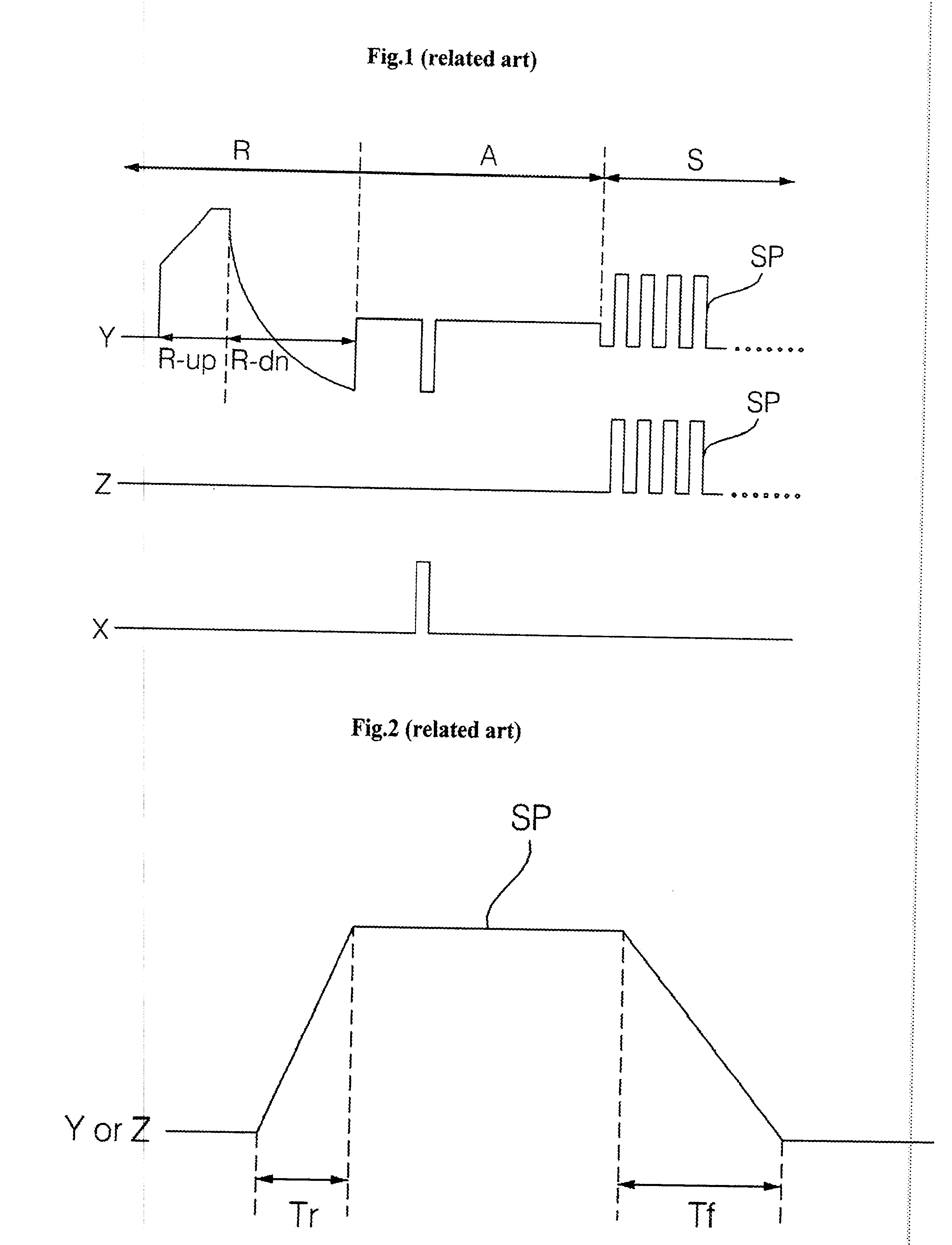

Plasma display apparatus and method for driving the same

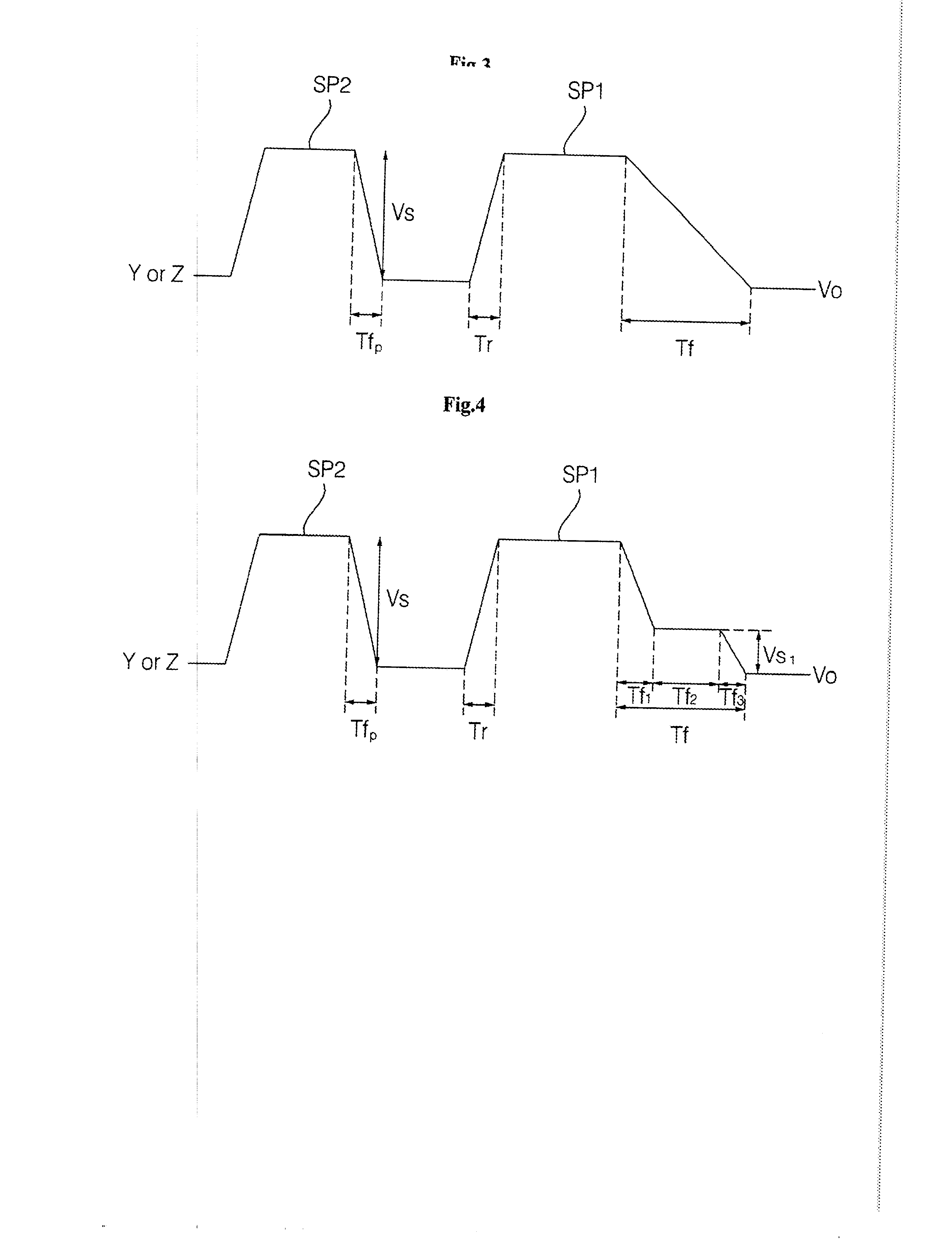

InactiveUS20060001603A1Extended fall timeDecrease in peak valueStatic indicating devicesFall timeElectromagnetic interference

The present invention relates to a plasma display panel, and more particularly, to a plasma display apparatus and a method of driving a plasma display panel including address electrodes (X) and scan electrodes (Y). The plasma display apparatus according to the present invention includes a plasma display panel including a plurality of scan electrodes and a plurality of address electrodes formed to cross the scan electrodes; a driving unit for driving the plurality of address electrodes; and a driving pulse controller for controlling the driving unit so that a voltage falling time of a data pulse supplied to one and more address electrode groups among a plurality of address electrode groups including one or more address electrodes in an address period ranges from no less than 50 ns to no more than 300 ns. According to The present invention, electric potential of the data pulse varies slwoly by prolonging a voltage falling time of a data pulse compared with a conventional voltage falling time so that the peak value of a displacement current becomes reduced. Accordingly, an EMI (ElectroMagnetic Interference) property is enhanced, thereby ensuring normal operations of a driving apparatus of a plasma display panel.

Owner:LG ELECTRONICS INC

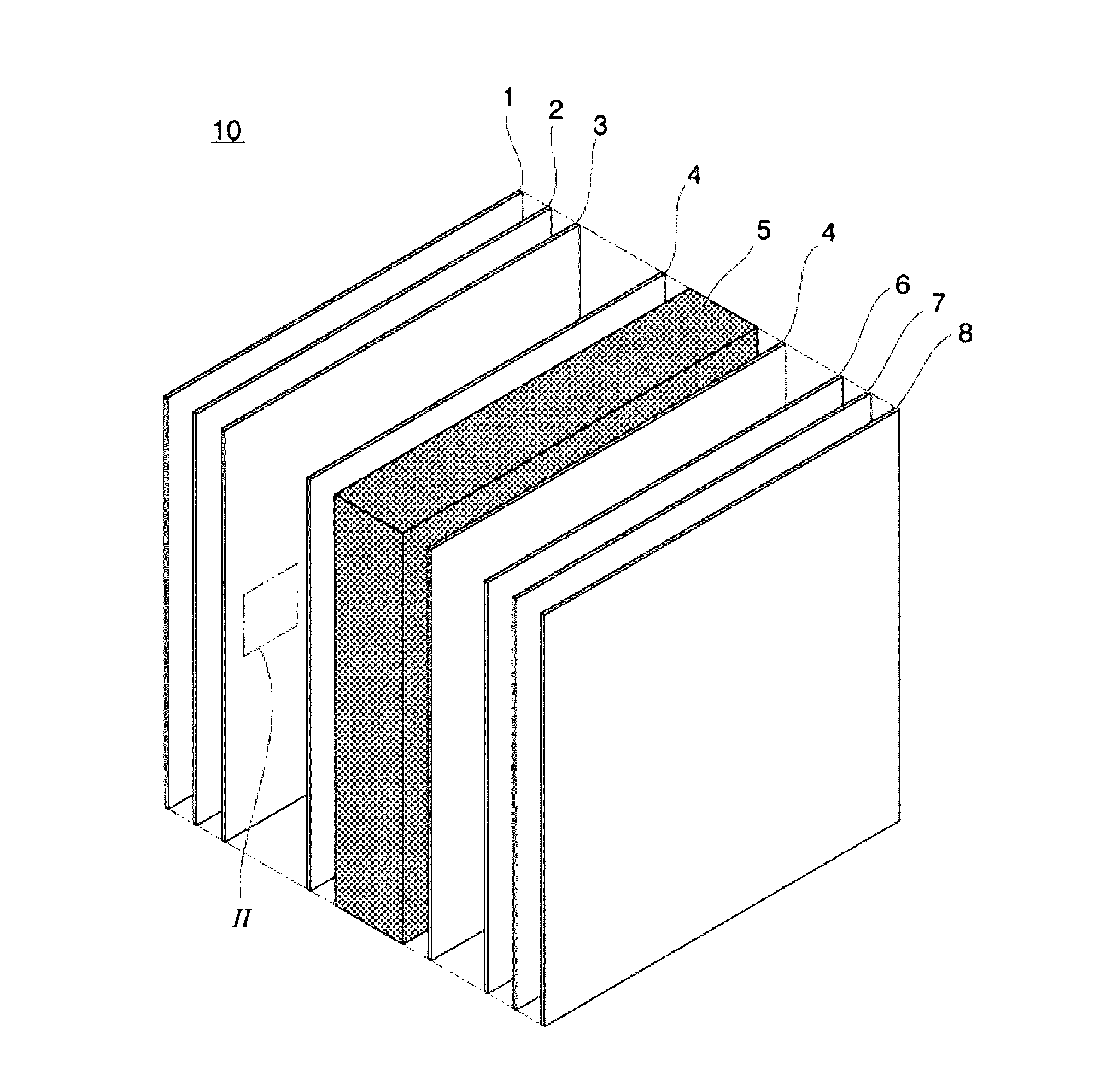

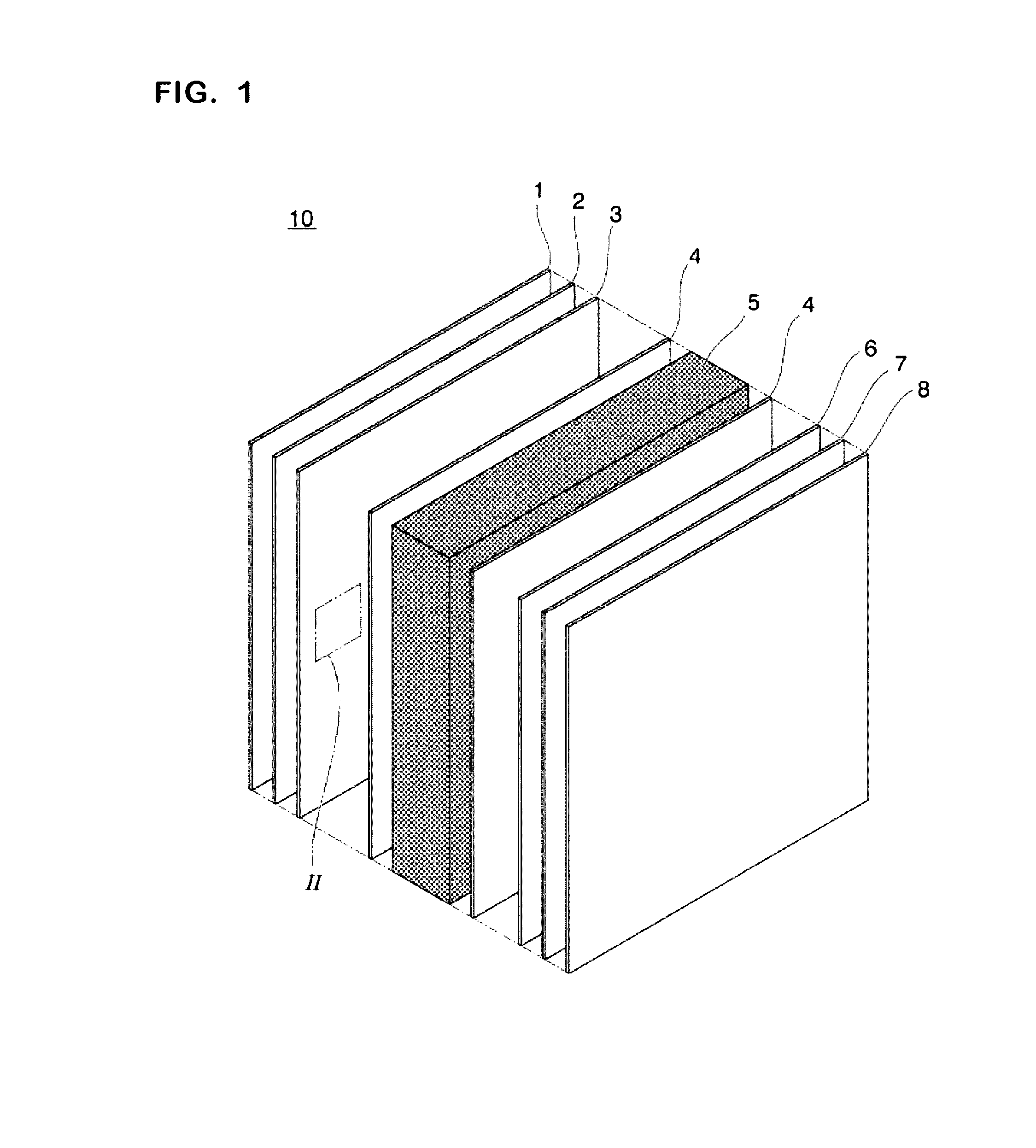

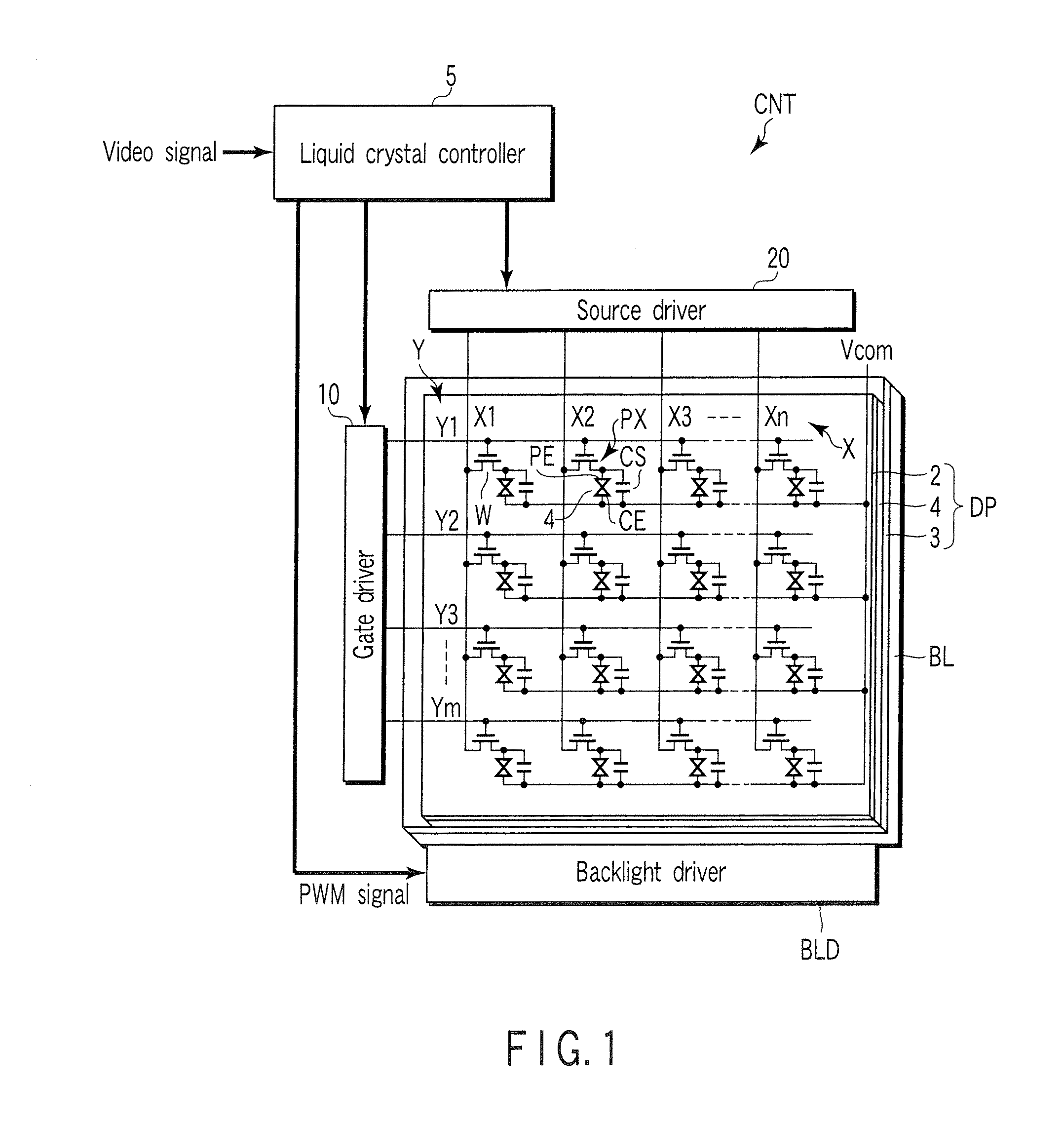

LCD device

ActiveUS20170045765A1Excellent in high transmittanceExtended downtimeLiquid crystal compositionsNon-linear opticsEngineeringCopolymer

Provided is an LCD device having excellent high speed responsiveness. This LCD device contains a polymer or a copolymer in a liquid crystal composition sandwiched between two transparent substrates, at least one of which has an electrode, and the content of the polymer or the copolymer is 1% by mass or greater and less than 40% by mass of the total mass of the liquid crystal composition and the polymer or the copolymer. This LCD device can be applied to various operation modes such as TN, STN, ECB, VA, VA-TN, TPS, FFS, a π cell, OCB, and cholesteric liquid crystals.

Owner:DAINIPPON INK & CHEM INC

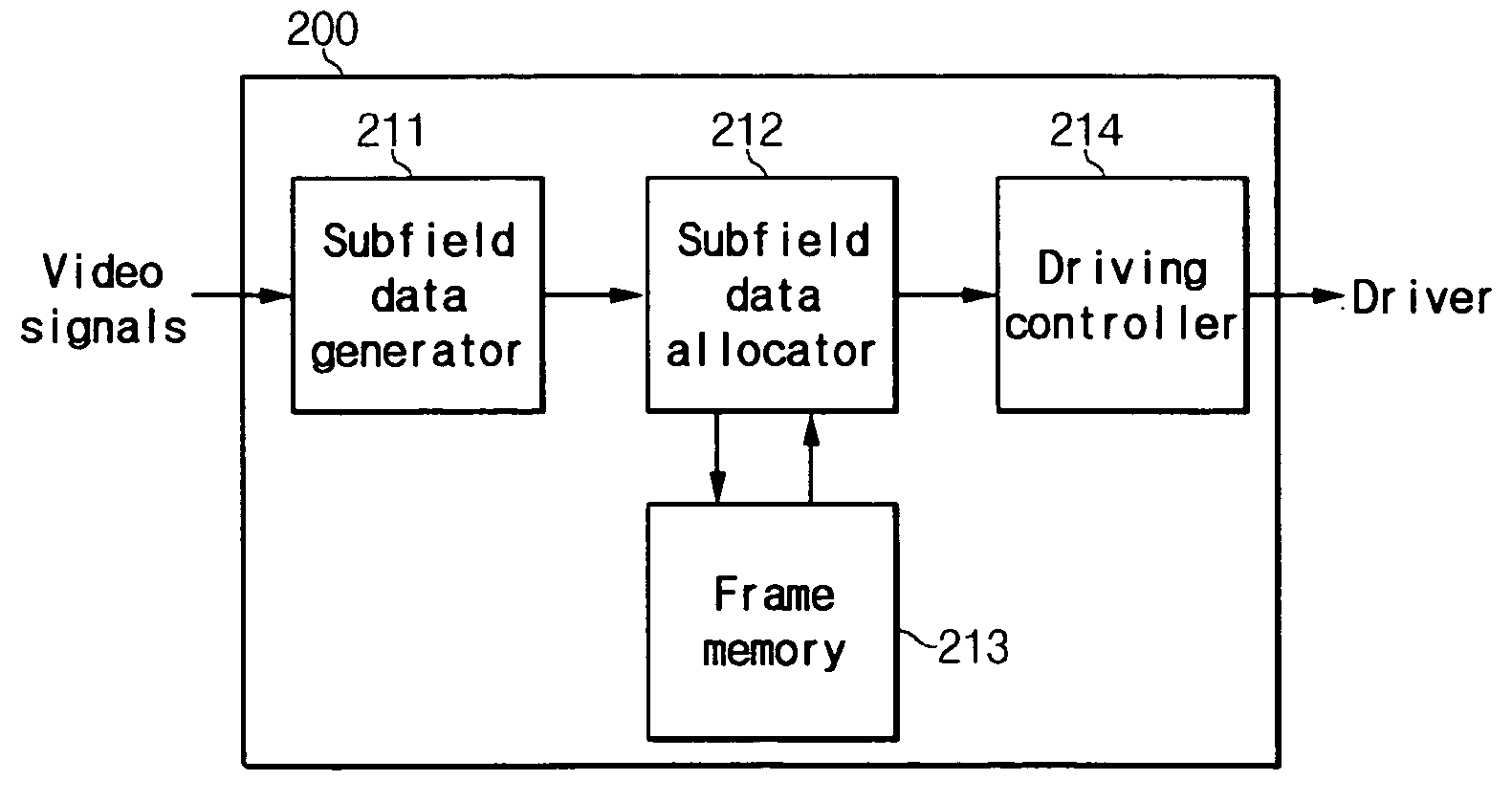

Plasma display panel and driving method thereof

InactiveUS20050156823A1Avoid fireReduce the starting voltageCathode-ray tube indicatorsCold-cathode tubesComputer scienceImage signal

Disclosed is a PDP driving method which may include generating subfield information that shows ON / OFF states of discharge cells from among a plurality of subfields from input image signals, generating address information that shows ON / OFF states of the discharge cells per subfield from the subfield data, counting the number of the discharge cells that are ON from among the discharge cells from the address data, and controlling a waveform applied during a reset period of a subsequent subfield.

