Spray cooling and granulating technique for geoceric acid or hydrogenatedoil

A technology of spray cooling and hardening oil, which is applied in the direction of liquid separation into beads and granulation, which can solve the problems of long stacking time and easy agglomeration of sliced products, and achieve the effects of reduced transportation costs, high stacking density, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

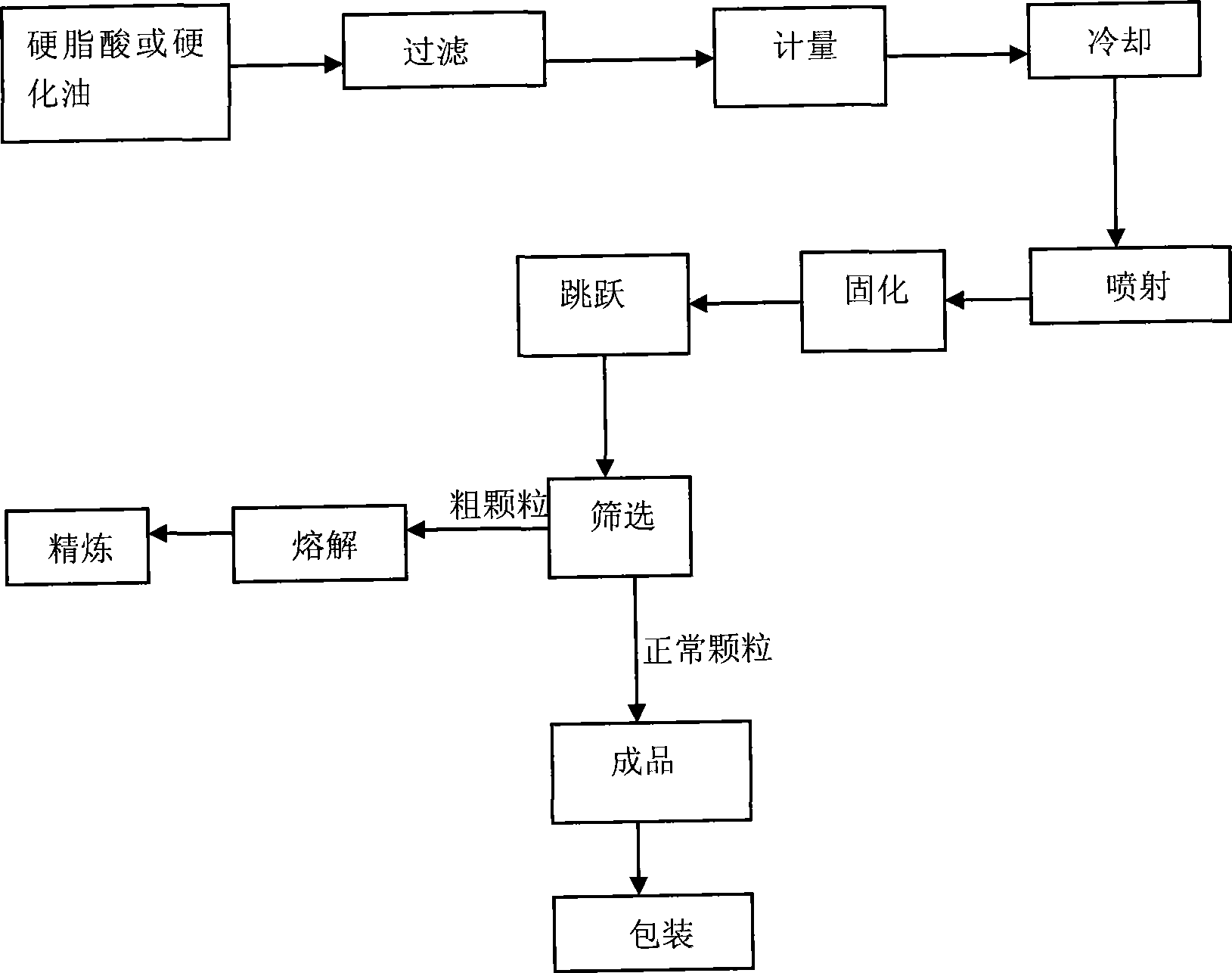

[0023] Select 6 tons of stearic acid or hardened oil with a freezing point higher than 50°C. As shown in the figure, the selected stearic acid or hardened oil material is pumped from the storage tank through a bag filter by a supply pump with a steam jacket Filter, remove impurities, and then enter the mass flow meter to measure the flow of the material pump, then send it to the fatty acid cooler to cool the material, and finally the material reaches the material nozzle placed at the top of the tower 4-6 meters. There are several shower heads, such as a shower head for showers. There are hundreds of identical small drilling holes on the shower head. The holes on the several shower heads total 3000-5000, and the size of the holes is 0.2-0.5mm. Stearic acid or hard The pressure of grease ejected from the nozzle is about 0.08MPa. In this way, the liquid droplets are sprinkled from the nozzle to the tower body from the top of the tower, and the inside of the spray tower is drawn by...

specific Embodiment 2

[0025] Select 12 tons of stearic acid or hardened oil whose freezing point is higher than 50°C. As shown in the figure, the selected stearic acid or hardened oil material is pumped from the storage tank through a bag filter by a supply pump with a steam jacket Filter, remove impurities, and then enter the mass flow meter to measure the flow of the material pump, then send it to the fatty acid cooler to cool the material, and finally the material reaches the material nozzle placed at the top of the tower 6-8 meters. There are several nozzles, such as shower heads for showers. There are hundreds of identical small drilled holes on the nozzles. There are 6000-10000 holes in the nozzles, and the size of the holes is 0.2-0.5mm. Stearic acid or hard The pressure of the grease sprayed by the nozzle is about 0.06MPa. In this way, the liquid droplets are sprinkled from the nozzle to the tower body from the top of the tower, and the inside of the spray tower is drawn by the induced draft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com