Patents

Literature

38results about How to "Enables continuous synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

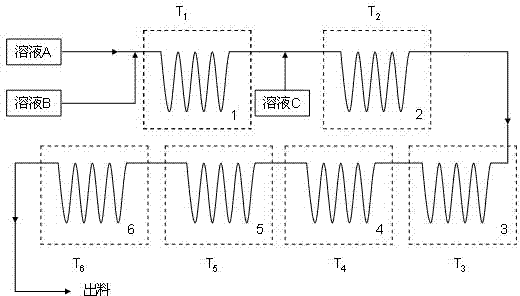

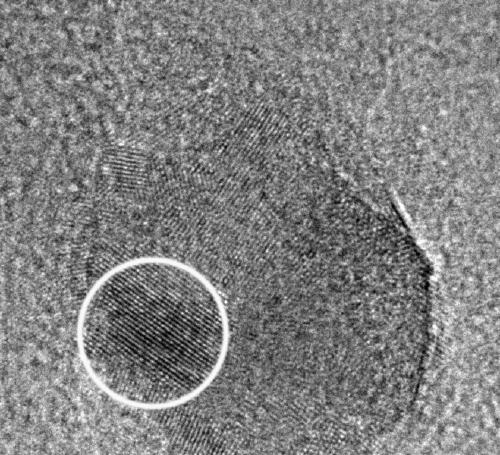

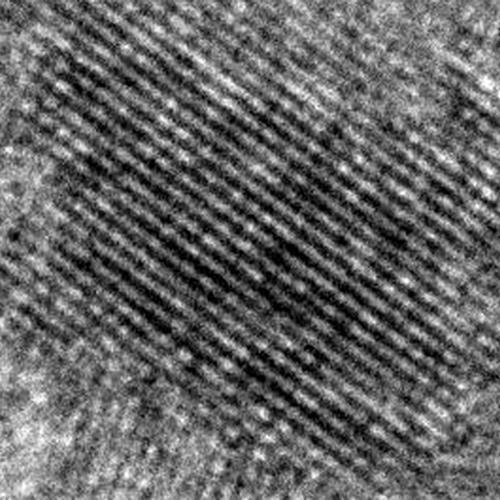

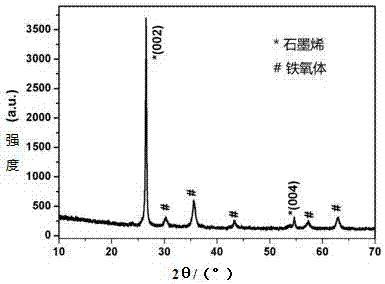

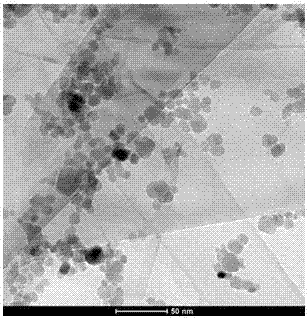

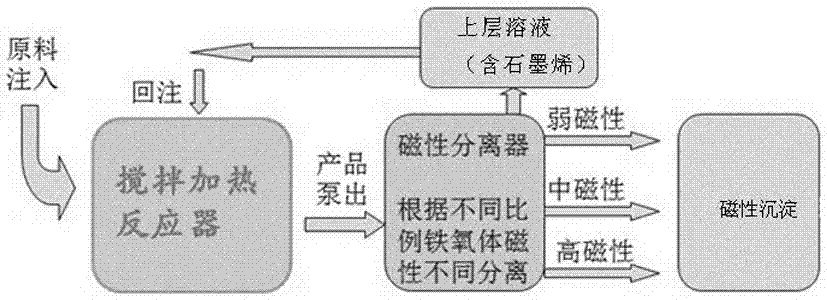

Continuous synthesis method of graphene/ferrite nanocomposite

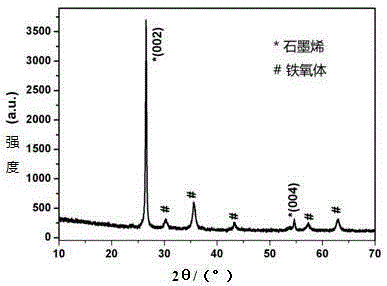

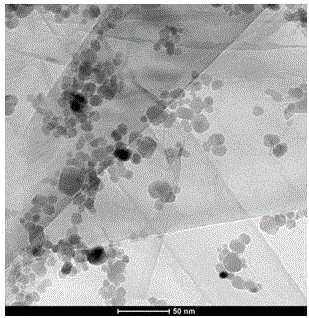

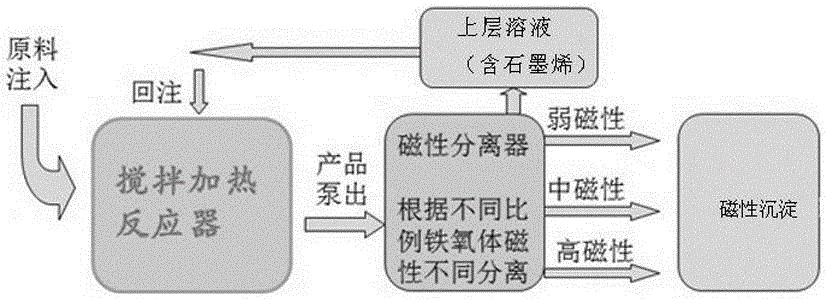

InactiveCN105199667AImprove absorbing performanceGood dispersionOther chemical processesNickel saltHigh volume manufacturing

The invention discloses a continuous synthesis method of a graphene / ferrite nanocomposite. According to the synthesis method, the graphene / ferrite nanocomposite is prepared by taking graphene, sodium hydroxide aqueous solution and ferric salt solution or ferric salt solution doped with nickel salt and zinc salt and adopting a reverse co-precipitation method. By adopting the synthesis method, continuous synthesis of the nanocomposite is realized by continuous material injection and continuous magnetic separation and output of products, obtained ferrite and graphene are mixed evenly and are combined firmly, and an excellent absorbing property is achieved. Therefore the synthesis method has the advantages of continuous synthesis capability, low synthesis temperature, low energy consumption, low cost and quantity production capability, and has better application prospect.

Owner:李同乐 +2

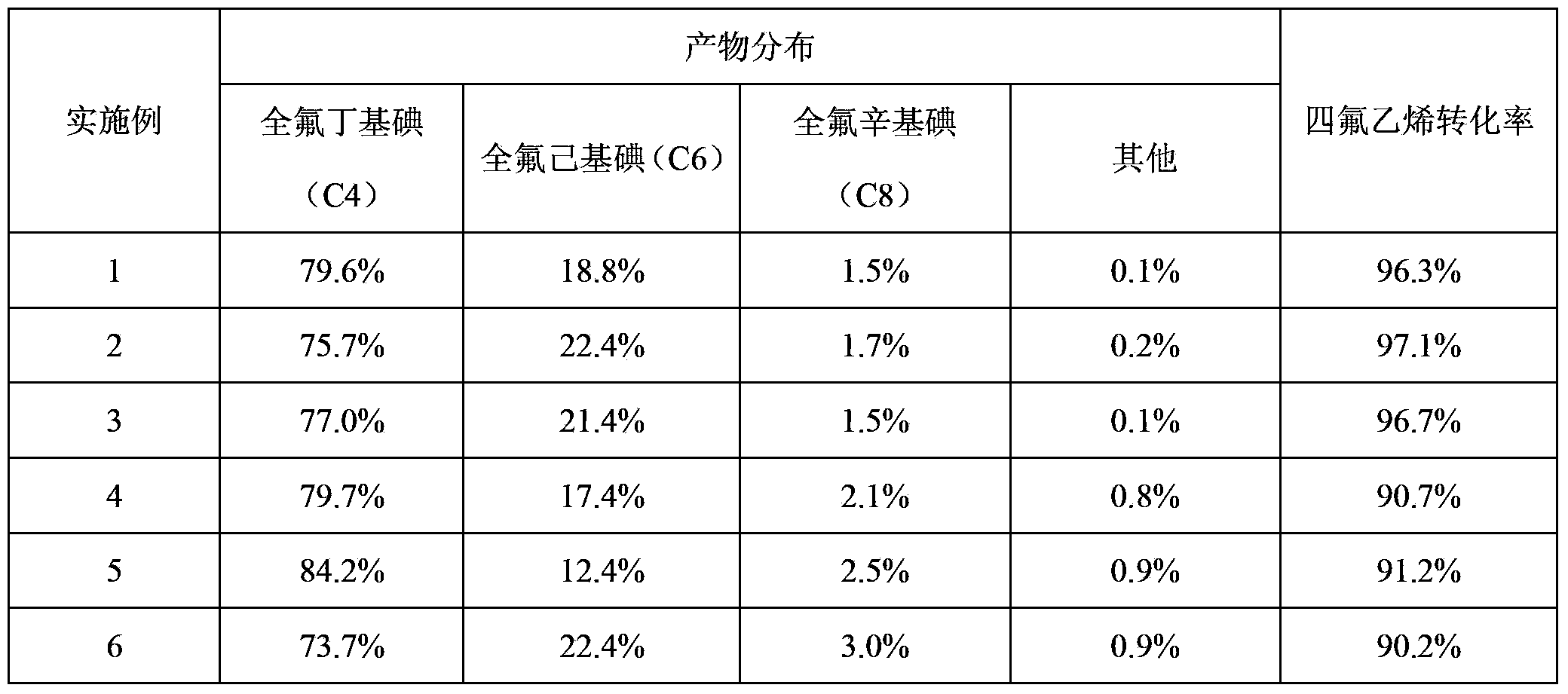

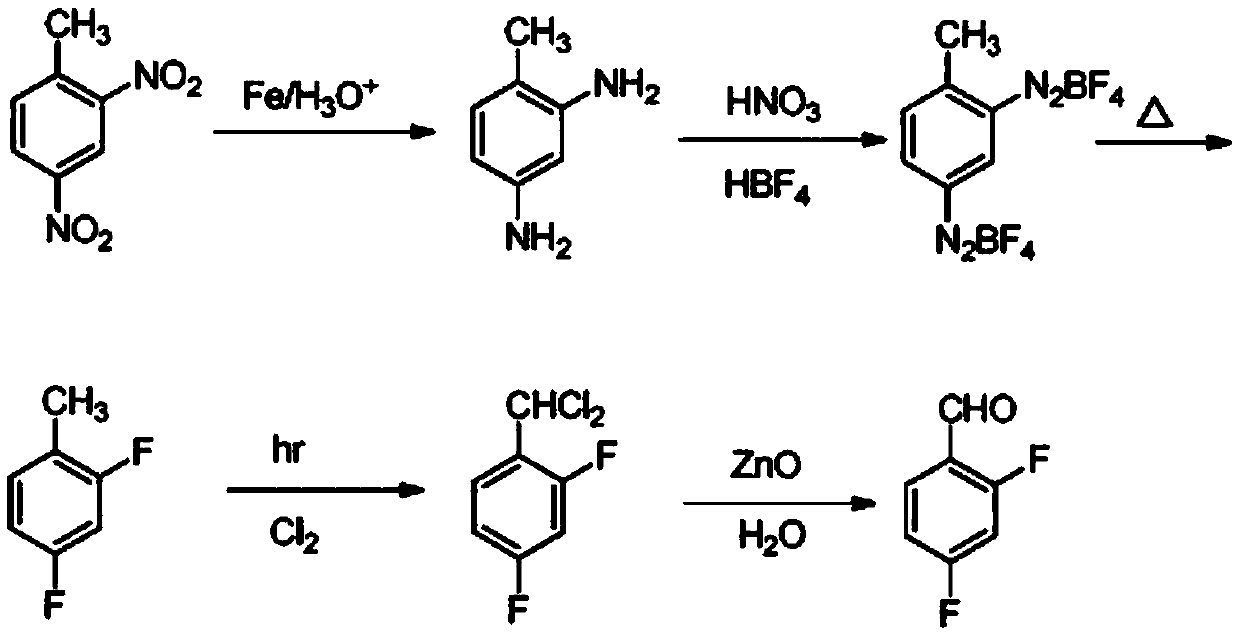

Continuous synthesis method of low-carbon-chain perfluoroalkyl iodide

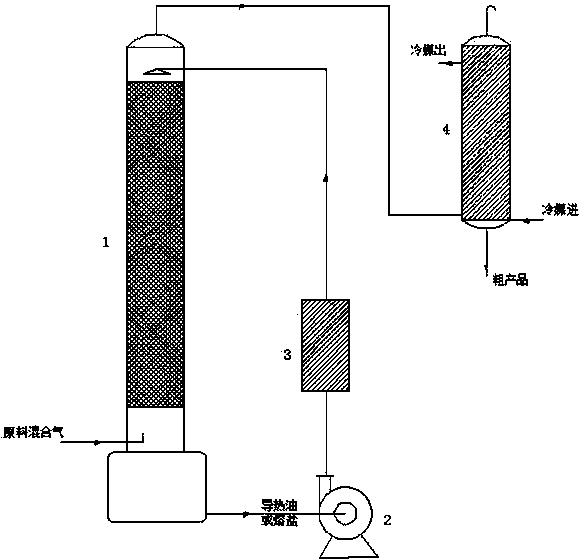

ActiveCN103524294AEnables continuous synthesisSimple processChemical recyclingHalogenated hydrocarbon preparationTetrafluoroethyleneSynthesis methods

The invention discloses a continuous synthesis method of low-carbon-chain perfluoroalkyl iodide, which comprises the following steps: (a) adding a heating medium and a catalyst in a mass ratio of 1:(0.005-0.1) into a filler tower; (b) leading the heating agent-catalyst mixture out of the bottom of the filler tower, heating by a heater through a circulating pump, returning to a circulating liquid inlet of the filler tower so that the heating agent containing the catalyst circularly flows from top to bottom in the filler tower, and meanwhile, continuously introducing pentafluoroethyliodide and tetrafluoroethylene in a volume ratio of (5-20):1 into the filler tower through the bottom to react at 200-370 DEG C; and (c) continuously leading the reaction product out of the top of the filler tower, and cooling by a condenser to obtain the low-carbon-chain perfluoroalkyl iodide. The method has the advantages of simple technique, high efficiency and favorable product composition distribution, and is safe and controllable; and the catalyst does not need to be separated and can be recycled.

Owner:JUHUA GROUP TECH CENT

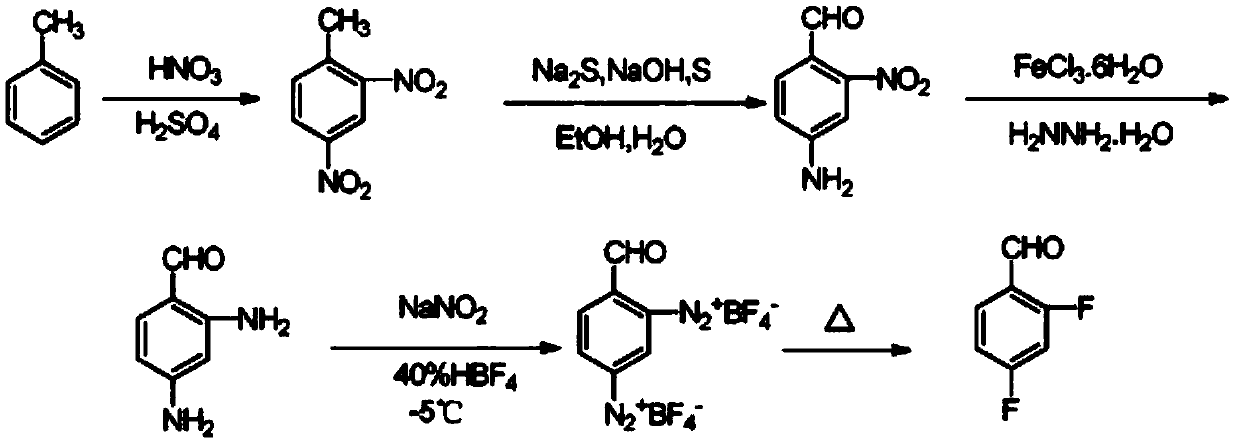

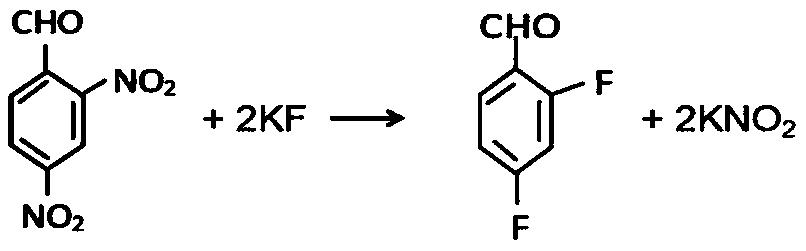

Method for synthesizing 2,4-difluorobenzaldehyde by using micro-channel reactor

InactiveCN111517931AContinuous responseImprove the mixing effectOrganic compound preparationChemical/physical/physico-chemical microreactorsPotassium fluorideProcess engineering

The invention discloses a method for synthesizing 2,4-dichlorophenol by using a micro-channel reactor. The method mainly comprises the following steps: with 2,4-dinitrobenzaldehyde and potassium fluoride as raw materials, carrying out a reaction in micro-channel reactor for 50-55 s at a temperature of 200-210 DEG C, and finally rectifying and purifying a product to obtain a refined 2,4-difluorobenzaldehyde product with a purity of more than or equal to 99%. According to the preparation method disclosed by the invention, micro-channel continuous synthesis of 2,4-difluorobenzaldehyde is realized, production cost is reduced by 10-15% compared with the production cost of a traditional intermittent tank method, yield can be increased by 1-2%, and production efficiency and yield are increased by30-35%. According to the method, the micro-channel continuous flow reactor is adopted, the micro-channel continuous flow reaction technology has the characteristics of continuous reaction process, good reaction liquid mixing effect, mild reaction conditions, short reaction time, good product consistency and the like, is particularly suitable for synthesis and preparation of 2,4-difluorobenzaldehyde, and provides a powerful technical support for large-batch low-cost continuous synthesis and production of 2,4-difluorobenzaldehyde.

Owner:NINGXIA DONGWU AGROCHEM

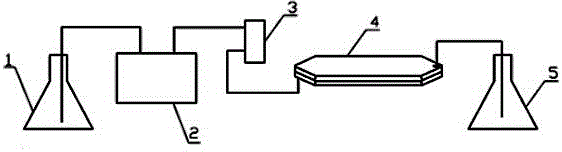

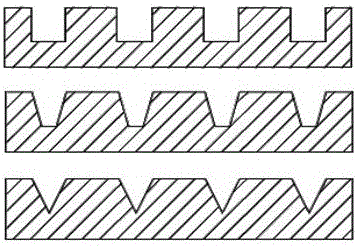

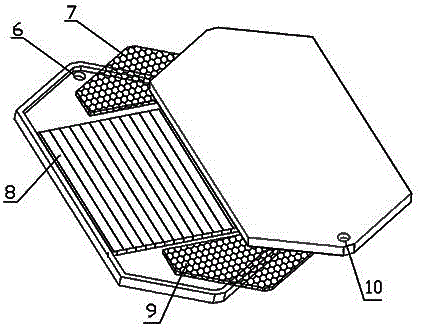

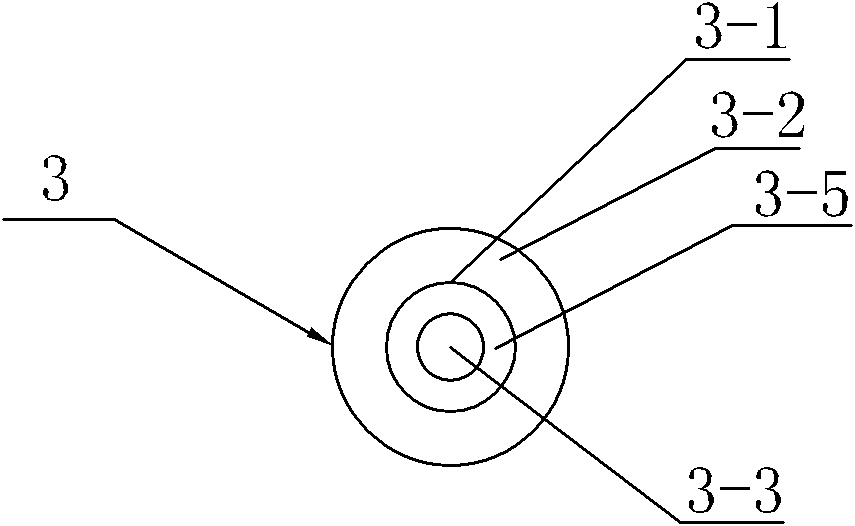

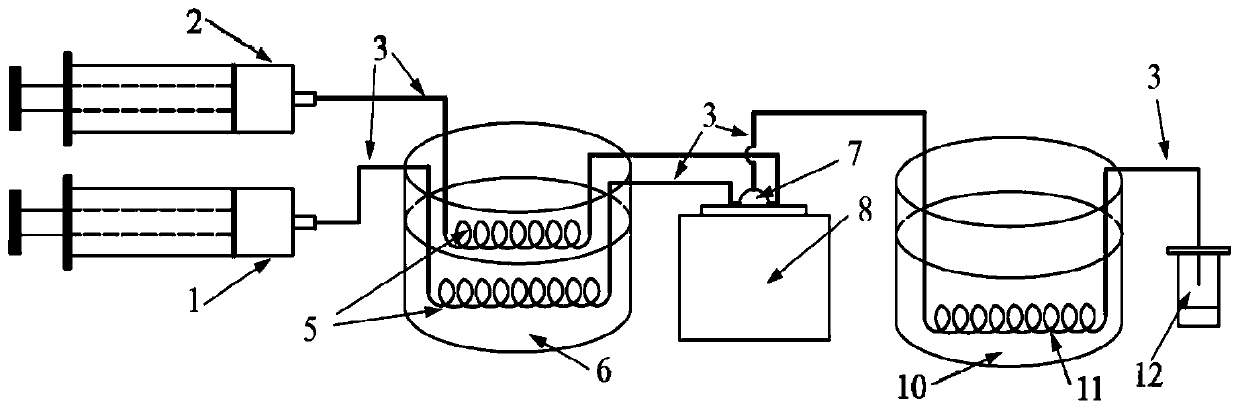

Method and device for quantum dot synthesis under auxiliary drive of capillary force

InactiveCN106423005AUniform particle sizeEnables continuous synthesisChemical/physical/physico-chemical microreactorsNanoopticsPhysicsQuantum dot

The invention discloses a method and a device for quantum dot synthesis under auxiliary drive of a capillary force. The device comprises a precursor liquid storage device (1), a magnetic pump (2), a flow meter (3), a micro-channel reactor (4) and a quantum dot collector (5). The method includes: pumping quantum dot precursor liquid into the micro-channel reactor (4), and enabling the precursor liquid to diffuse into capillary microgrooves (8) to react under capillary force drive of a first capillary liquid suction core (7) in an inlet area; enabling obtained quantum dot solution to flow out of the micro-channel reactor (4) under capillary force drive of a second capillary liquid suction core (9) in an outlet area and flow into a quantum dot collector (5) through a guide tube, so that the quantum dot solution is obtained. The method and the device for quantum dot synthesis under auxiliary drive of the capillary force have advantages that continuous synthesis of quantum dots under low-power or even powerless conditions is realized, uniformity of the quantum dots is effectively improved, and the synthesis method is simple in operation, low in process cost and beneficial for industrial production of the quantum dots.

