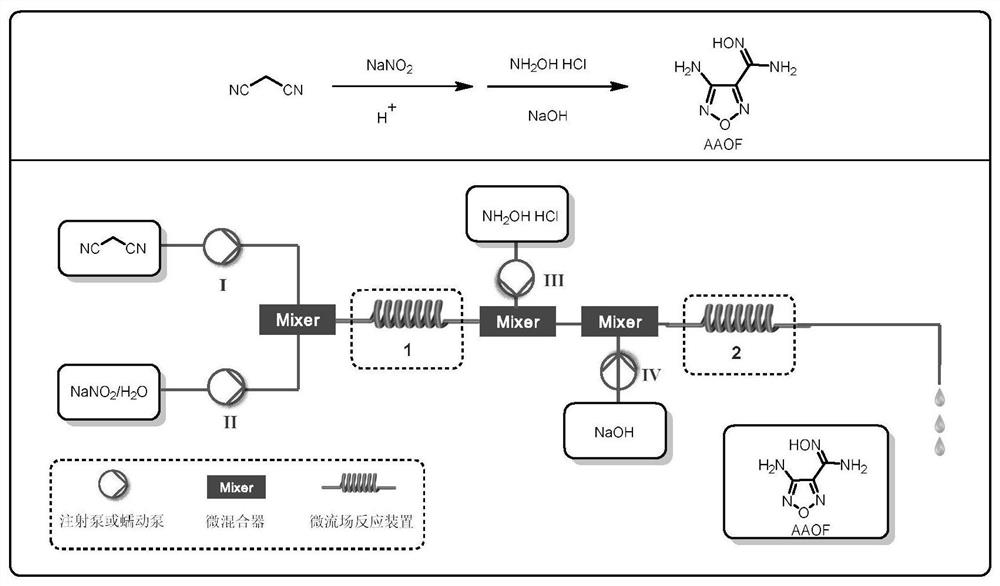

Method for preparing 3-amino-4-amidoxime furazan by using micro-flow field reaction technology

An amidoxime-based and reaction technology, applied in the field of chemical synthesis, can solve the problems of uncontrollable safety, cumbersome operation process, violent reaction, etc., and achieve the effects of good material mixing effect, high reaction conversion rate and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