Owner:SAMSUNG SDI CO LTD

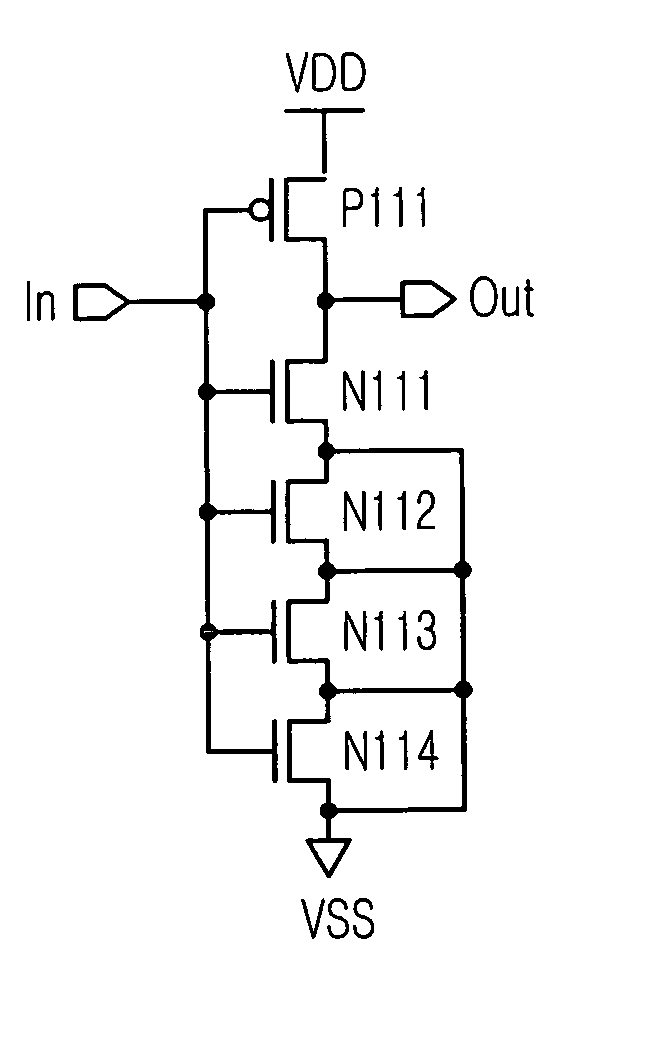

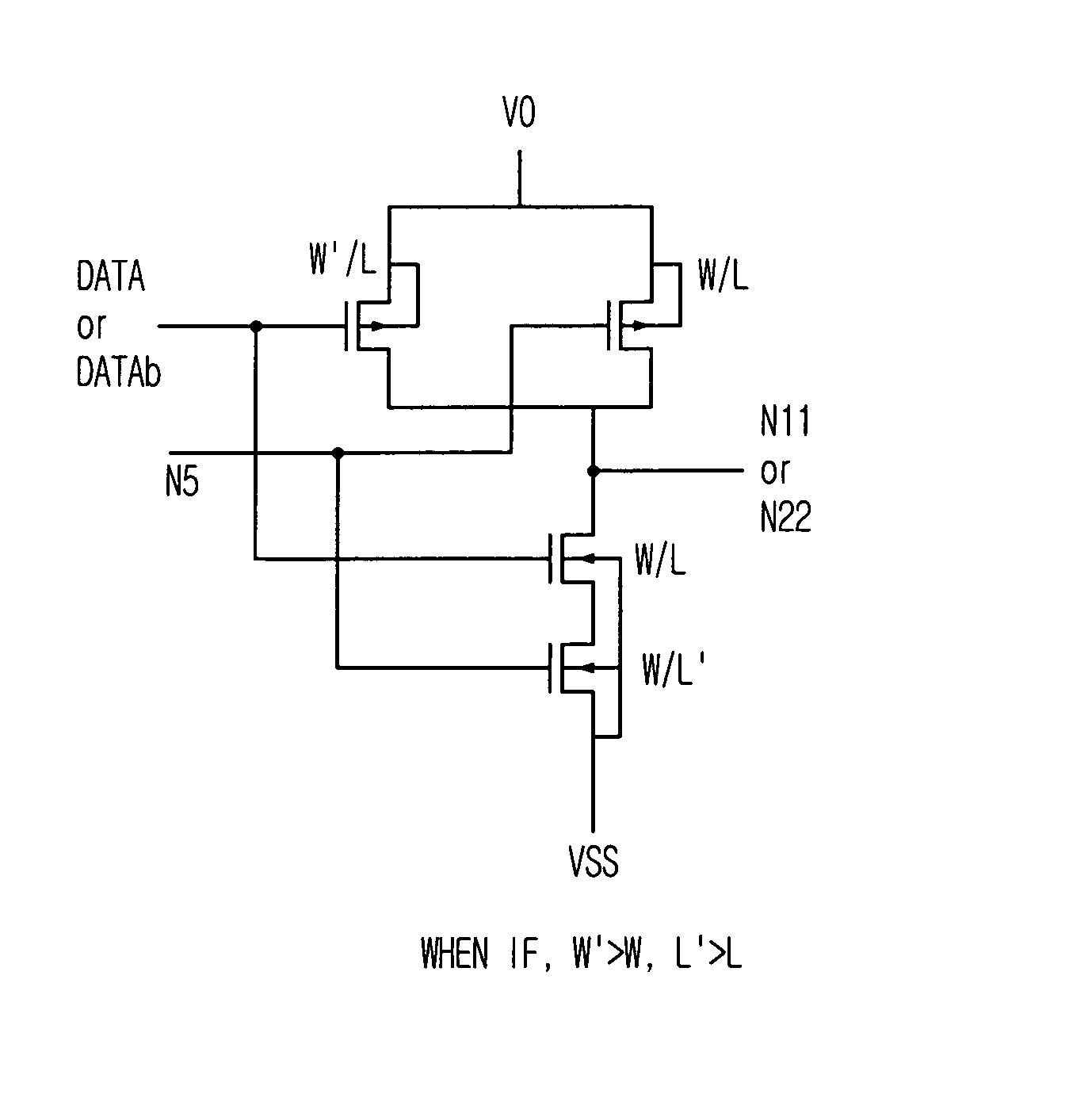

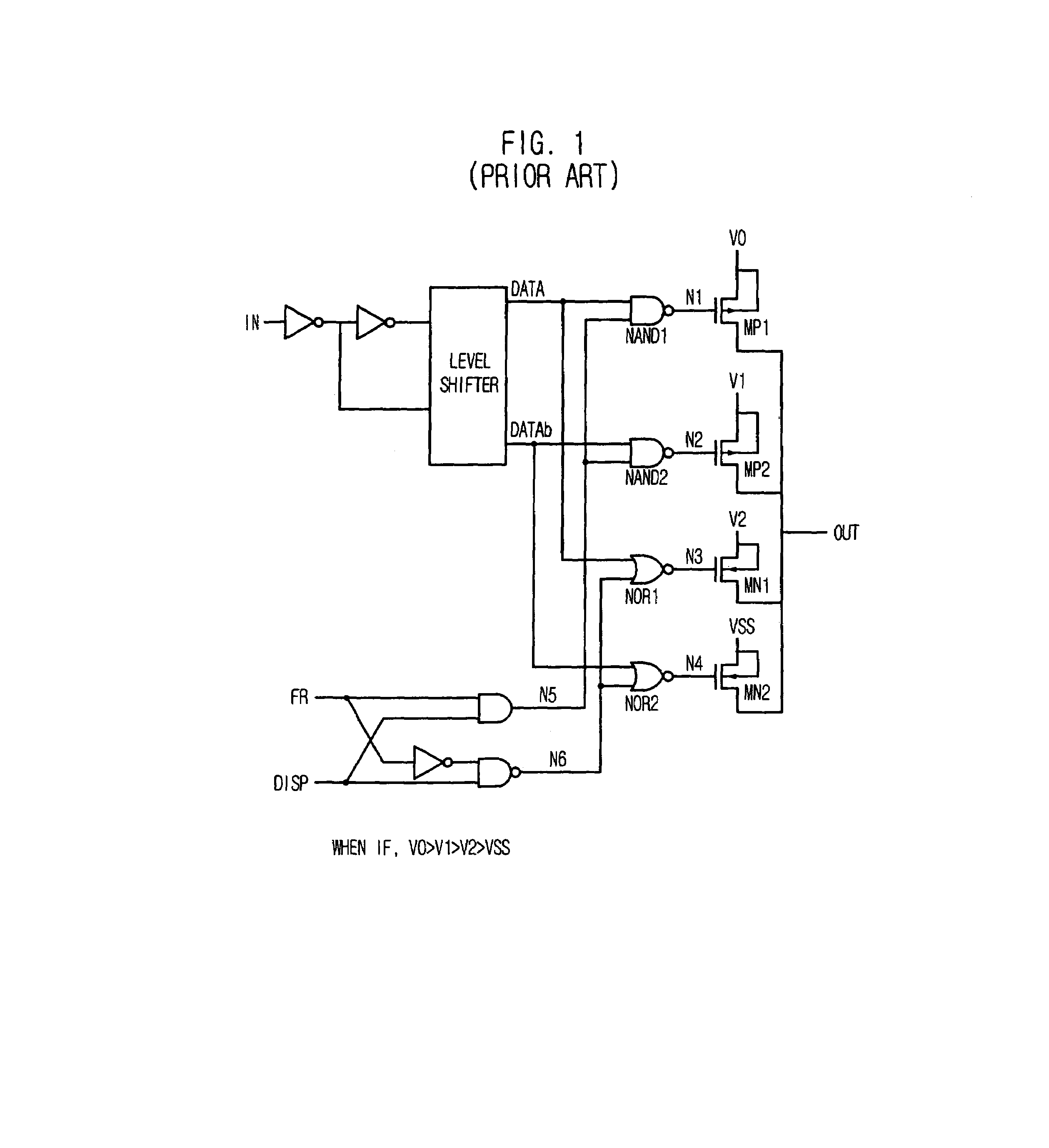

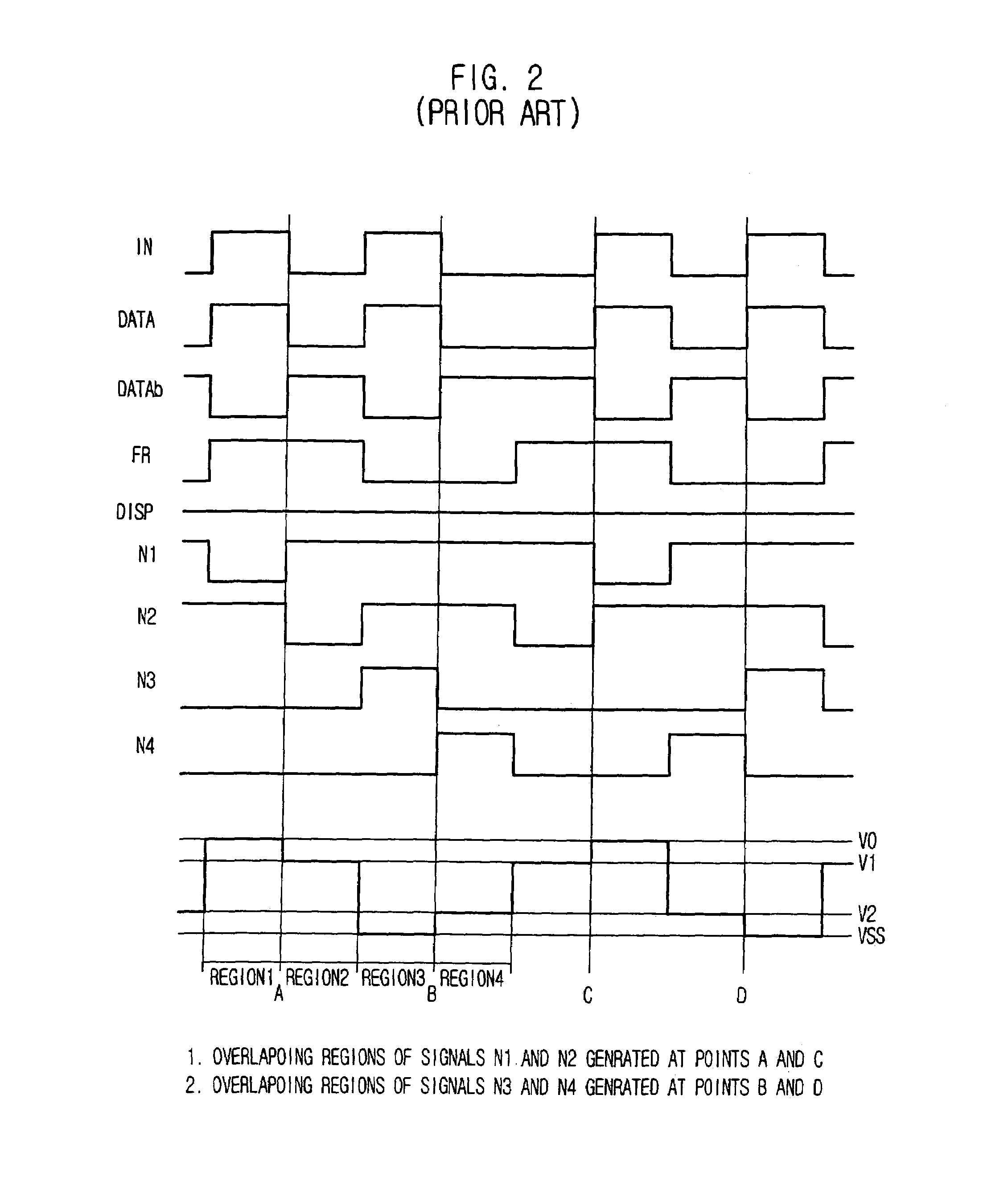

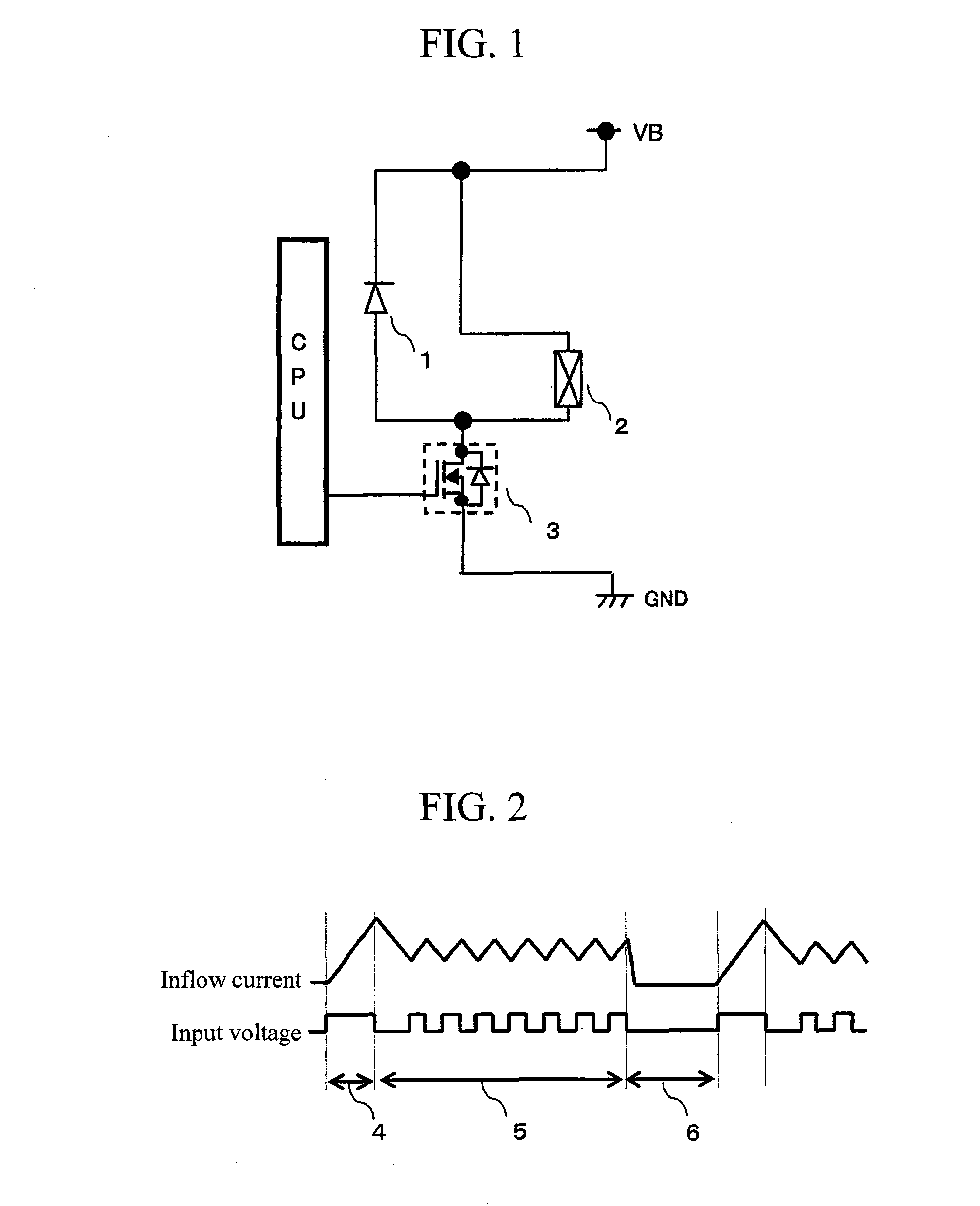

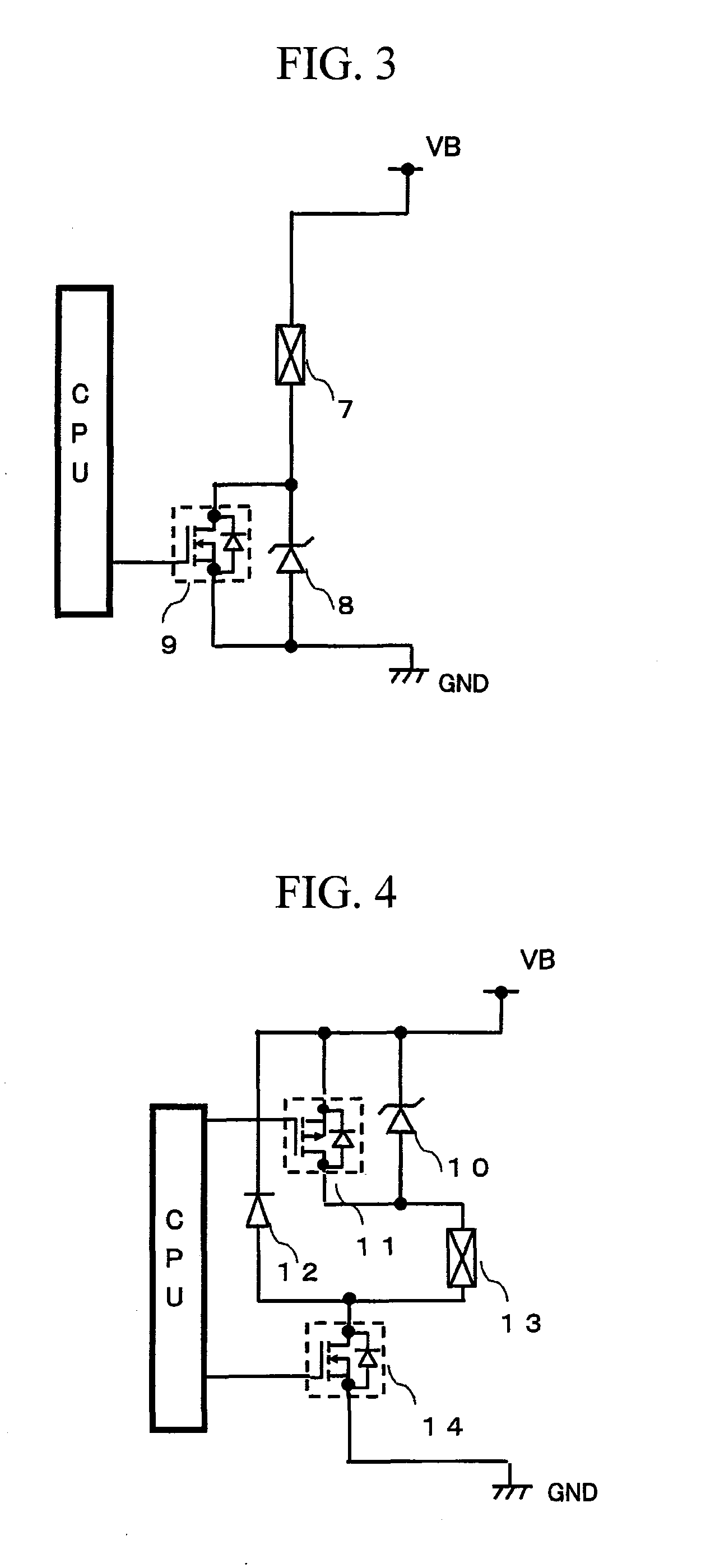

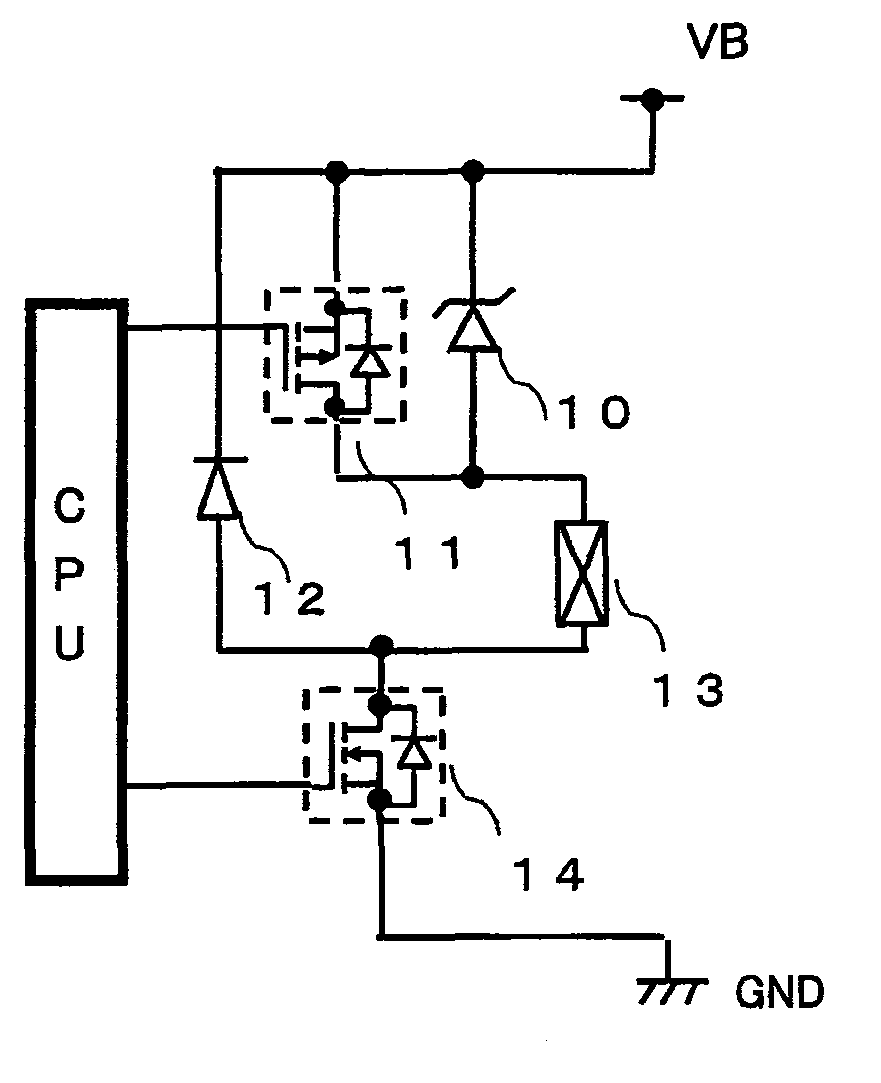

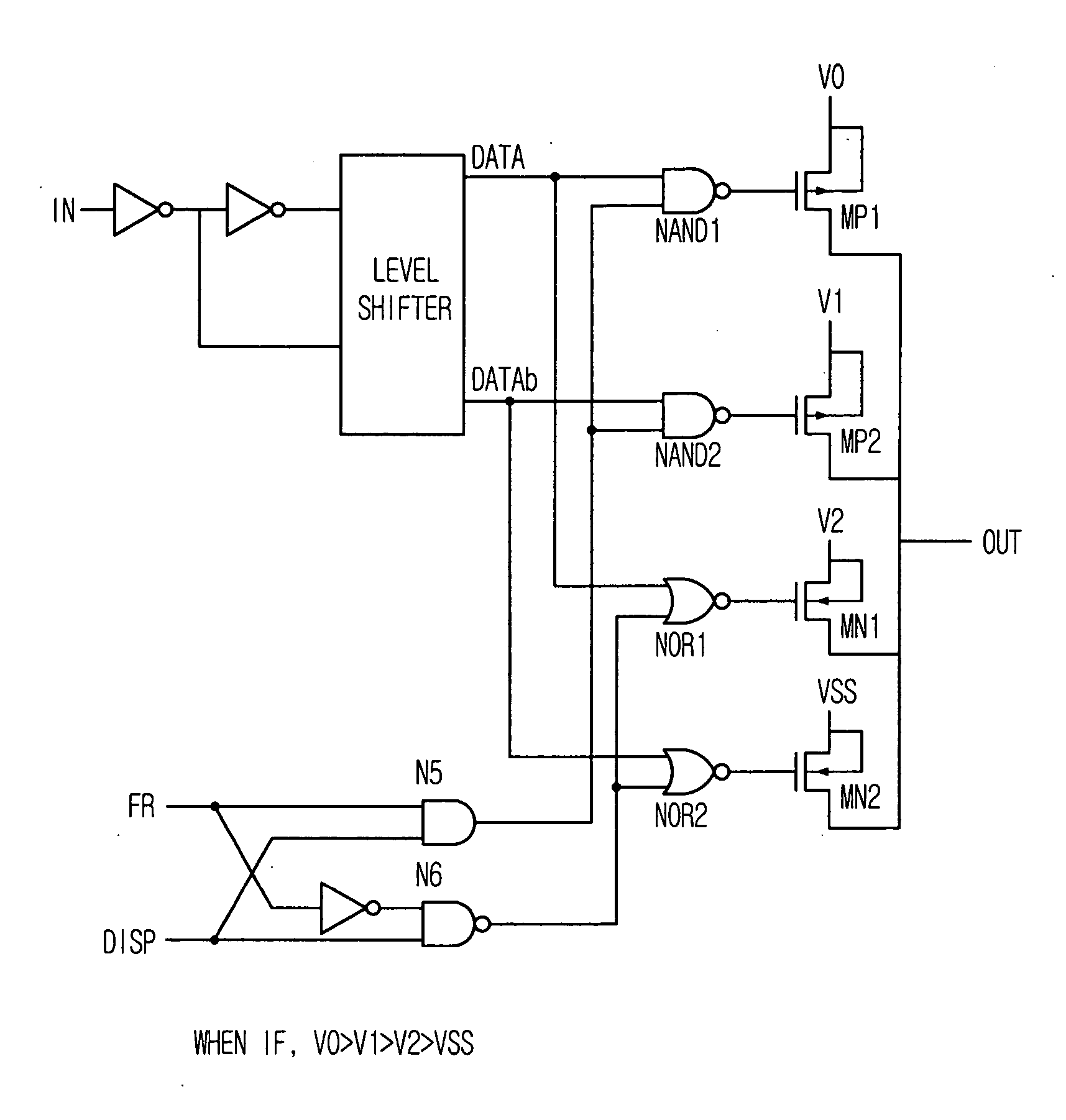

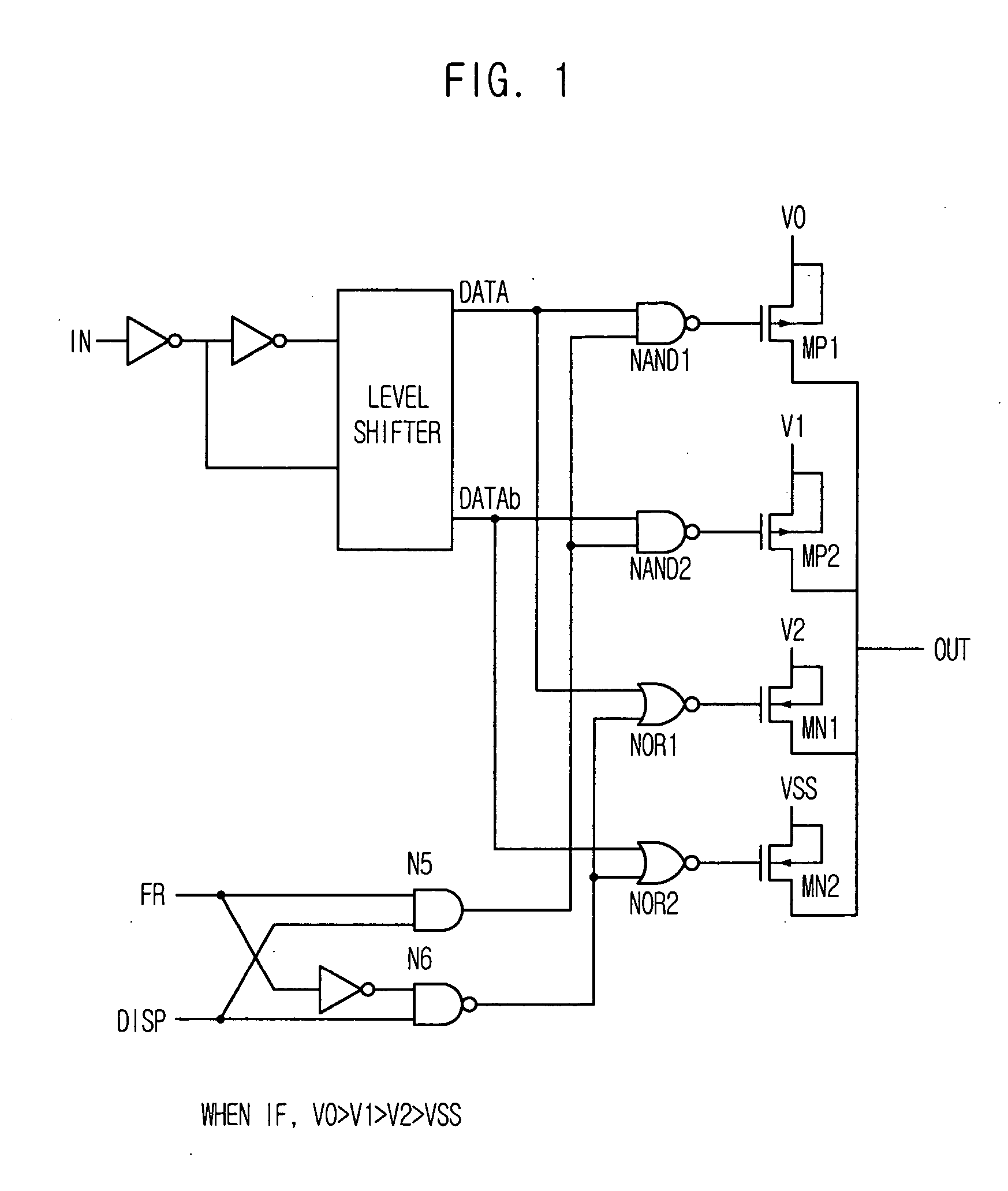

Multi-level voltage output control circuit and logic gate therefor

ActiveUS7068075B2Extended rise timeExtended fall timePower reduction in field effect transistorsStatic indicating devicesEngineeringLogic gate

A multi-level voltage output control circuit selectively outputs one of multi-level power voltages by driving gates of two MOS transistors, which act as switching devices for the multi-level power voltages, with two output signals, the two output signals having complementary phases to each other and generated from two logic gates receiving two input signals which have an identical timing and complementary phases to each other, wherein the two logic gates advance or slow down a rising timing and / or a falling timing of the two output signals by differently adjusting a size of PMOS transistors and that of NMOS transistors, which construct the logic gates, thereby excluding a case in which the two output signals are in a same logic state at the same time.