Owner:SOUTH CHINA UNIV OF TECH

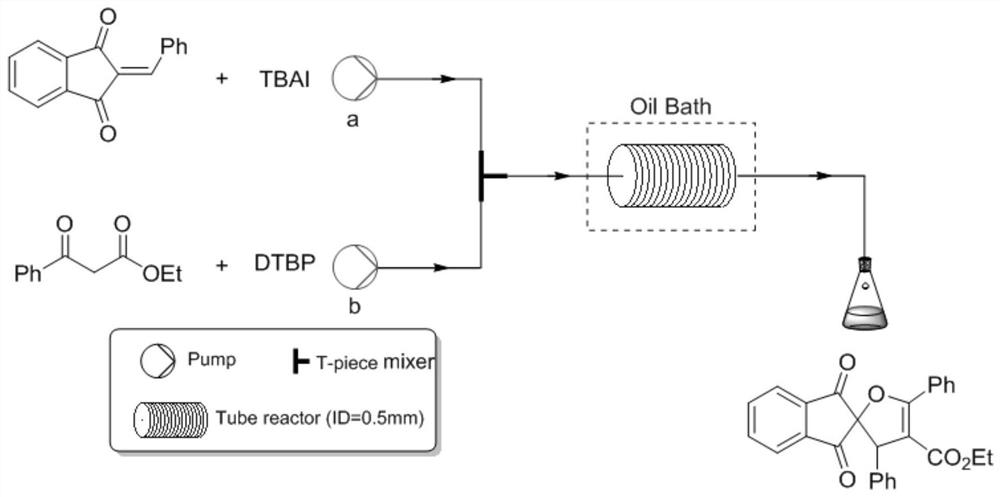

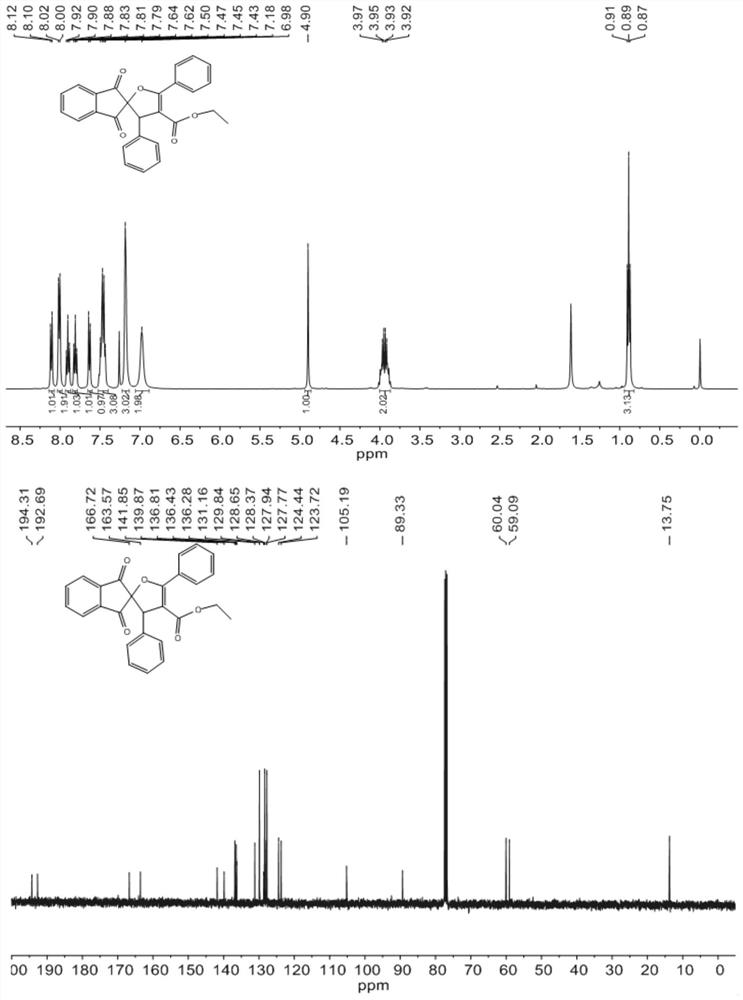

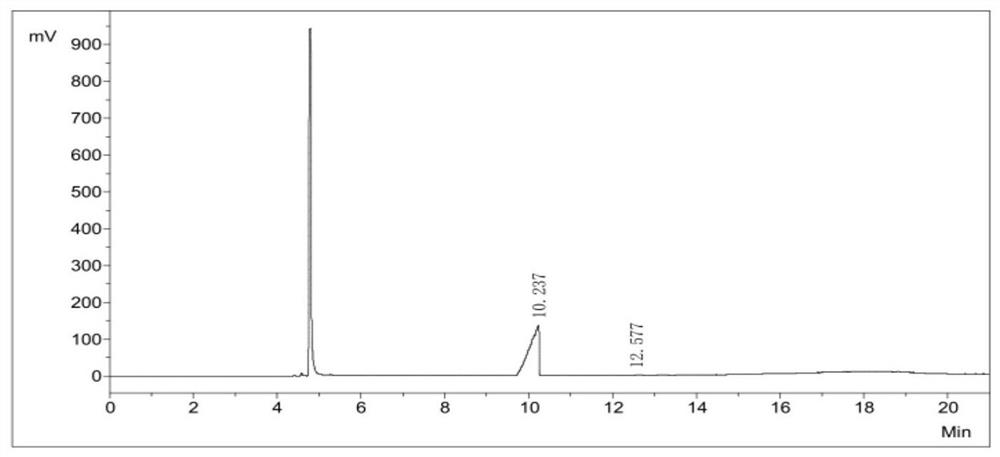

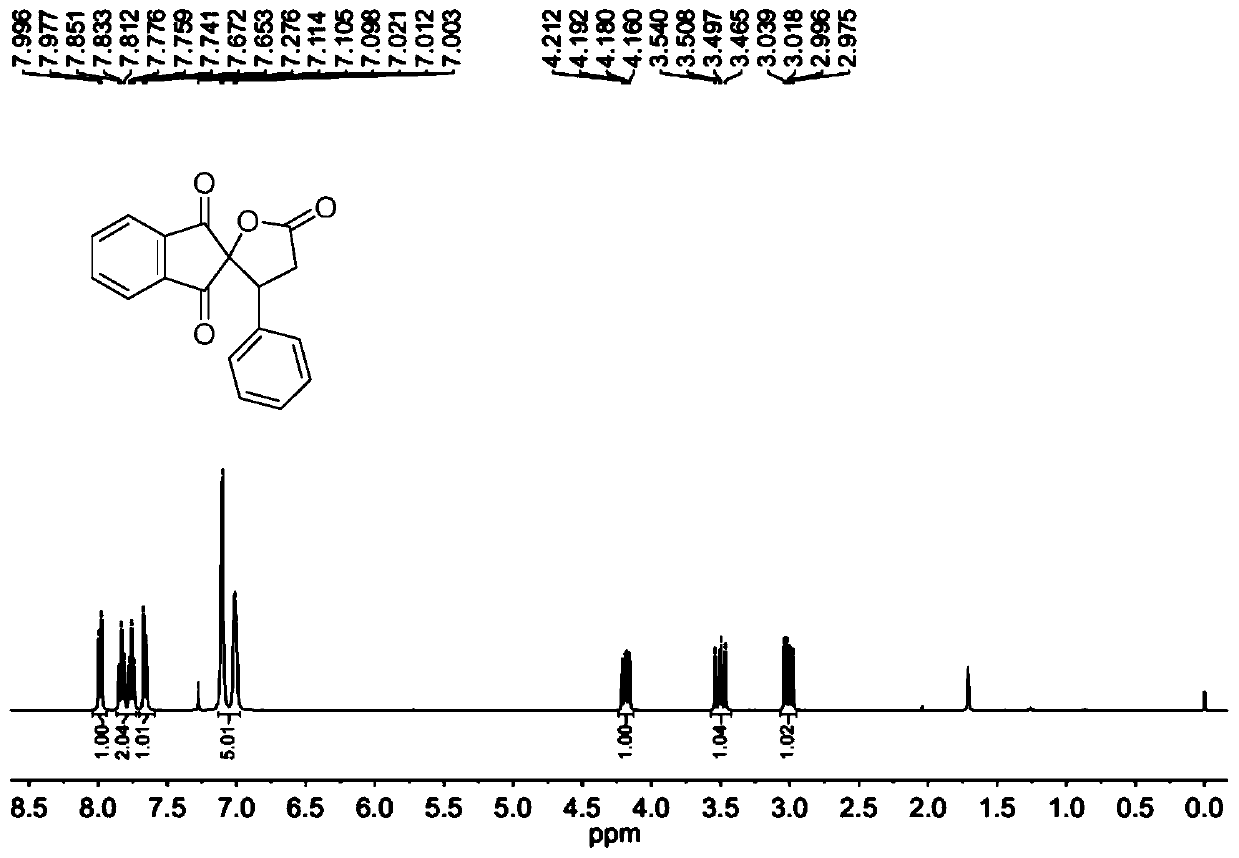

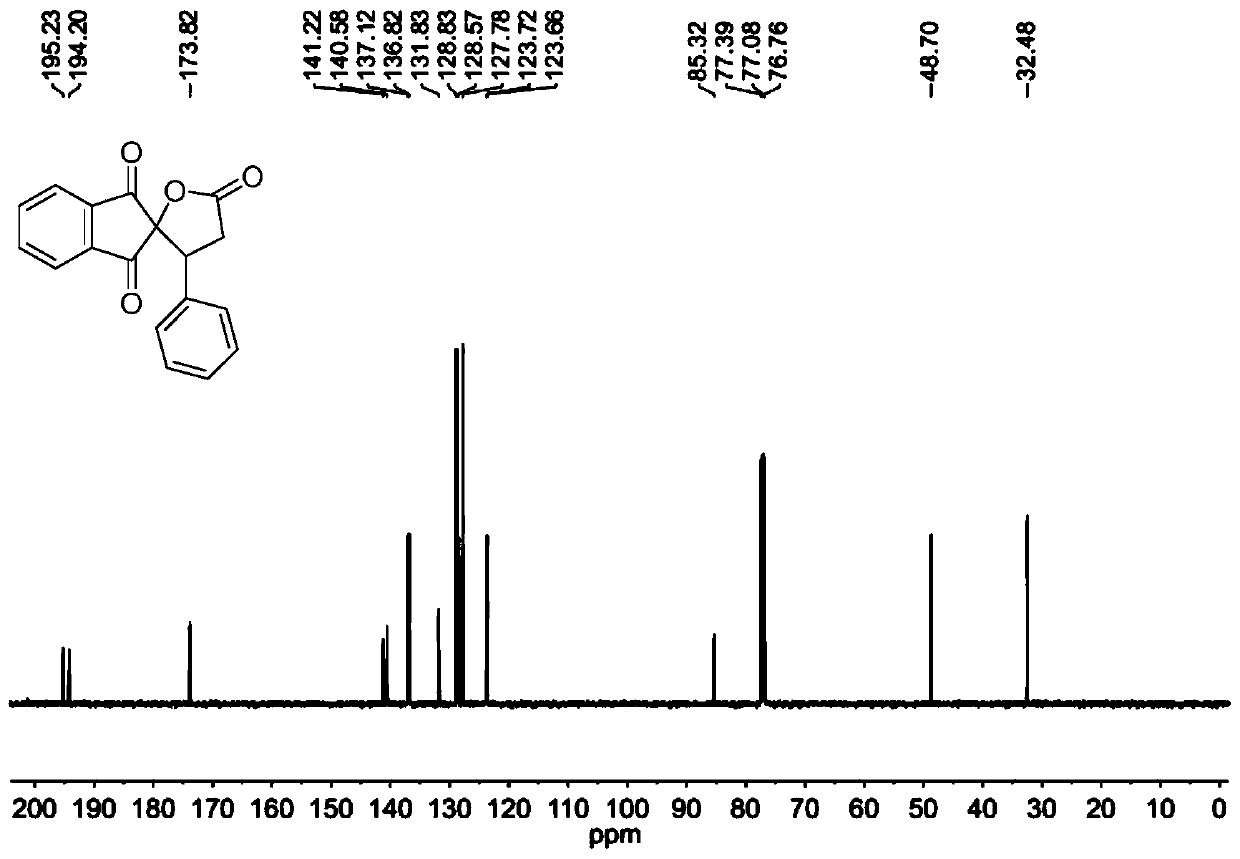

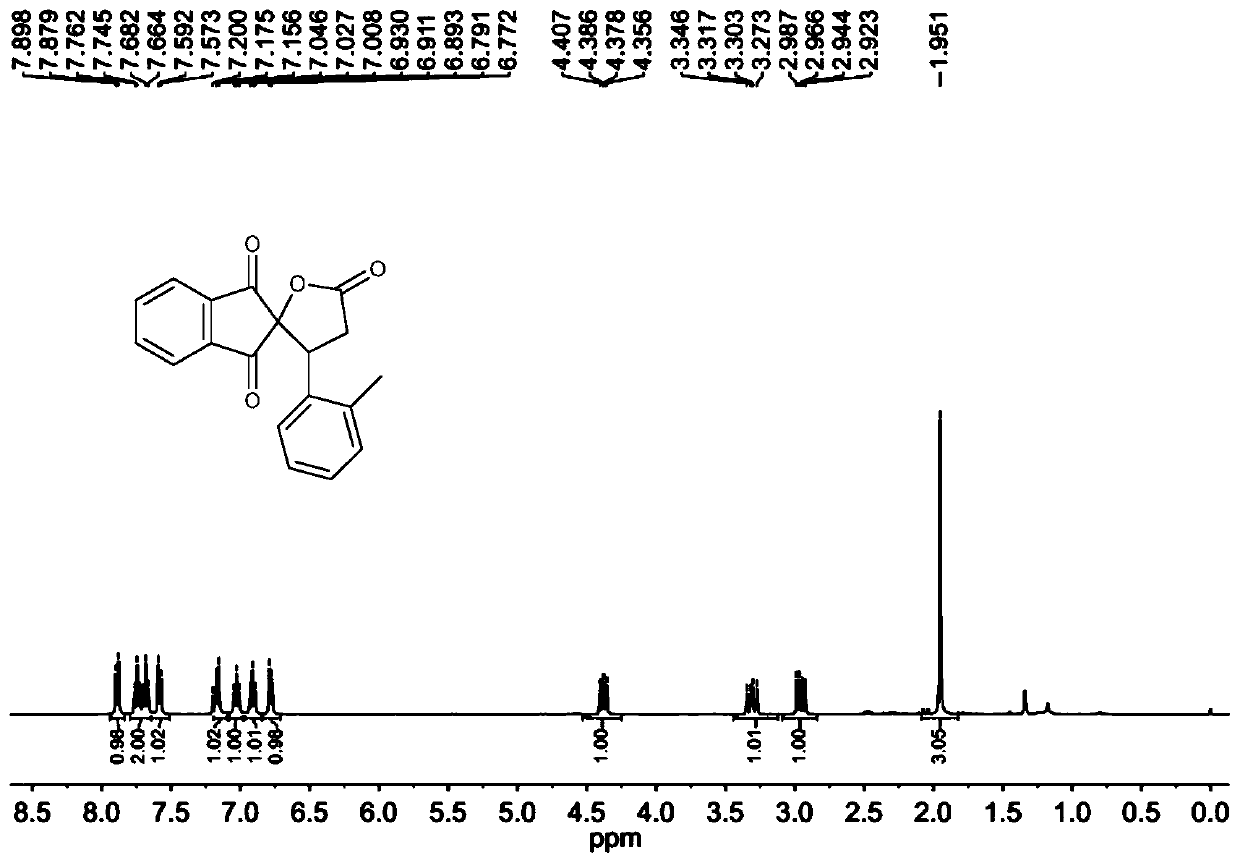

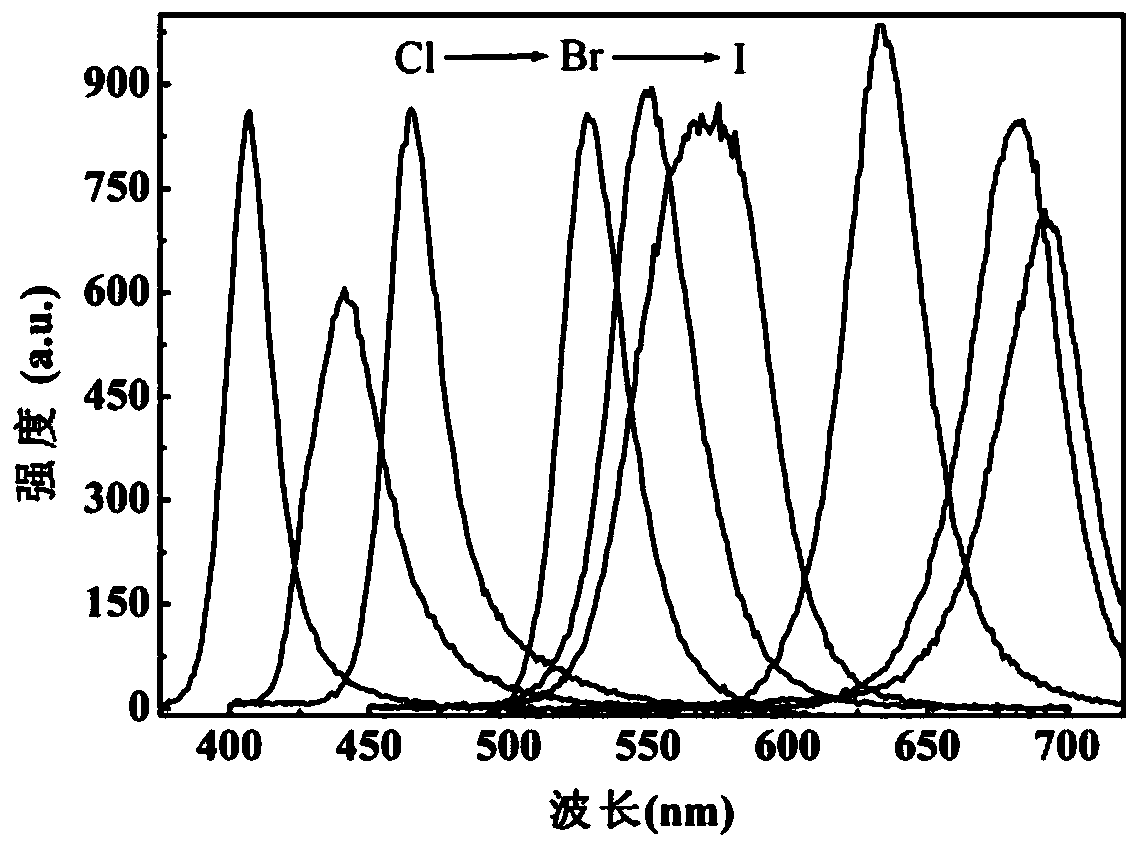

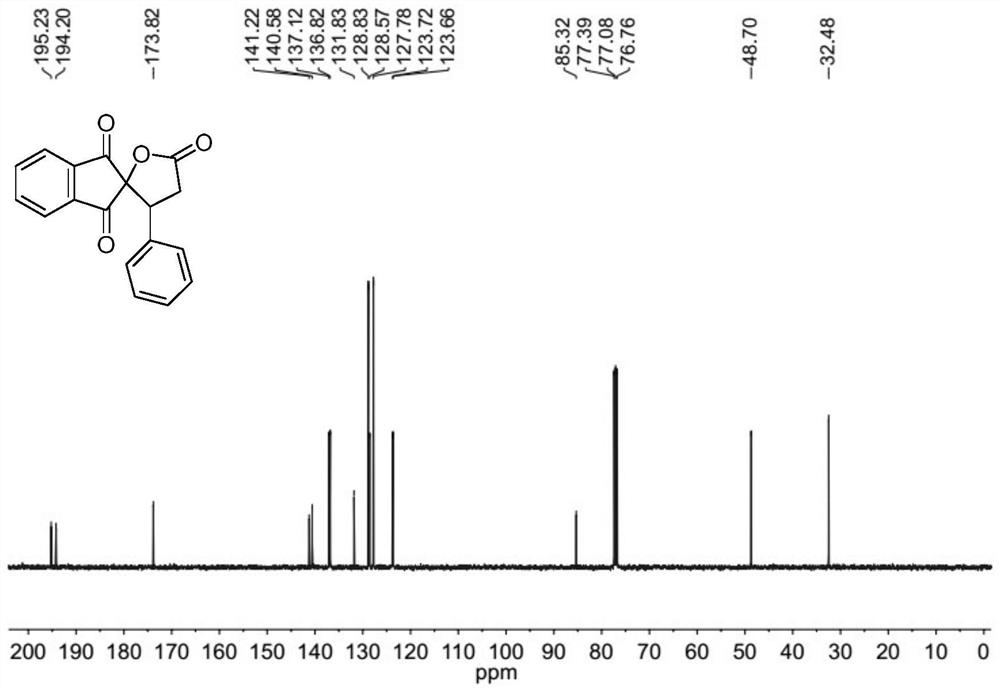

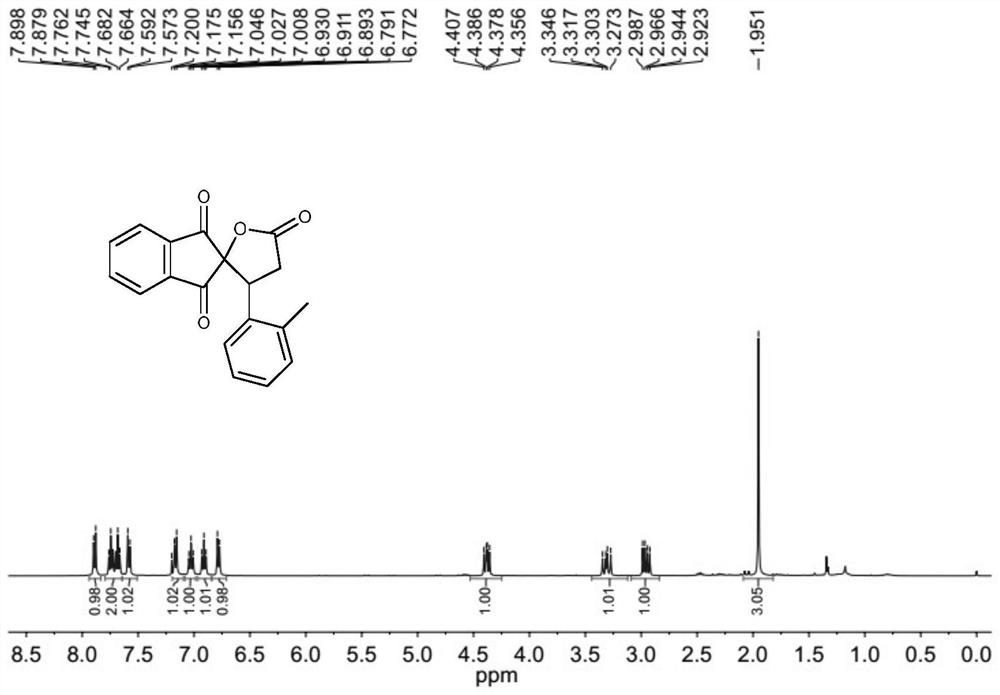

Method for synthesizing dihydrofuran containing 1, 3-indandione spiro skeleton by using micro-channel reaction device

