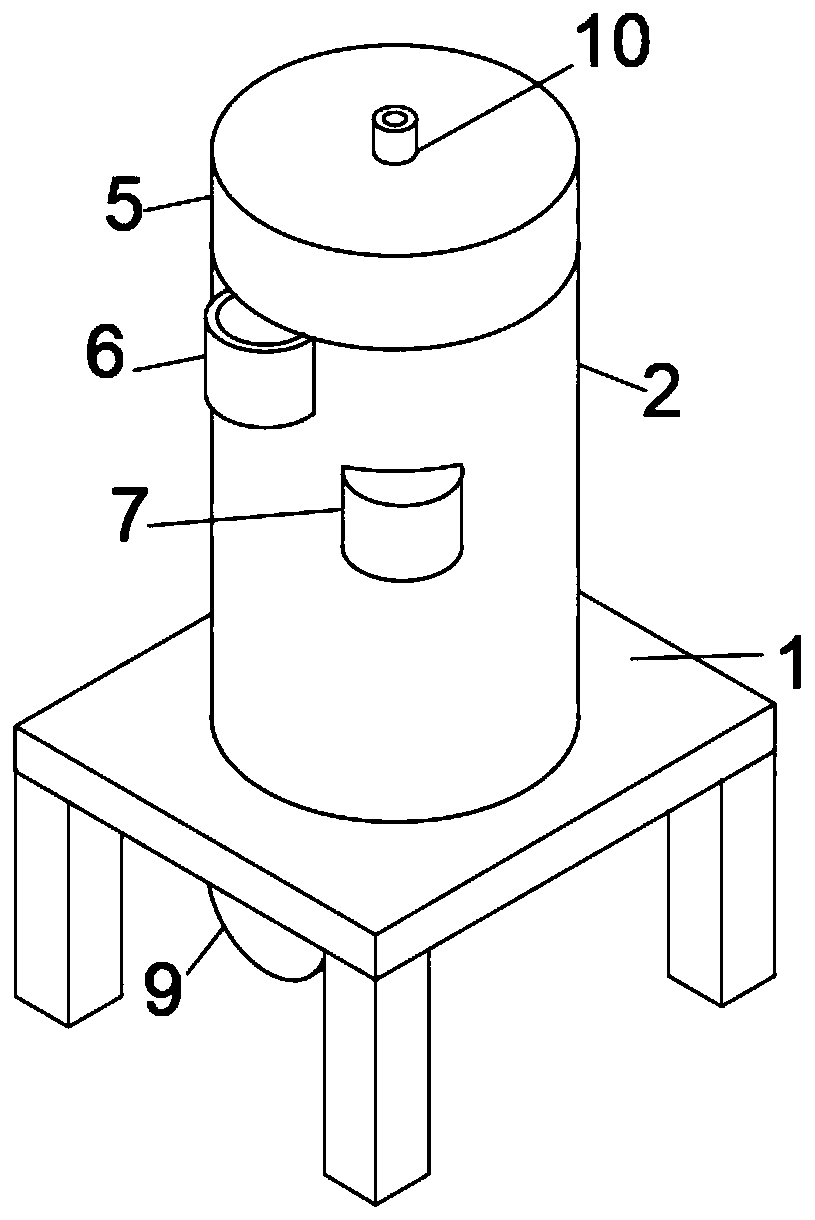

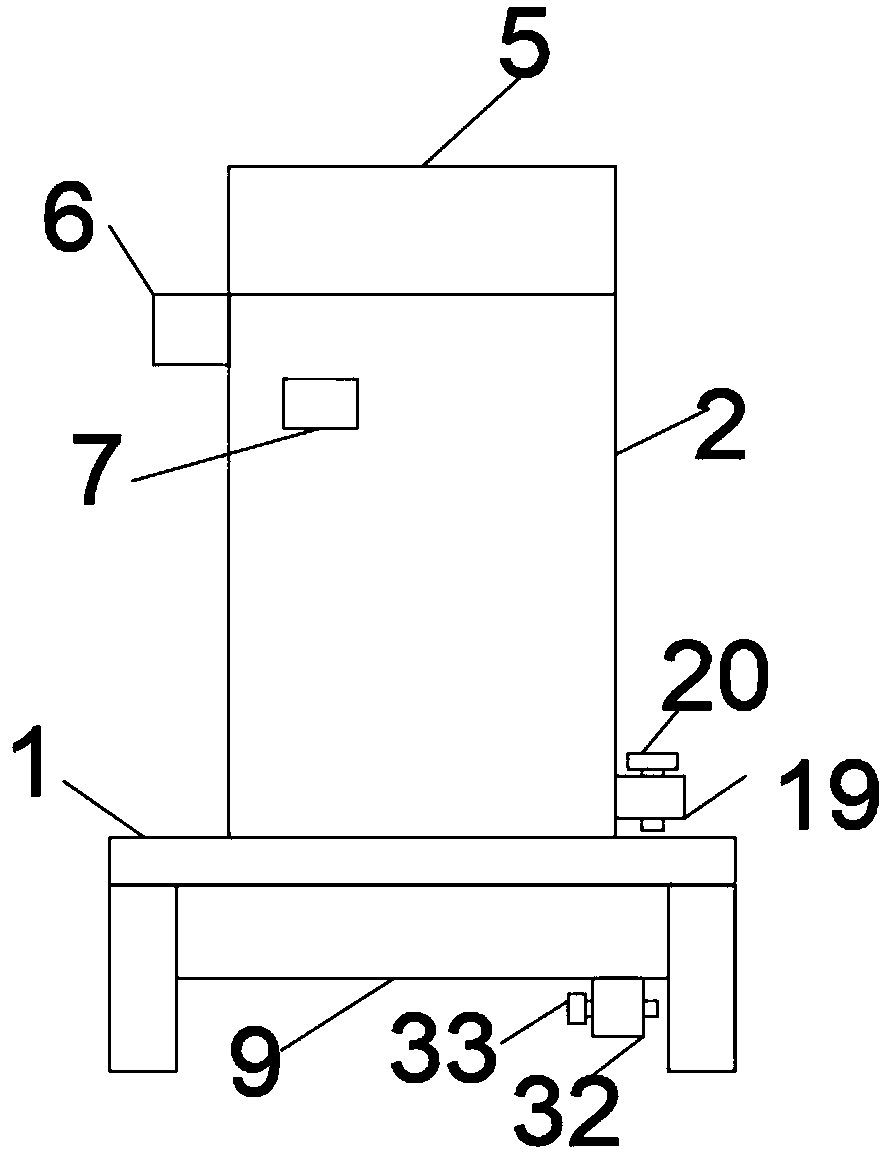

Plastic masterbatch dust removal, cleaning and drying integrated device

A plastic masterbatch and integrated technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of plastic masterbatch re-pollution, high slag content of masterbatch, low efficiency, etc., and reduce the conversion time , reduce pollution and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