Owner:MAGNACHIP SEMICONDUCTOR LTD

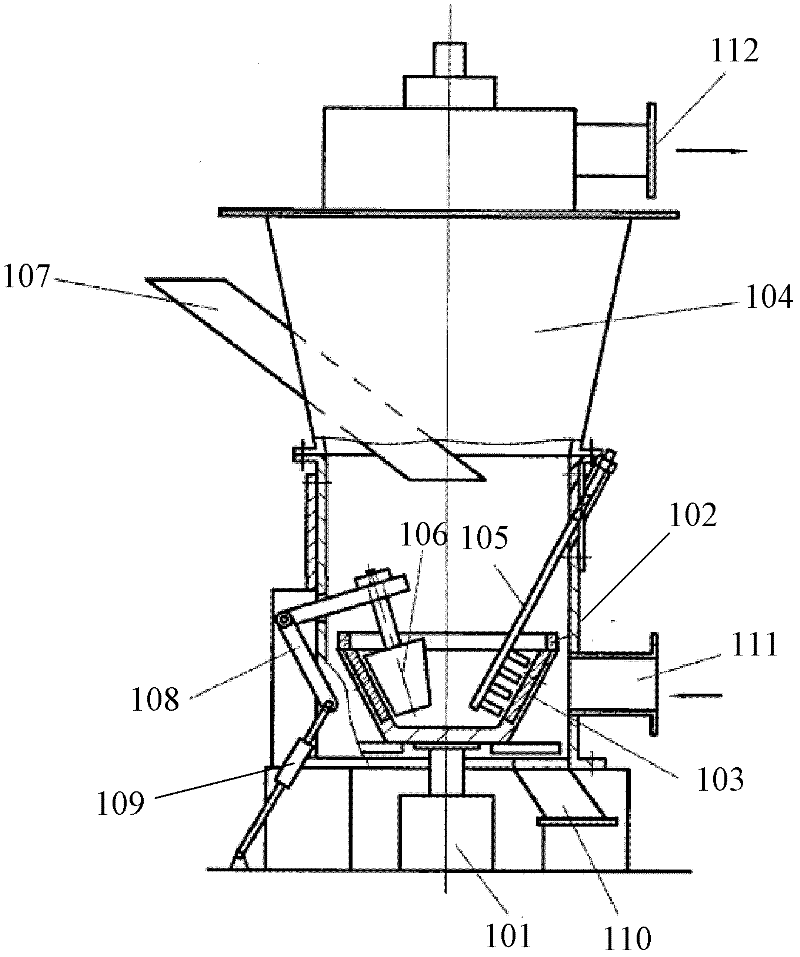

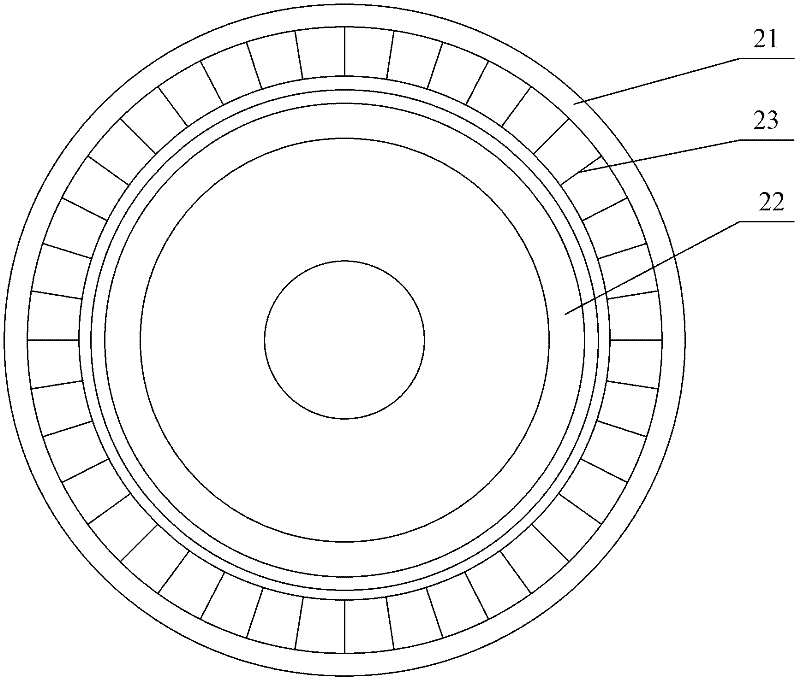

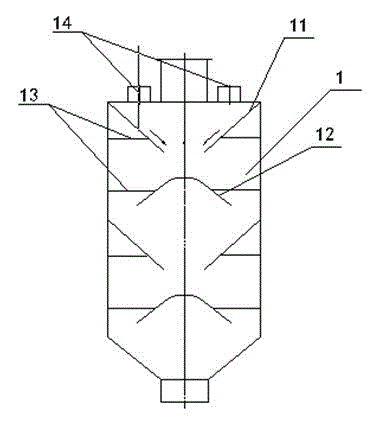

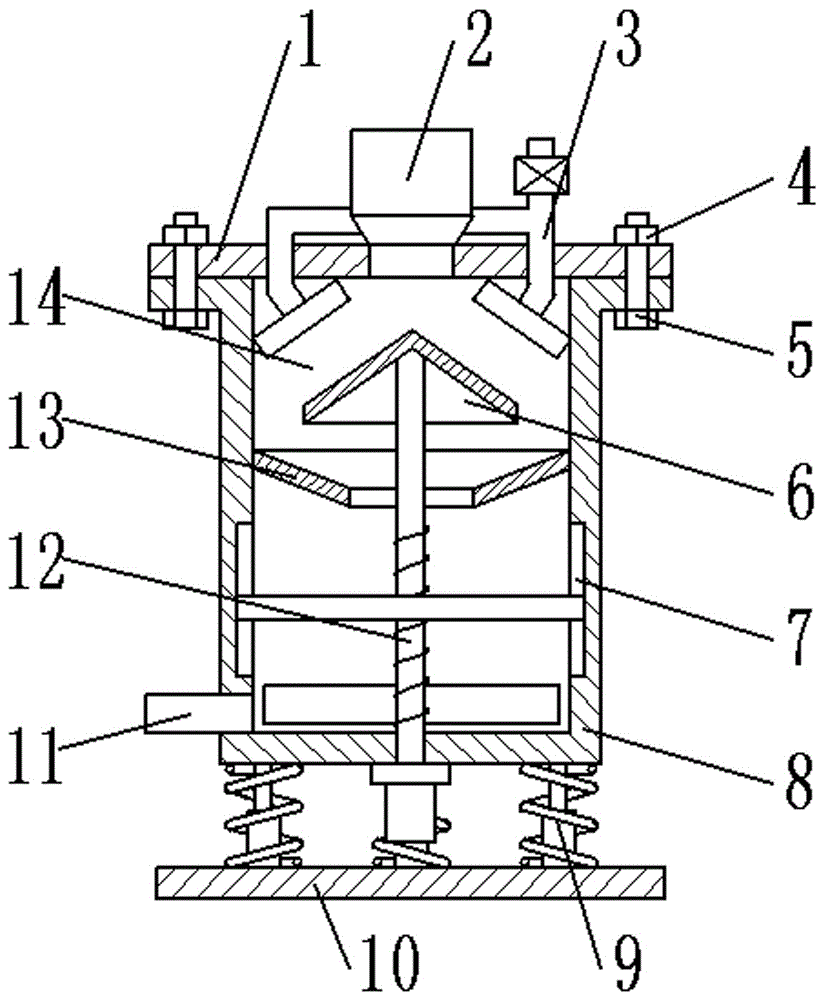

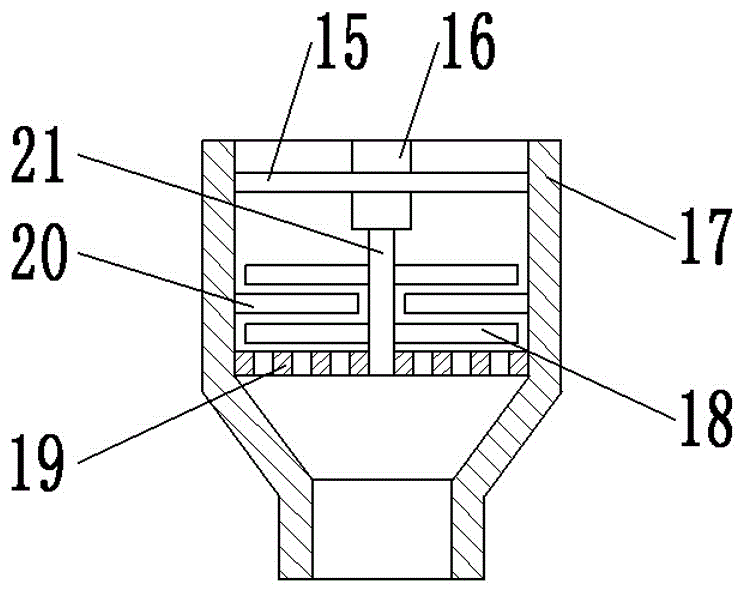

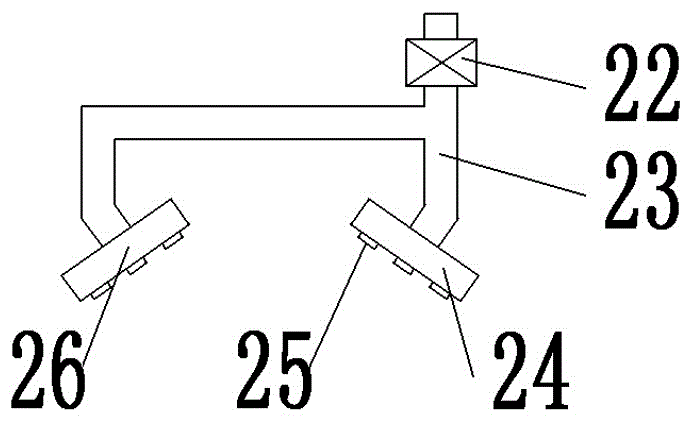

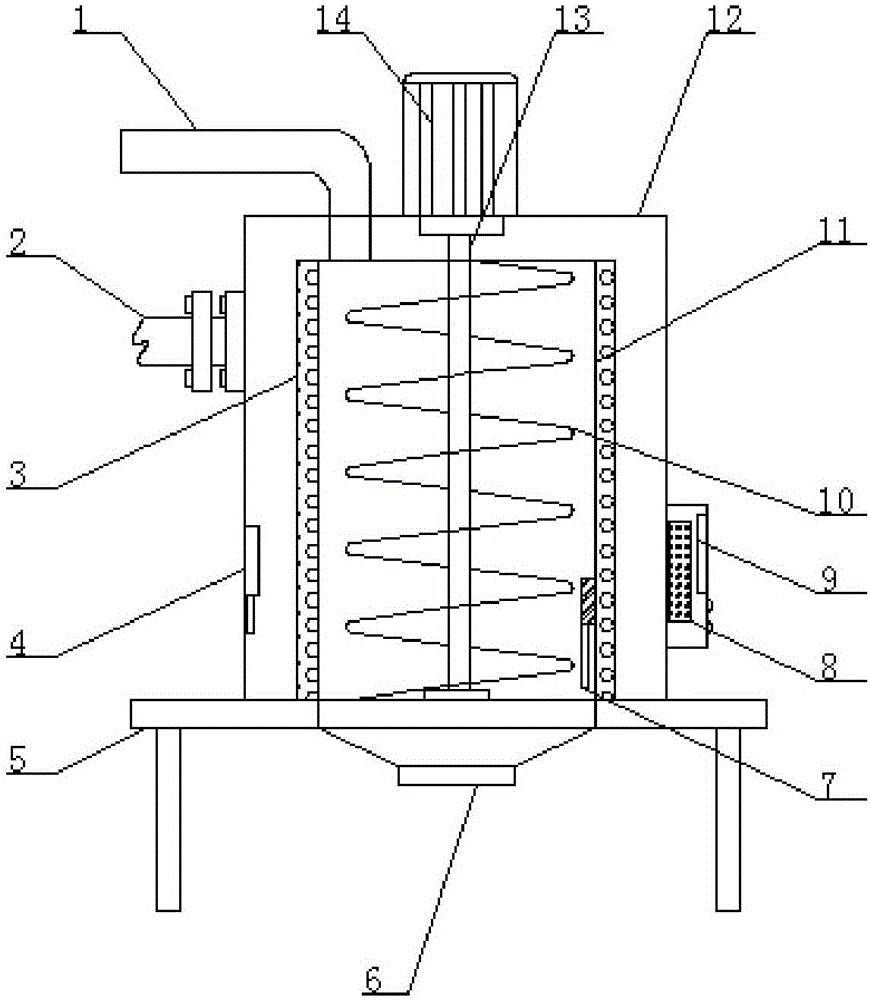

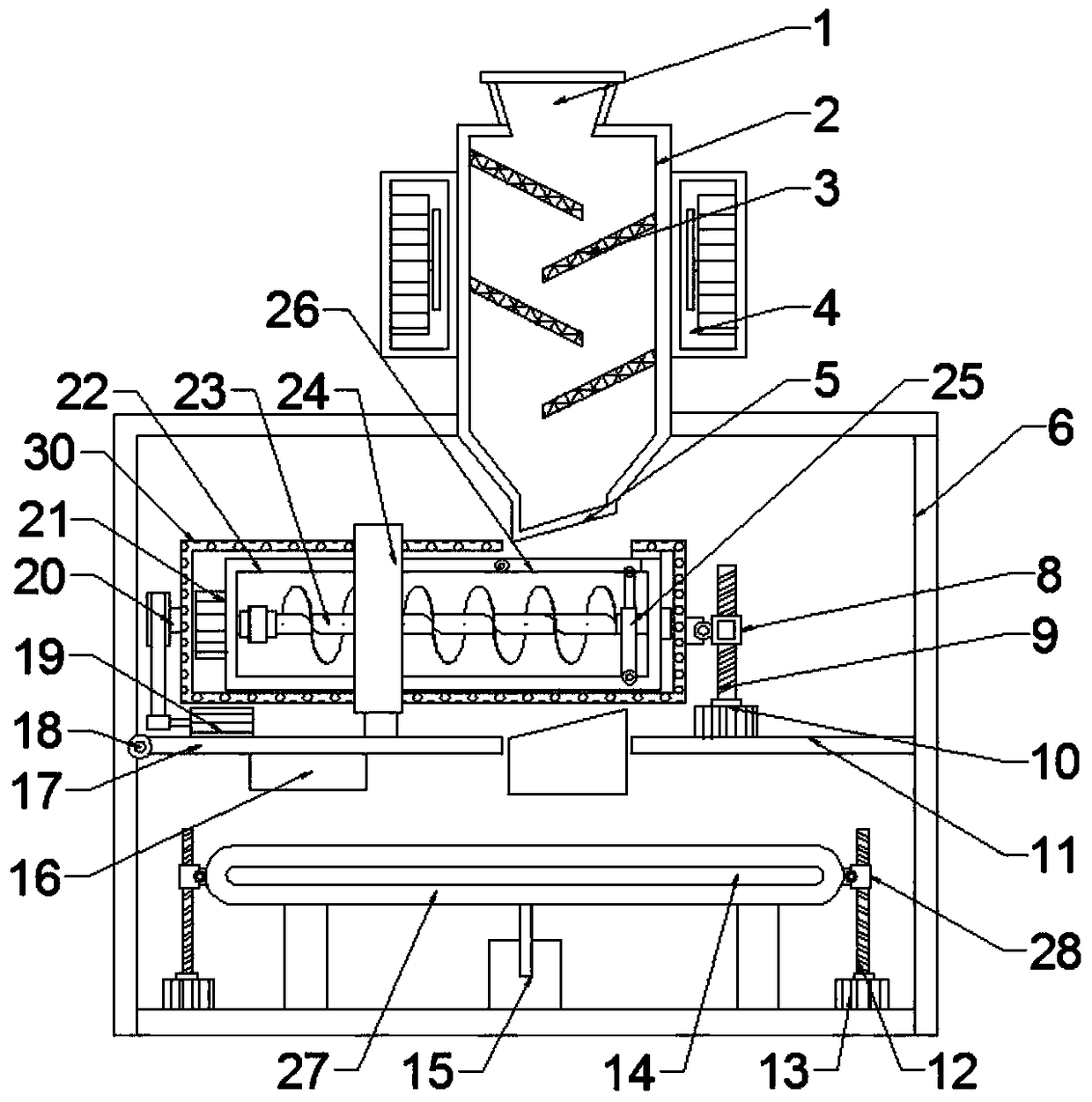

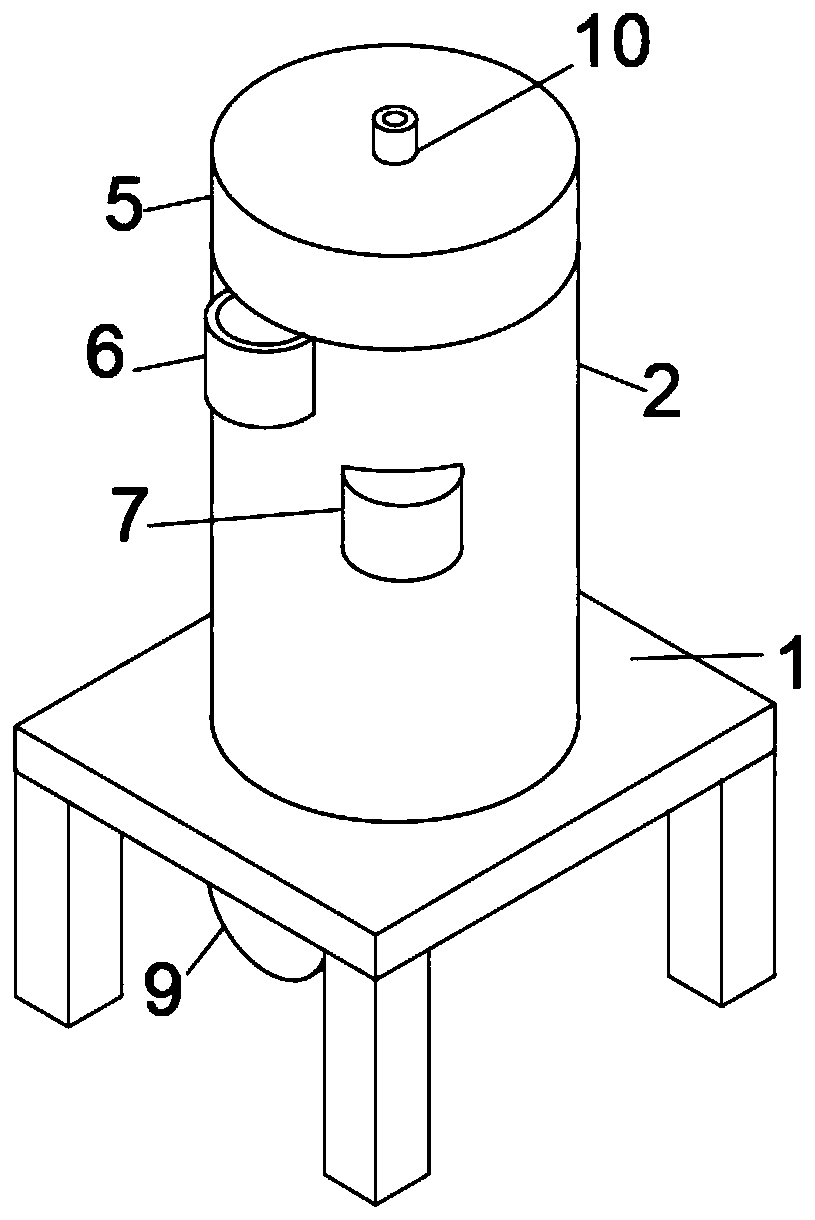

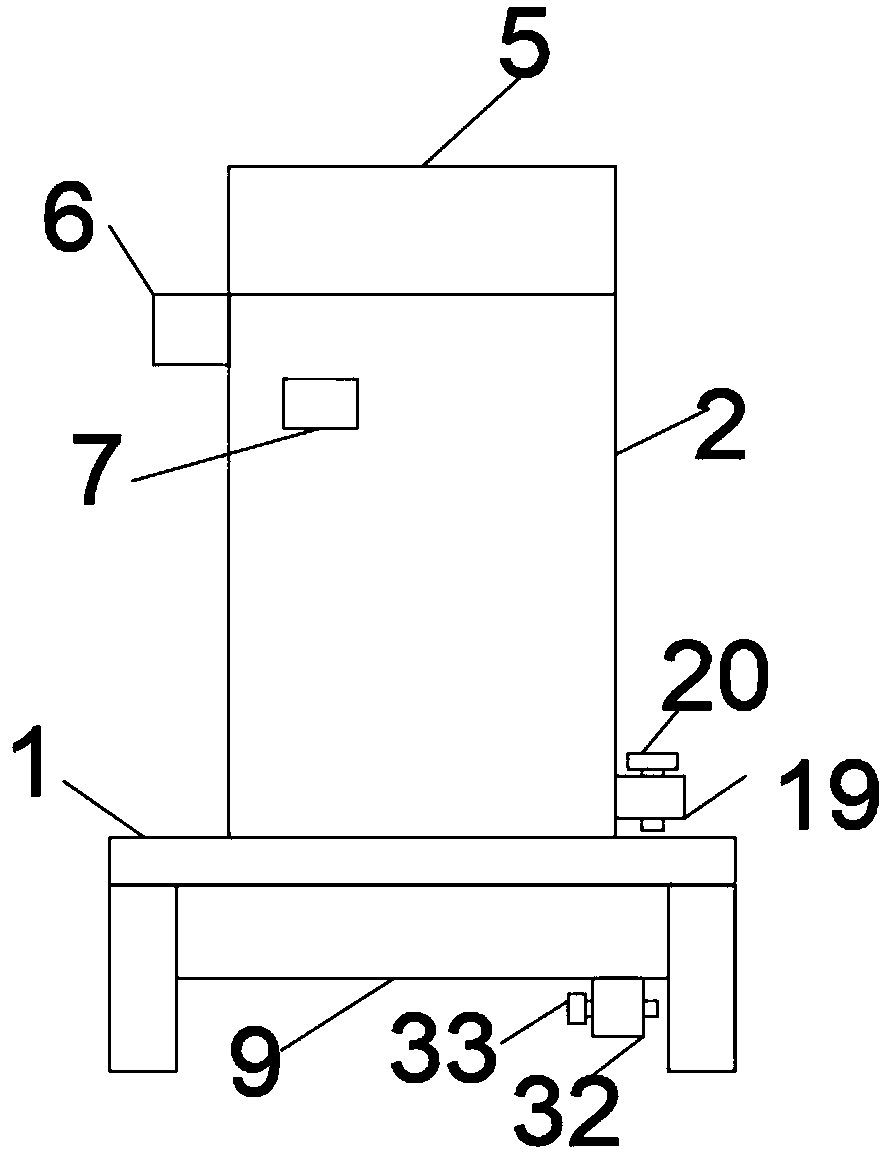

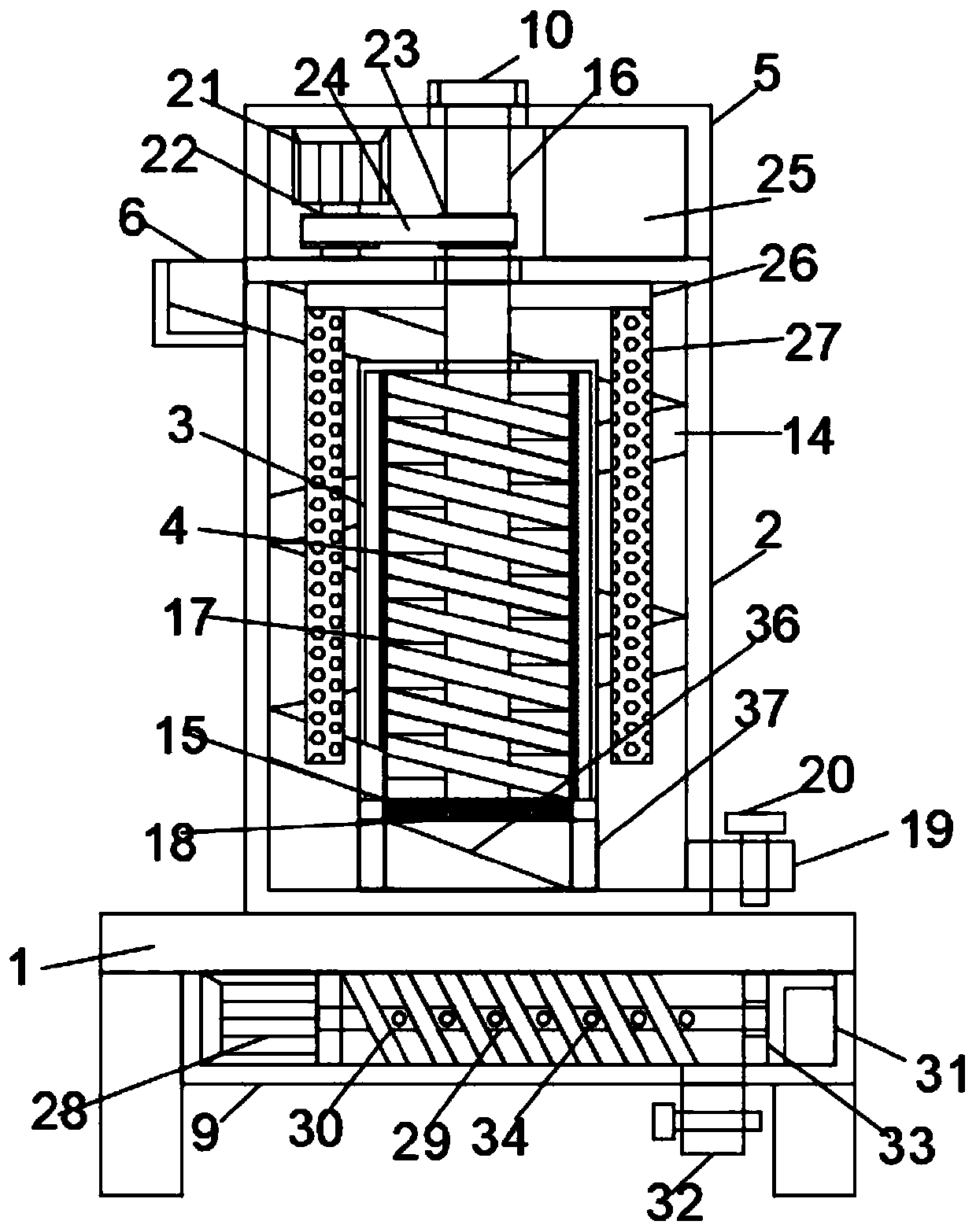

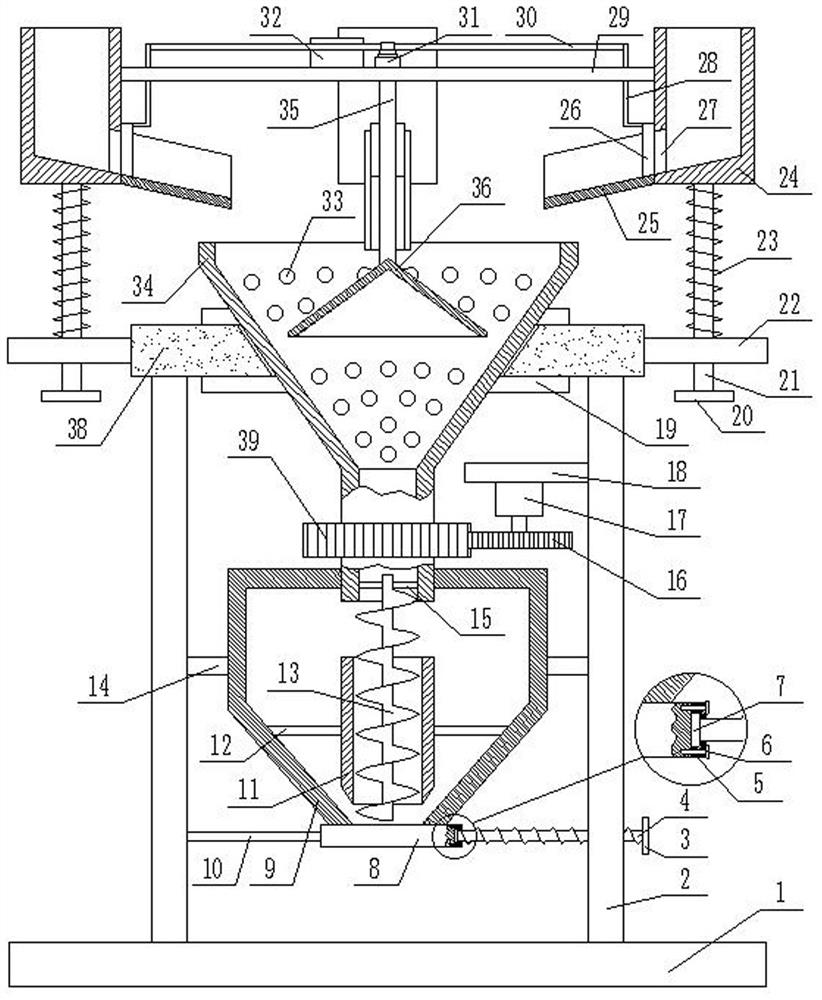

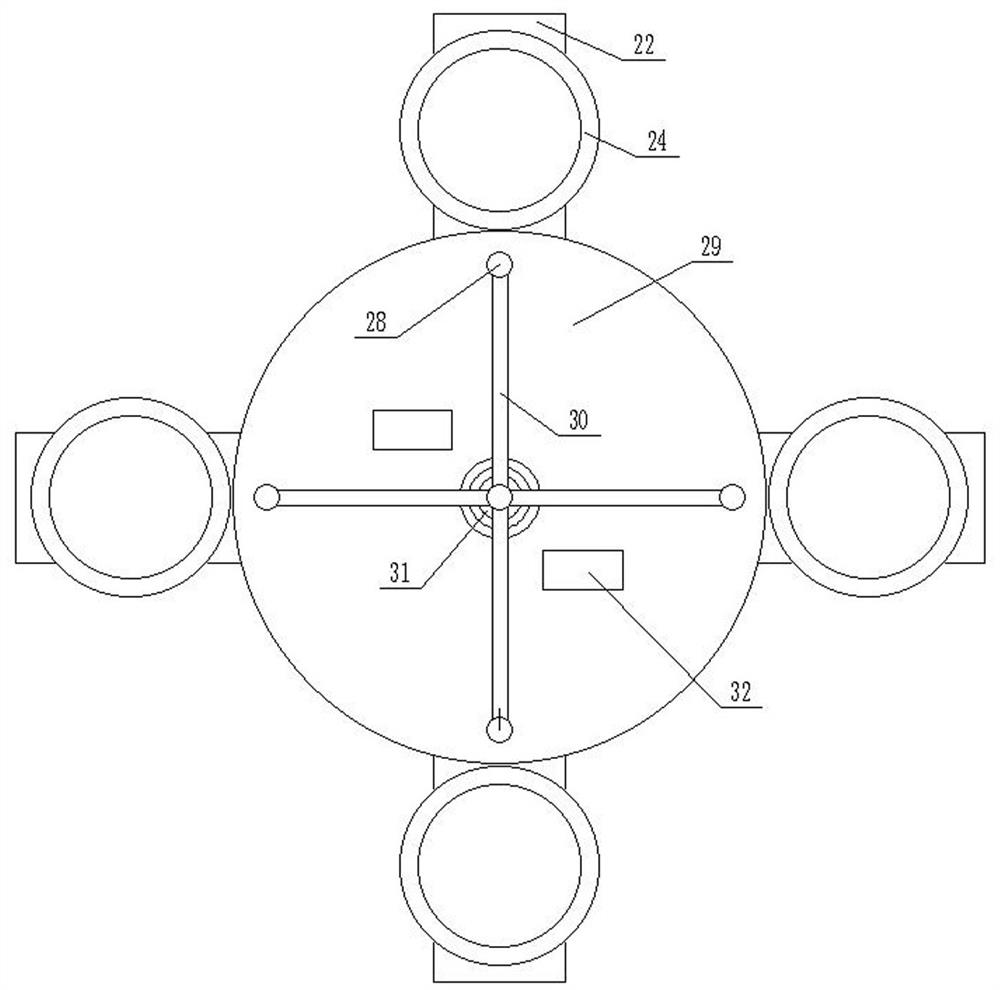

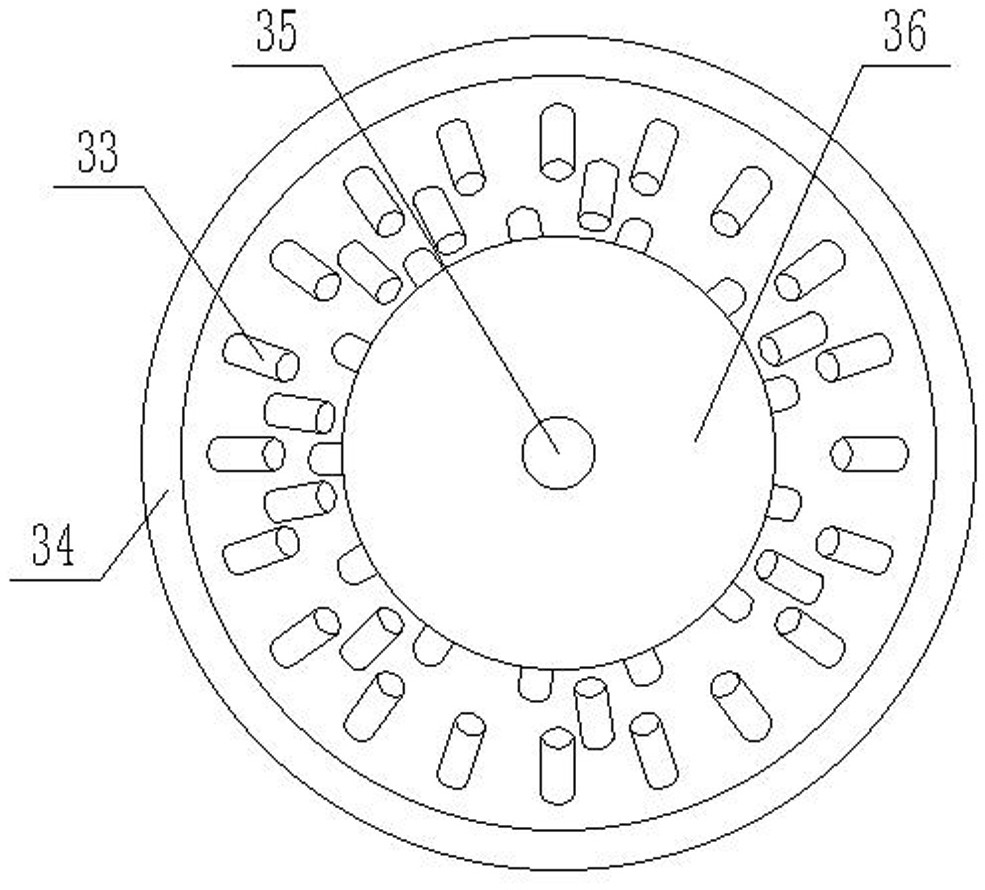

Material dispersing device for vertical grinder

The invention discloses a material dispersing device for a vertical grinder. The material dispersing device comprises a positive cone ring and a negative cone ring which are arranged in an annular space between a grinder shell of the vertical grinder and a grinding barrel of the vertical grinder; and the positive cone ring and the negative cone ring are distributed axially at a certain interval along the grinder shell. Due to the adoption of the material dispersing device for the vertical grinder, the falling