PendingCN112209907AAvoid multi-step reactionsAtom utilization is highOrganic chemistryChemical/physical/physico-chemical microreactorsFuranPtru catalyst

The invention discloses a method for synthesizing a dihydrofuran compound containing a 1, 3-indandione spiro skeleton as shown in a formula III by using a micro-channel reaction device, which comprises the following steps: by using a 2-benzylidene-1, 3-indandione compound I and a benzoyl ethyl acetate compound II as reaction raw materials, carrying out continuous reaction by using the micro-channel reaction device to prepare the dihydrofuran compound containing a 1, 3-indandione spiro skeleton. The micro-channel reaction device comprises a feeding pump, a micro-mixer and a micro-reactor whichare sequentially connected through a pipeline. Compared with the prior art, the new dihydrofuran containing the 1, 3-indandione spiro skeleton is prepared by taking the 2benzylidene 1, 3-indandione compound as the substrate for the first time, and the method avoids multi-component reaction, uses a non-metal catalyst and a low-toxicity solvent, and is a quick, efficient, green and environment-friendly synthetic product, wherein R1 is selected from halogenated benzene, C1-C4 alkyl benzene, C1-C4 alkoxy benzene, nitrobenzene, furan or naphthalene, and R2 is selected from halogenated benzene, C1-C4 alkyl benzene, C1-C4 alkoxy benzene, nitrobenzene, furan, thiophene, pyridyl or naphthalene.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

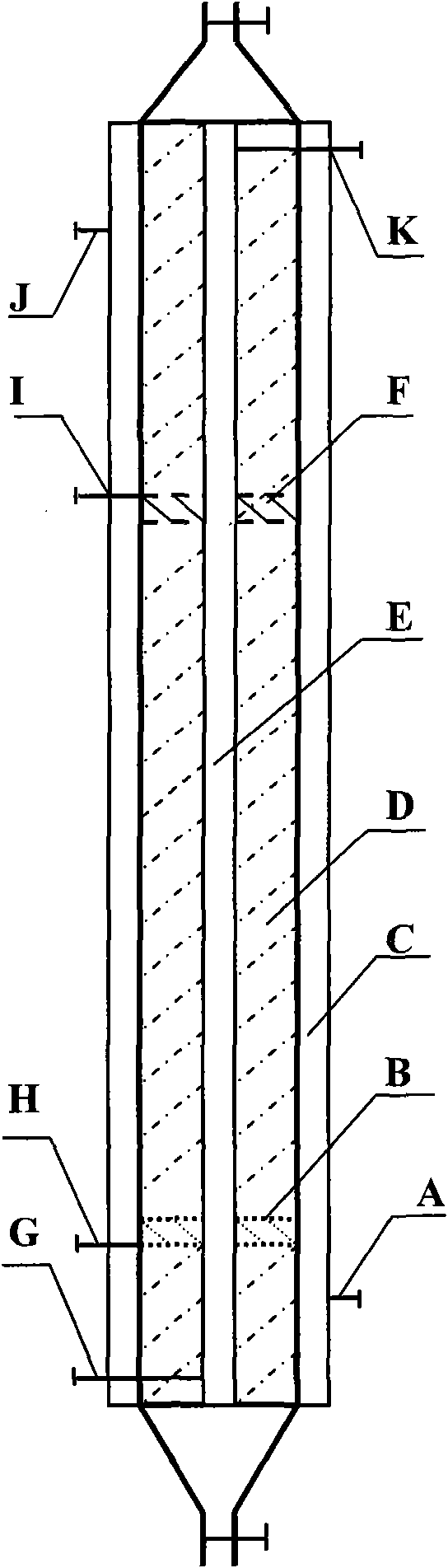

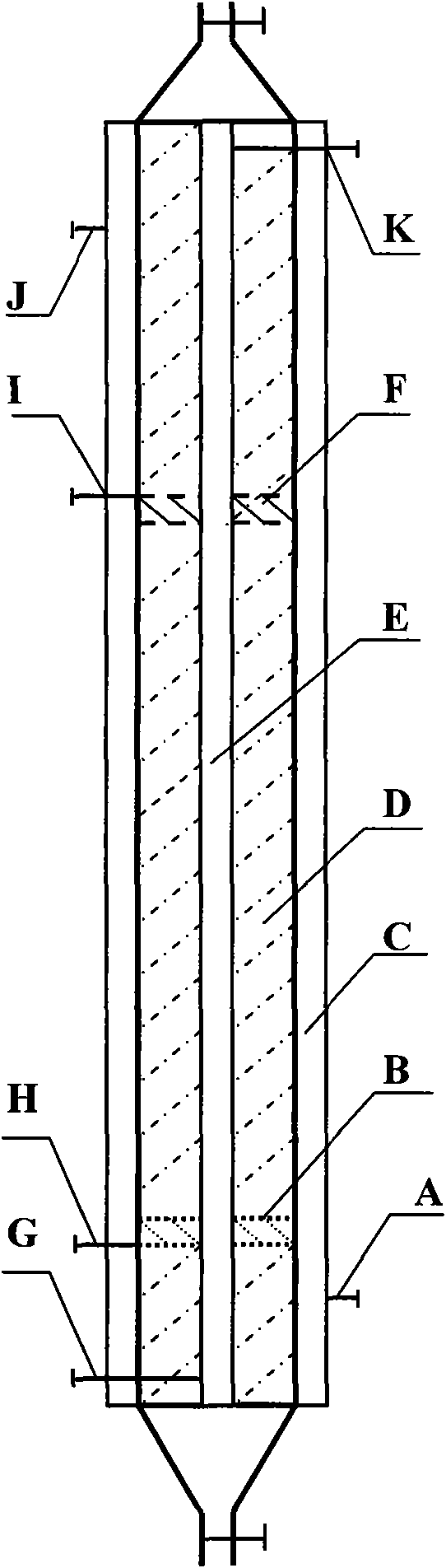

Reactor for preparing tetrabromoethane by addition reaction of bromine and acetylene and synthesis process

InactiveCN101766980AEnables continuous synthesisIncrease productivityGas-gas reaction processesPreparation by halogen additionBromineReaction temperature

The invention relates to a reactor for preparing tetrabromoethane by addition reaction of bromine and acetylene and a synthesis process; the reactor is characterized in that: the reactor is mainly composed of a central cooling pipe, a reaction pipe filled with fillers and an outer cooling pipe; continuous synthesis of the tetrabromoethane is realized by continuous countercurrent contact reaction of the bromine and the acetylene in the reaction pipe, so as to improve the production efficiency; by adjusting the temperature and flow rate of the cooling water in the inner and outer cooling pipes, the addition reaction temperature can be controlled, the problems of safety and more by-products are solved owning to overhigh reaction temperature; by adopting the reactor and the synthesis process, the explosive mixture of acetylene and air is prevented from being formed in the reaction process, so as to improve the reaction safety.

Owner:QILU UNIV OF TECH

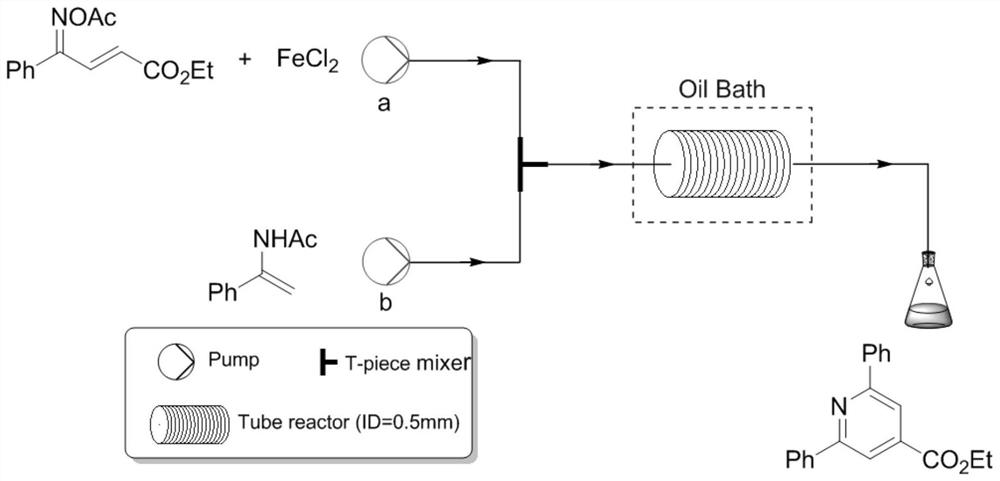

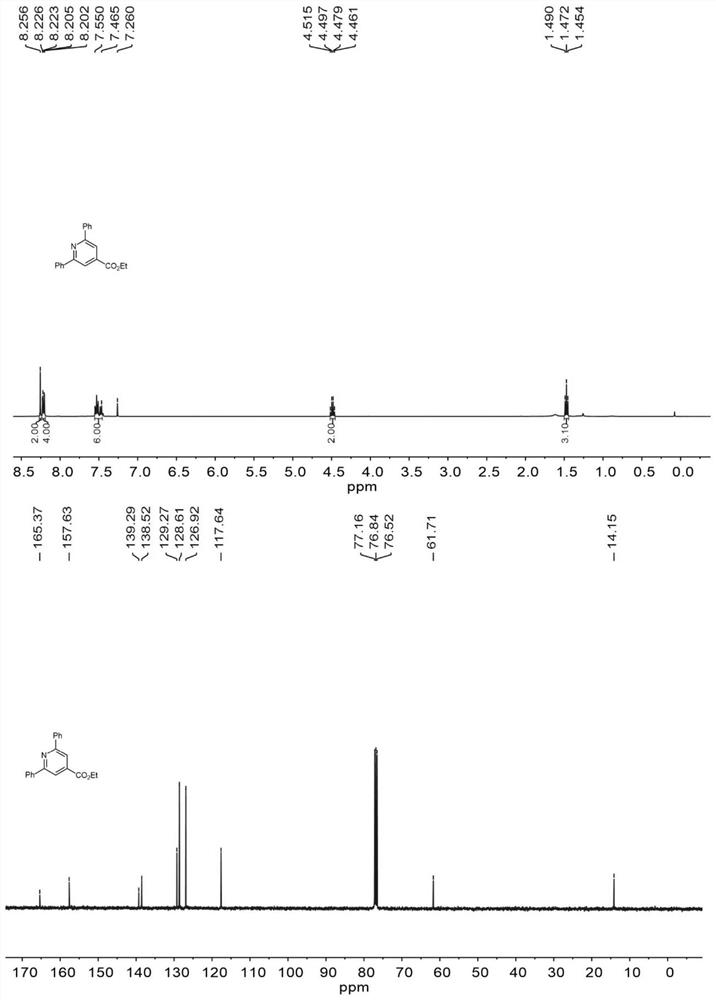

Method for synthesizing pyridine compound by using microchannel reaction device

ActiveCN113307766AAvoid multi-step reactionsAvoid reactionOrganic chemistryChemical/physical/physico-chemical microreactorsFuranPtru catalyst

The invention discloses a method for synthesizing a pyridine compound shown as III by using a micro-channel reaction device, which comprises the following steps: taking an alpha, beta-unsaturated ketoxime ester compound I and an N-acetyl amide compound II as reaction raw materials, adding a catalyst, and continuously reacting by using the micro-channel reaction device to prepare the pyridine compound. Compared with the prior art, the novel pyridine compound is prepared by taking the alpha, beta-unsaturated ketoxime ester compound and the N-acetyl amide compound as substrates, multi-component reaction is avoided, and the product is rapidly and efficiently synthesized by using the metal catalyst. Wherein R1 and R2 are independently selected from non-substituted or substituted phenyl, furyl, naphthyl or C1-C5 alkyl; and the substituted phenyl group is selected from phenyl groups substituted by halogen, C1-C5 alkyl groups or C1-C5 alkoxy groups.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

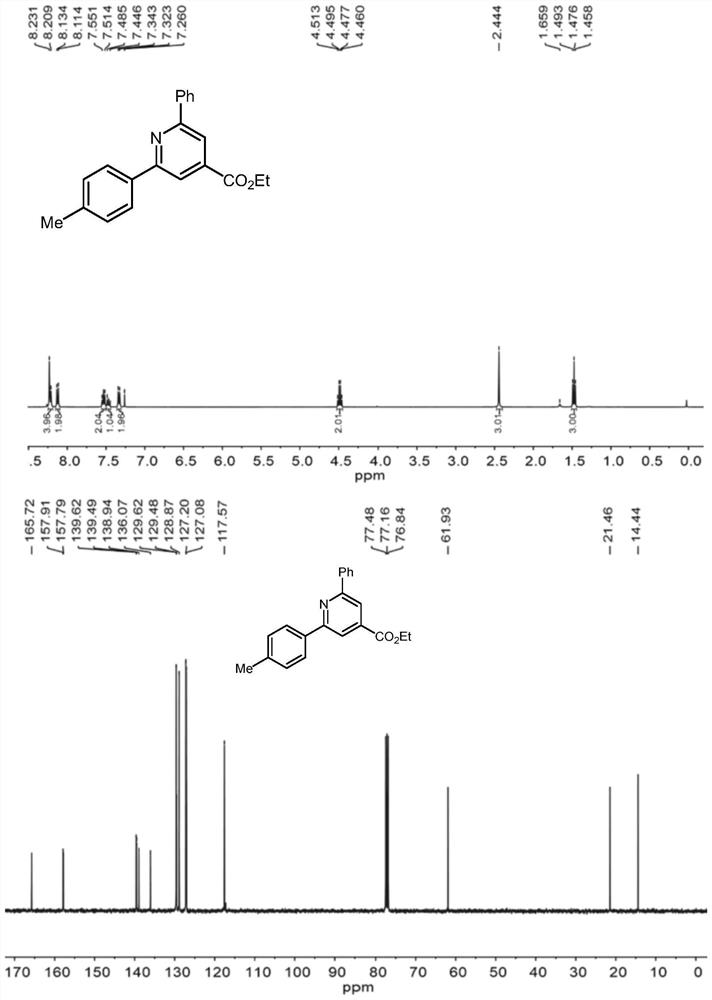

Preparation method and device of diiodosilane

PendingCN114835126AImprove heat transfer efficiencyHigh product contentChemical/physical/physico-chemical microreactorsHalogenated silanesSemiconductor materialsEthyl acetate

The invention relates to a preparation method and device of diiodosilane, and relates to the field of synthesis methods of semiconductor materials, the preparation method comprises the following steps: 1, mixing and dissolving iodine with at least one of chloroform, dichloromethane and dichloroethane according to a volume ratio of 1: (2-5); the phenylsilane is mixed with at least one of ethyl acetate, tert-butyl acetate and butyl acetate according to the mass ratio of 100: (1-5); pre-cooling the iodine solution and the phenylsilane solution at-40 to 0 DEG C; then pumping the mixture into a microchannel reactor, carrying out mixed reaction for 100-300 seconds in a low-temperature microchannel at-40-10 DEG C, and then introducing the mixture into a room-temperature microchannel at 20-30 DEG C to react for 100-400 seconds, so as to obtain a reaction mixture; and 2, carrying out vacuum rectification on the reaction mixture obtained in the step 1, and collecting the product with the fraction temperature of 35-40 DEG C under 20 + / -3 mmHg to obtain the high-purity diiodosilane. The diiodosilane is synthesized through the microchannel reactor, the original synthesis period can be shortened to be within 700 seconds, and the obtained mixture product is high in content and low in impurity metal ion content.

Owner:安徽敦茂新材料科技有限公司

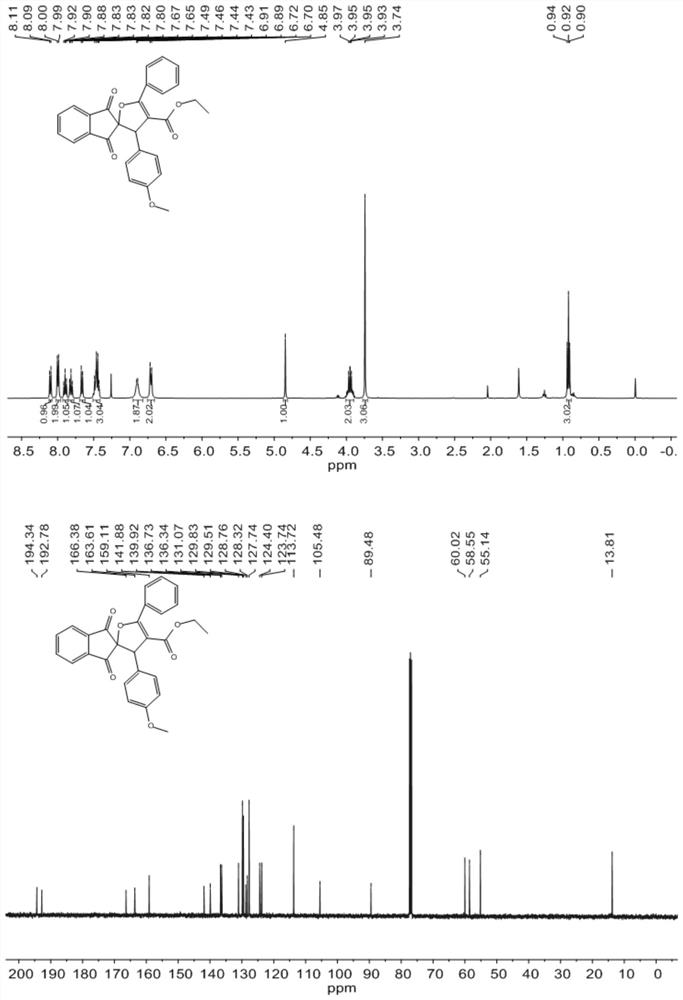

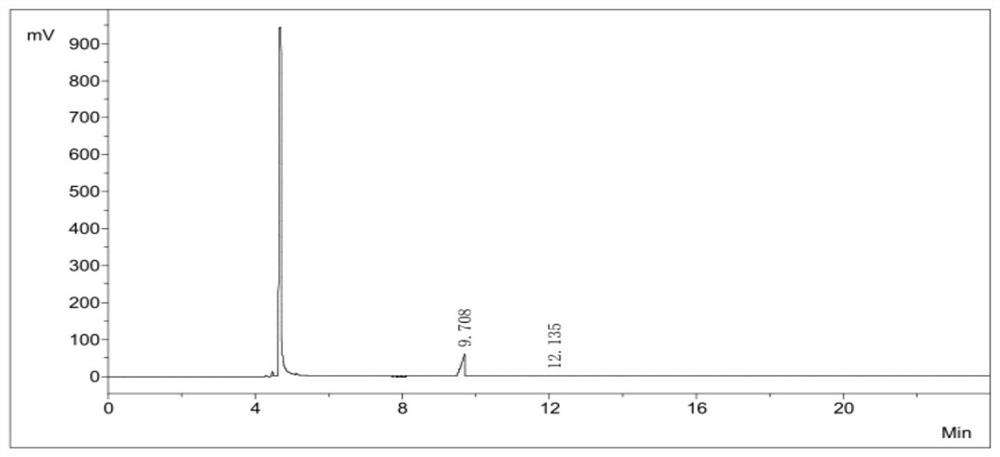

Method for synthesizing gamma-butyrolactone containing spiro 1, 3-indandione structure by using micro-channel reaction device

ActiveCN111233884AImprove catalytic performanceHigh yieldOrganic chemistryChemical/physical/physico-chemical microreactorsMicroreactorPtru catalyst

The invention discloses a method for synthesizing gamma-butyrolactone containing a spiro 1, 3-indandione structure by using a micro-channel reaction device. The method comprises the following steps: (1) dissolving a 2-benzal-1,3-indandione compound and malonic acid cyclic (sub)isopropyl ester in an organic solvent to prepare a homogeneous solution A; (2) dissolving a catalyst and an oxidant in anorganic solvent to prepare a homogeneous solution B; (3) respectively pumping the homogeneous solution A and the homogeneous solution B into a micro-mixer in a micro-channel reaction device at the same time, mixing, and introducing into a micro-reactor to carry out reactions; and (4) collecting the effluent of the micro-reactor to obtain the product. Compared with the prior art, gamma-butyrolactone containing a spiro 1,3-indandione structure is prepared by taking the 2-benzal-1,3-indandione compound as the substrate for the first time, the method avoids the use of acidic raw materials and expensive metals, and the used non-metal catalyst also has an excellent catalytic performance.

