Casting cooling device

A cooling device and casting technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of low air-cooled cooling efficiency, high scrap rate, poor quality of pure water-cooled cooling, etc., and achieve uniform cooling and improved cooling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

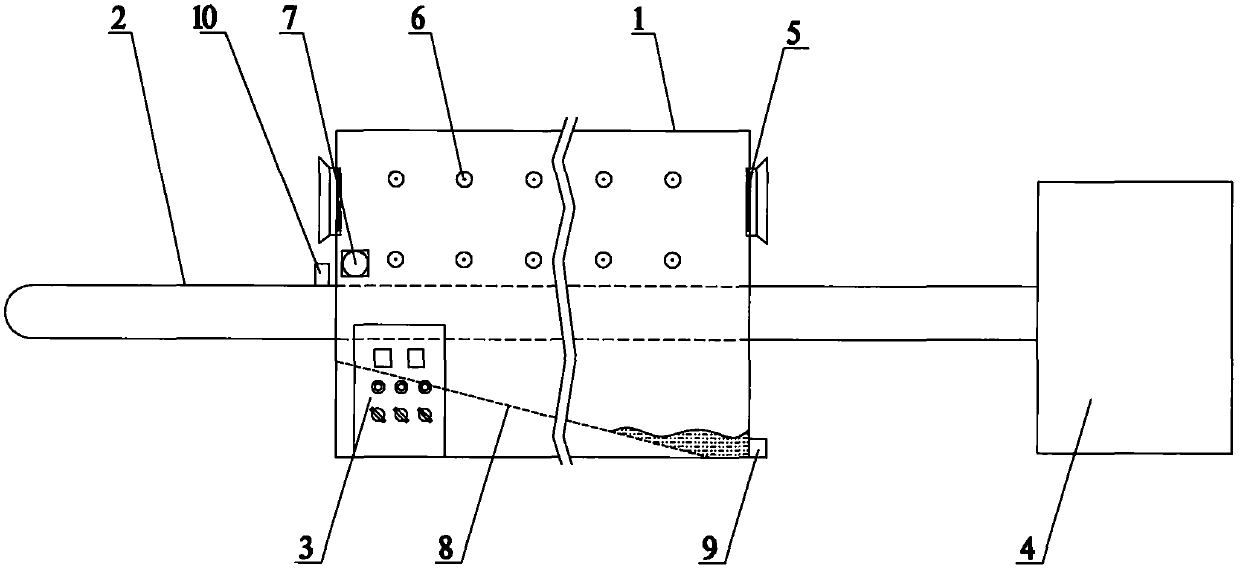

[0014] The cooling device for castings of the present invention includes a cooling box 1, a conveyor belt 2 and a control box 3, the cooling box 1 is a sealed box structure, and the conveyor belt 2 passes through the cooling box 1 along the length direction of the cooling box 1 One end of the conveyor belt 2 is connected to the annealing furnace 4, the control box 3 is arranged at one end of the bottom of the cooling box 1, the conveyor belt 2 is a steel mesh conveyor belt, and the two ends of the cooling box 1 are respectively provided with convection fans 5, and The rotation directions of the two convection fans 5 are consistent, so that the airflow in the cooling box 1 runs against the moving direction of the conveyor belt 2; the inner walls of both sides above the conveyor belt 2 in the cooling box 1 are provided with atomizing nozzles 6 in a straight line, A temperature sensor 7 is arranged on the side wall next to the atomizing nozzle 6 at the outlet end of the cooling bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com