time of a ground material ground with a roller mill in the falling process can be prolonged, the material is fully dispersed in the rolling processes of the positive cone ring and the negative cone ring and can be repeatedly impacted, dispersed and separated by rising air flow, the powder selecting efficiency is increased, and the yield of the grinder is remarkably increased. The invention further discloses a material dispersing device for a vertical grinder. The material dispersing device comprises dispersing plates obliquely arranged in an annular space between the grinder shell and the grinding barrel; a plurality of layers of dispersing plates are arranged at intervals along the axial direction of the grinder shell; and each layer of dispersing plates consists of a plurality of dispersing plates which are arranged at intervals along the circumference of the grinder shell.

Owner:郝志刚

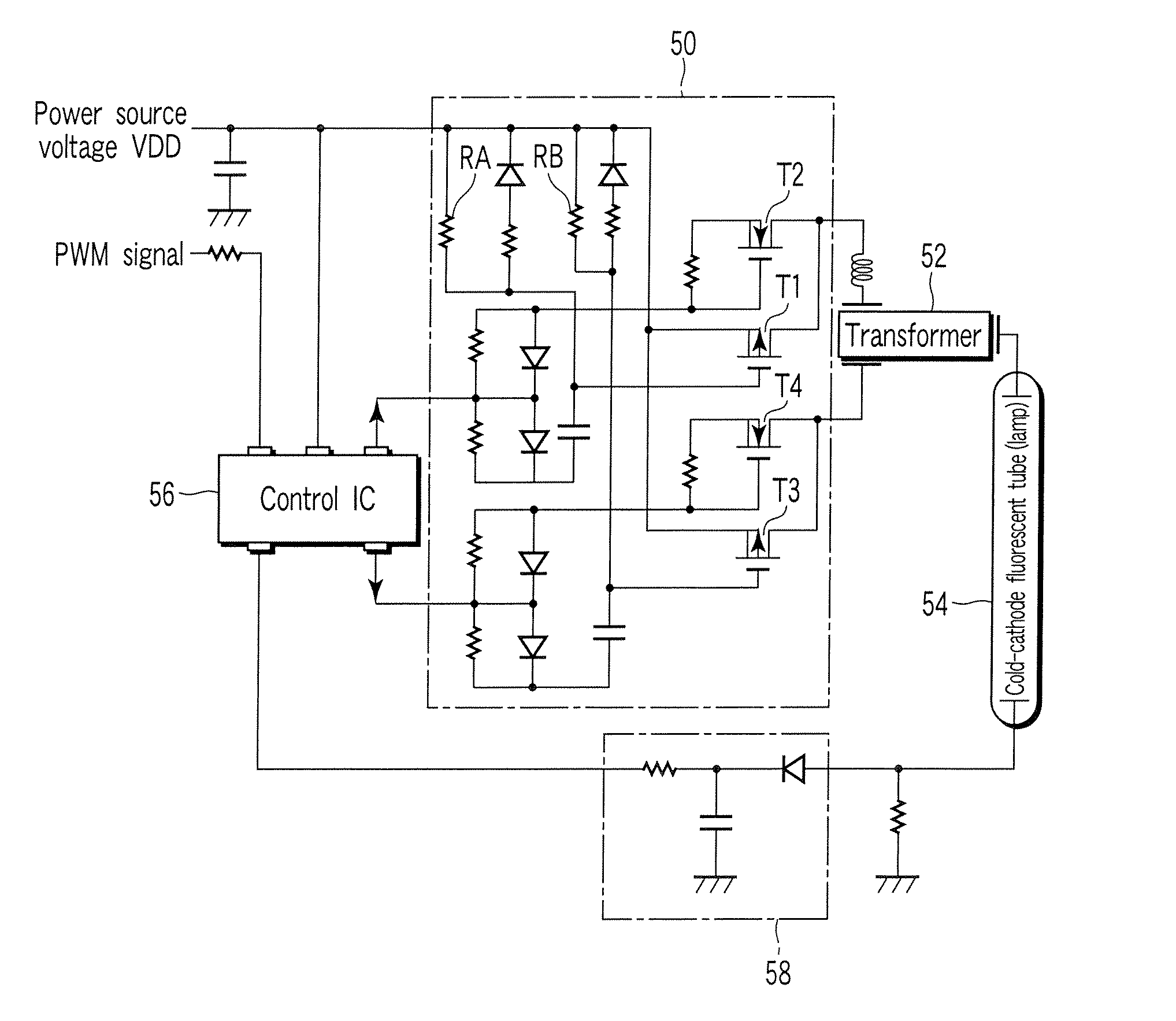

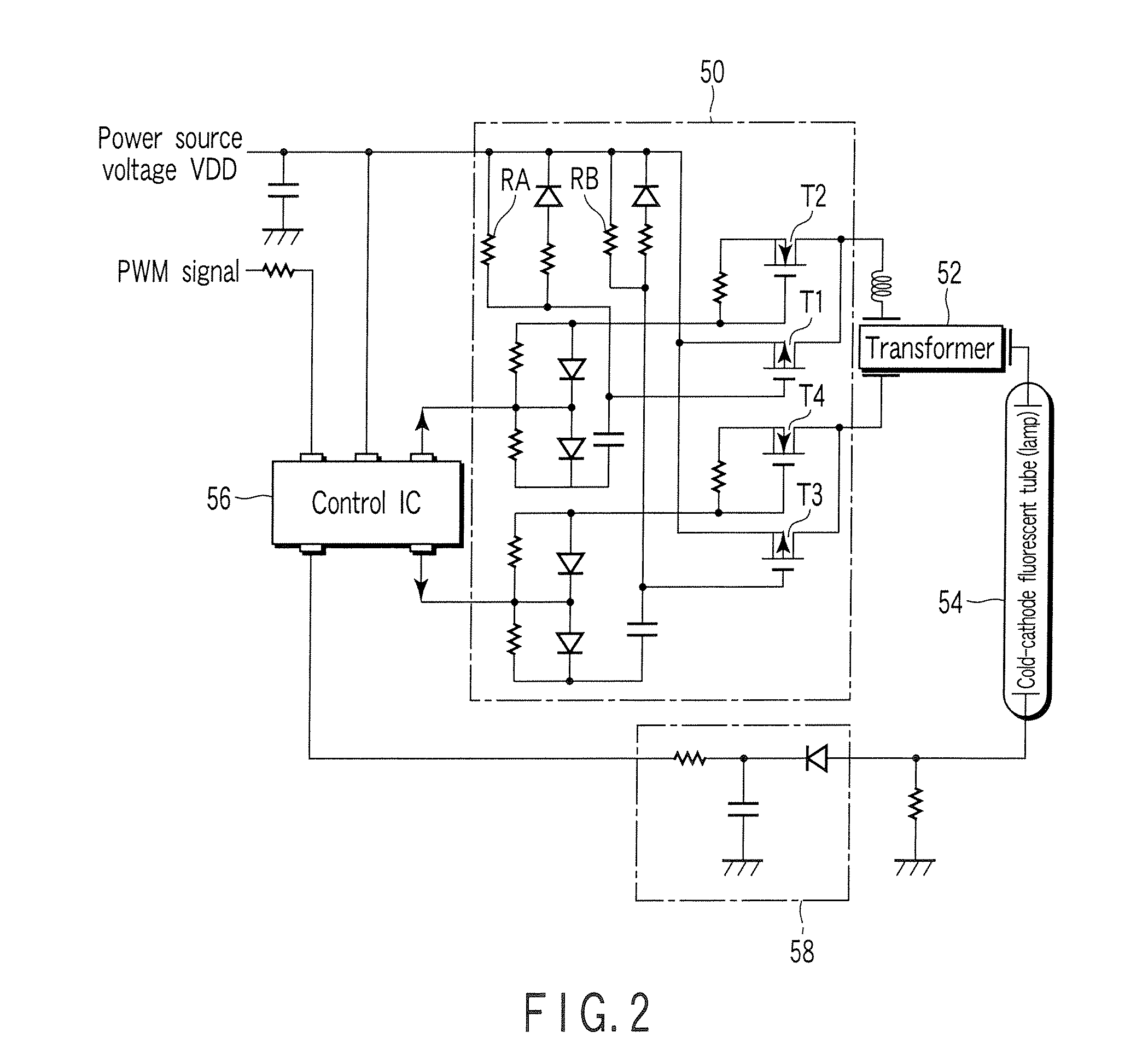

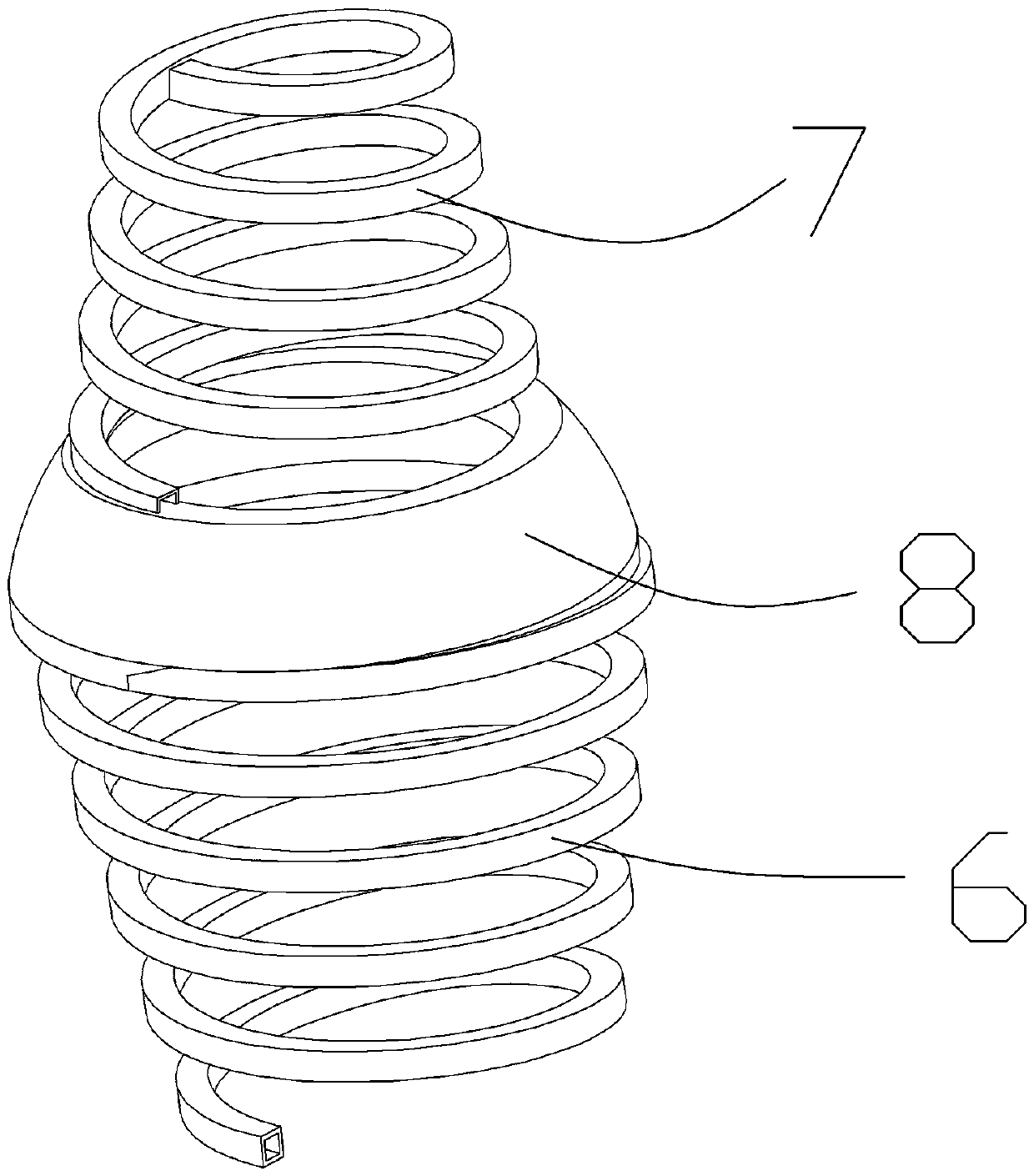

Light source driving device

InactiveUS20070018942A1Suppress noiseIncrease in manufacturing costElectrical apparatusStatic indicating devicesFall timeCold cathode