Owner:NANJING UNIV OF TECH

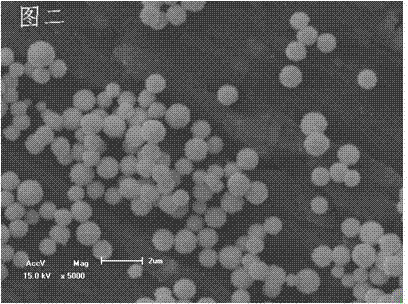

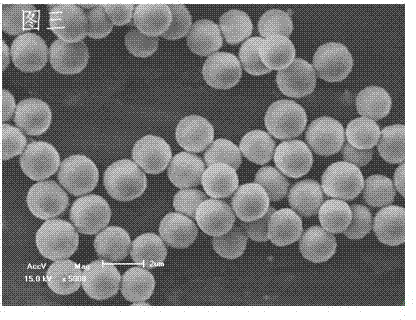

Method and device for continuously synthesizing spherical micro-nano cuprous oxide powder

ActiveCN102153129BNot easy to remixAvoid antimixingNanotechnologyCopper oxides/halidesMicro nanoOxide

The invention provides a method for continuously synthesizing spherical micro-nano cuprous oxide powder, and a segmented pipe type reactor for realizing the method, belonging to the technical field of nanometer materials. The method includes the steps as follows: fully mixing copper sulfate solution with sodium hydroxide solution by a pipeline and then leading the mixed solution to enter the pipetype reactor for preheating; adding glucose solution in the mixed solution; later leading the mixed system to pass through a segment or a serial-connection multi-pipe type reactor so as to raise temperature to 50-70 DEG C in a continuous or gradient way; and filtering the mixed system after oxidation reduction in the pipe type reactor, washing the mixed system with water and ethanol in sequence, conducting vacuum drying, and finally obtaining the spherical micro-nano cuprous oxide powder. The spherical micro-nano cuprous oxide powder obtained by the method is within the range of 0.5-2Mum in particle size and smooth on surface, has a cubic phase in crystal form, and has high uniformity of particle size distribution, excellent dispersivity, good sphericity and high purity. The method is easy to control in synthesizing process, low in cost, energy-saving and environment-friendly, and beneficial to industrialized production.