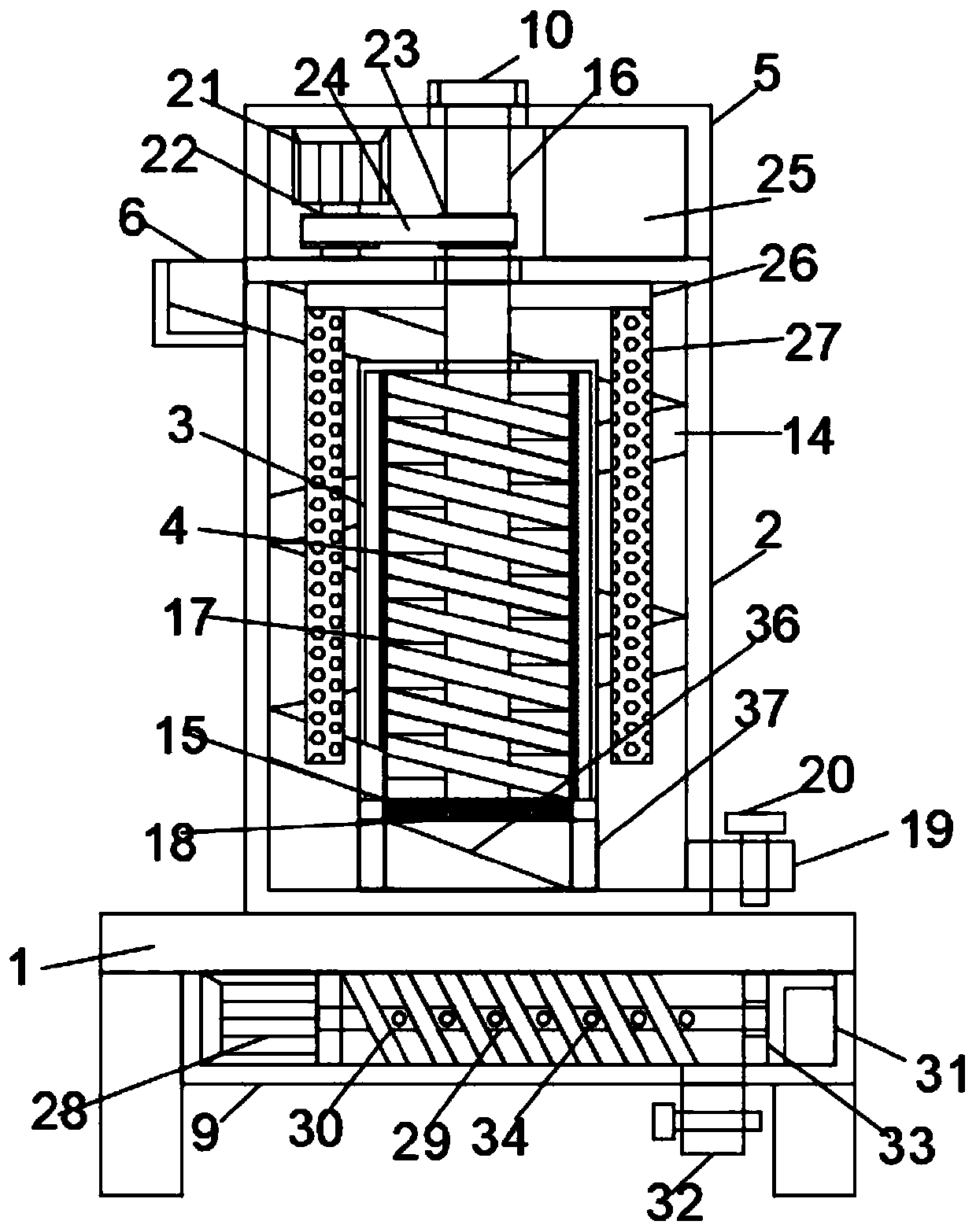

[0039] Embodiment: Pour the plastic masterbatch from the feeding trough 6, the plastic masterbatch enters from the head end of the filter cartridge 14, and slides downward in a spiral manner, and the blower is opened so that the blower device can carry out the plastic masterbatch in the filter cartridge 14. Blow air until the plastic masterbatch enters the water filter cylinder 4 from the feed pipe 15. Driven by the first transmission device, the first auger 17 moves the plastic masterbatch upwards. At this time, the connecting seat 10 and the external input The water device is connected, and water is poured into the first rotating shaft 16, and the water flows out from the nozzle 35 on the first rotating shaft 16 to clean the plastic masterbatch spirally lifted by the first auger, and the sewage enters the inner cylinder 3 from the water filter cylinder 4 between, and leak from the filter plate 18, discharge the inner cylinder 4 through the water outlet 37, and then discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com