A light source driving device includes a switching circuit which switches a direct-current voltage supplied externally, a piezoelectric transformer which raises the voltage output from the switching circuit and which allows an alternating current to flow through a cold-cathode fluorescent tube, and a control circuit to change the duty ratio as a ratio per unit time at which the alternating current is output from the switching circuit in order to dim the cold-cathode fluorescent tube. The switching circuit includes resistors RA, RB which set the tilt of the envelope waveform to increase the fall time of the envelope waveform of the alternating current flowing through the cold-cathode fluorescent tube.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

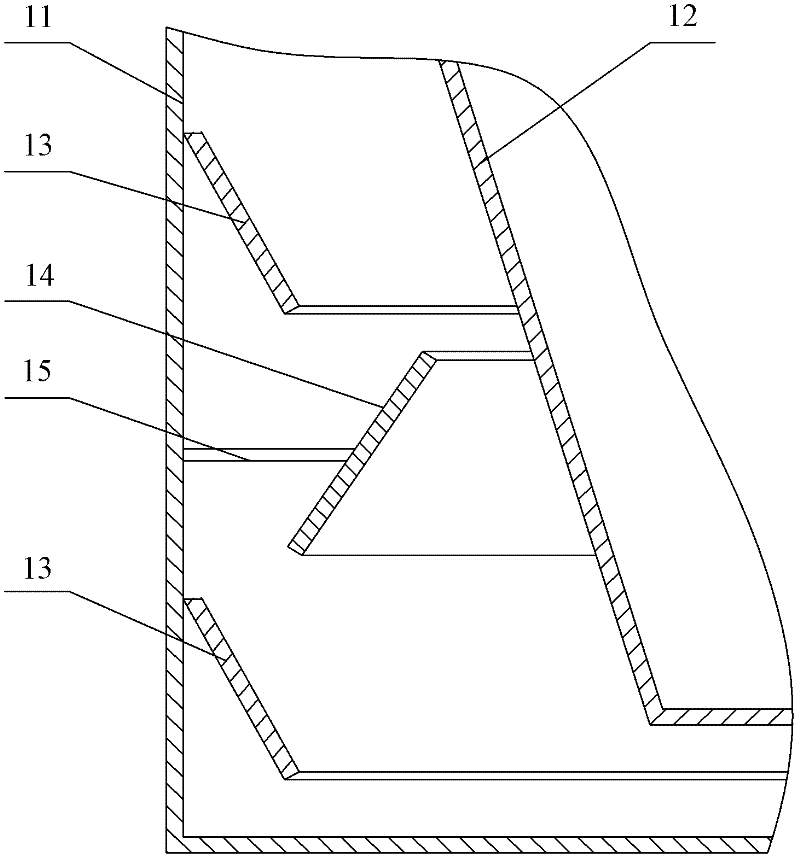

A charging barrel used for mixing dry powder and mortar

The invention relates to a charging barrel used for mixing dry powder and mortar. The charging barrel is characterized in that the charging barrel comprises a barrel body and blanking baffle plates, and the blanking baffle plates are disposed at the inner wall of the barrel body. The beneficial effects of the charging barrel are that material dropping time is increased by arranging the blanking baffle plates on the inner wall of the barrel body; and a process of mixing, convergence, dispersing and convergence again of materials is achieved by stagger arrangement of peak-shape baffle plates and hopper-shape baffle plates, thus allowing the materials to be fully mixed, and laying foundations for subsequent mixing of the materials.

Owner:JIANGSU MORNING ENVIRONMENTAL PROTECTION TECH CO LTD

Plasma display panel and driving method thereof

InactiveUS7453421B2Avoid fireReduce the starting voltageCathode-ray tube indicatorsCold-cathode tubesComputer scienceImage signal

Disclosed is a PDP driving method which may include generating subfield information that shows ON / OFF states of discharge cells from among a plurality of subfields from input image signals, generating address information that shows ON / OFF states of the discharge cells per subfield from the subfield data, counting the number of the discharge cells that are ON from among the discharge cells from the address data, and controlling a waveform applied during a reset period of a subsequent subfield.

Owner:SAMSUNG SDI CO LTD

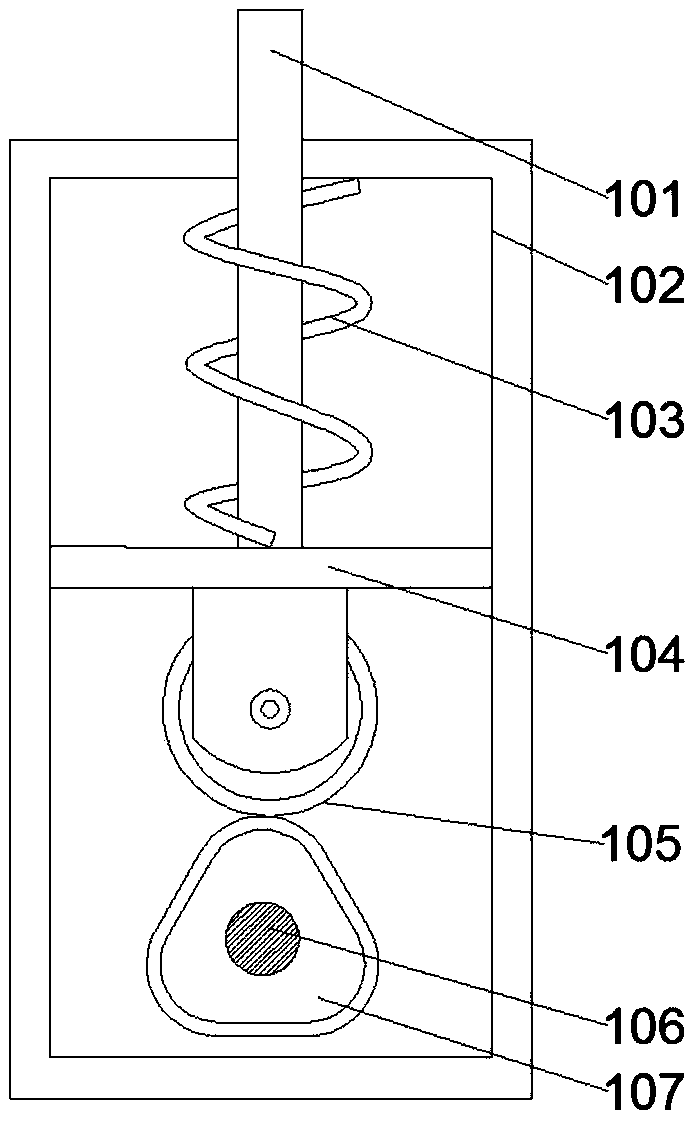

Chemical stirring and dissolving equipment for crushing solid materials

InactiveCN106731949AFast dissolutionWell mixedRotary stirring mixersTransportation and packagingEngineeringKnife blades

The invention provides a chemical stirring and dissolving equipment for crushing solid materials. The chemical stirring and dissolving equipment comprises a tank body and an upper cover, wherein a dissolving cavity is arranged in the tank body; a solid material adding device and a liquid inlet device are arranged on the upper cover; the solid material adding device consists of a crushing tank, a crushing motor, a crushing rotary shaft, a rotary knife blade and a fixed knife blade; the liquid inlet device consists of a tee pipe, a pressurizing pump, a first spray head and a second spray head; a stirring device is arranged in the dissolving cavity, and consists of a threaded screw, a screw motor, a stirring sheet and a lifting plate; the top part of the threaded screw is fixedly connected with an upper material guide tray; a lower material guide tray is arranged under the upper material guide tray; the bottom surface of the tank body is connected with the bottom plate through a damping device. The chemical stirring and dissolving equipment has the advantages that the solid material is crushed by the solid material adding device; the liquid can be fully mixed with the solid material by the liquid inlet device, so as to facilitate dissolving; the dissolving speed of the material is accelerated by the stirring device, and the working efficiency is improved.

Owner:李伟科

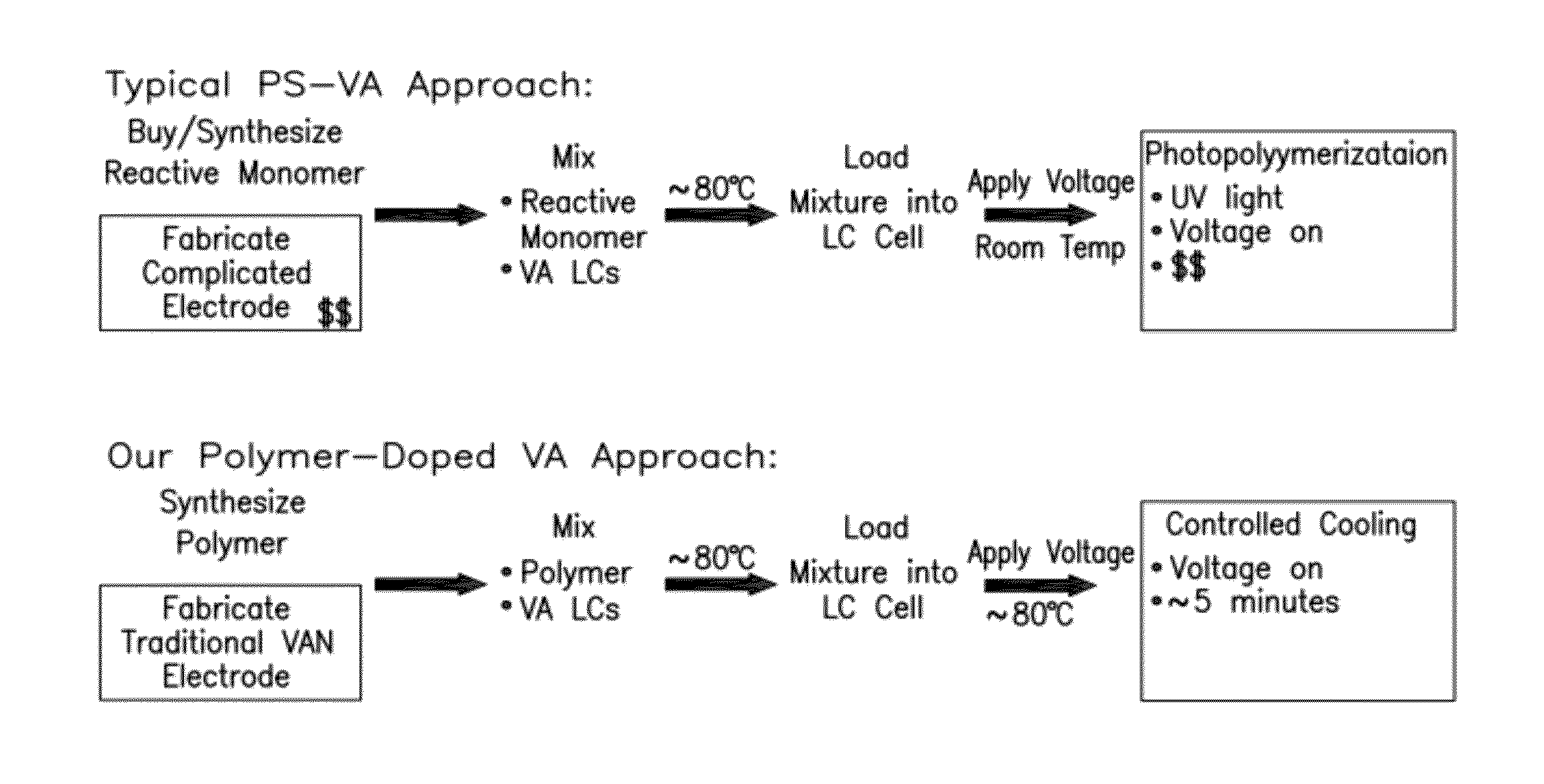

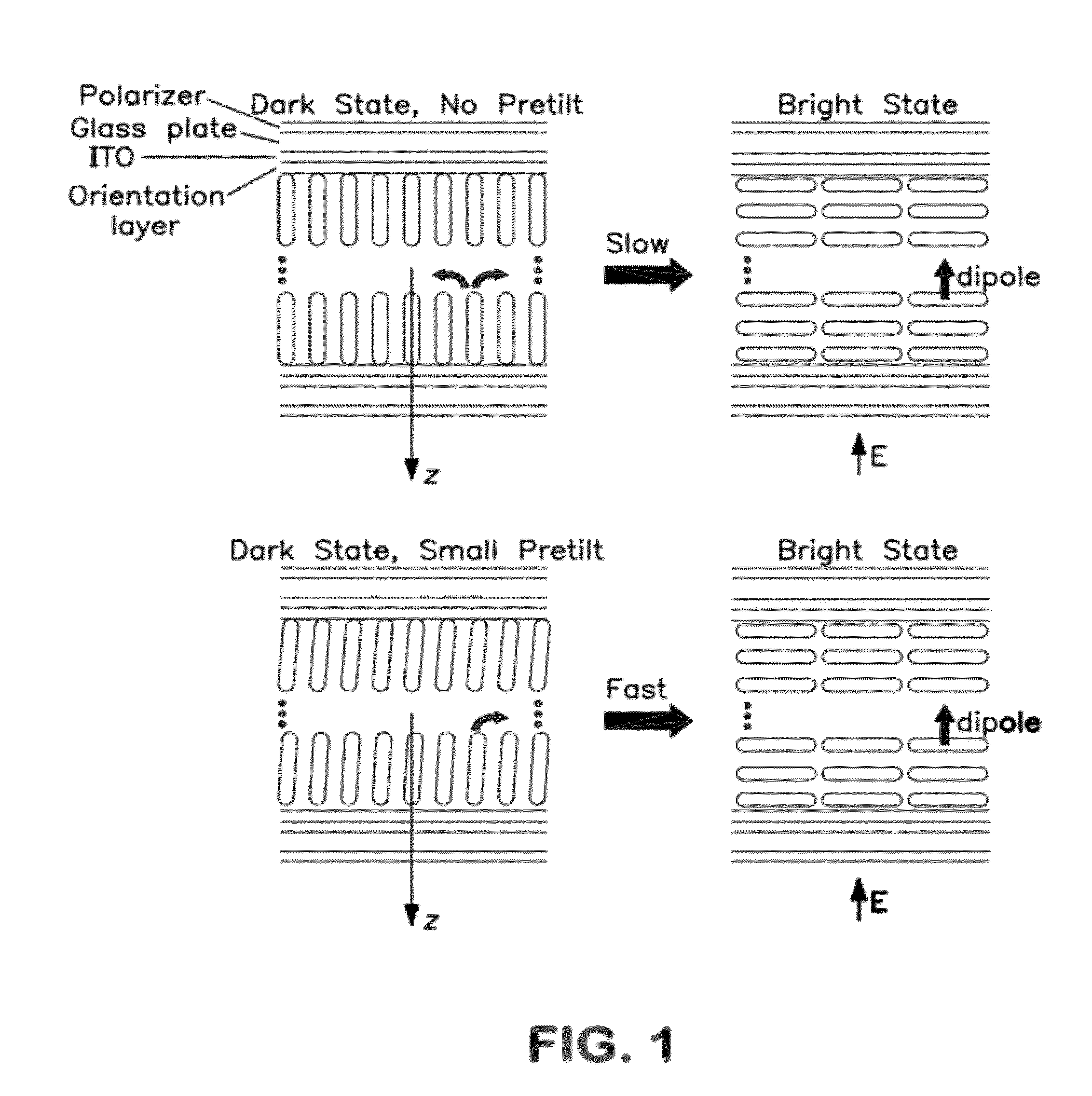

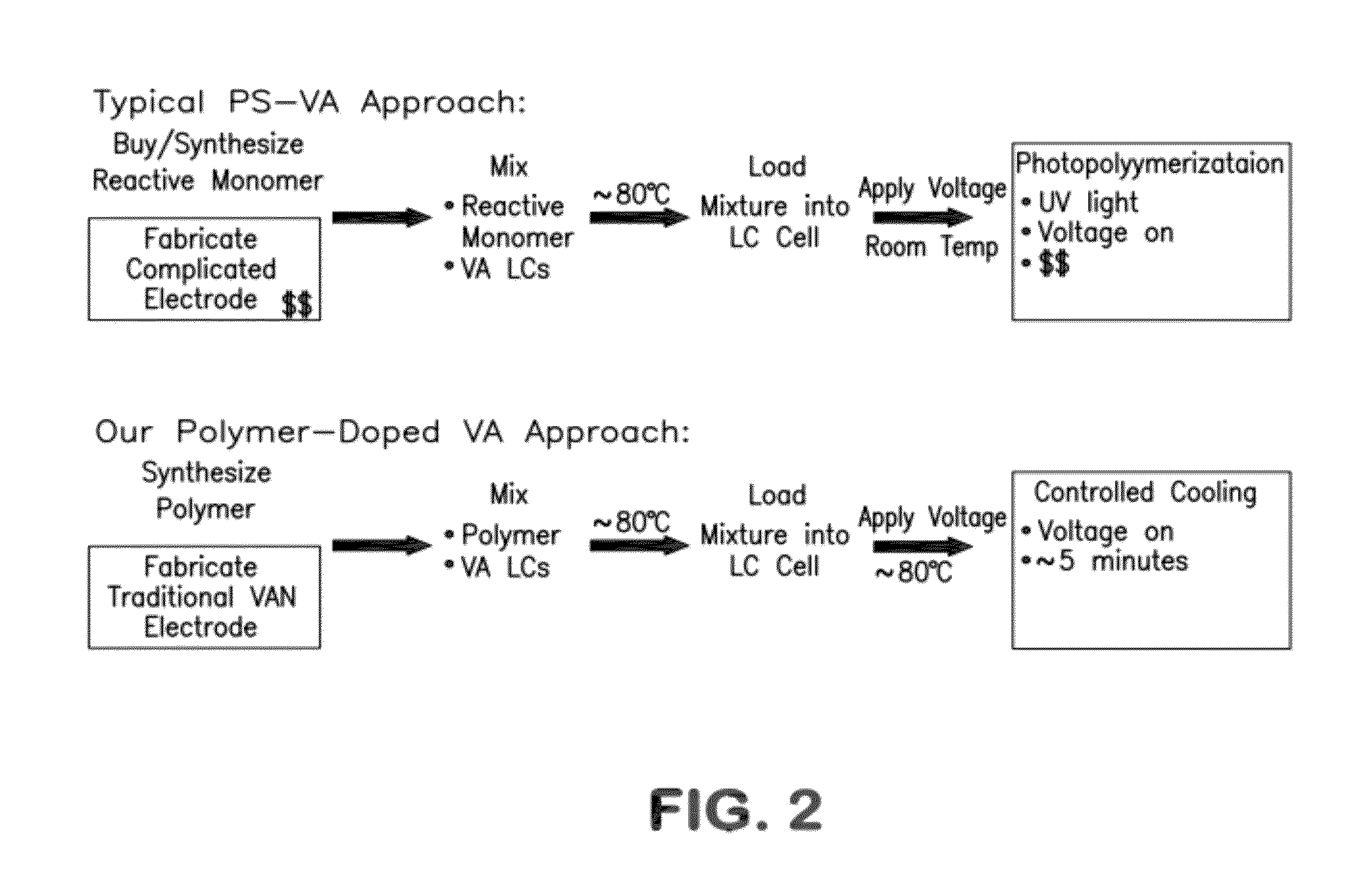

Polymer-doped vertically-aligned nematic liquid crystals

ActiveUS20120105791A1Speed up the processIncrease contrastLiquid crystal compositionsCrystallographyHost material

A system having a vertically-aligned negative delta E nematic liquid crystal host material and a small amount of liquid crystal polymer is provided. The liquid crystal polymer improves the switching speed of a vertically aligned nematic system without sacrificing contrast or viewing angle.