Owner:JINCHUAN GROUP LIMITED +1

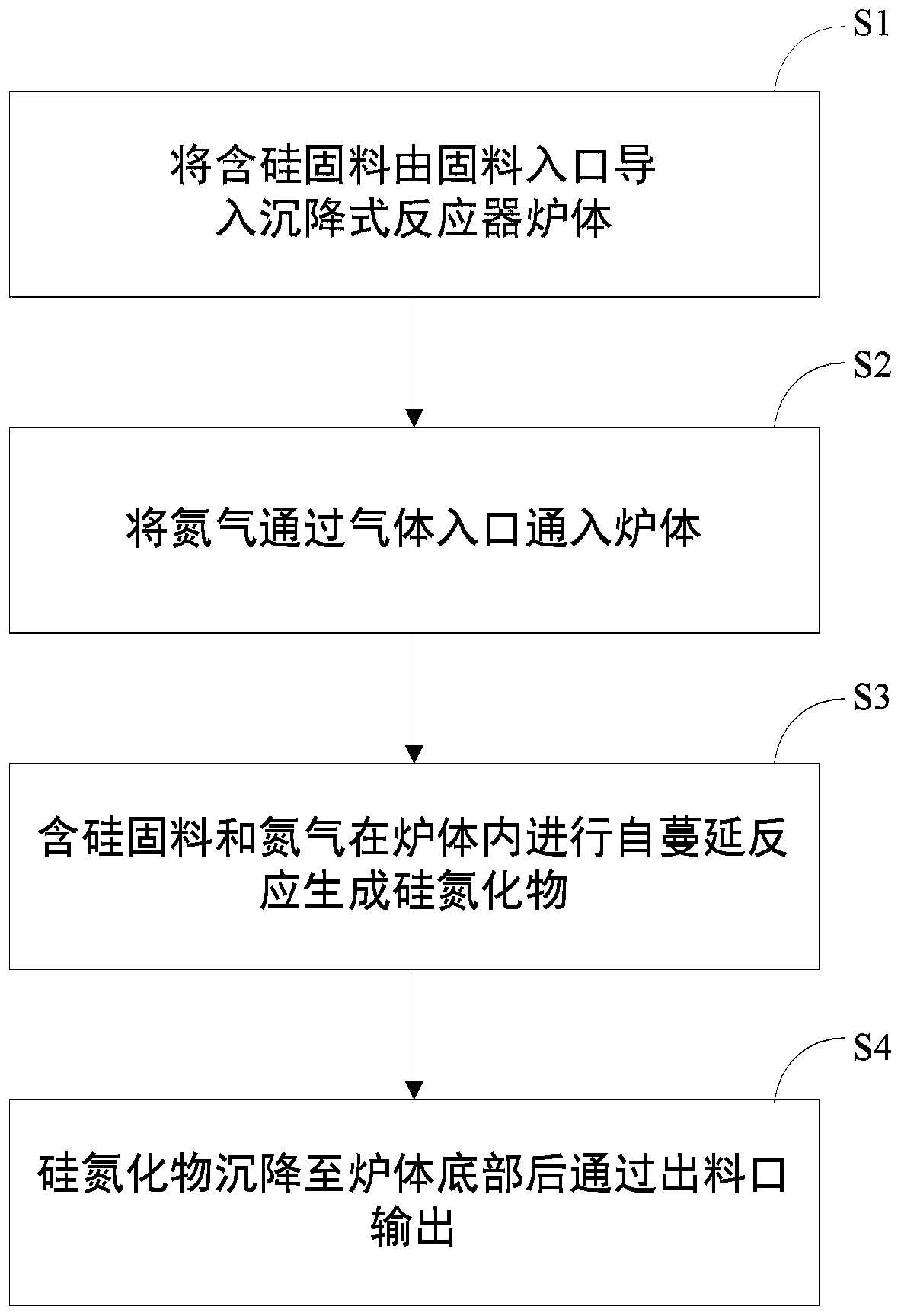

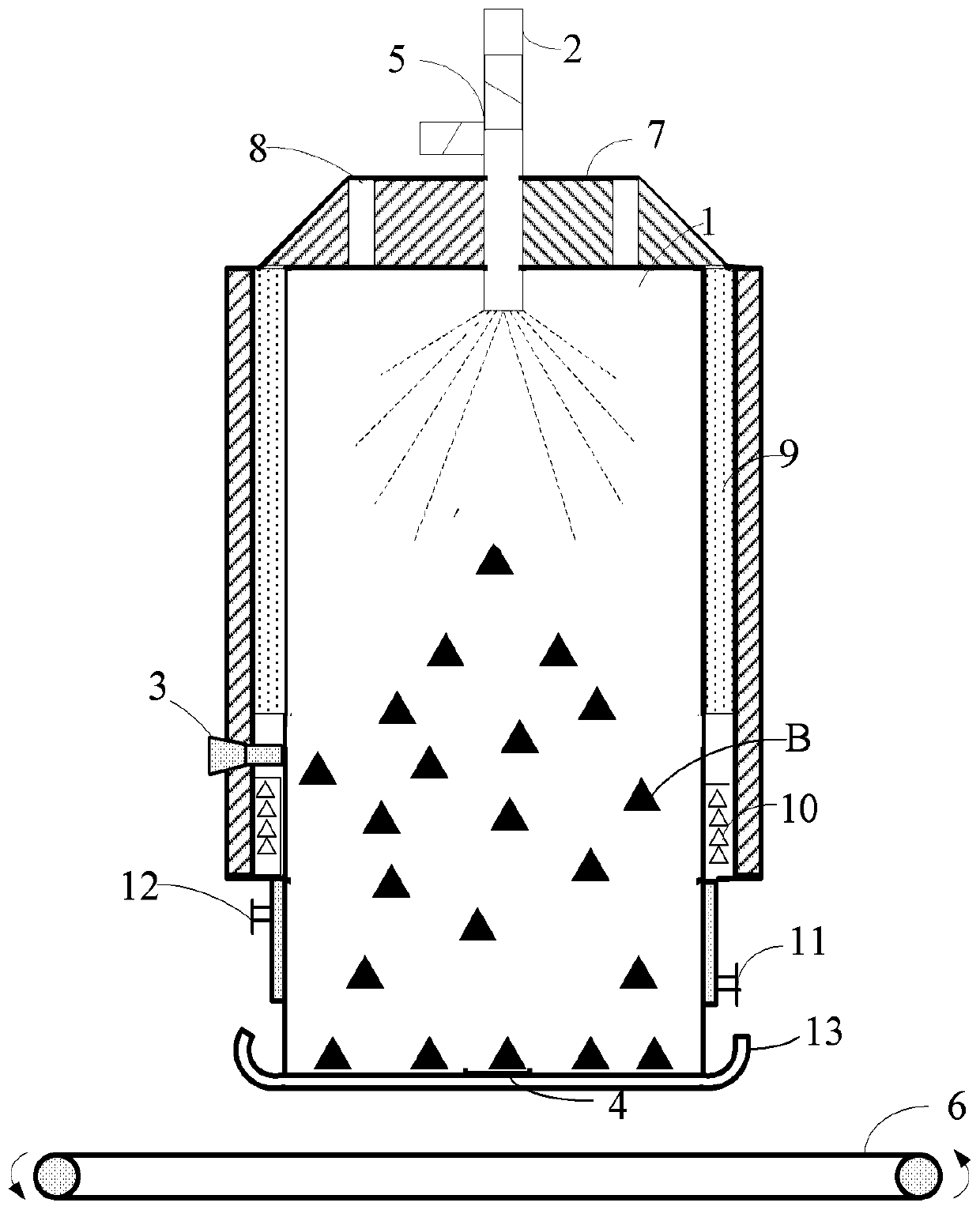

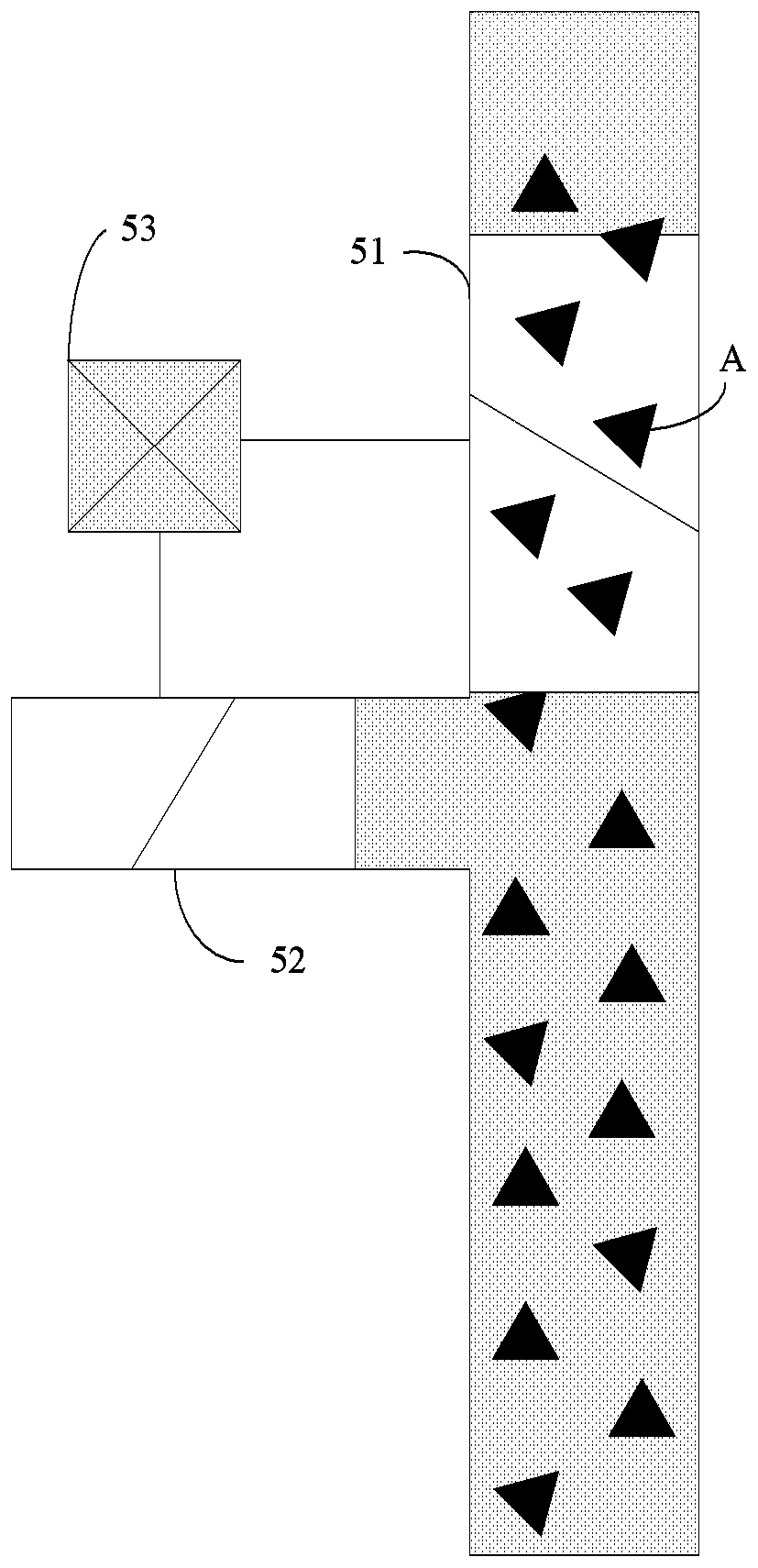

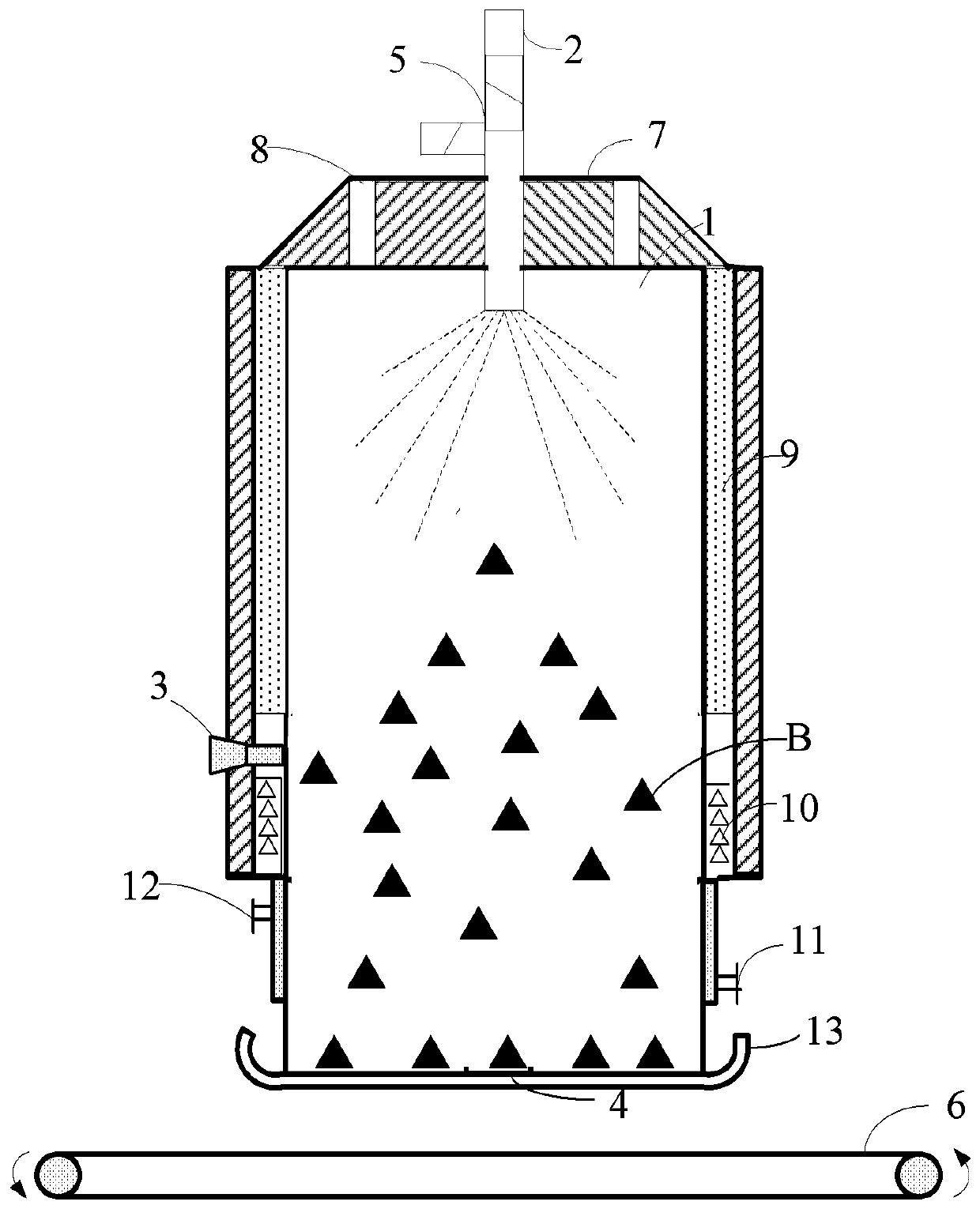

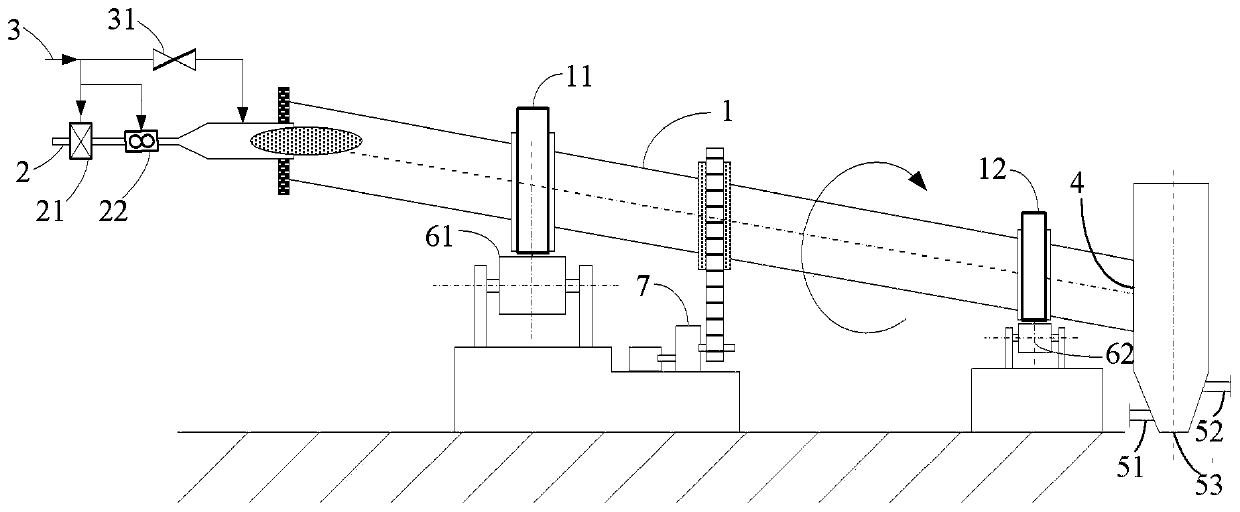

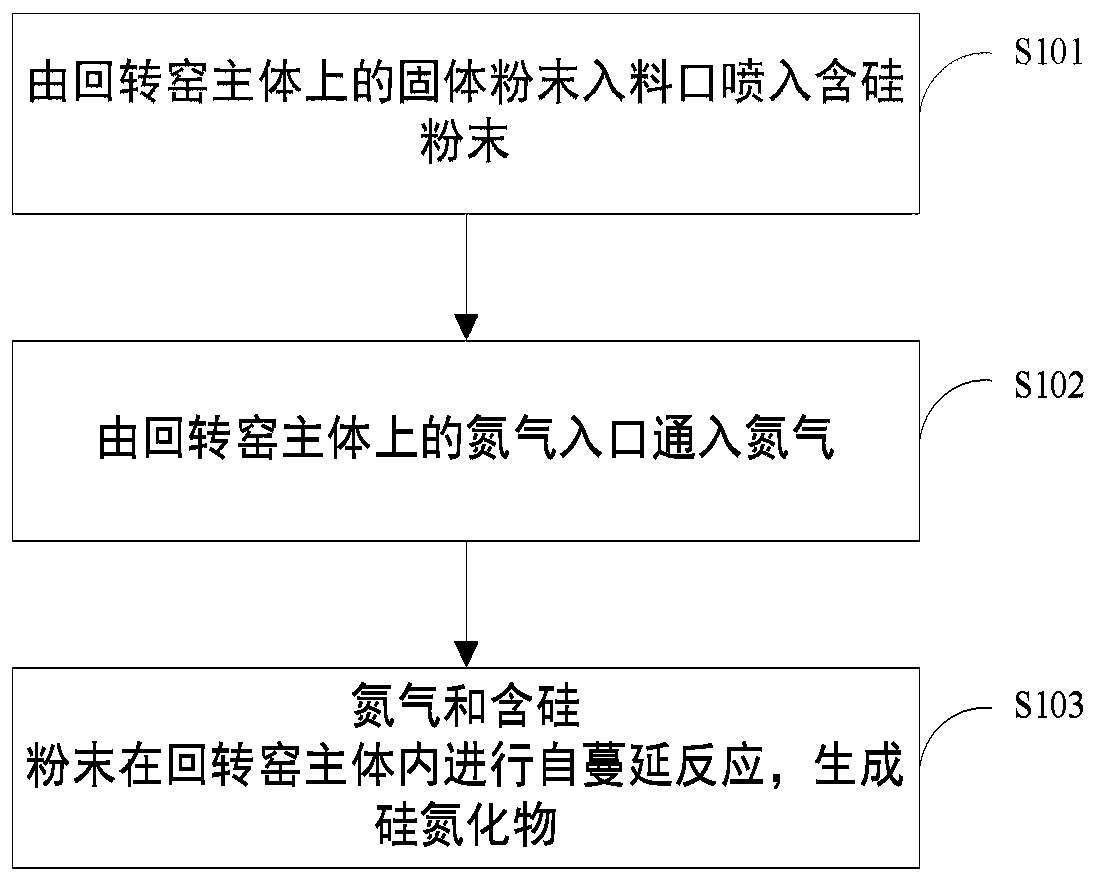

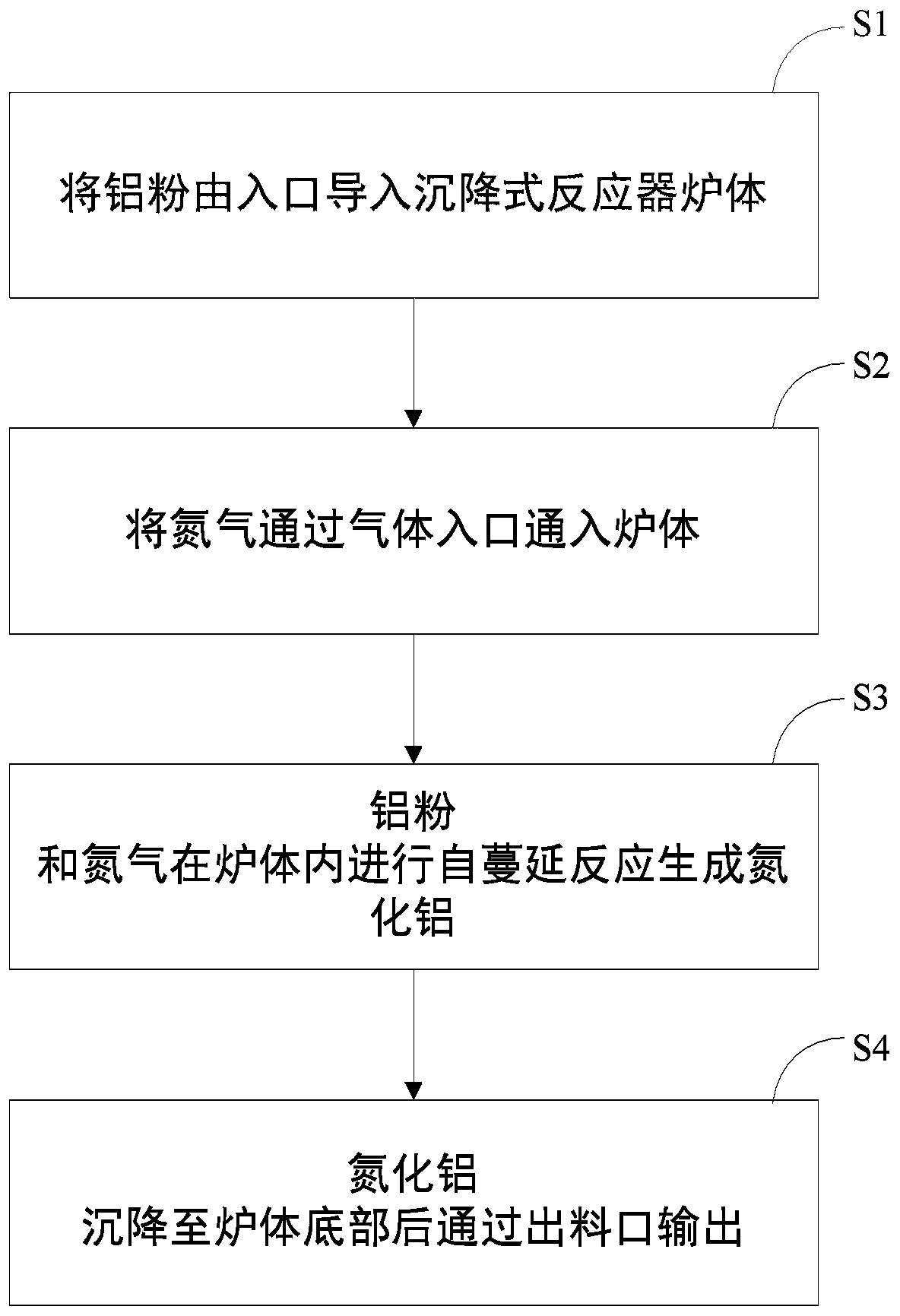

Method for preparing silicon nitride in sedimentation-type and self-propagating mode

The invention provides a method for preparing silicon nitride in a sedimentation-type and self-propagating mode. The method is characterized in that a silicon-containing solid material is introduced into a sedimentation-type reactor furnace body from a solid material inlet; nitrogen is introduced into the furnace body through a gas inlet; the silicon-containing solid material and nitrogen are subjected to a self-propagating reaction in the furnace body to generate the silicon nitride; the silicon nitride settles to the bottom of the furnace body and is then output through a discharge port. According to the method for preparing the silicon nitride in the sedimentation-type and self-propagating mode provided by the invention, a sedimentation-type mode is adopted for preparation, and continuous synthesis of the silicon nitride can be realized.

Owner:宁夏时星科技有限公司

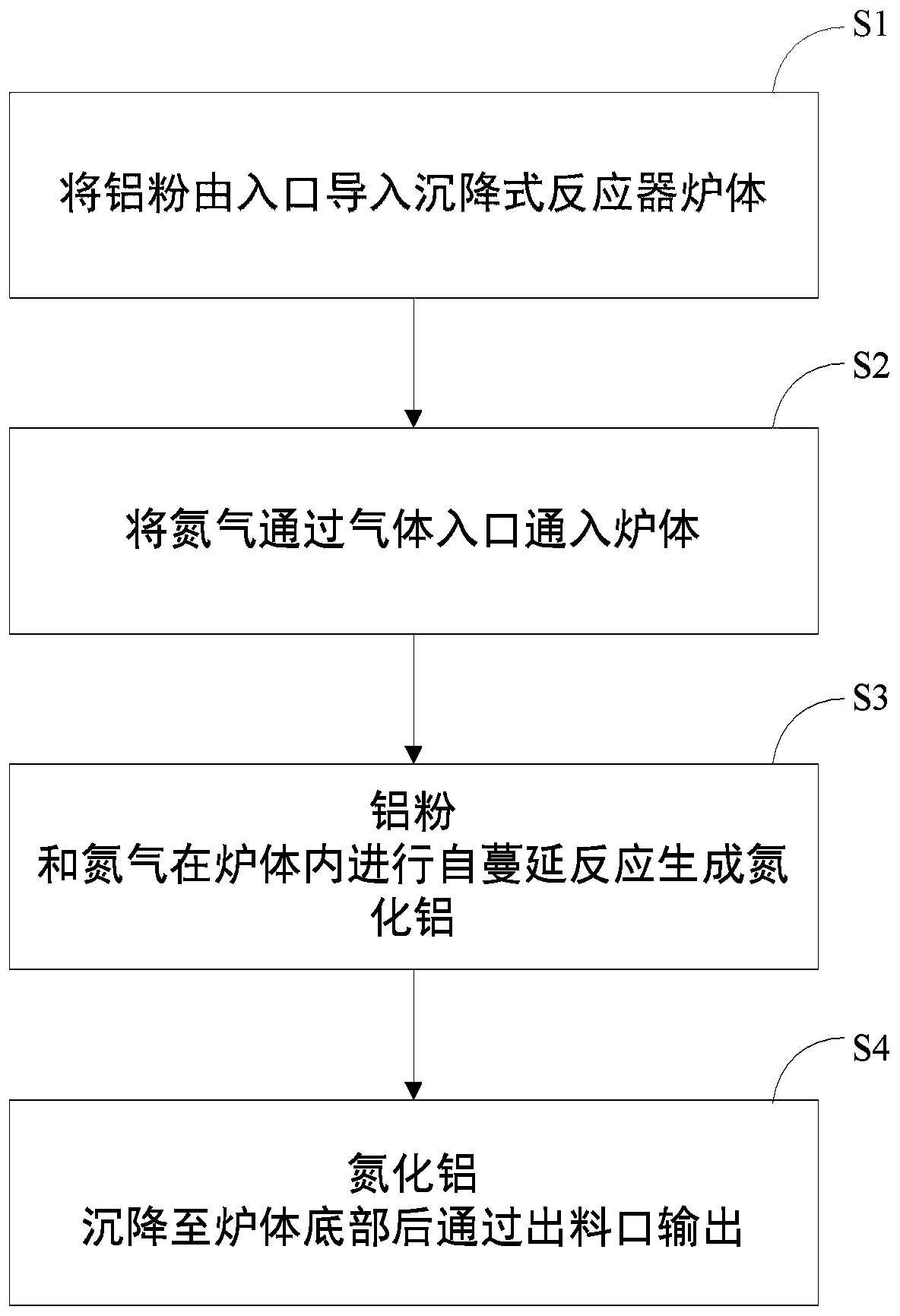

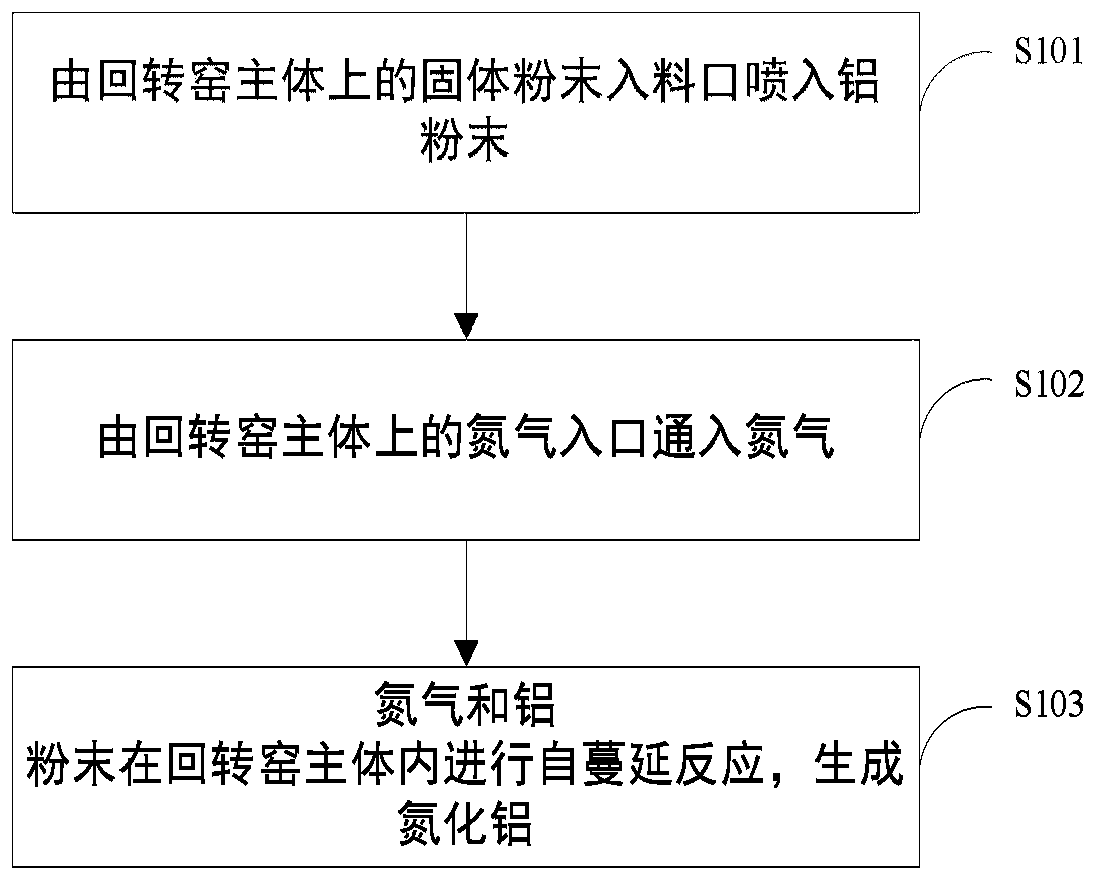

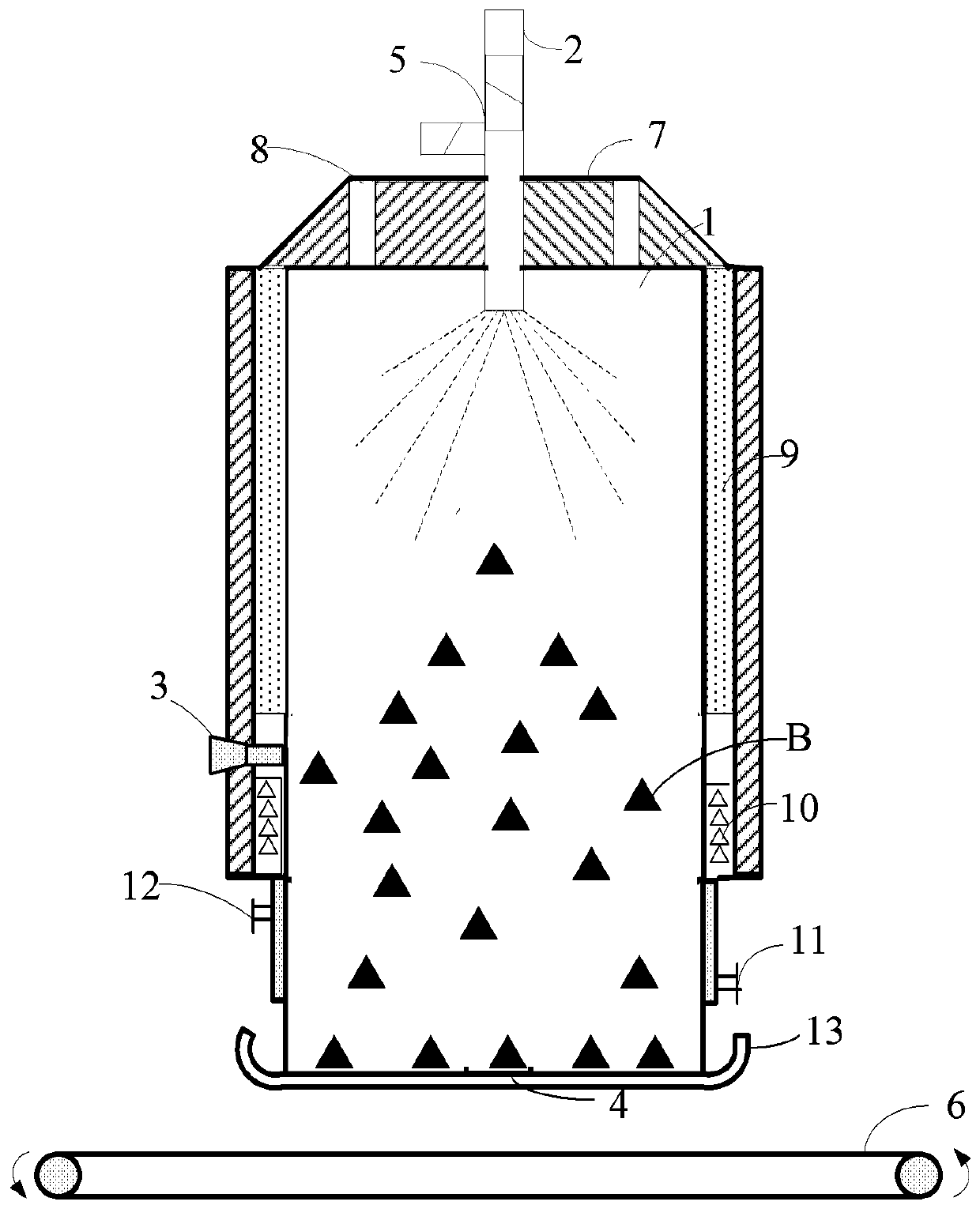

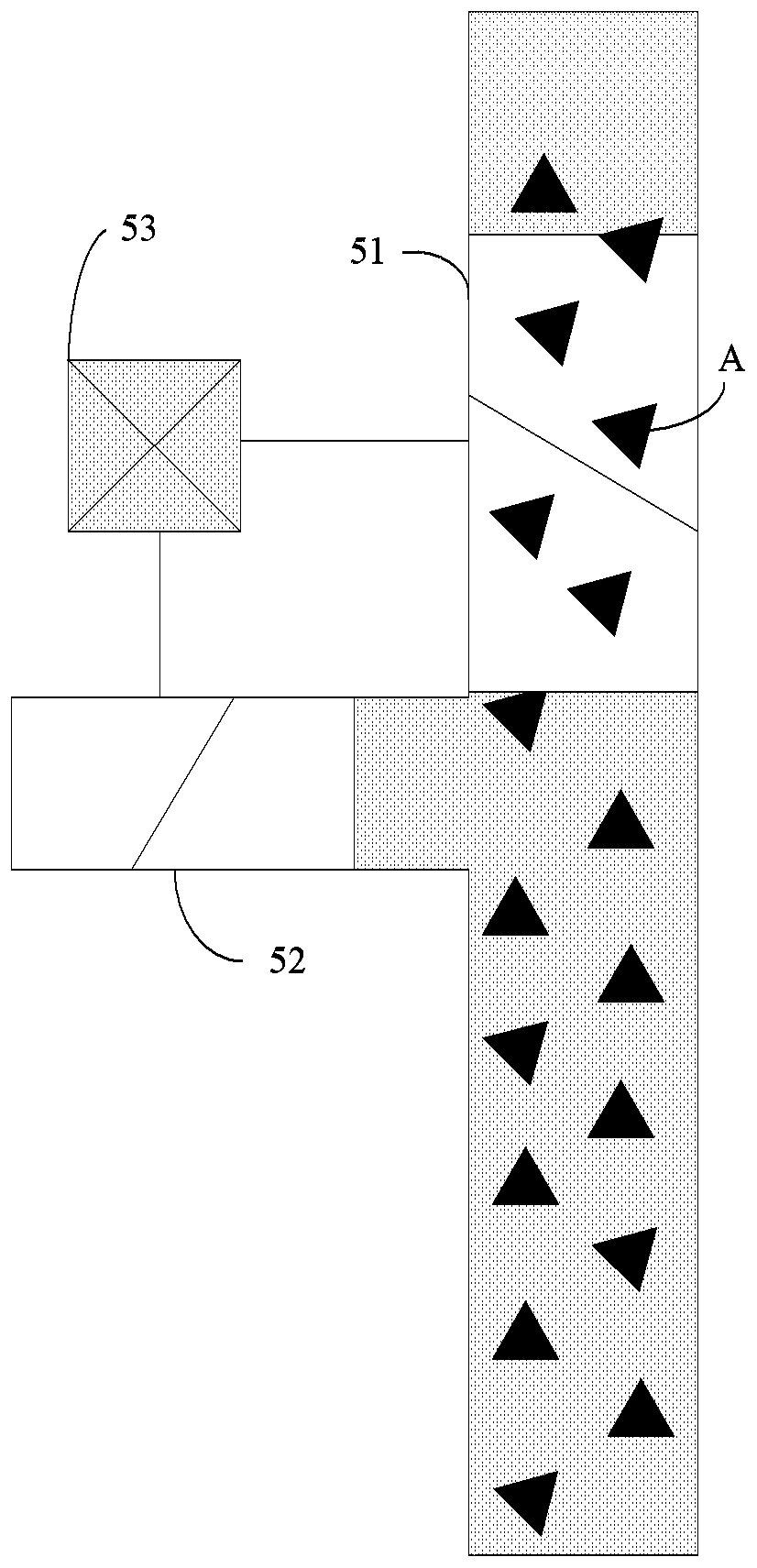

Sedimentation type self-propagating aluminum nitride preparation method

The invention relates to a sedimentation type self-propagating aluminum nitride preparation method. The method comprises the steps of introducing aluminum powder into a sedimentation type reactor furnace body from a solid material inlet; introducing nitrogen into the furnace body through a gas inlet; triggering a self-propagating reaction between the aluminum powder and the nitrogen in the furnacebody in order to generate aluminum nitride; settling the aluminum nitride to the bottom of the furnace body and then discharging the aluminum nitride through a discharge hole. The sedimentation typeself-propagating aluminum nitride synthesis method can realize the continuous synthesis of aluminum nitride and is particularly efficient and capable of saving energy for the preparation of aluminum nitride.

