Full-automatic device for quickly drying desulfurized gypsum

A technology of drying device and desulfurization gypsum, applied in the field of desulfurization gypsum rapid drying device, can solve the problems of product quality decline, enterprise profit decline, whiteness decline, etc., and achieves the advantages of reducing energy consumption, prolonging falling time, and ensuring product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

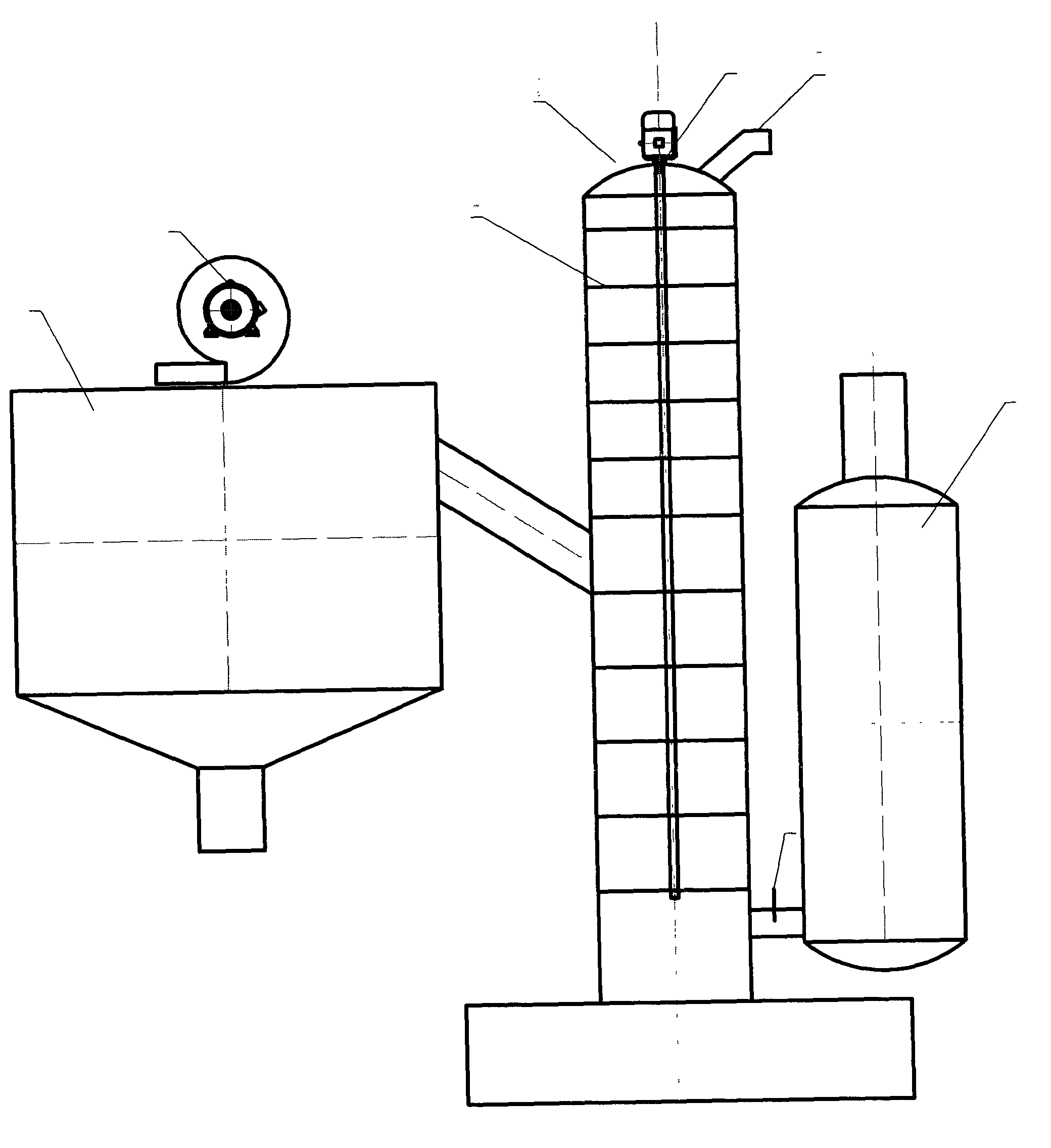

[0018] As shown in the drawings, the present invention includes: an electric hot blast furnace 1, a vertical dynamic drying furnace 2, a rotating vertical shaft 3 and a screen 4 installed thereon, a desulfurization gypsum feed port 7 and a hot blast temperature control thermocouple 8, Induced fan 6 and electrostatic precipitator 5.

[0019] The specific settings of each part can be used in the following ways:

[0020] As shown in the figure, when the desulfurized gypsum enters the vertical dynamic drying furnace 2 through the desulfurized gypsum feed port 7, the material is sprinkled on the continuously rotating screen 4; through the continuous rotation of the rotating vertical shaft 3, the material passes through layers The sieve falls due to gravity; when it falls to the next layer of sieve, it is blocked by the rotating potential energy to eliminate the acceleration of the material; at the same time, the high temperature generated by the electric heating stove 1 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com