Owner:CALIFORNIA INST OF TECH +1

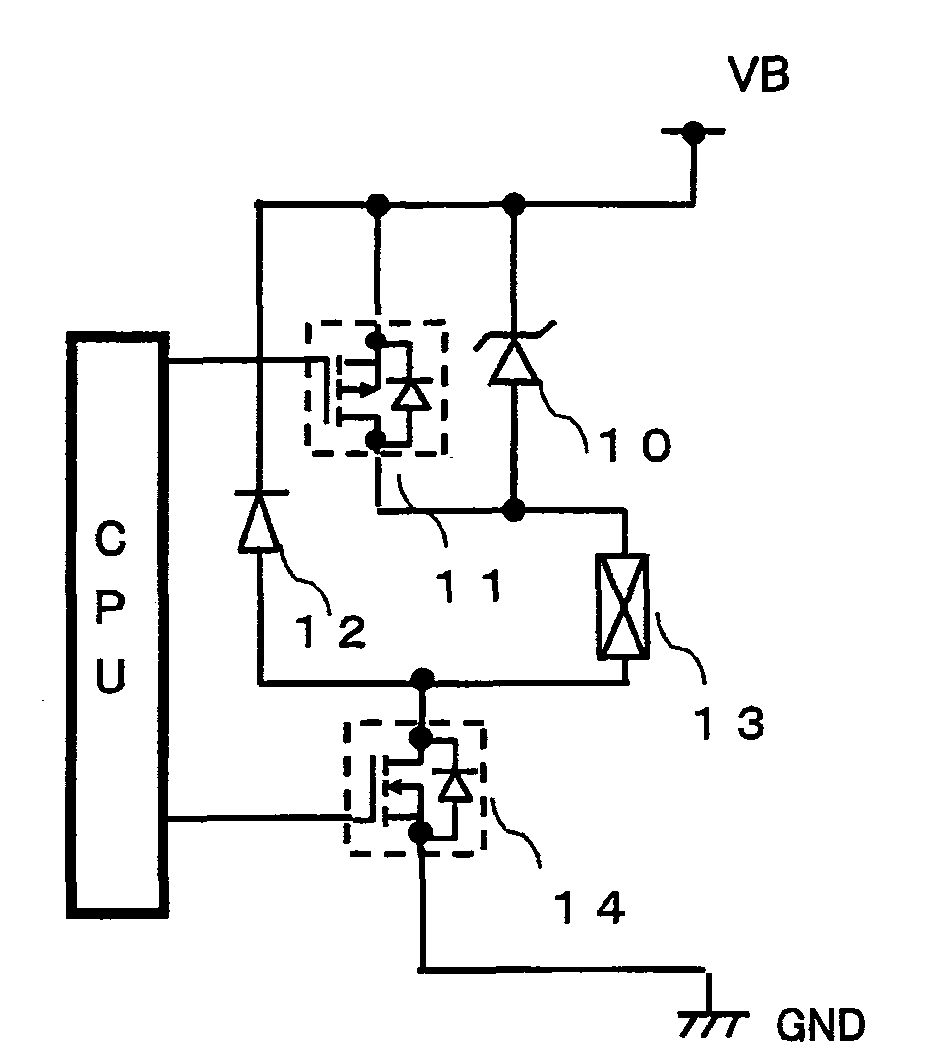

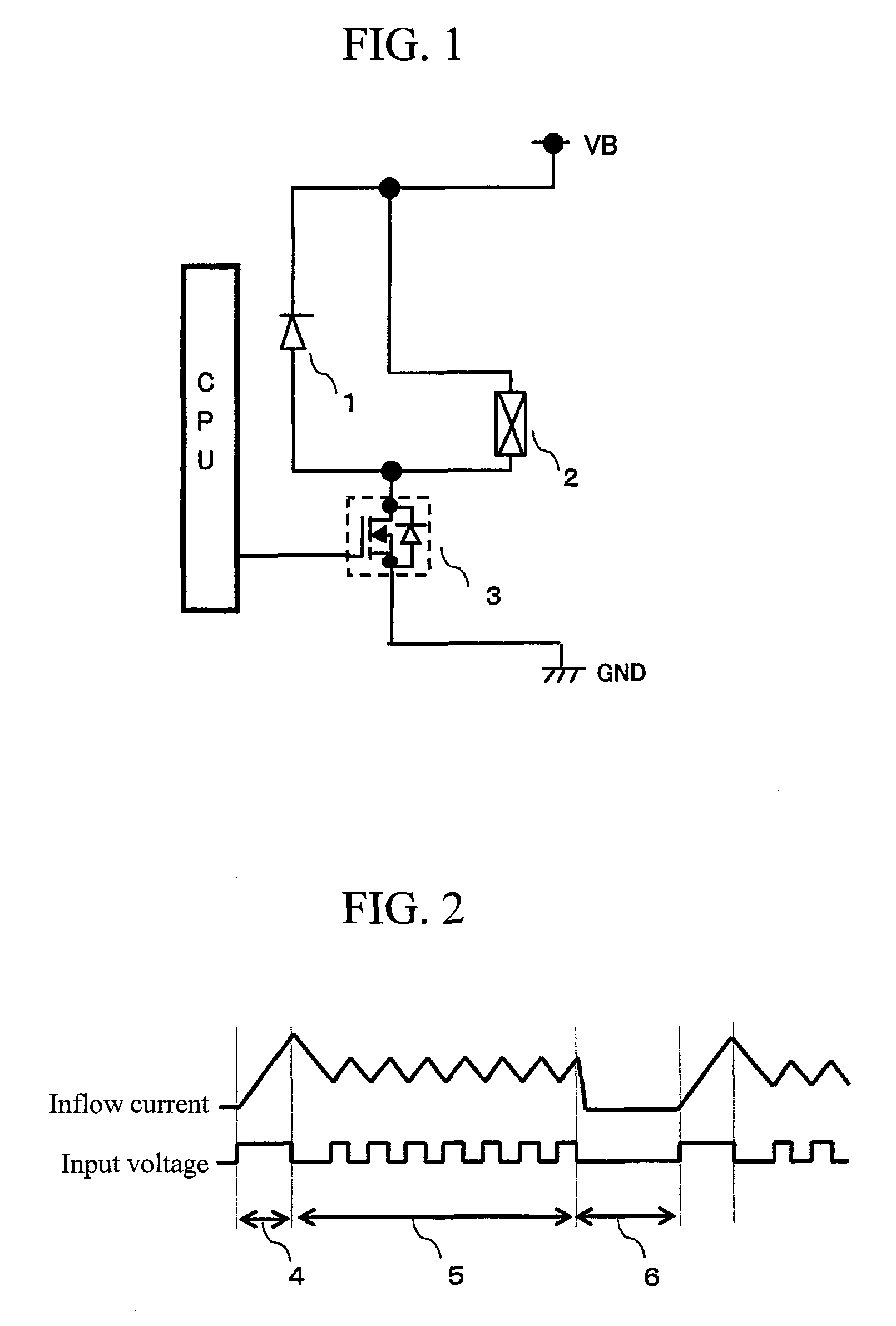

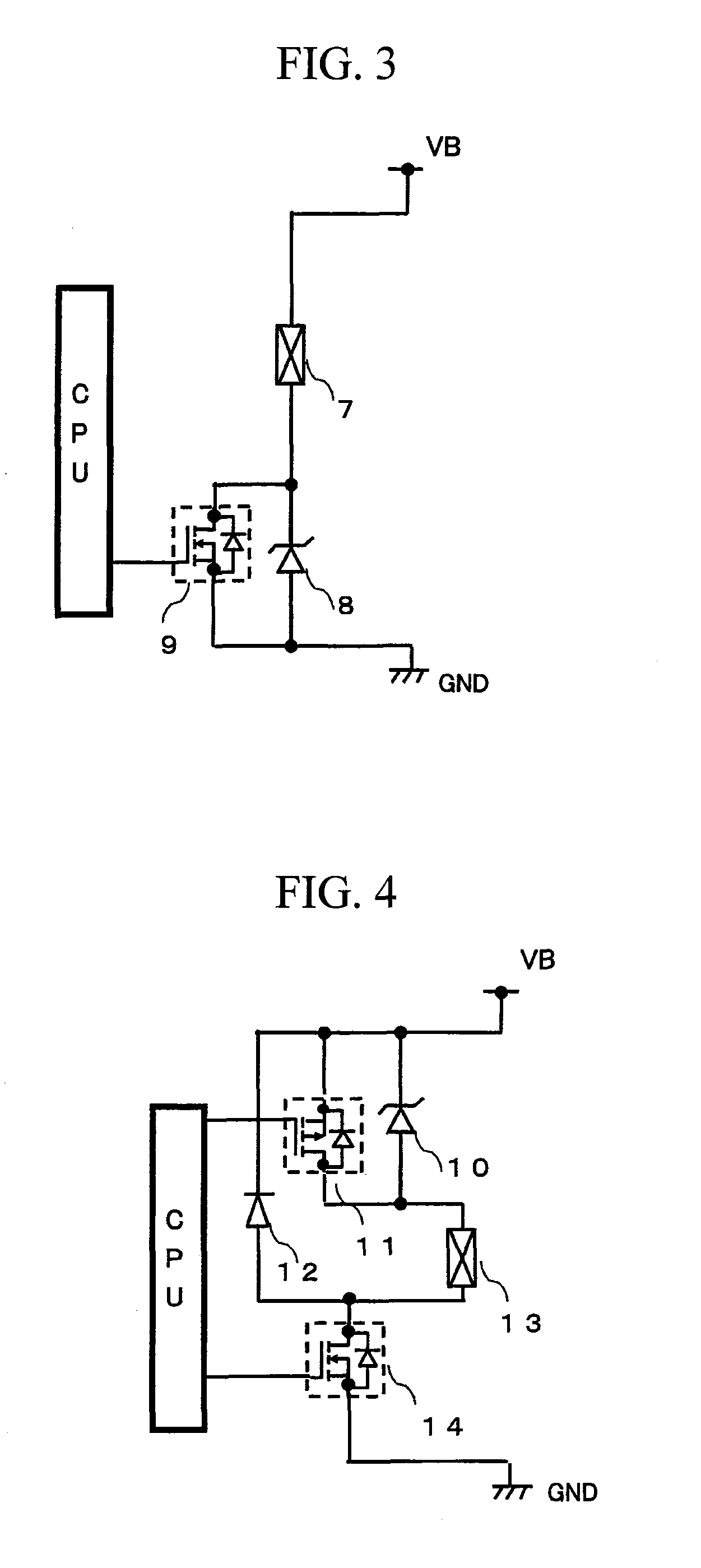

High-Pressure Fuel Pump Drive Circuit for Engine

ActiveUS20080030917A1Save energy consumptionExtended fall timeElectrical controlMagnetsZener diodeHigh pressure

There is provided a high-pressure fuel pump drive circuit for manipulating the electric current to be passed to a solenoid coil for controlling a high-pressure pump. This circuit is characterized in that a first switching element, the solenoid coil and a second switching element are connected in series with each other in a rout from a source voltage side to the ground side, that a flywheel diode for passing electric current to a power source is disposed parallel with the solenoid and with the first switching element, and that a Zener diode connected with the power source is disposed parallel with the second switching element, wherein a counter electromotive force to be developed at the opposite ends of solenoid coil on the occasion when the second switching element is changed from ON to OFF is consumed by the flywheel diode provided that the first switching element is in a state of ON, and the counter electromotive force is more rapidly consumed by the Zener diode provided that the first switching element is turned OFF.

Owner:HITACHI ASTEMO LTD

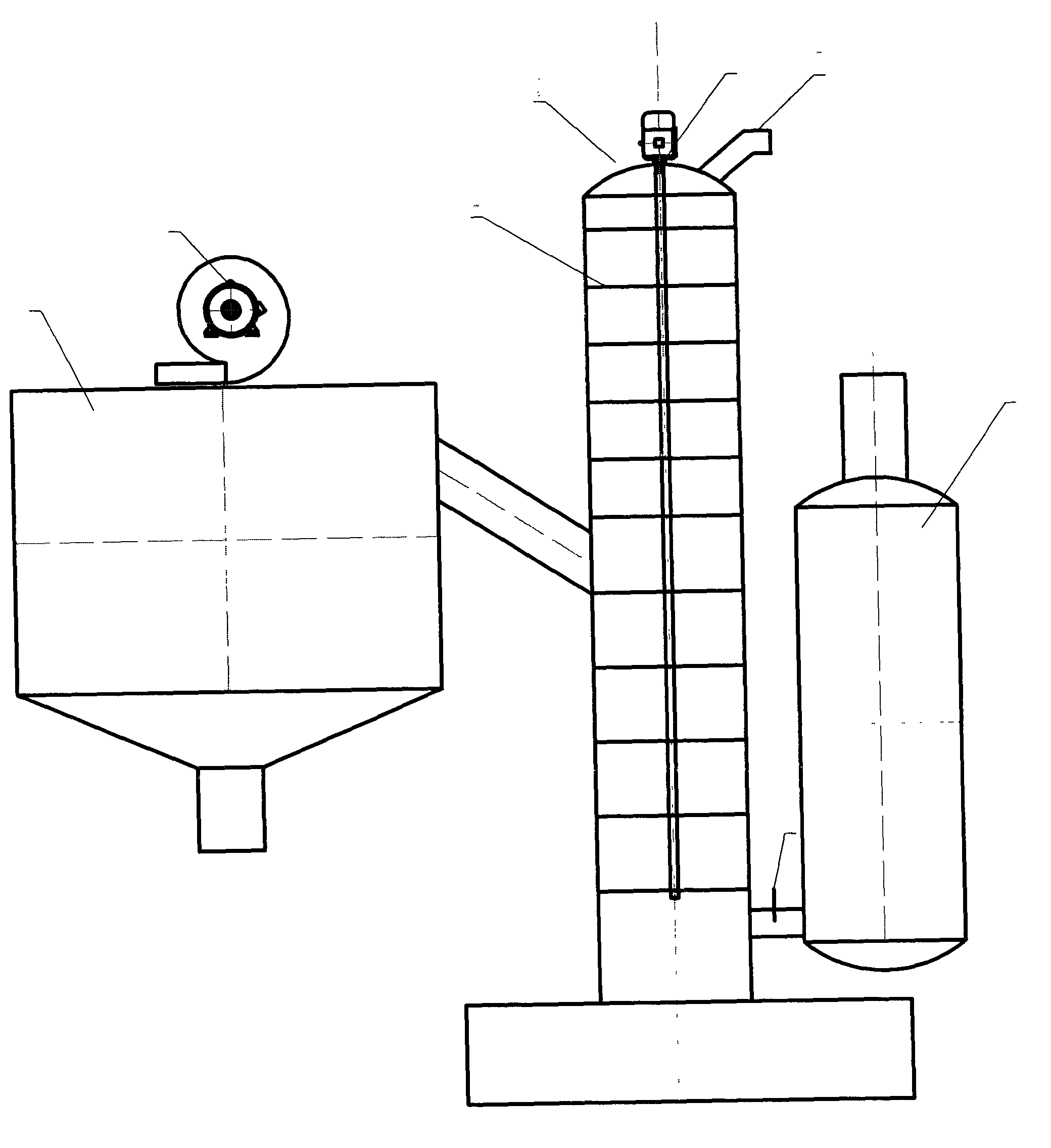

Drum-type grain dryer

InactiveCN106440753AExtended fall timeImprove efficiencyDrying gas arrangementsDrying solid materialsMicrocomputerEngineering

The invention discloses a drum-type grain dryer, which comprises a temperature sensor, a moisture meter and a dryer body. A feed delivery pipe is arranged on the top part of the dryer body; a motor is arranged at one side of the feed delivery pipe; a hot air conveying pipe is arranged on one side of the dryer body; a drying bin is arranged in the dryer body; air exhausting meshes are arranged on outer walls of the drying bin; the temperature sensor is arranged on an inner wall of the drying body; a rotary shaft is arranged under the motor; and a drying channel is arranged on the rotary shaft. The drum-type grain dryer provided by the invention adopts a vertical structure so as to be simple in post-maintenance; the drying channel is arranged inside the drying bin, so that the falling time of grain can be effectively prolonged so as to help the grain to be heated uniformly; hot air is utilized for penetrating through the air exhausting meshes to dry the grain, so that an air flow can be uniform, and local excess heating is prevented; and a communication device is arranged, so that workers can remotely control a microcomputer controller, and the use efficiency of manpower resources is improved.

Owner:成都君华睿道科技有限公司

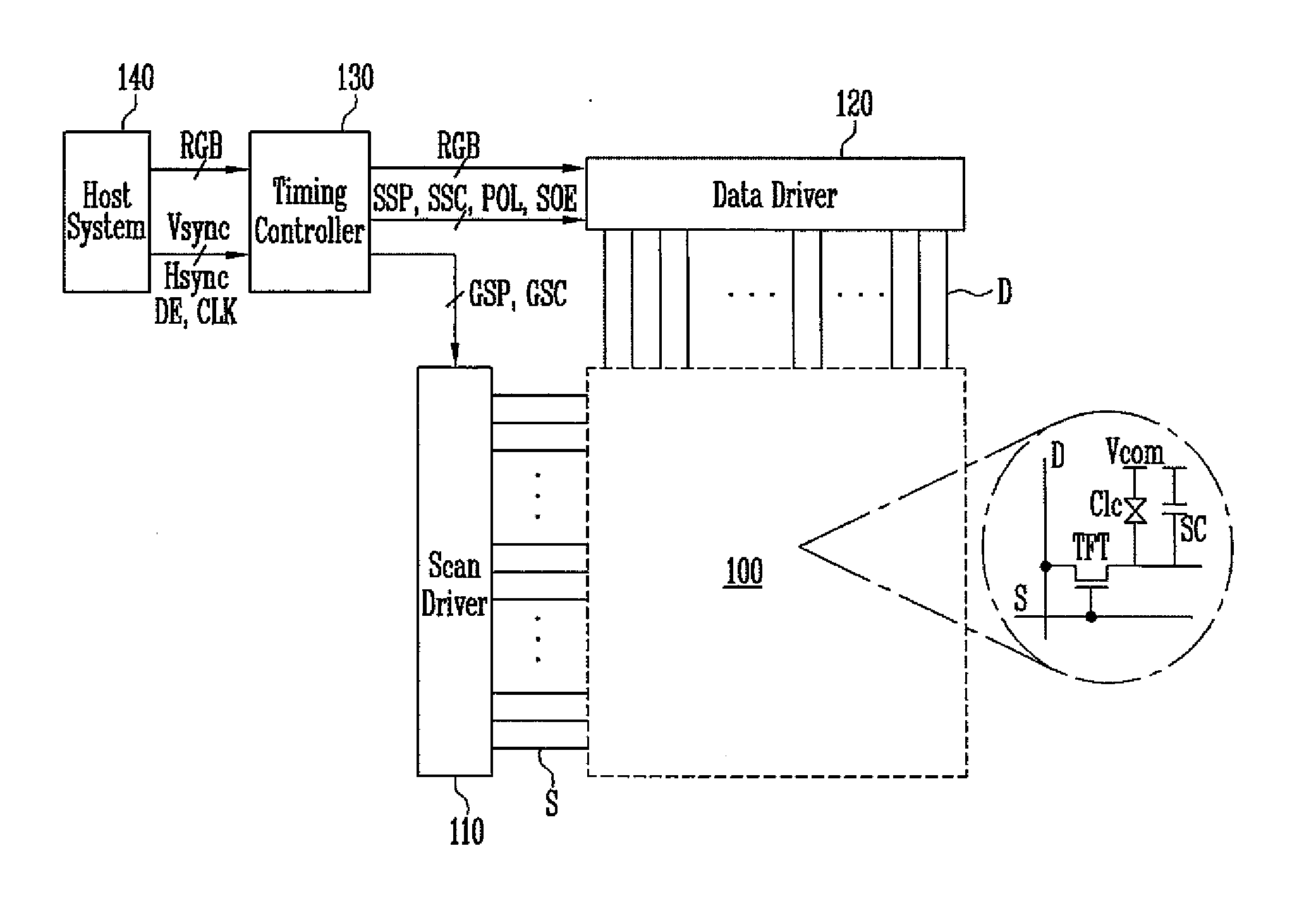

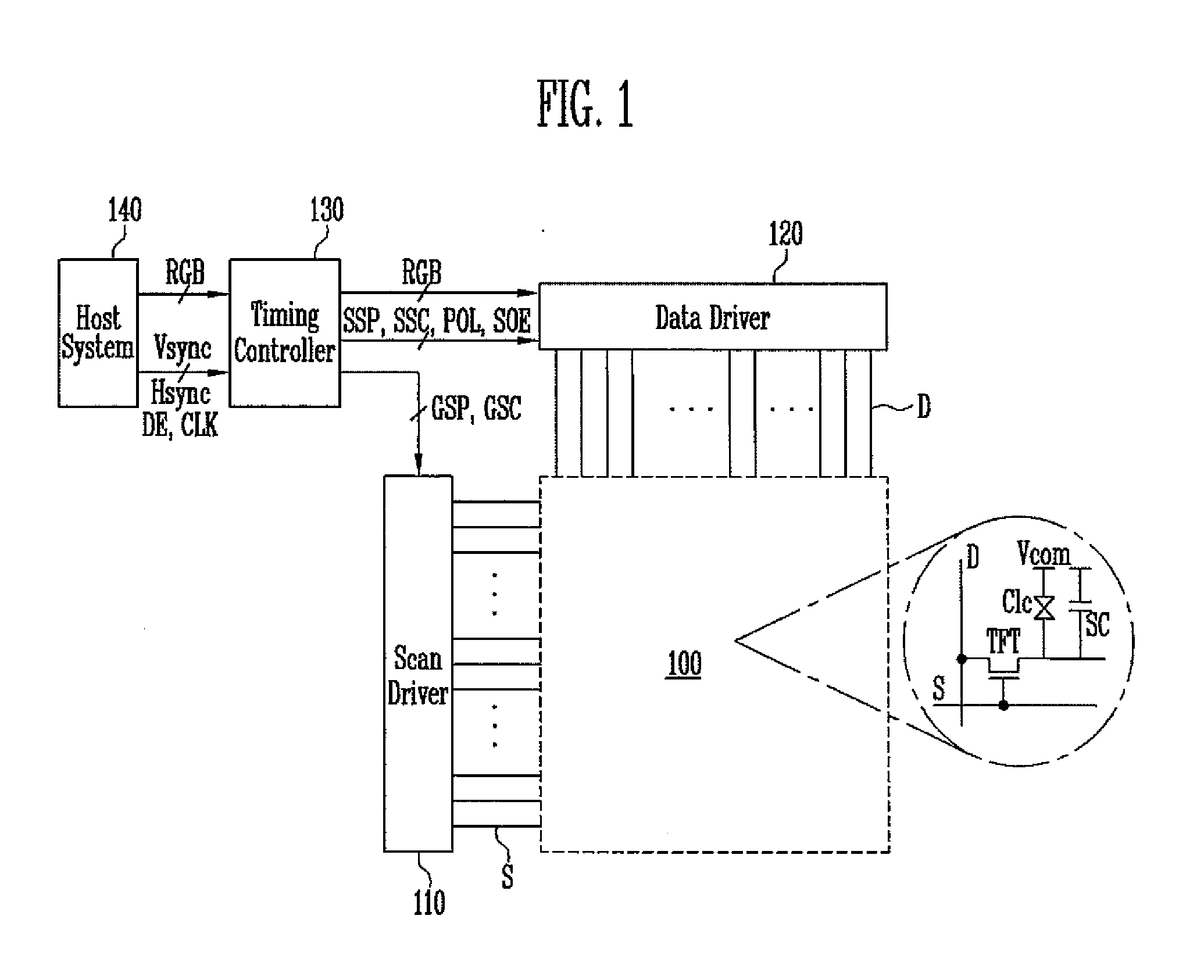

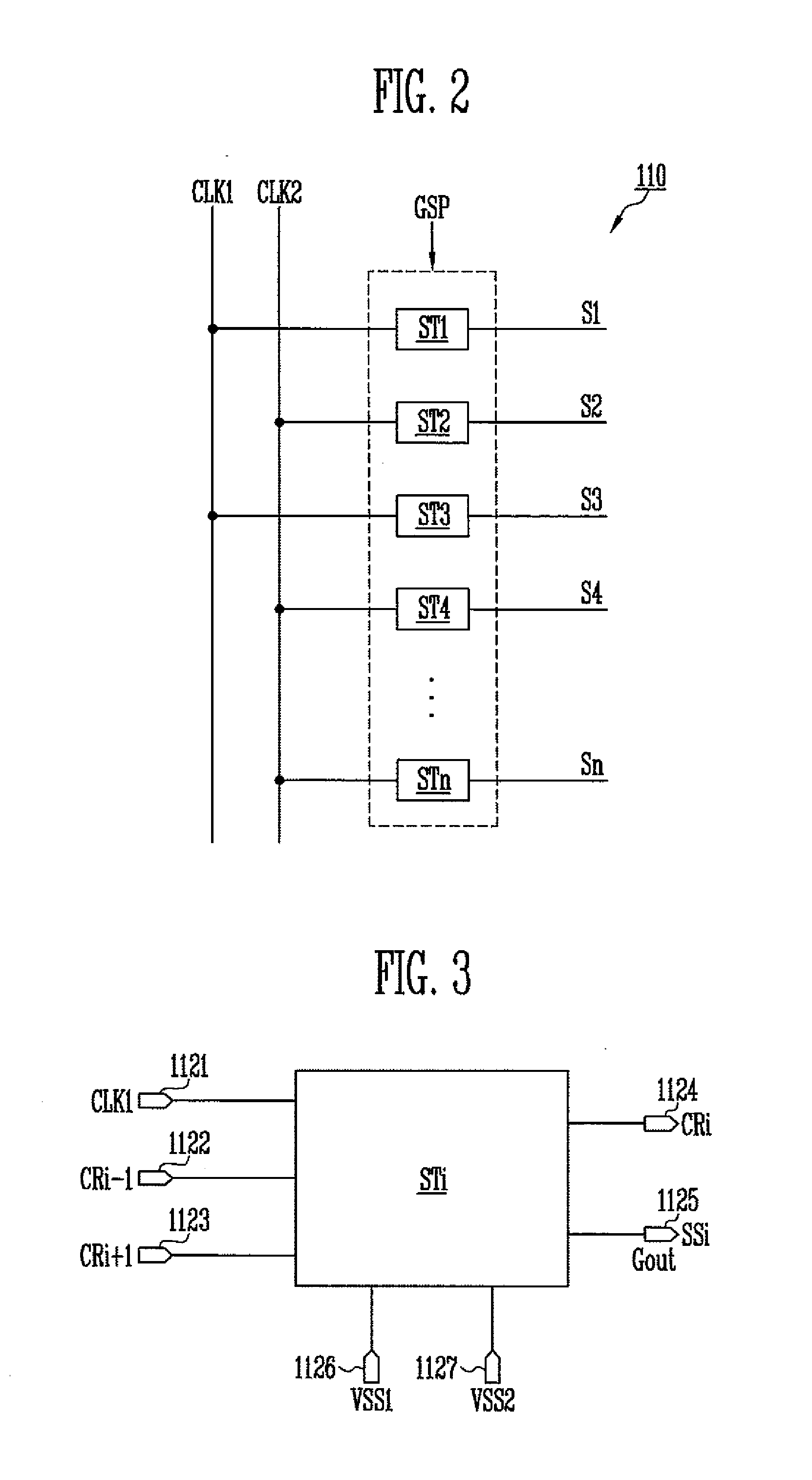

Stage circuit and scan driver using the same

ActiveUS20170032756A1Reducing and minimizing areaExtended fall timeStatic indicating devicesDigital storageVoltageClock signal

A stage circuit includes an output part configured to supply a carry signal to a first output terminal and a scan signal to a second output terminal, in response to a voltage of a first node, a voltage of a second node, and a first clock signal being supplied to a first input terminal, a controller configured to control the voltage of the second node in response to the first clock signal being supplied to the first input terminal, a pull-up part configured to control the voltage of the first node in response to a carry signal of a previous stage being supplied to a second input terminal, and a pull-down part configured to control the voltage of the first node in response to the voltage of the second node and the carry signal of a next stage being supplied to a third input terminal.