Owner:宁夏时星科技有限公司

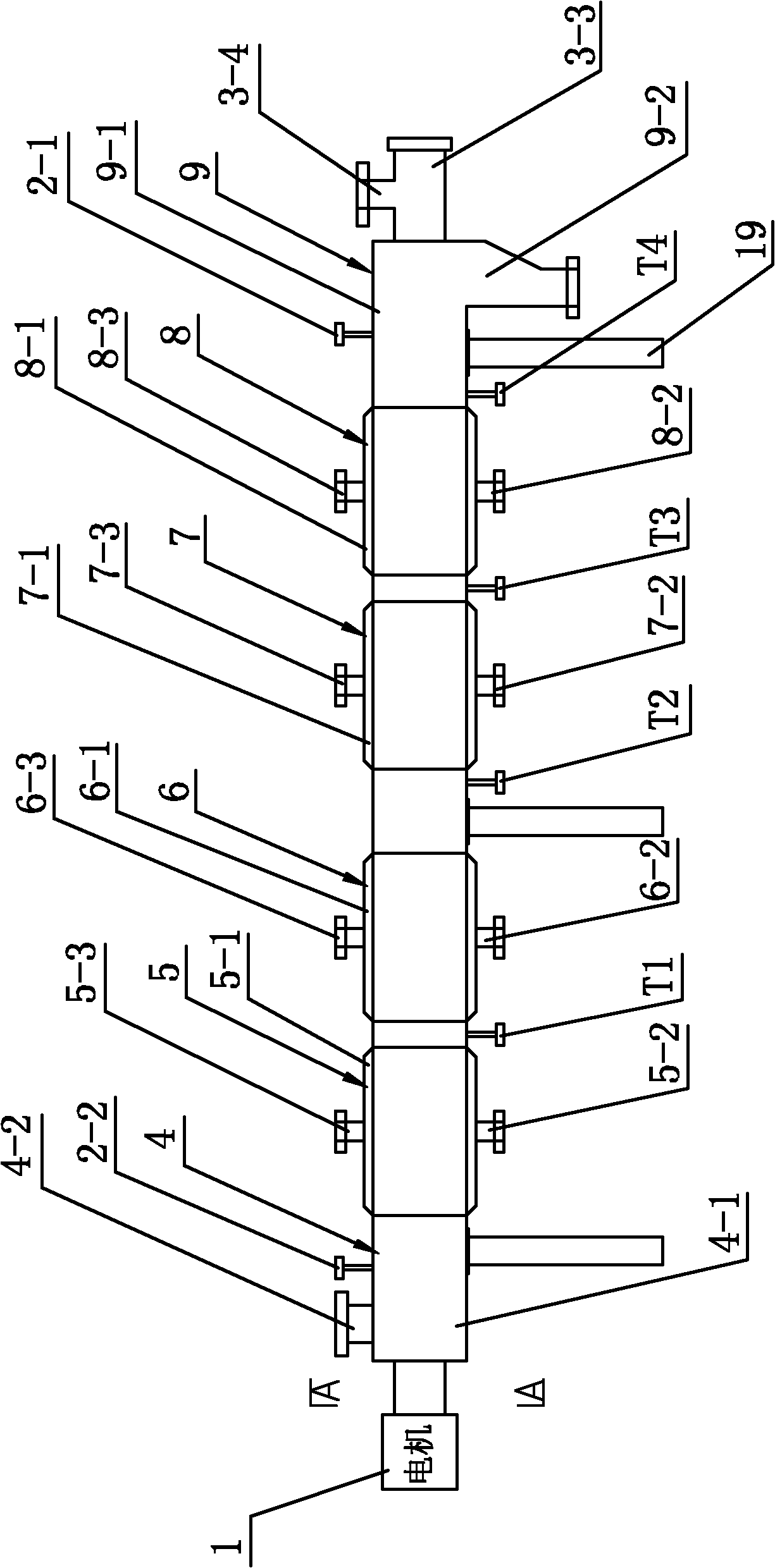

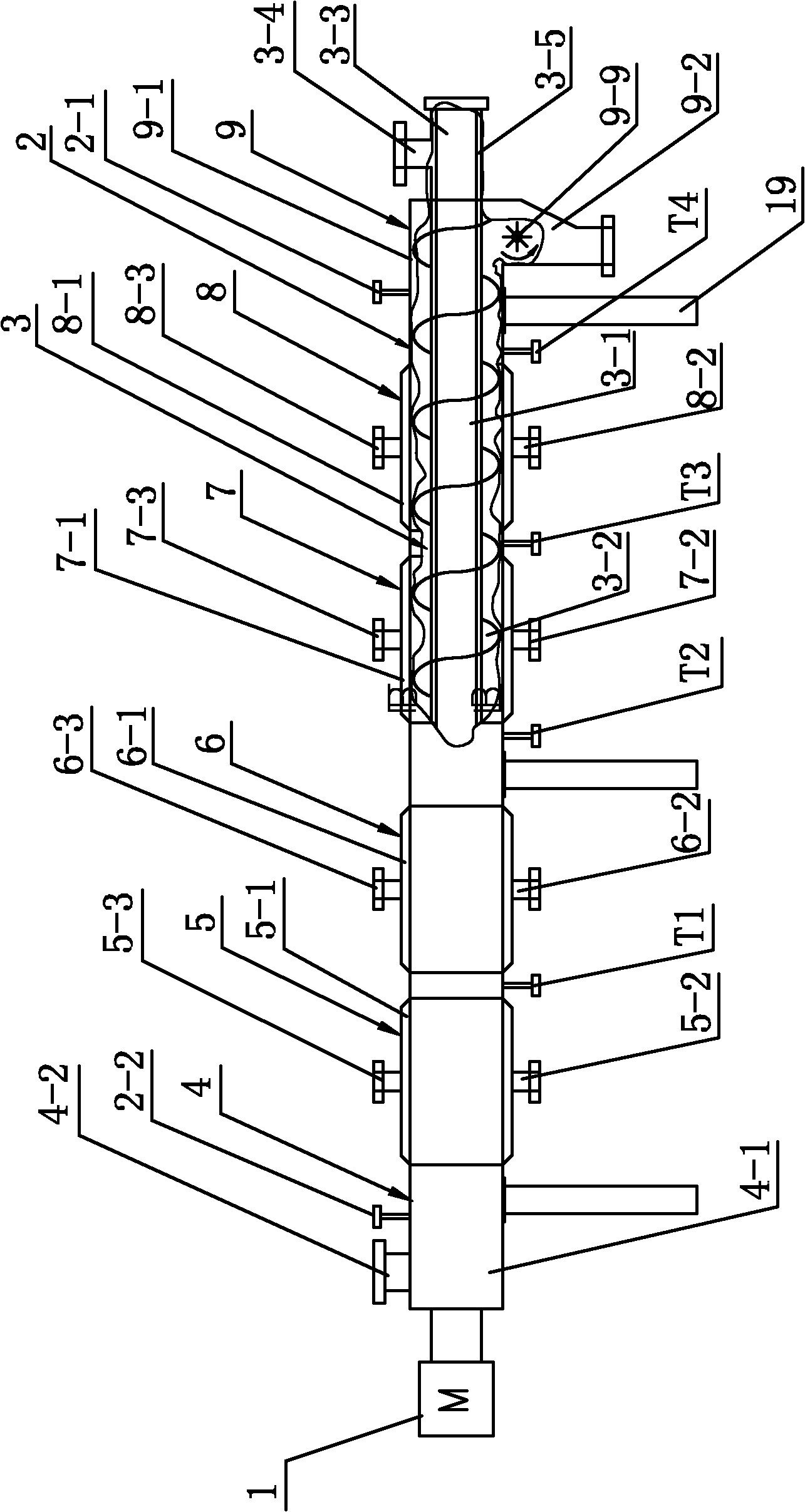

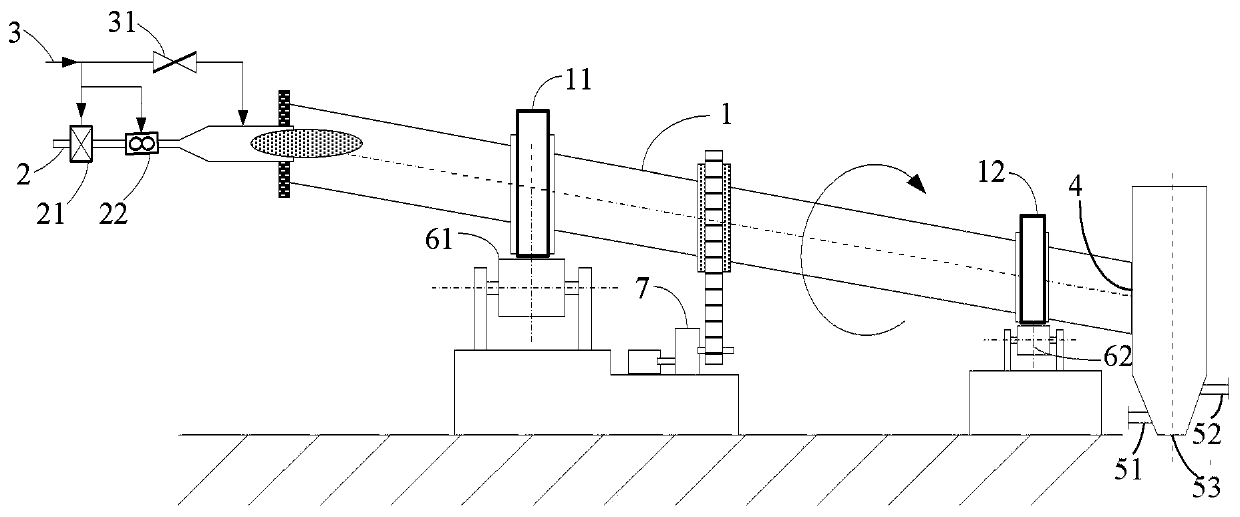

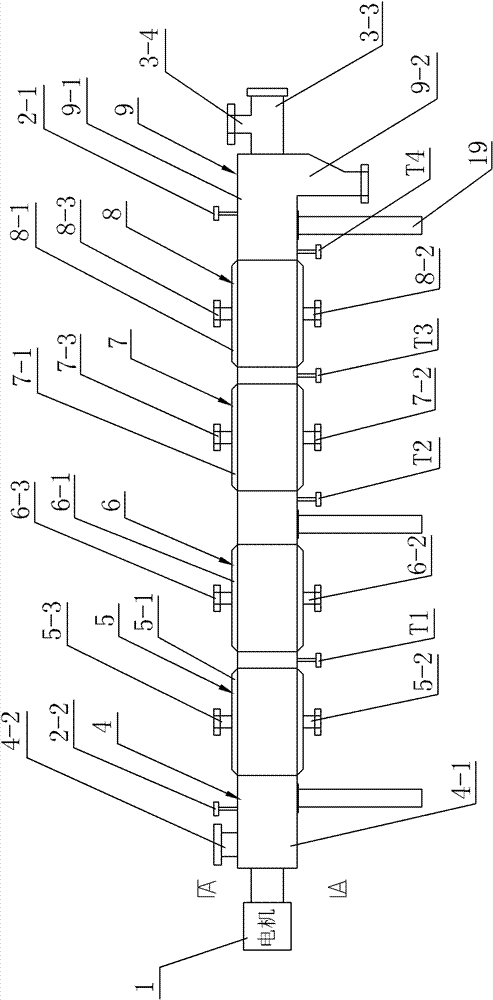

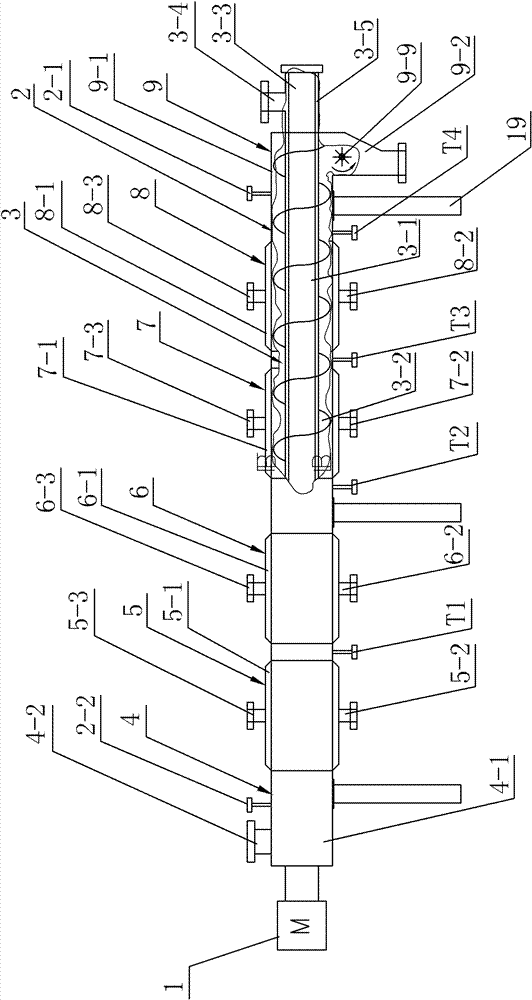

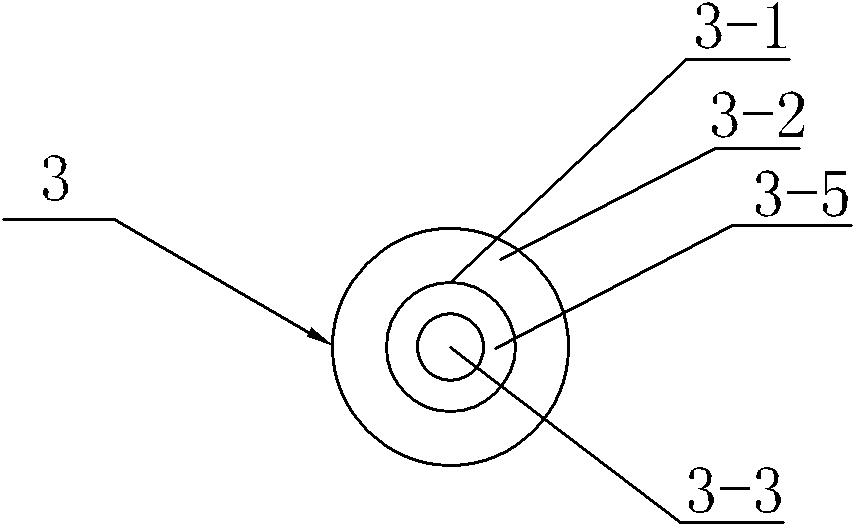

Magnesium-silicide spiral cooling device

InactiveCN101928007AAchieve continuous coolingEnables continuous synthesisMetal silicidesSpiral bladePropeller

The invention discloses a magnesium-silicide spiral cooling device. The magnesium-silicide spiral cooling device comprises a motor, a cooler and a spiral propeller arranged in the cooler, wherein the spiral propeller mainly comprises a hollow shaft and spiral blades arranged on the hollow shaft; a cooling water introduction pipe is arranged in the hollow shaft; a cooling water return channel is formed in a gap between the inner wall of the hollow shaft and the outer wall of the cooling water introduction pipe; the first end of the cooling water return channel is connected with a cooling waterdelivery pipe; and a front end cylinder, a multi-level cooling water jacket and a tail end cylinder are arranged outside the cooler from the second end to the first end of the cooler in turn. The magnesium-silicide spiral cooling device has the advantages that: due to the combination of the spiral propeller and the cooler, continuous cooling of high-temperature magnesium silicide powder can be realized, and continuous synthesis of magnesium silicide is facilitated; and the high-temperature magnesium silicide powder moves forward with the turnover of the spiral propeller, and therefore the heat transfer is enhanced, the cooling of the magnesium silicide powder is uniform, the cooling rate is stable and a mild expansion condition is provided so as to ensure the reaction activity of the magnesium silicide and prevent the cooled magnesium silicide from caking.

Owner:SEDIN NINGBO ENG +1

Method for preparing 3-aminopropionitrile from waste liquid containing 3,3-iminodipropionitrile

InactiveCN112679382AHigh yieldAchieve reuseOrganic compound preparationCarboxylic acid nitrile purification/separationAminopropionitrileDistillation

The invention provides a method for preparing 3-aminopropionitrile from a waste liquid containing 3,3-iminodipropionitrile, wherein the method comprises the following steps: respectively introducing the waste liquid containing 3,3-iminodipropionitrile and an ammonia water solution into a micro-channel reactor to react, to obtain a reaction feed liquid; and carrying out deamination and distillation on the reaction feed liquid to obtain 3-aminopropionitrile. Firstly, the treatment method for preparing the 3-aminopropionitrile from the 3,3-iminodipropionitrile in the 3,3-iminodipropionitrile waste liquid can effectively realize reutilization of resources, and the yield of the 3-aminopropionitrile is relatively high; and secondly, the micro-channel reactor is adopted to strengthen mass and heat transfer in the reaction process, improve the reaction efficiency and realize continuous synthesis of the process, so that the high-temperature residence time can be shortened, the whole process is easy to control, the reutilization of beta-aminopropionitrile byproducts is improved favourably, and the consumption is reduced.

Owner:HANGZHOU XINFU TECH CO LTD

Synthesis method of low-carbon-chain perfluoroalkyl iodine

ActiveCN107602338AEnables continuous synthesisSimple processHalogenated hydrocarbon preparationTetrafluoroethyleneSynthesis methods

The invention discloses a synthesis method of low-carbon-chain perfluoroalkyl iodine. The synthesis method includes the steps of: continuously feeding pentafluoroethane, iodine vapor, tetrafluoroethylene and a fluorine / nitrogen gas mixture together into a tubular reactor to perform a reaction to produce a gas mixture; and alkaline-washing, drying and separating the gas mixture to prepare a mixtureof various perfluoroalkyl iodine products. In the method, molar ratio of the pentafluoroethane to the iodine vapor is 1:1-2; the molar ratio of the pentafluoroethane to the tetrafluoroethylene is 1:5-20; the molar ratio of the pentafluoroethane to the fluorine gas in the fluorine / nitrogen gas mixture is 1:0.001-1:0.01. Reaction temperature is 250-380 DEG C and reaction retention time is 1-15 s. The method has simple processes and high efficiency, is safe and controllable, and has good product component distribution.

Owner:JUHUA GROUP TECH CENT

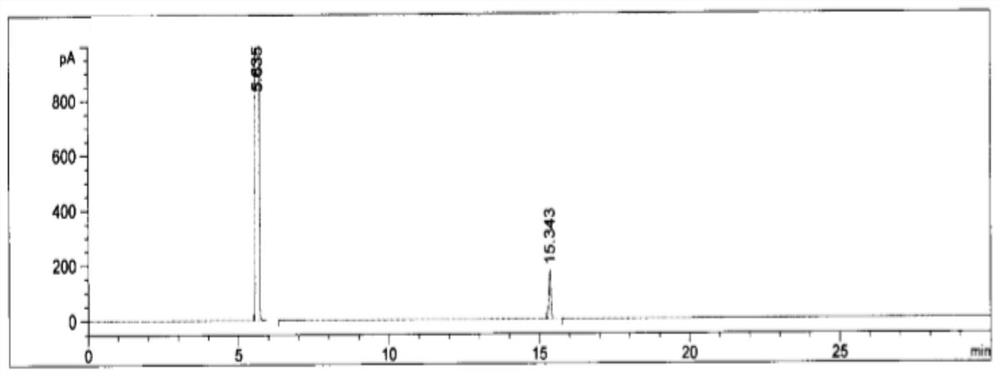

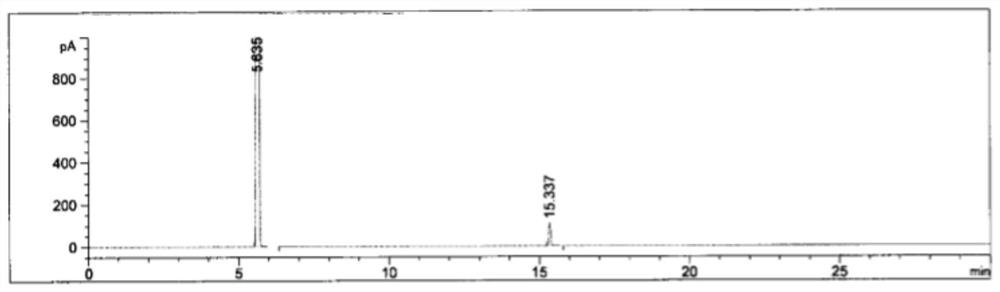

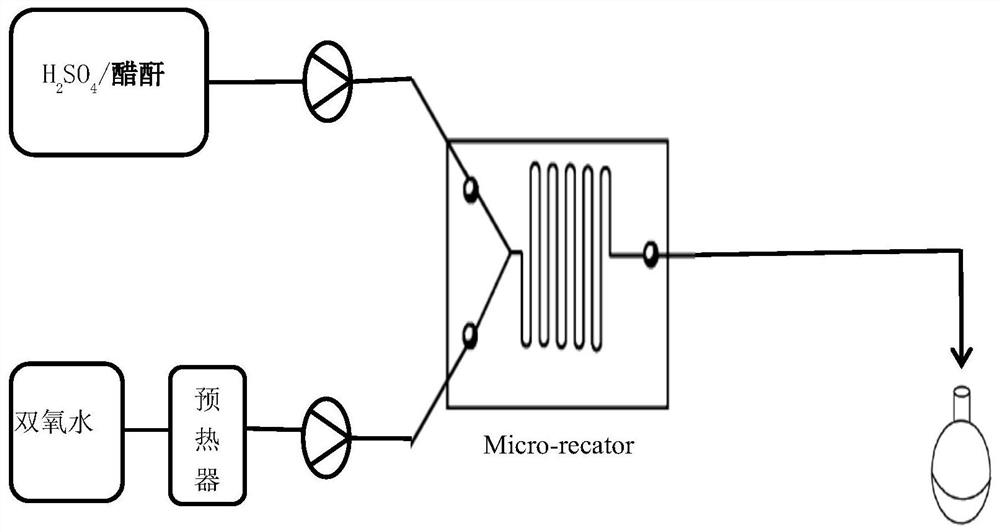

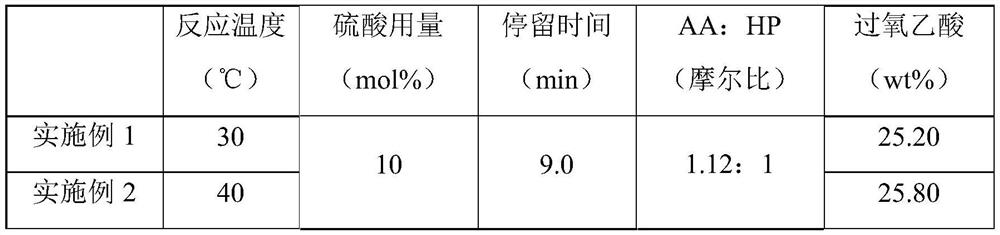

Method for continuously synthesizing peracetic acid by using microreactor

PendingCN114716358AImprove mixing efficiencyEfficient mass and heat transferOrganic compound preparationChemical industryAcetic anhydrideSulfuric acid

The invention provides a method for continuously synthesizing peracetic acid by using a microreactor. According to the method, acetic anhydride (AA) is used as a raw material, concentrated sulfuric acid is used as a catalyst, and hydrogen peroxide (HP) is oxidized in a microreactor to generate peracetic acid (PAA). The concentration of the hydrogen peroxide is 30-50wt%, the molar ratio of the acetic anhydride to the hydrogen peroxide is (1-1.2): 1, the dosage of the catalyst concentrated sulfuric acid is 5-15mol%, the retention time is 3-20 minutes, and the reaction temperature is 30-80 DEG C. The method comprises the following steps: fully mixing acetic anhydride and concentrated sulfuric acid, mixing with hydrogen peroxide preheated by a micro preheater in a micro reactor to initiate a reaction, controlling the reaction temperature through a heat exchanger, and controlling the concentration of generated peracetic acid to be 21-35wt%. According to the invention, continuous preparation of peracetic acid is realized by adopting the microreactor, the process flow is simplified, the reaction period is short, the reaction is easy to control, peracetic acid can be rapidly and conveniently obtained when the device is used and opened, and the safety of the preparation process is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

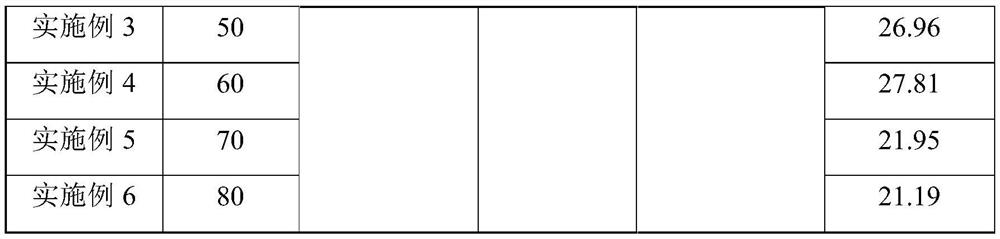

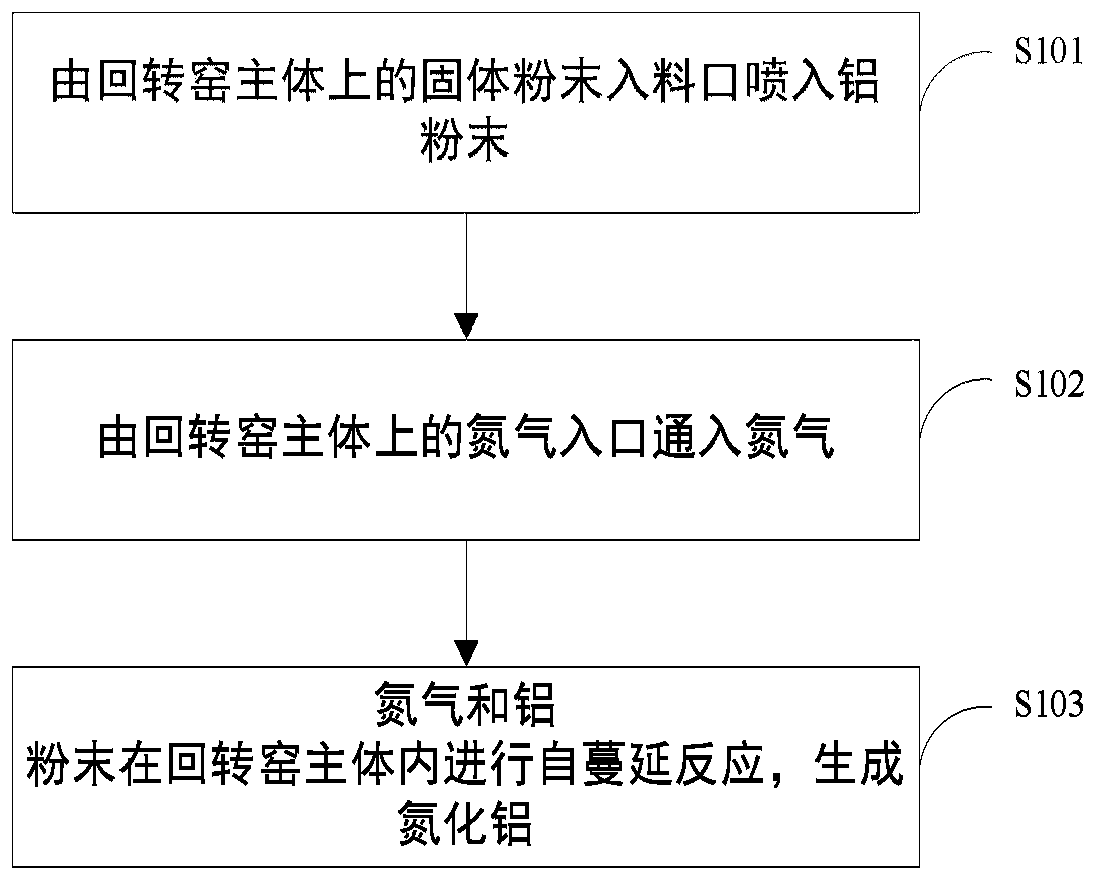

Method for synthesizing aluminum nitride by rotary kiln method

The invention discloses a method for synthesizing aluminum nitride by a rotary kiln method. The method comprises: spraying aluminum powder from a solid powder inlet of a rotary kiln main body; introducing nitrogen from a nitrogen inlet of the rotary kiln main body; and carrying out a self-propagating reaction of nitrogen and aluminum powder in the rotary kiln main body to form the nitride. The method for synthesizing aluminum nitride by the rotary kiln method can realize massive and continuous synthesis of aluminum nitride.

