Self-synchronizing vertical screening dewatering screen

A screening and dehydration, self-synchronizing technology, applied in sieve, filtration separation, solid separation, etc., can solve the problems of unfavorable dehydration of fine materials, low production efficiency, and easy clogging of screens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

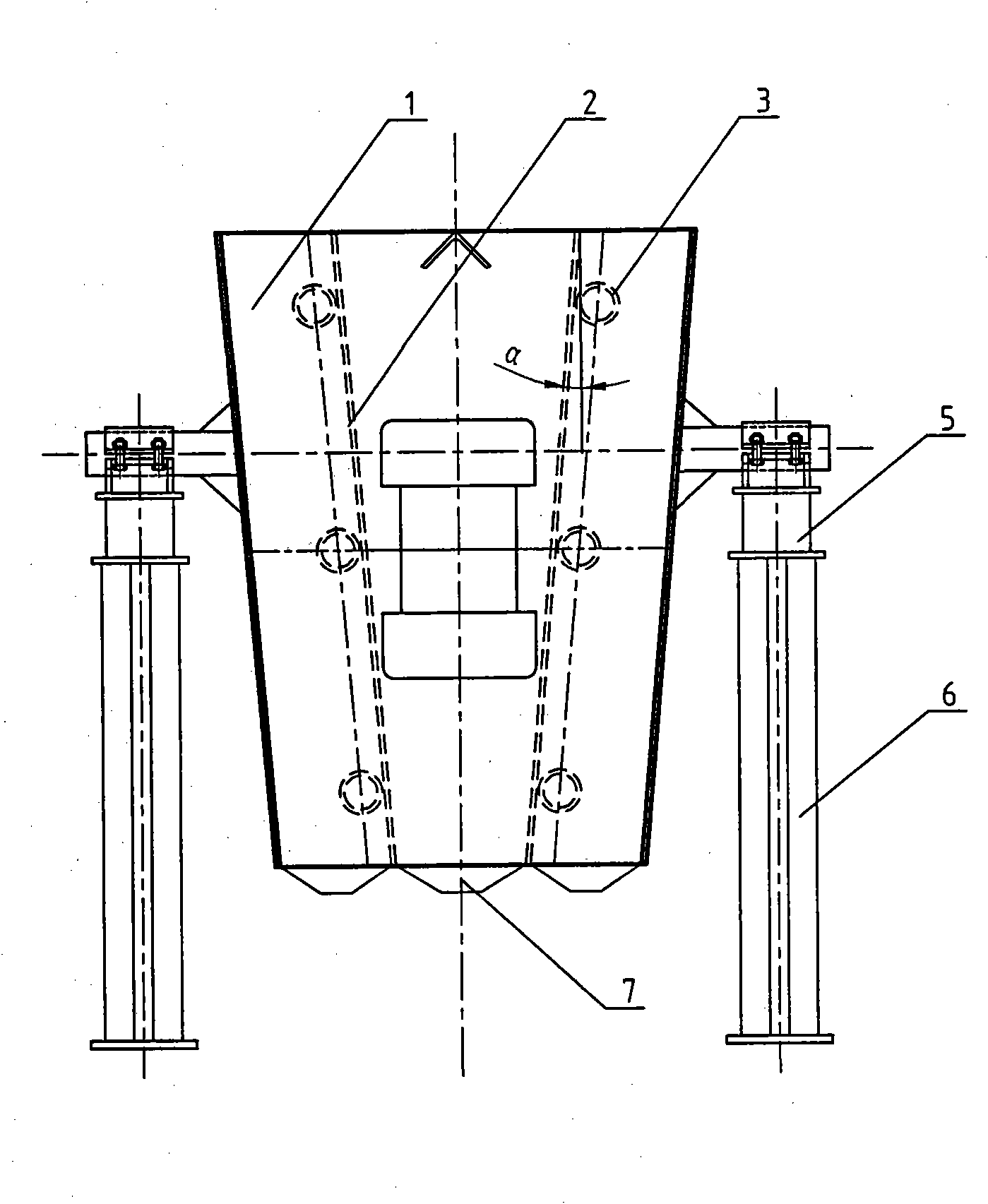

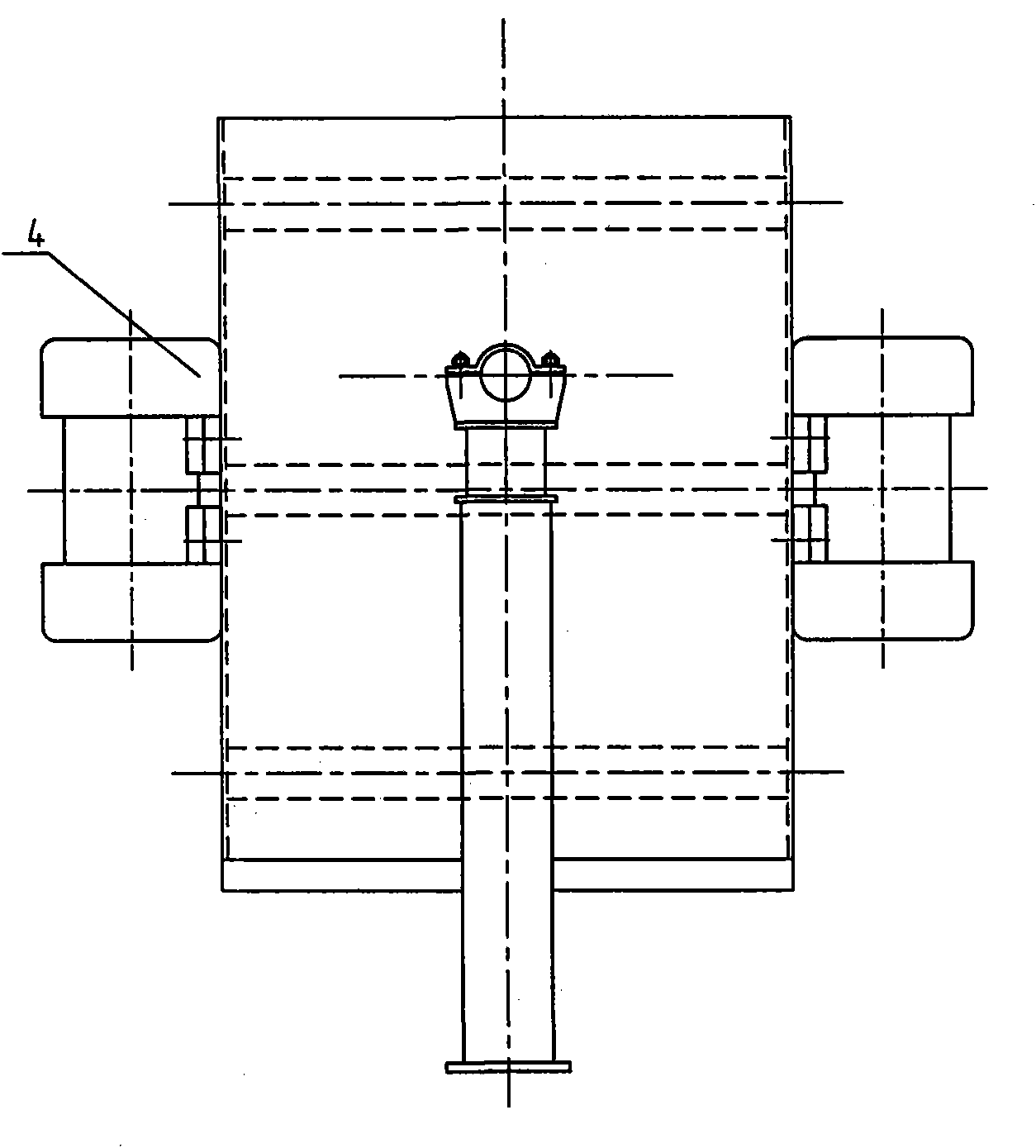

[0013] As shown in the figure: a self-synchronous vertical screening dewatering screen, which includes a screen box 1, a screen 2 inside the screen box, a vibration motor 4, a shock-absorbing spring 5 and a bracket 6 outside the screen box, the screen The box is supported by several connecting pipe beams 3, and a screen 2 is fixed inside the screen box, which is placed at an angle α between the screen and the vertical line. There are vibration motors 4 on both sides of the screen box, and a discharge chute 7 at the bottom of the screen box. Case is fixed on the support 6 by shock-absorbing spring 5, and support is fixed on the ground.

[0014] The angle α between the screen 2 and the vertical line is 0-15°.

[0015] The screens 2 in the screen box are arranged in pairs.

[0016] There are vibration motors 4 on both sides of the screen box, and the screen box 1 vibrates left and right under the drive of the vibration motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com