Owner:SAMSUNG DISPLAY CO LTD

High-pressure fuel pump drive circuit for engine

ActiveUS7881035B2Save energy consumptionSuppress feverElectrical controlMagnetsPower flowZener diode

There is provided a high-pressure fuel pump drive circuit for manipulating the electric current to be passed to a solenoid coil for controlling a high-pressure pump. This circuit is characterized in that a first switching element, the solenoid coil and a second switching element are connected in series with each other in a rout from a source voltage side to the ground side, that a flywheel diode for passing electric current to a power source is disposed parallel with the solenoid and with the first switching element, and that a Zener diode connected with the power source is disposed parallel with the second switching element, wherein a counter electromotive force to be developed at the opposite ends of solenoid coil on the occasion when the second switching element is changed from ON to OFF is consumed by the flywheel diode provided that the first switching element is in a state of ON, and the counter electromotive force is more rapidly consumed by the Zener diode provided that the first switching element is turned OFF.

Owner:HITACHI ASTEMO LTD

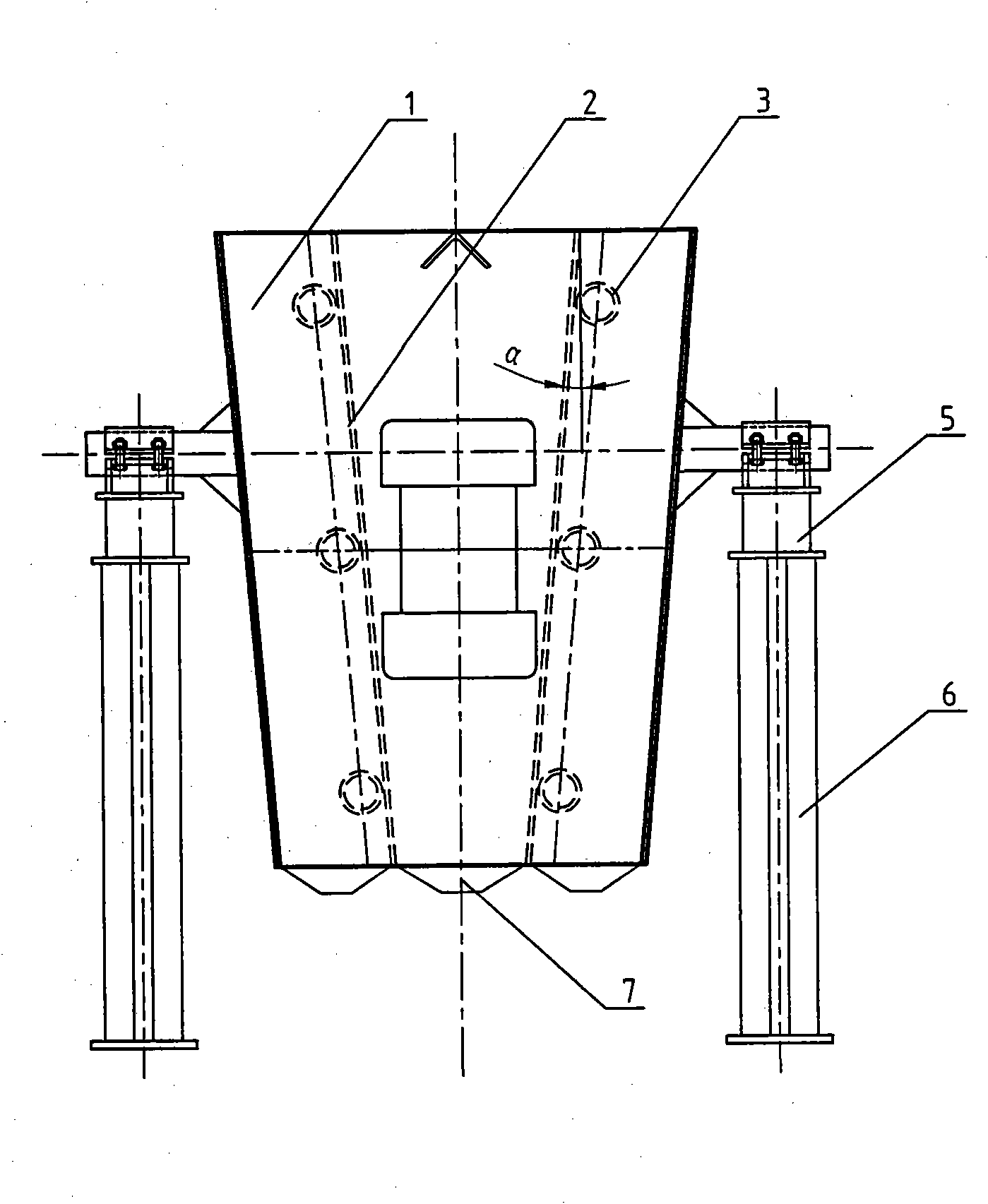

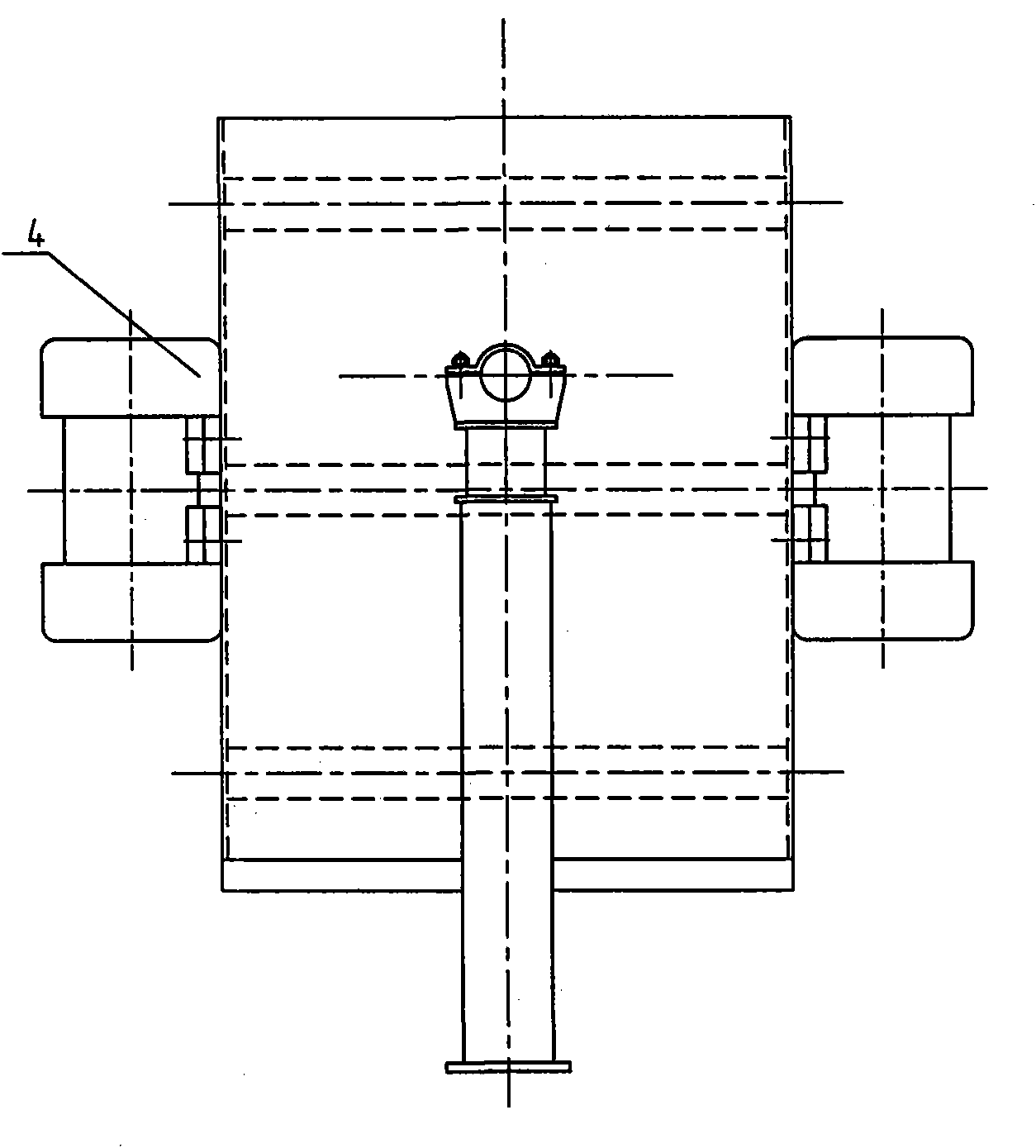

Self-synchronizing vertical screening dewatering screen

InactiveCN101920133AExtended fall timeIncrease contact areaSievingScreeningPulp and paper industryAngle alpha

The invention relates to a dewatering screen, in particular to a self-synchronizing vertical screening dewatering screen which is applicable to dewatering classification of coal slurry and other fine materials and belongs to the technical field of coal mine mechanical processing. The dewatering screen comprises a screen box, a screen mesh is arranged in the screen box, vibrating motors, a damping spring and a support are arranged outside the screen box, and the dewatering screen is characterized in that a plurality of connecting pipes are arranged in the screen box for supporting, the screen mesh is fixedly arranged in the screen box, the screen mesh is placed by forming an angle alpha with the vertical line, the vibrating motors are arranged on two sides of the screen box, a discharge chute is arranged at the lower part of the screen box, the screen box is fixed on the support through the damping spring, and the support is fixed on the ground. The screen box can vibrate left and right under the drive of the vibrating motors, thereby forcing materials to carry out collision back and forth between two opposite screen surfaces and fall while swinging, prolonging the fall time of the materials, simultaneously increasing the contact area between the materials and the screen surfaces and further well achieving the purposes of dewatering and screening.

Owner:陆信

Multi-level voltage output control circuit and logic gate therefor

ActiveUS20050218932A1Extended rise timeExtended fall timePower reduction in field effect transistorsStatic indicating devicesEngineeringLogic gate

A multi-level voltage output control circuit selectively outputs one of multi-level power voltages by driving gates of two MOS transistors, which act as switching devices for the multi-level power voltages, with two output signals, the two output signals having complementary phases to each other and generated from two logic gates receiving two input signals which have an identical timing and complementary phases to each other, wherein the two logic gates advance or slow down a rising timing and / or a falling timing of the two output signals by differently adjusting a size of PMOS transistors and that of NMOS transistors, which construct the logic gates, thereby excluding a case in which the two output signals are in a same logic state at the same time.

Owner:MAGNACHIP SEMICONDUCTOR LTD

Gliding robot that can jump and take off autonomously

InactiveCN101734299BIncrease elastic potential energyHigh quick return characteristicVehiclesEngineeringMechanical engineering

The invention discloses a gliding robot capable of jumping and taking off autonomously. device and a gliding driving device for driving the gliding device, the gliding device includes: a front frame, a back frame, wings and an opening and closing mechanism, the wings are fixed between the front frame and the back frame, the front frame and the back frame The back frame is connected with the opening and closing mechanism, and the opening and closing mechanism is connected with the gliding driving device to expand the wings. The take-off angle adjustment mechanism of the present invention enables the robot to independently adjust the take-off angle, thereby adjusting the jumping height, jumping distance and stability. Landing increases the flexibility of robot activities.

Owner:SOUTHEAST UNIV

Fixation and dust-removal device for tea processing

InactiveCN108782827AExtended fall timeAvoid gatheringGas current separationPre-extraction tea treatmentEngineeringResistance wire

The present invention discloses a fixation and dust-removal device for tea processing. The device comprises a feeding shell, a dust-removal box and baffle plates. The device is characterized in that the feeding shell is arranged at the middle part of the upper end of the dust-removal box; a plurality of baffle plates are equally spaced on the inner wall of the dust-removal box; a plurality of holes are arranged on the left side and the right side surface of the dust-removal box; an air suction fan is arranged on the surface of one side of the dust-removal box; and the dust-removal box is fixedly provided with a fan at one end parallel to one end connecting the air suction fan. The fixation and dust-removal device carries out treatment on tea leaves; tea leaves to be processed are fed through the feeding shell; the air suction fan matches with the fan to perform dust removal on the tea leaves passing through the dust-removal box; a filter screen is arranged on the surface of each baffleplate; the baffle plates prolong the falling time of tea leaves in the dust-removal box; a screw rod is started to change the angle of a heating shell; the heating shell carries out fixation on tea leaves by resistance wires; and a spiral rotating shaft is provided to prevent tea leaves from accumulating in one place.

Owner:ANHUI XINXUTANG TEA CO LTD

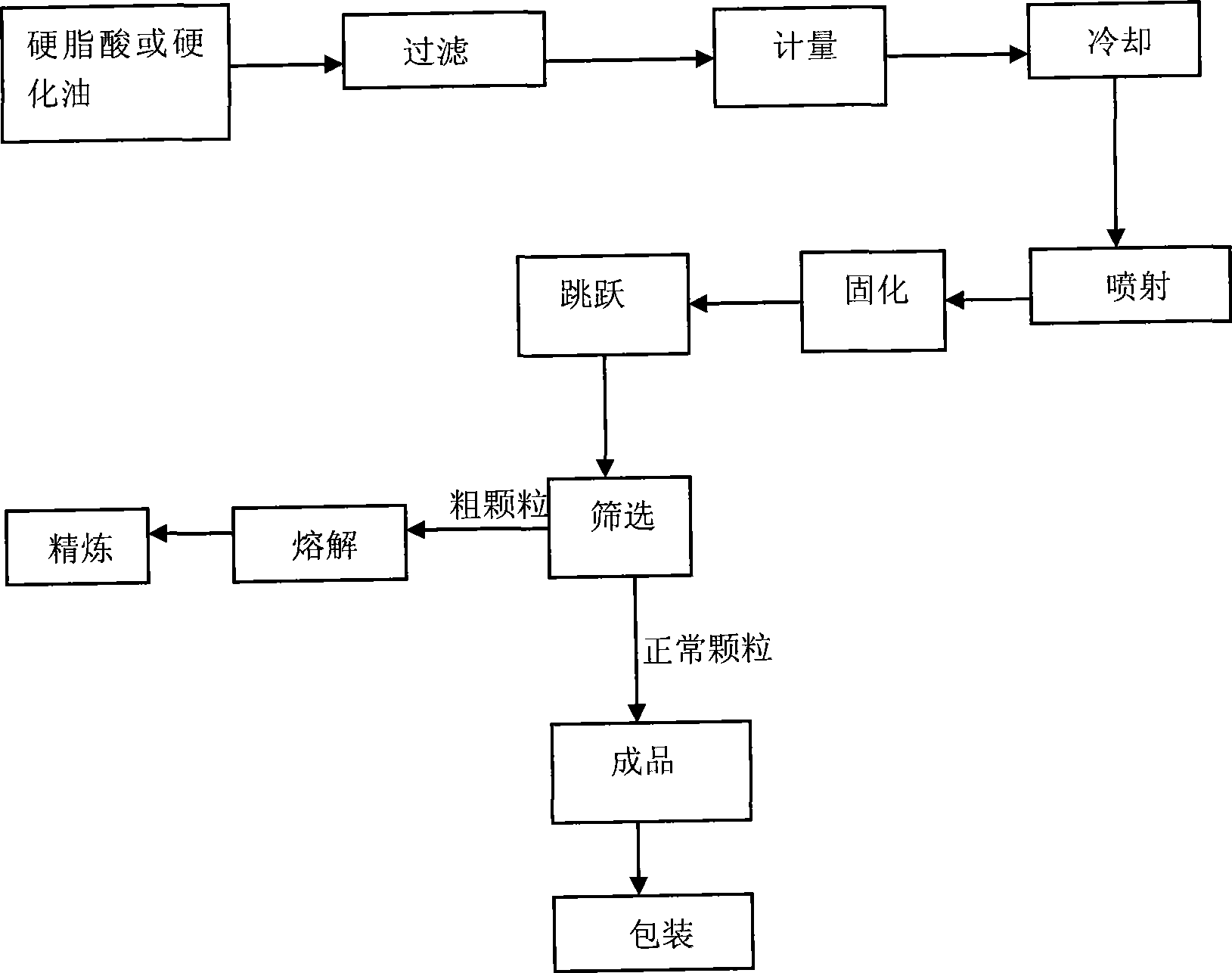

Spray cooling and granulating technique for geoceric acid or hydrogenatedoil

InactiveCN101433814AExtended fall timeSimple processGranulation by liquid drop formationCold airVolumetric Mass Density

The invention discloses a spray cooling granulating process for stearic acid or hardening oil, which comprises the following steps: selecting the stearic acid or the hardening oil of which the freezing point is higher than 50 DEG C, filtering impurities through a filter, cooling the stearic acid or the hardening oil and sending the stearic acid or the hardening oil to a tower top spraying head after measuring materials through a quality meter, and spraying the stearic acid or the hardening oil in a tower body through a material spraying head; and after the curing in the tower body, screening the stearic acid or the hardening oil through a vibrating screen with about 10 meshes to obtain normal granules, namely the finished product. The process adopts the spraying head to spray materials into the tower body and cold air is blown in the tower body from bottom to top to increase the falling time of the materials, so the materials are cooled and formed, and the process is simple and easy to operate; the stearic acid or the hardening oil granules prepared by the process has a long piling up time and uneasy caking of a slicing product; and the stearic acid or the hardening oil granule products produced by the granulating process has larger piling up density than stearic acid or hardening oil slices, and can effectively reduce the transport cost.

Owner:RUGAO SHUANGMA CHEM

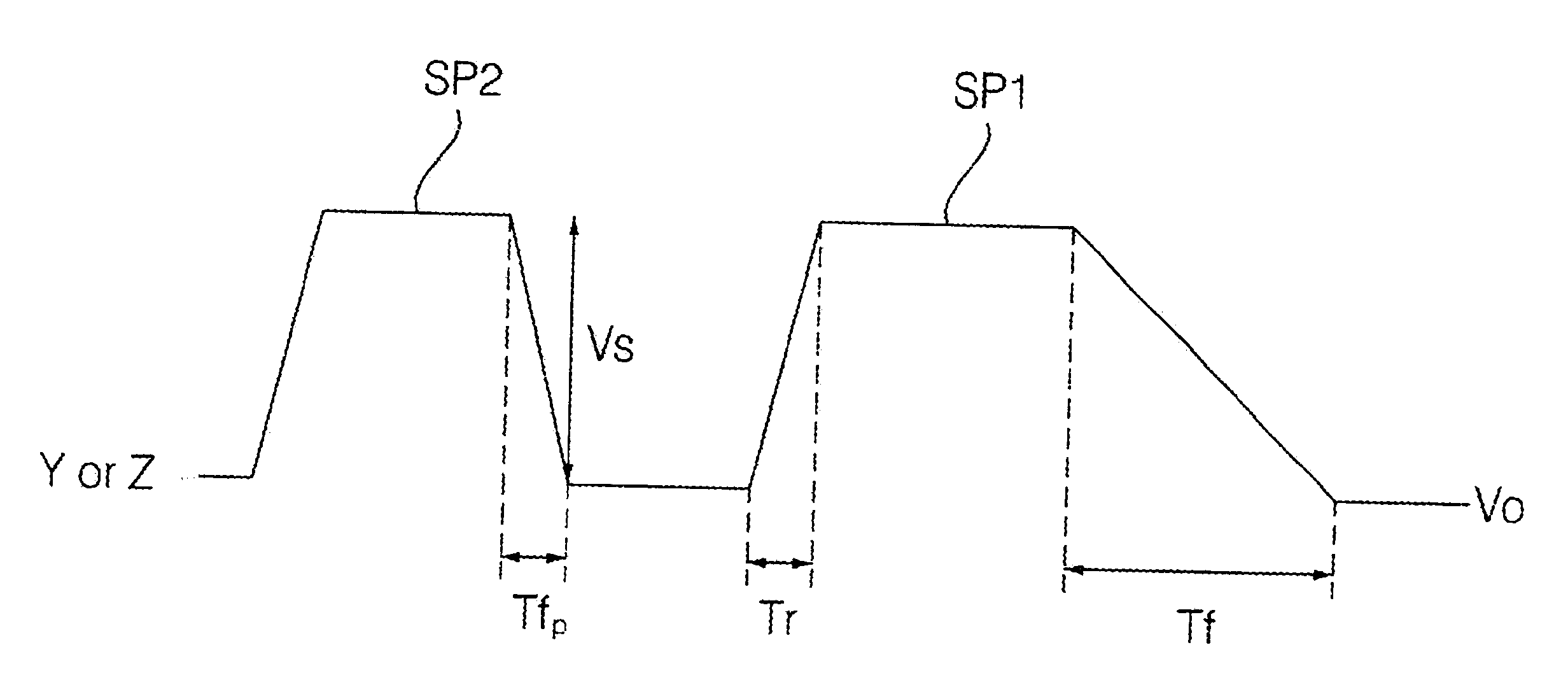

Plasma display apparatus

InactiveUS20070152918A1Prevent erroneous dischargeExtended fall timeStatic indicating devicesMixing operation control apparatusOptoelectronicsPlasma display

Provided a plasma display apparatus. The apparatus includes a first electrode and a driver. The first electrode is formed at an upper substrate. The driver applies a sustain pulse to the first electrode. The driver applies a driving waveform whose, in one subfield, any one sustain pulse (SP1) has a longer falling time than another sustain pulse (SP2) applied earlier than the sustain pulse (SP1).

Owner:LG ELECTRONICS INC

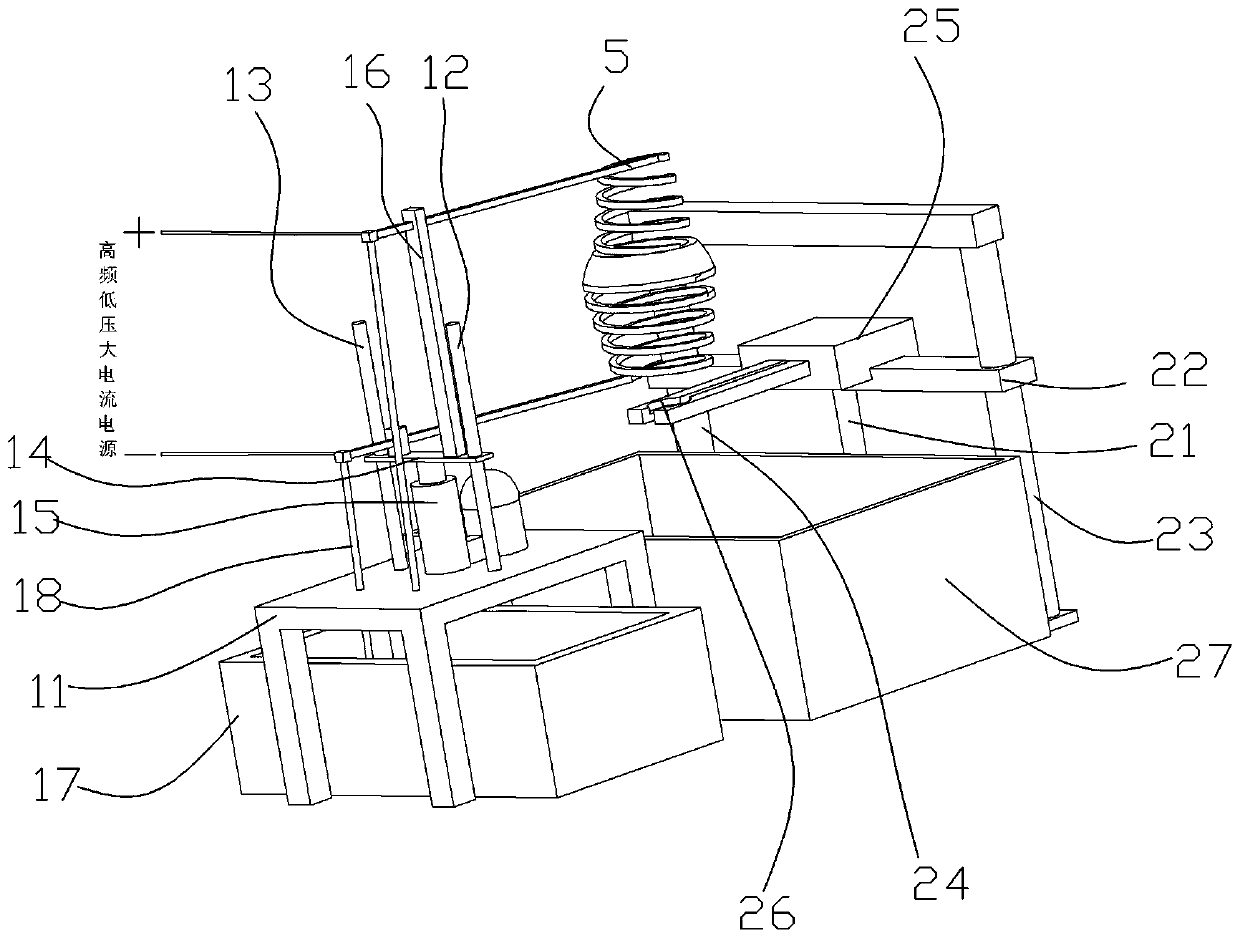

Shaft processing method

ActiveCN111575448AEvenly heatedGood for simultaneous coolingIncreasing energy efficiencyFurnace typesEngineeringWater circulation

The invention relates to a shaft processing method, which comprises the following specific steps of: inserting the lower end of a thin-diameter segment of a shaft into a cylindrical groove, and starting a finger air cylinder to clamp and fix the shaft; driving a second electric pushing rod to enable the lower end surfaces of the clamping fingers of the finger air cylinder and a quenching water tank to keep a distance of 10-30 cm; starting a first electric pushing rod to enable a top plate to downwards move to drive an induction coil to downwards move, inserting the shaft into the induction coil to enable the lower end surface of the induction coil and the upper end surface of the clamping fingers of the finger air cylinder to keep a distance of 0.5-4 cm; injecting cooling water into the circulation hole of the induction coil to circularly cool the induction coil, starting a high-frequency low-voltage big-current power supply to provide high-frequency low-voltage big current for the induction coil, carrying out induction heating on the shaft, and controlling time to be 2-5 minutes; and after the shaft is finished being heated, starting the finger air cylinder to open the clamping fingers, and enabling the shaft to fall into the quenching water tank from a gap between two clamping fingers. According to the shaft processing method, the problem in a shaft thermal treatment processthat a junction between a circumferential side surface of a thick-diameter segment and a transition platform is molten so as to change the processing shape and size of the shaft is solved.