Owner:宁夏时星科技有限公司

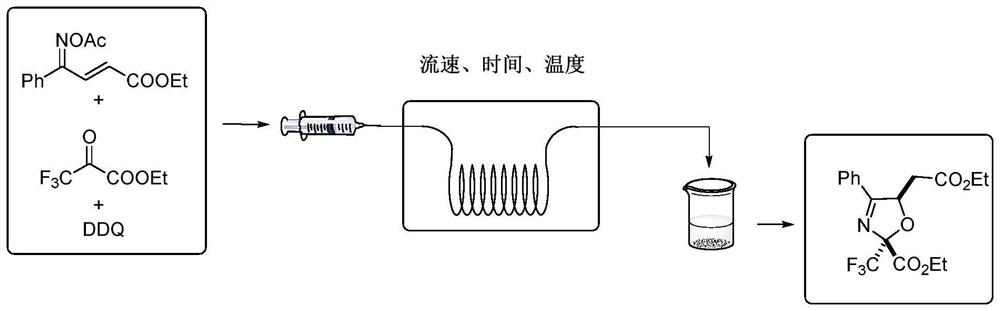

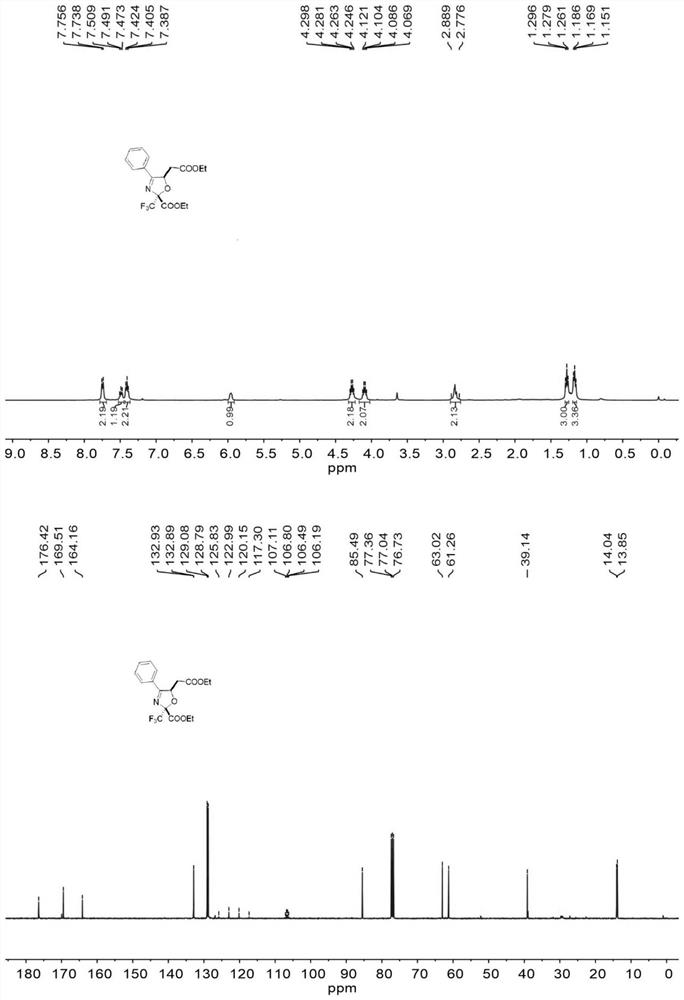

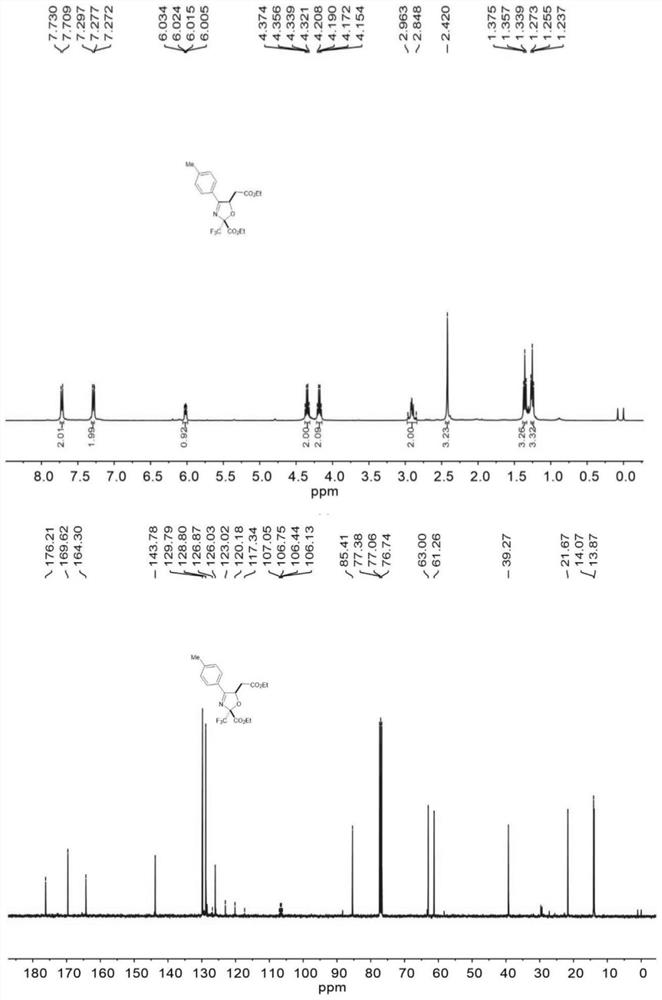

Synthesis method of dihydrooxazole compound

PendingCN114524777AAvoid multi-step reactionsAvoid reactionOrganic chemistryChemical/physical/physico-chemical microreactorsFuranCombinatorial chemistry

The invention discloses a synthesis method of a dihydrooxazole compound shown as III, which comprises the following steps: taking an alpha, beta-unsaturated ketoxime ester compound I and ethyl trifluoropyruvate II as reaction raw materials, adding dichloro dicyanobenzoquinone, and continuously reacting by using a microchannel reaction device to prepare the dihydrooxazole compound. Compared with the prior art, the method has the advantages that the alpha, beta-unsaturated ketoxime ester compound and the ethyl trifluoropyruvate are used as substrates to prepare the novel dihydrooxazole compound, multi-component reaction is avoided, and the product is rapidly and efficiently synthesized. In the formula (I), R1 is selected from non-substituted or substituted phenyl, halogen, C1-C5 alkyl, C1-C5 alkoxy, furyl, naphthyl or C1-C5 alkyl; r2 is selected from C1-C5 ester groups; the substituted phenyl group is selected from phenyl groups substituted by halogen, C1-C5 alkyl groups or C1-C5 alkoxy groups.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

Method for Synthesizing Aluminum Nitride by Rotary Kiln Method

The invention discloses a method for synthesizing aluminum nitride by a rotary kiln method. The method comprises: spraying aluminum powder from a solid powder inlet of a rotary kiln main body; introducing nitrogen from a nitrogen inlet of the rotary kiln main body; and carrying out a self-propagating reaction of nitrogen and aluminum powder in the rotary kiln main body to form the nitride. The method for synthesizing aluminum nitride by the rotary kiln method can realize massive and continuous synthesis of aluminum nitride.

Owner:宁夏时星科技有限公司

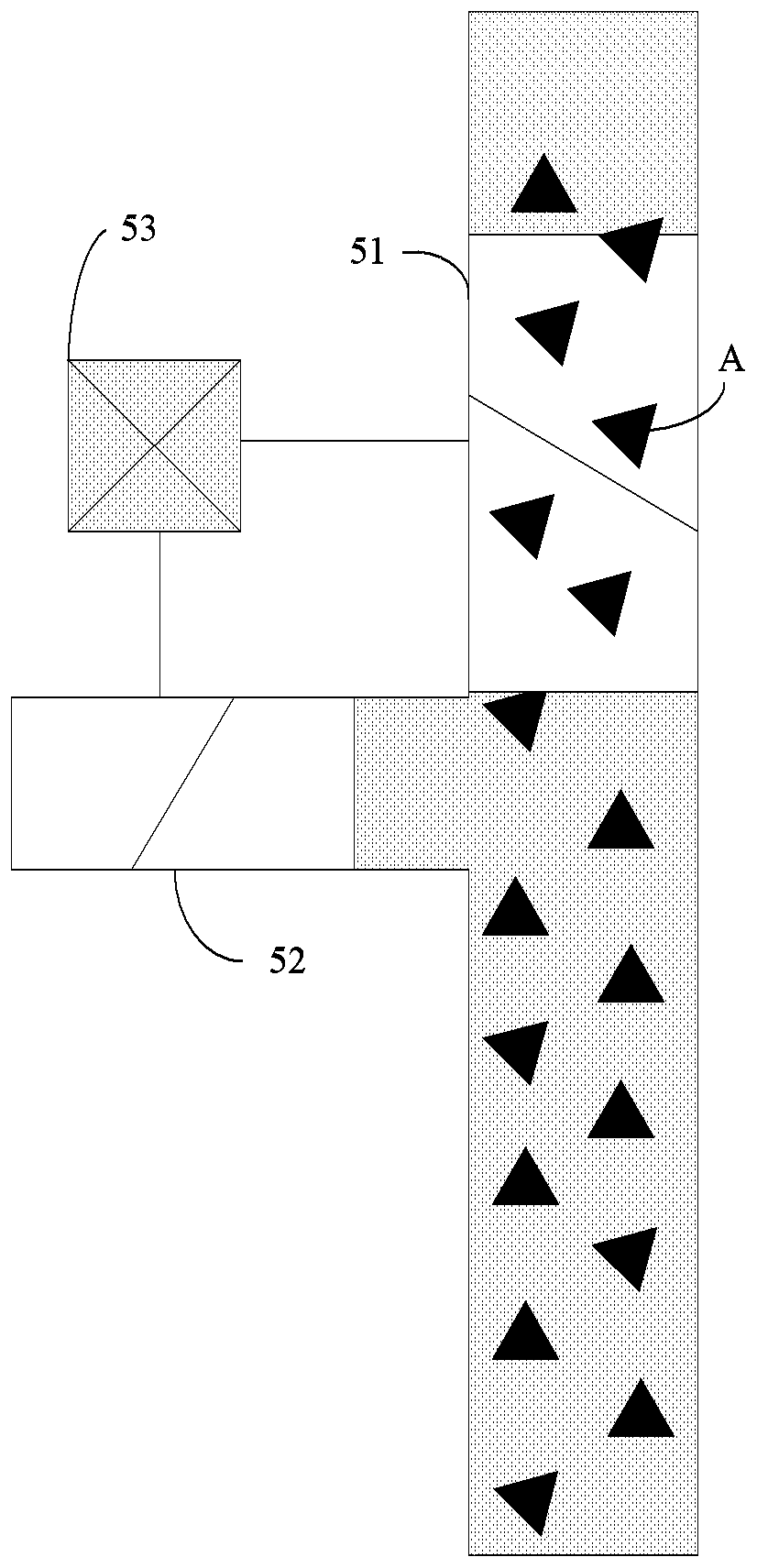

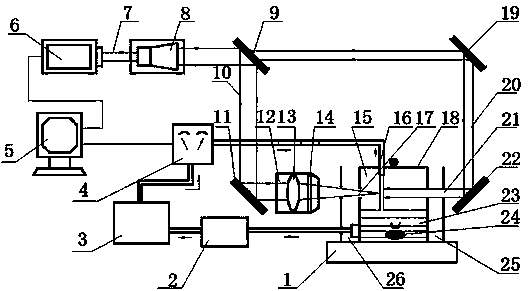

A kind of method and device for improving the synthesis efficiency of nano-diamond

InactiveCN106082206BEnables continuous synthesisGood dispersionDiamondNanotechnologyDispersityBeam splitter

The invention relates to a method and device for improving the synthesis efficiency of nano-diamond. The device comprises a laser generation system, a workpiece system and an auxiliary system. The spot diameter of a laser emitted by a high-powder pulse laser device is enlarged by a beam expanding mirror, two laser beams are generated after the laser is reflected and split by a beam splitter, the first laser beam passes through a focusing lens to irradiate a circularly flowing graphite water column through a light entrance, the second laser beam irradiates the graphite water column through another light entrance, graphite particles in a solution absorb laser energy and then quickly form high-temperature high-pressure plasmas, and the nanoscale diamond is generated in the extremely-short and nonequilibrium process. According to the method and device, the problems that in the nano-diamond synthesis process, the laser acting area is small, and the synthesis efficiency is low are solved, continuous synthesis at normal temperature under normal pressure is achieved, and the nano-diamond particles with good dispersity and uniform size distribution are obtained.

Owner:JIANGSU UNIV

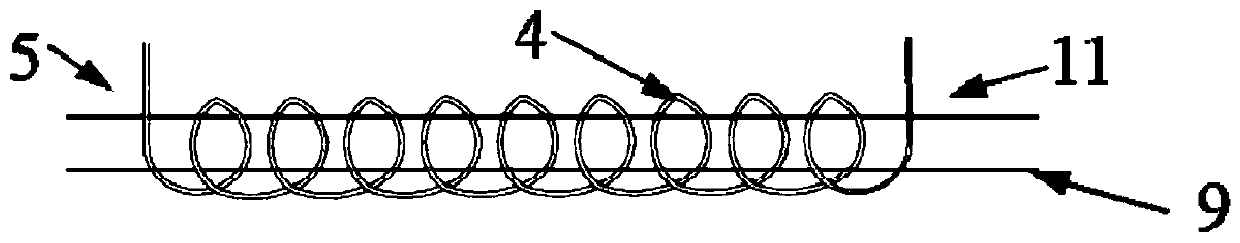

Device and method for rapidly and continuously synthesizing multi-morphology cesium lead halide cluster perovskite quantum dots

ActiveCN107474833BDifferent temperature can be controlledStable at different temperaturesLuminescent compositionsFluorescenceCapillary Tubing

The invention relates to a device and a method for rapidly and continuously synthesizing multi-morphology Cs-Pb halo-cluster perovskite quantum dots. The device is characterized in that a Cs precursor injector and a lead halide precursor injector are connected to two first annular microchannels arranged in a constant-temperature oil bath through polytetrafluoroethylene connecting tubes respectively, and the two annular microchannels are connected with a micromixer arranged on a heating magnetic stirrer and then sequentially connected with a second annular microchannel and a liquid collector through the polytetrafluoroethylene connecting tubes. The polytetrafluoroethylene capillary tubes are adopted as the microchannels, stable reaction temperature and precise reaction time are provided for a reaction, the prepared perovskite quantum dots are uniform in size and have three different morphologies including spherical, rod-like and cubic morphologies, and meanwhile, the perovskite quantum dots with the fluorescence spectrum range being 395-700 nm can be synthesized rapidly by changing types and ratio of halogen elements and the reaction temperature.

Owner:EAST CHINA UNIV OF SCI & TECH

A method for synthesizing gamma-butyrolactone containing spirocyclic 1,3-indanedione structure using microchannel reaction device

ActiveCN111233884BImprove catalytic performanceHigh yieldOrganic chemistryChemical/physical/physico-chemical microreactorsMicroreactorMalonic acid

The invention discloses a method for synthesizing γ-butyrolactone containing a spirocyclic 1,3-indanedione structure by using a microchannel reaction device, which comprises the following steps: (1) 2-benzylidene-1,3 Indanediones and cyclo(sub)isopropyl malonate are dissolved in an organic solvent to make a homogeneous solution A; (2) catalysts and oxidants are dissolved in an organic solvent to make a homogeneous solution B; (3) The homogeneous solution A and the homogeneous solution B are respectively simultaneously pumped into the micro-mixer in the microchannel reaction device, and after mixing, they are passed into the micro-reactor for reaction; (4) the effluent of the micro-reactor is collected to obtain final product. Compared with the prior art, the present invention uses 2-benzylidene-1,3-indandione compounds as substrates for the first time to prepare new gamma-butyrolactone containing spiro ring 1,3-indandione structure, The method avoids the use of acidic raw materials and expensive metals, and the non-metallic catalyst used also has excellent catalytic performance.

Owner:NANJING TECH UNIV

Treatment method of β-alanine by-product

ActiveCN108383743BEnables continuous synthesisAvoid decompositionOrganic compound preparationAmino-carboxyl compound preparationPropanoic acidBiochemical engineering

The invention belongs to the technical field of chemistry, and particularly relates to a treatment method of β-alanine by-products; first, the production waste liquid and ammonia water containing 3,3-iminodipropionate sodium are passed into a microchannel reactor respectively, and the Continuous reaction at 180-210°C for 10-30 minutes, followed by deamination, dehydration and drying treatment to obtain sodium β-alanine; the method provided by the invention has low treatment cost and high resource utilization rate.