Owner:广西汇恒机械制造有限公司

Plastic masterbatch dust removal, cleaning and drying integrated device

InactiveCN111589792AExtended fall timeEasy to cleanDrying gas arrangementsCleaning using gasesMasterbatchWater filter

The invention discloses a plastic masterbatch dust removal, cleaning and drying integrated device. The device comprises a base frame, the lower end face of the base frame is provided with a drying conveying device, an outer cylinder and a box body are mounted on the upper end face of the base frame, a spiral groove is spirally formed in the inner wall of the outer cylinder, a blowing device is mounted in the spiral groove, a filter cylinder is mounted on the outer side of the spiral groove, an inner cylinder with a water filter cylinder is mounted in the outer cylinder, a feeding groove is formed in the outer cylinder, the filter cylinder communicates with the water filter cylinder through a feeding pipe, a first rotating shaft with a first packing auger is mounted in the water filter cylinder, the first rotating shaft is provided with a spray opening, the upper end of the box body is provided with a connecting base communicating with the first rotating shaft, the two sides of the inner cylinder are provided with leaking pipes communicating with the drying conveying device, the spiral filter cylinder, the inner cylinder, the water filter cylinder and the drying conveying device aremounted, plastic masterbatch can be subjected to dust removal, cleaning and drying integrated operation, efficiency is improved, and the pollution to the plastic masterbatch in the equipment conversion process can be reduced.

Owner:HEFEI DEJIE ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

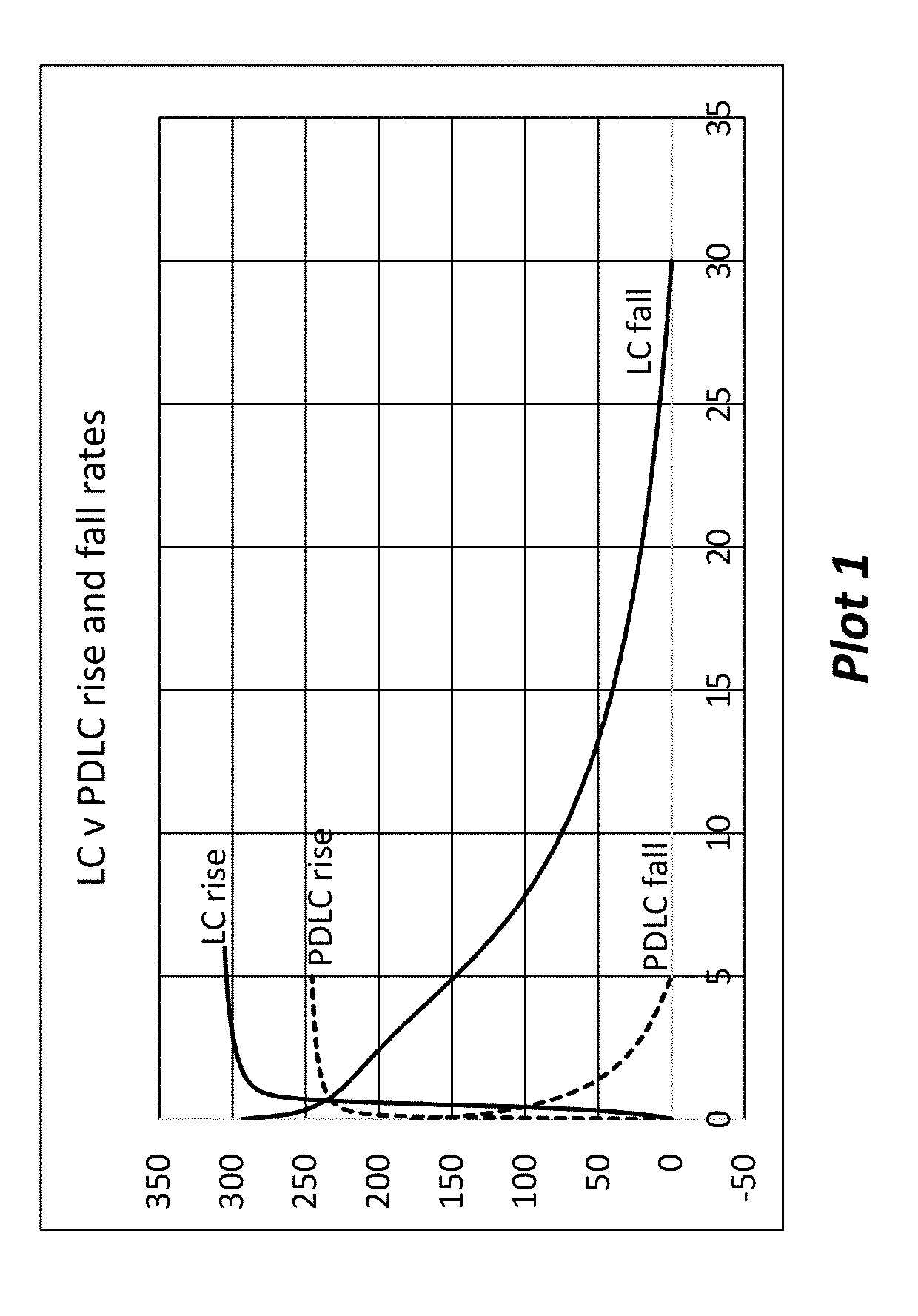

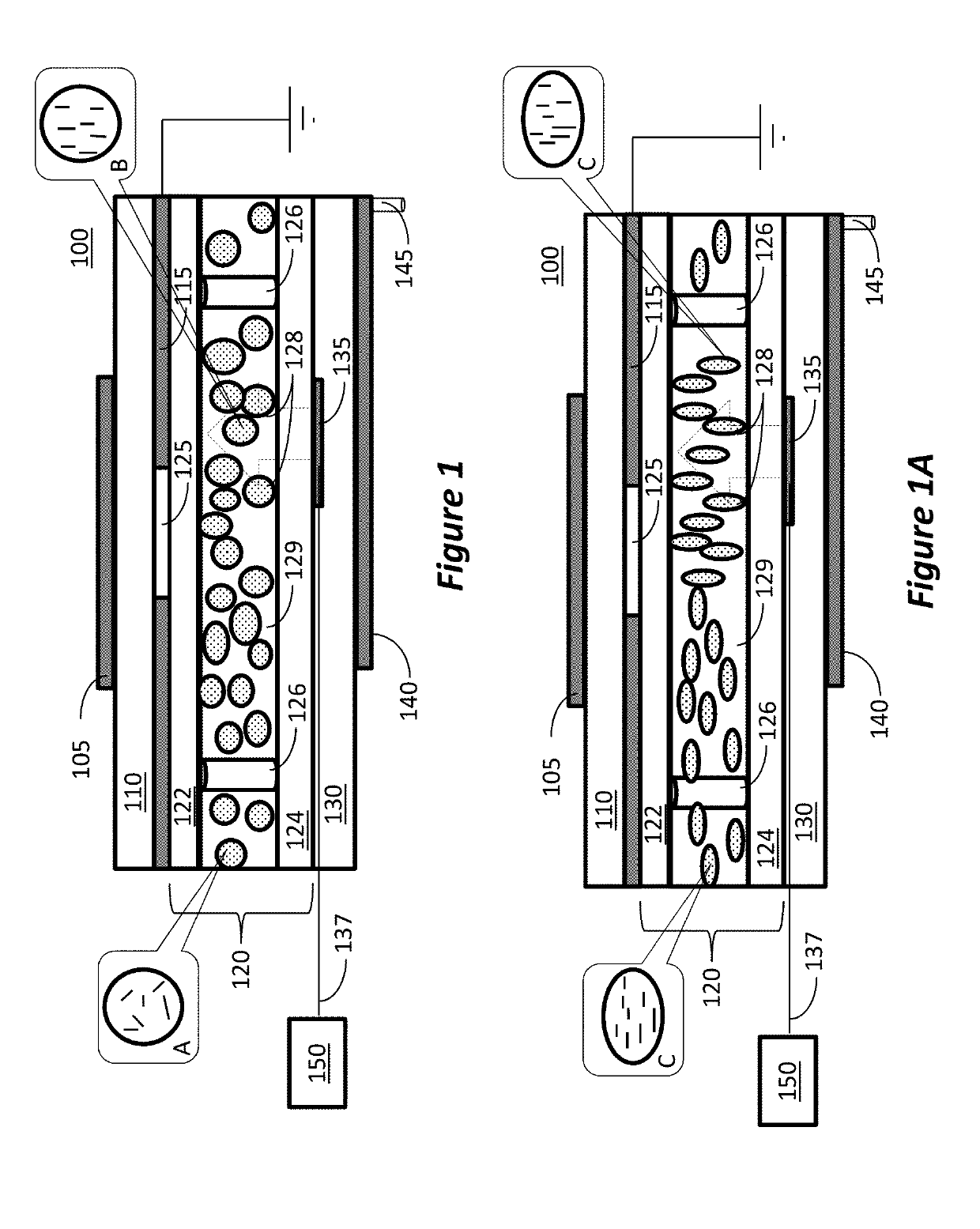

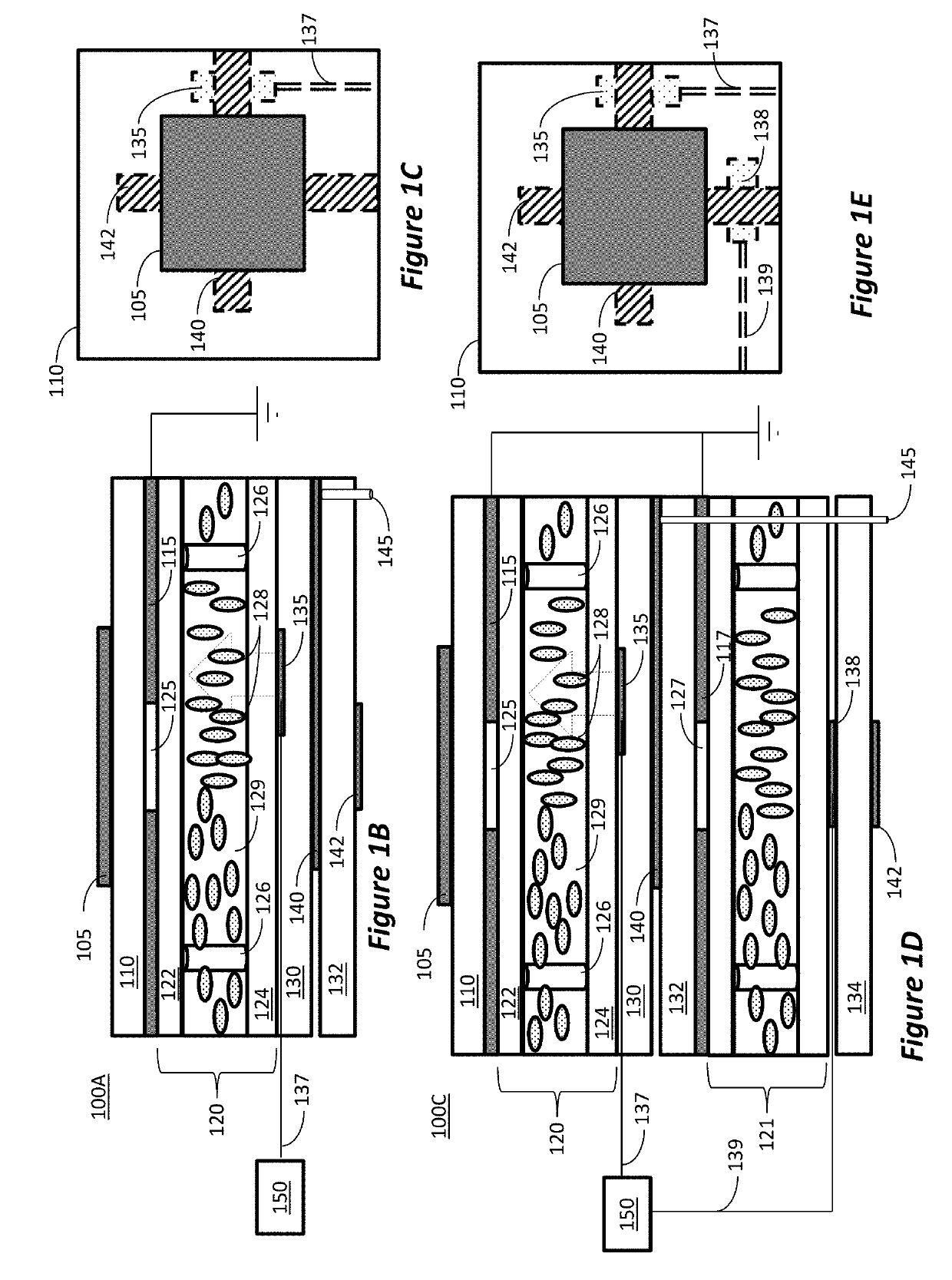

Polymer dispersed/shear aligned phase modulator device

ActiveUS20190123454A1Fall time muchRise time muchRadiating elements structural formsIndividually energised antenna arraysControl lineGround plane

An antenna comprising: a variable dielectric constant (VDC) layer; a plurality of radiating patches provided over the VDC layer; a plurality of signal lines, each terminating in alignment below one of the radiating patches; a plurality of control lines, each corresponding to one of the signal lines; a ground plane; wherein the VDC layer comprises: a polymer dispersed liquid crystal (PDLC) layer or a PDLC layer in a polymerized and sheared state.

Owner:WAFER LLC +1

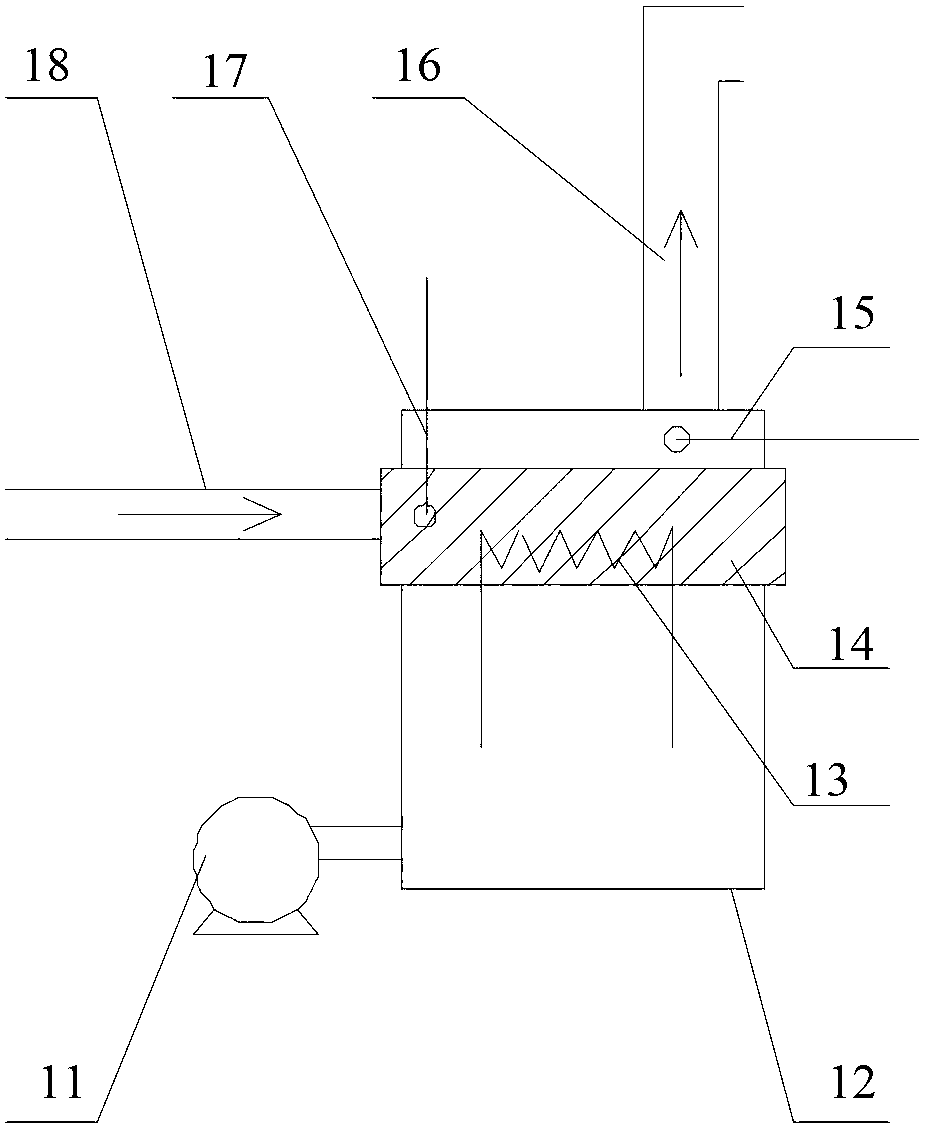

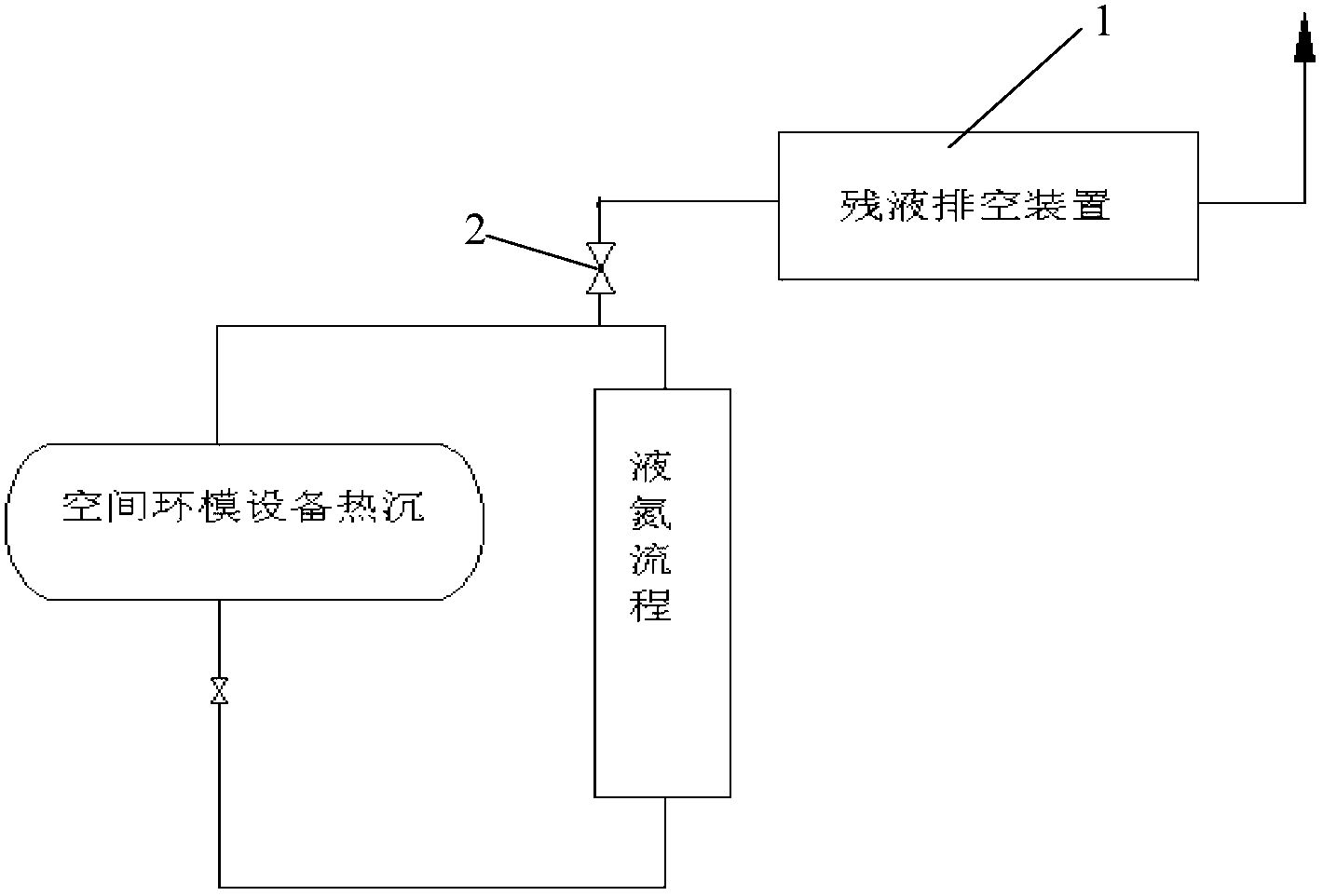

Residual liquid emptier

ActiveCN103016951ASolve the problem of direct discharge to the outsideGuaranteed full gasificationContainer discharging methodsContainer filling under pressureProcess engineeringAir blower

The invention provides a residual liquid emptier. The residual liquid emptier comprises an air blower, a residual liquid vaporizing chamber, a heater, a residual liquid collector, an outlet temperature measuring device, an emptying tube, an inlet temperature measuring device and a residual liquid inlet tube, wherein the residual liquid collector is arranged on the upper part of the residual liquid vaporizing chamber; the air blower is connected to the bottom of the residual liquid vaporizing chamber; the heater is arranged in the residual liquid vaporizing chamber and is connected with the residual liquid collector; the residual liquid inlet tube is connected with the residual liquid collector; the emptying tube is connected with the residual liquid vaporizing chamber; the inlet temperature measuring device is arranged at the connected part of the residual liquid inlet tube and the residual liquid collector; and the outlet temperature measuring device is arranged at the connected part of the emptying tube and the residual liquid vaporizing chamber. The residual liquid emptier can be used for vaporizing liquid nitrogen within a short time for effectively avoiding influence on environmental and personal injury or device damage caused by direct emission of the liquid nitrogen, and has the beneficial effects of high vaporizing efficiency, energy conservation and an extensive applicable range.

Owner:SHANGHAI YUDA IND

Tobacco leaf uniform mixing structure

ActiveCN111671124AEfficient mixingEffective control of mixingTobacco preparationMechanical engineeringHorticulture

The invention relates to the technical field of tobaccos, in particular to a tobacco leaf uniform mixing structure. According to the structure, the ascending height of a second baffle can be freely adjusted, the falling amount of the tobaccos in a placing barrel can be effectively controlled, during the vibration process, the tobaccos can effectively and quickly fall into a funnel, at the moment,the funnel is rotated, the tobacco falling into the inner side of the funnel falls along with an arc-shaped track, so that various tobaccos are preliminarily and effectively mixed, the inner side of the funnel is fixedly connected with a plurality of fixing rods, so that the falling time of the tobaccos can be effectively prolonged, the tobaccos stacked together are scattered in the falling process, so that the stirring effect is effectively achieved, under the arrangement of a conical cover body, the amount of tobacco falling between the conical cover body and the inner side wall of the funnel can be effectively controlled, the mixing degree of the tobacco can be further improved, the tobacco falling to the bottom end of the funnel is repeatedly turned over to be mixed through the arrangement of a reel, and then secondary mixing is conducted.

Owner:GANSU TOBACCO IND

Full-automatic device for quickly drying desulfurized gypsum

The invention discloses a full-automatic device for quickly drying desulfurized gypsum. The device comprises a vertical dynamic drying furnace, an electric hot air furnace, an electric dust collector, an induced draft fan and a thermocouple, wherein the vertical dynamic drying furnace is used for evaporating natural moisture and crystallized moisture under the forced action of hot air circulation in the furnace in the natural gravity falling process of desulfurized gypsum powder; the electric hot air furnace is applied to a hot air source generating device; the electric dust collector is used for separating dried desulfurized gypsum powder from air current; the induced draft fan is used for guiding high-temperature air current to pass through the surface of the desulfurized gypsum powder to accelerate the heat exchange and increase the production efficiency; and the thermocouple is used for controlling the hot air temperature of the electric hot air furnace. A screen mesh arranged on a rotating vertical shaft of the vertical dynamic drying furnace has the functions of scattering material agglomerates and prolonging the falling time of the powder in a dynamic rotating state. Coal combustion is not taken as a heat source in the entire production process, so that the air pollution is avoided to the maximum extent and clean production is realized.

Owner:员苏让

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com