Owner:ANHUI ANLITAI BIOTECH CO LTD

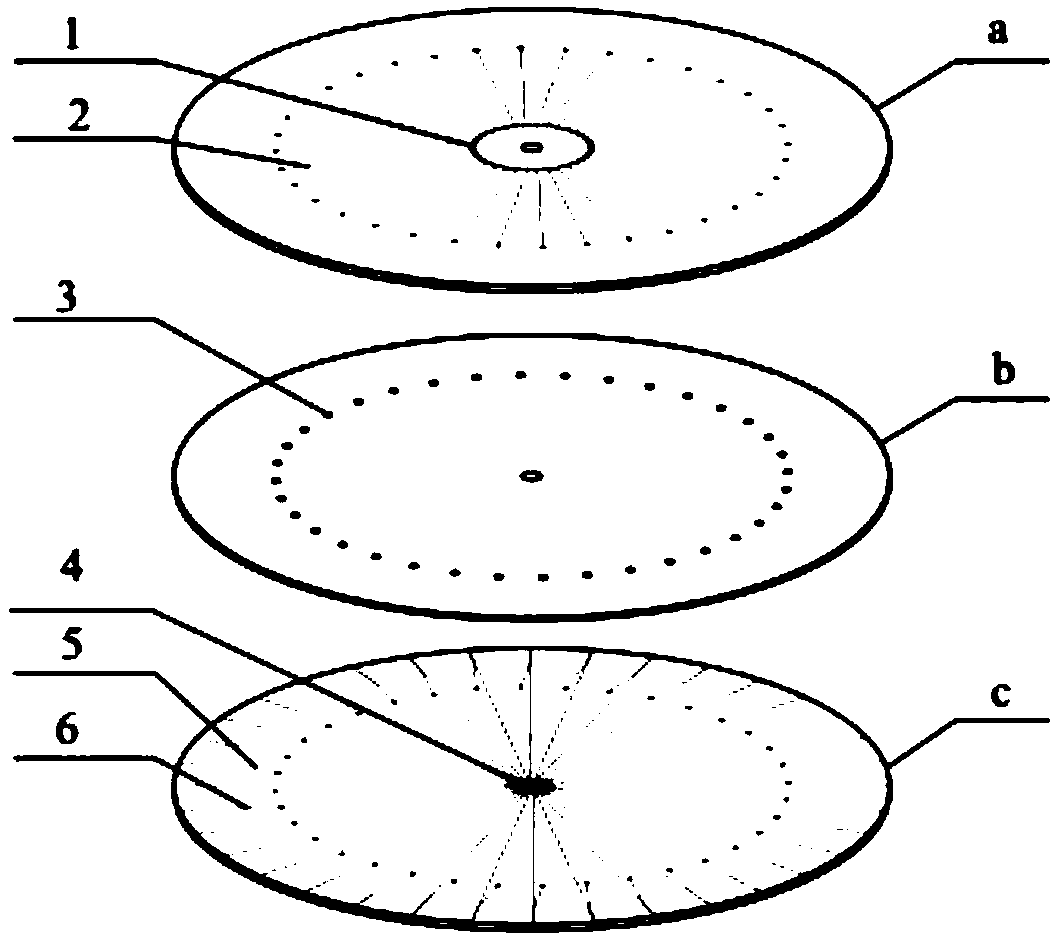

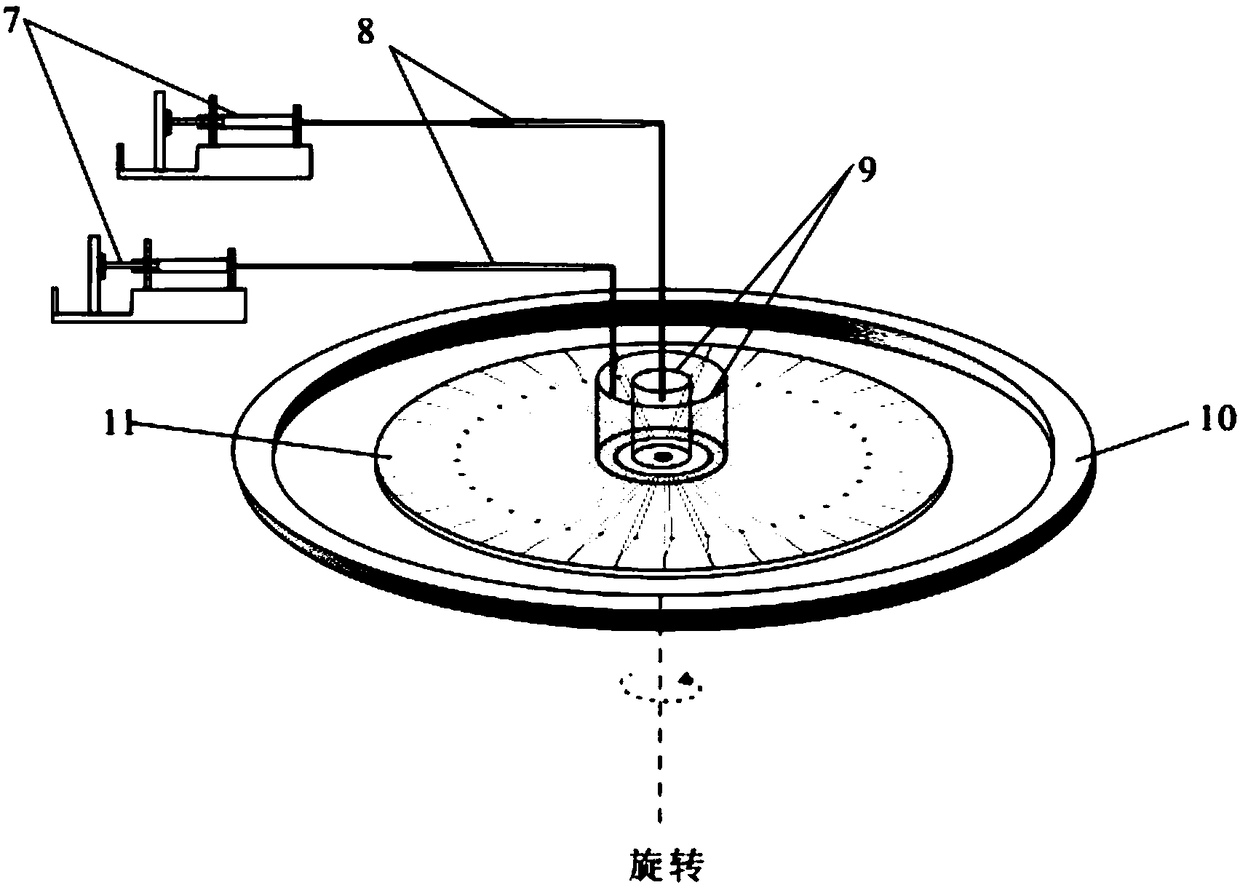

A centrifugal microfluidic chip and a method for continuously synthesizing janus particles

ActiveCN106311107BEnables continuous synthesisHigh synthetic yieldChemical/physical/physico-chemical microreactorsJanus particlesCentrifugation

A centrifugal microfluidic chip and a method for continuously synthesizing Janus particles; the chip is composed of an upper substrate, a middle substrate and a lower substrate; the upper substrate is provided with an upper central circular hole, an annular liquid pool, and several upper layers The dispersed circular channels are connected with several first-level straight channels; the middle layer substrate is provided with a central circular hole in the middle layer; the lower substrate is provided with a central liquid pool, a lower dispersed circular channel, several second-level straight channels and several third-level straight channels. Straight channel; Method: 1) Fix the centrifugal microfluidic chip on the suction cup of the glue homogenizer; 2) Inject different test solutions into the central liquid pool and the annular liquid tank; open the glue homogenizer and rotate and centrifuge to form a biphasic phase at the outlet of the channel liquid droplets; 3) biphasic liquid droplets are thrown into an external annular liquid pool to form Janus particles; the method of the invention ensures the continuous introduction of test liquids and realizes the continuous synthesis of biphasic particles; the array synthesis channel, high-speed rotation drive liquid and continuous Synthesis, improve the synthesis rate of Janus particles.

Owner:NORTHEASTERN UNIV LIAONING

Method for Synthesizing Silicon Nitride by Rotary Kiln Method

The invention discloses a method for synthesizing silicon nitride by a rotary kiln process. The method comprises the steps: spraying siliceous powder from a solid powder charging opening in a rotary kiln main body; introducing nitrogen gas from a nitrogen gas inlet in the rotary kiln main body; and subjecting the nitrogen gas and the siliceous powder to a self-propagation reaction in the rotary kiln main body, thereby producing the silicon nitride. According to the method for synthesizing the silicon nitride by the rotary kiln process, disclosed by the invention, the mass continuous synthesisof the silicon nitride can be achieved.

Owner:宁夏时星科技有限公司

A continuous synthesis method of graphene/ferrite nanocomposites

InactiveCN105199667BImprove absorbing performanceGood dispersionOther chemical processesNickel saltHigh volume manufacturing

The invention discloses a continuous synthesis method of a graphene / ferrite nanocomposite. According to the synthesis method, the graphene / ferrite nanocomposite is prepared by taking graphene, sodium hydroxide aqueous solution and ferric salt solution or ferric salt solution doped with nickel salt and zinc salt and adopting a reverse co-precipitation method. By adopting the synthesis method, continuous synthesis of the nanocomposite is realized by continuous material injection and continuous magnetic separation and output of products, obtained ferrite and graphene are mixed evenly and are combined firmly, and an excellent absorbing property is achieved. Therefore the synthesis method has the advantages of continuous synthesis capability, low synthesis temperature, low energy consumption, low cost and quantity production capability, and has better application prospect.

Owner:李同乐 +2

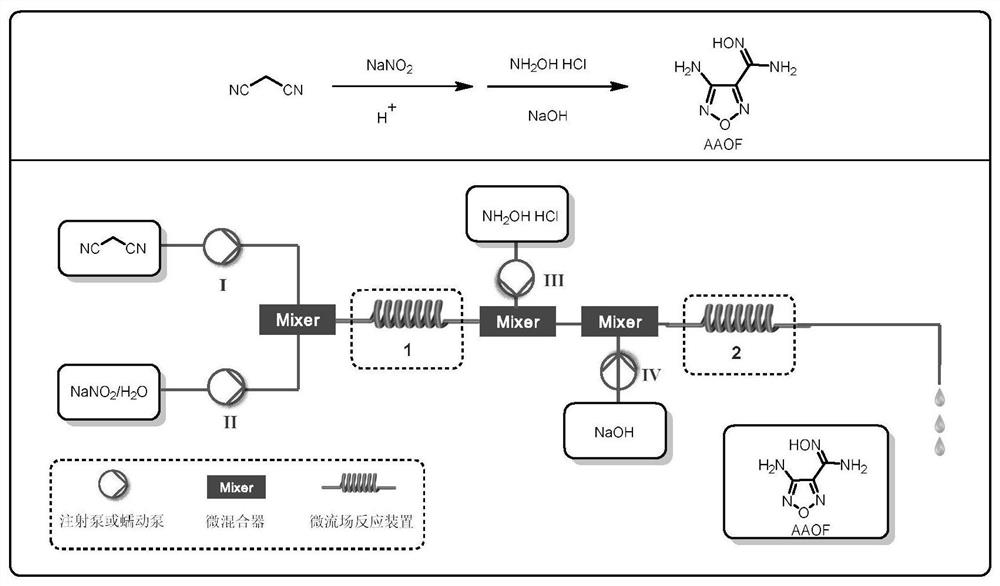

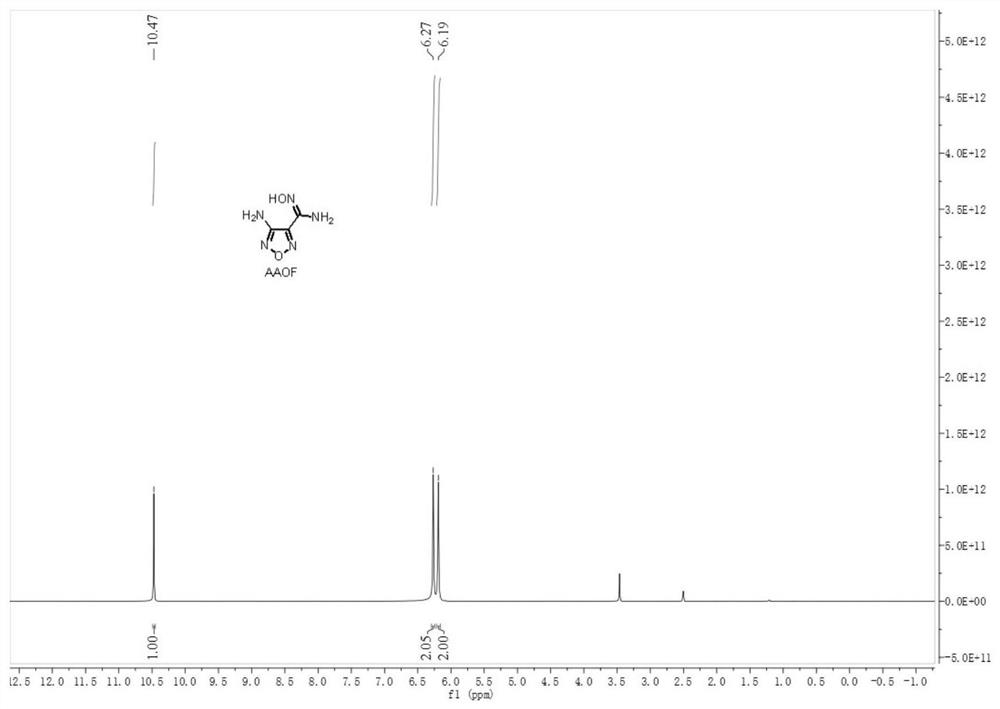

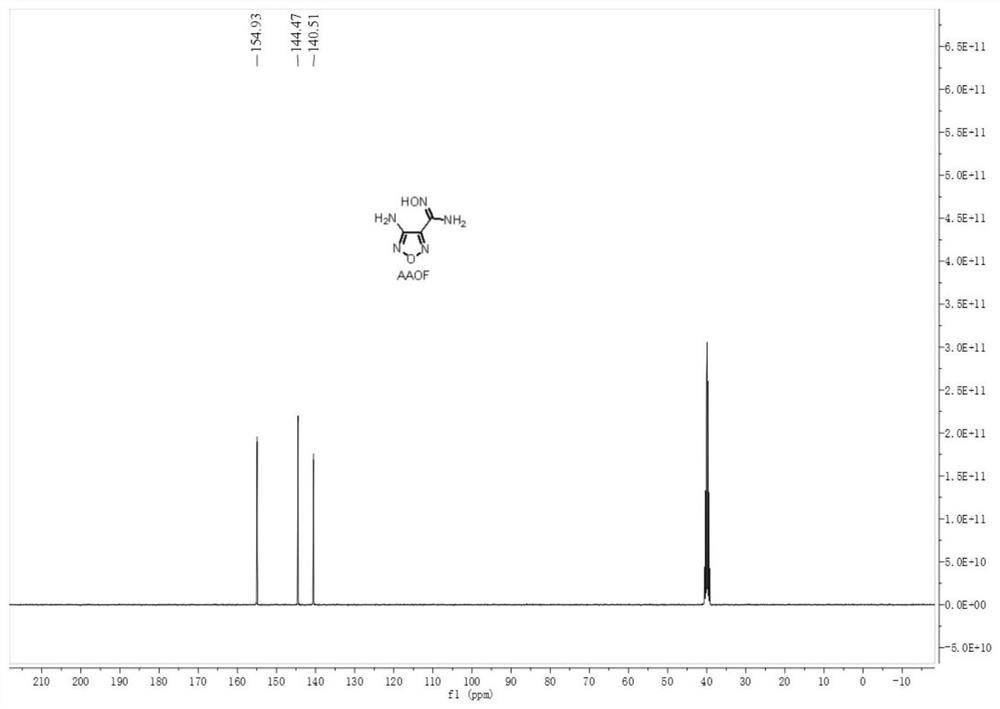

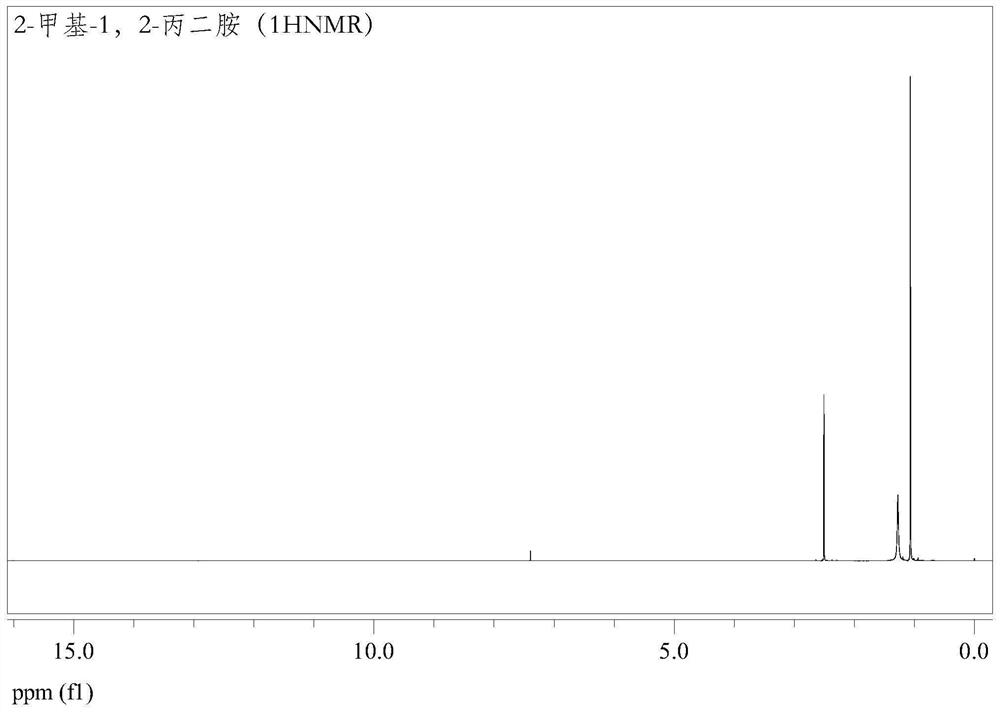

Method for preparing 3-amino-4-amidoxime furazan by using micro-flow field reaction technology

ActiveCN112341403AEnables continuous synthesisAvoid separation stepsOrganic chemistryChemical/physical/physico-chemical microreactorsFurazanHydroxylamine

The invention discloses a method for preparing 3-amino-4-amidoxime furazan by using a micro-flow field reaction technology. The method comprises the following steps: (1) respectively pumping a malononitrile solution and a sodium nitrite aqueous solution into a first micro-mixer in a micro-flow field reaction device at the same time, mixing, and introducing into a first module to carry out a firstreaction; (2) while the step (1) is carried out, respectively and simultaneously pumping the hydroxylamine hydrochloride aqueous solution and the effluent of the first module into a second micro-mixerin the micro-flow field reaction device for mixing; and (3) while the step (2) is carried out, respectively pumping the sodium hydroxide aqueous solution and the effluent of the second micro-mixer into a third micro-mixer in the micro-flow field reaction device at the same time, mixing, and introducing into a second module to carry out a second reaction, thereby obtaining the reaction liquid containing the 3-amino-4-amidoxime furazan. The problems that a traditional feeding process is tedious, the reaction time is long, and ice bath energy consumption is high are solved.

Owner:NANJING UNIV OF TECH

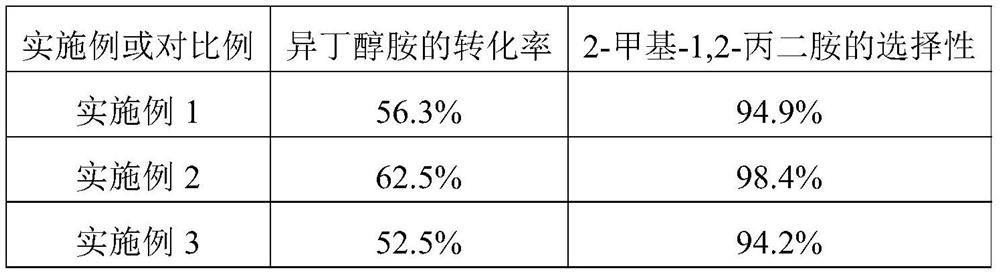

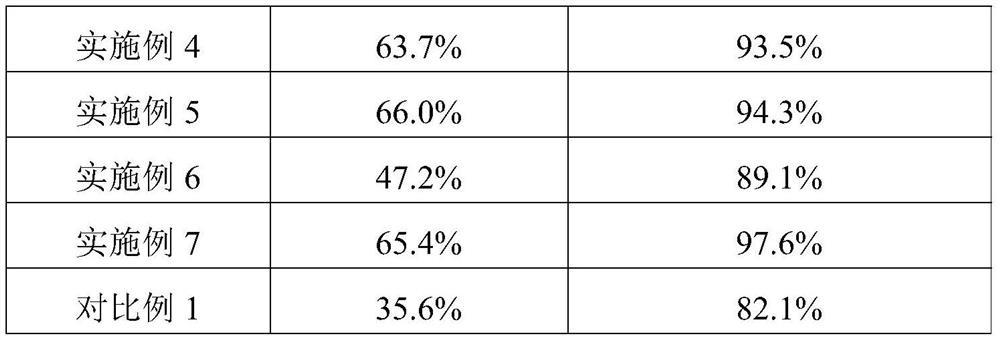

Active metal-modified oxide catalyst, preparation method and application thereof

PendingCN114700102AHigh synthesis efficiencyGood stabilityOrganic compound preparationHeterogenous catalyst chemical elementsDiamineChemistry

The invention provides an active metal-modified oxide catalyst as well as a preparation method and application thereof, and the active metal-modified oxide catalyst comprises active metal, a first auxiliary agent, a second auxiliary agent and a modified oxide load, the preparation method of the active metal-modified oxide catalyst comprises the four steps of oxide loading modification, magnesium nitrate treatment, catalyst material preparation and active metal-modified oxide catalyst preparation, and the finally prepared active metal-modified oxide catalyst can be used as a catalyst for 2-methyl-1, 3, 4-trimethyl-1, 3-pentanediol monoisobutyrate. The catalyst is used in 1, 2-propane diamine synthesis reaction. The active metal-modified oxide catalyst disclosed by the invention is good in stability and excellent in catalytic performance, and the conversion rate of reaction raw materials and the high selectivity of products can be improved by applying the catalyst to a synthetic reaction of 2-methyl-1, 2-propane diamine, namely the synthetic efficiency of 2-methyl-1, 2-propane diamine can be improved.

Owner:XIAN MODERN CHEM RES INST

Preparation method of subsidence self-propagating aluminum nitride

ActiveCN110204342BEnables continuous synthesisNo leaksNitrogen compoundsChemical industryAluminium powderNitrogen gas

The invention relates to a sedimentation type self-propagating aluminum nitride preparation method. The method comprises the steps of introducing aluminum powder into a sedimentation type reactor furnace body from a solid material inlet; introducing nitrogen into the furnace body through a gas inlet; triggering a self-propagating reaction between the aluminum powder and the nitrogen in the furnacebody in order to generate aluminum nitride; settling the aluminum nitride to the bottom of the furnace body and then discharging the aluminum nitride through a discharge hole. The sedimentation typeself-propagating aluminum nitride synthesis method can realize the continuous synthesis of aluminum nitride and is particularly efficient and capable of saving energy for the preparation of aluminum nitride.

Owner:宁夏时星科技有限公司

Magnesium-silicide spiral cooling device

InactiveCN101928007BAchieve continuous coolingEnables continuous synthesisMetal silicidesSpiral bladePropeller

The invention discloses a magnesium-silicide spiral cooling device. The magnesium-silicide spiral cooling device comprises a motor, a cooler and a spiral propeller arranged in the cooler, wherein the spiral propeller mainly comprises a hollow shaft and spiral blades arranged on the hollow shaft; a cooling water introduction pipe is arranged in the hollow shaft; a cooling water return channel is formed in a gap between the inner wall of the hollow shaft and the outer wall of the cooling water introduction pipe; the first end of the cooling water return channel is connected with a cooling waterdelivery pipe; and a front end cylinder, a multi-level cooling water jacket and a tail end cylinder are arranged outside the cooler from the second end to the first end of the cooler in turn. The magnesium-silicide spiral cooling device has the advantages that: due to the combination of the spiral propeller and the cooler, continuous cooling of high-temperature magnesium silicide powder can be realized, and continuous synthesis of magnesium silicide is facilitated; and the high-temperature magnesium silicide powder moves forward with the turnover of the spiral propeller, and therefore the heat transfer is enhanced, the cooling of the magnesium silicide powder is uniform, the cooling rate is stable and a mild expansion condition is provided so as to ensure the reaction activity of the magnesium silicide and prevent the cooled magnesium silicide from caking.

Owner:SEDIN NINGBO ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com