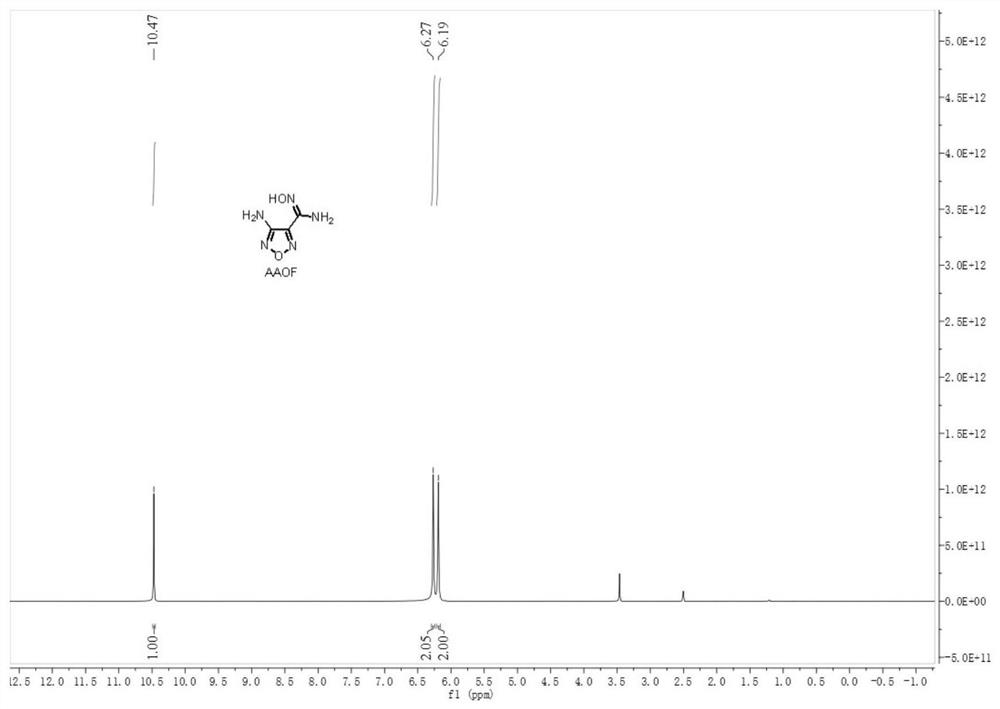

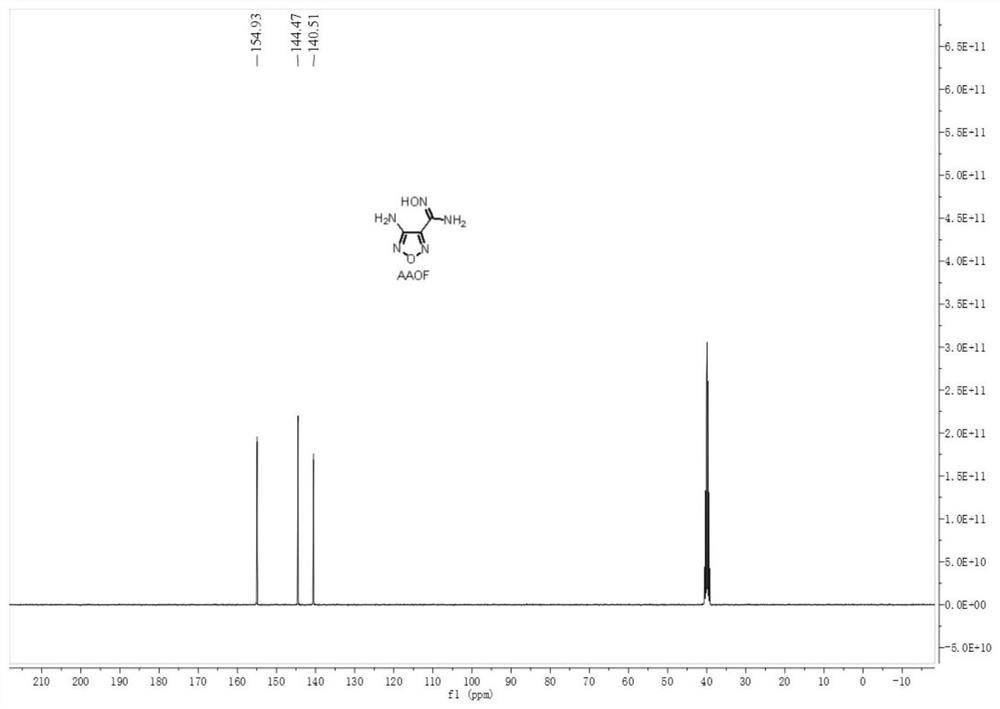

Embodiment 1

[0036] Weigh 1.32g of malononitrile (20mmol, 1.0equiv) and add it to 5% v / v acetic acid aqueous solution to prepare a 20mL solution as material I; weigh 2.76g of NaNO 2(40mmol, 2.0equiv) was added to water to prepare a 10mL solution as material II; 2.76g of hydroxylamine hydrochloride (40mmol, 2.0equiv) was weighed and added to water to prepare a 10mL solution as material III; 1.6mL 25mol / L of sodium hydroxide (40mmol, 2.0equiv) solution, as material IV. Material I and material II are simultaneously transported to the microchannel reactor for mixing, and then transported to the low-temperature module for reaction after mixing. Among them, the flow rate of material I is 5.0mL / min, the flow rate of material II is 2.5mL / min, the inner diameter of the low temperature module microchannel reactor is 1.0mm, the length is 20m, and the volume is 15.7mL. The reaction temperature is 10°C, and the residence time of the reaction is 2.1 min. Then pump in material III and material IV in s...

Embodiment 2

[0038] Weigh 1.32g of malononitrile (20mmol, 1.0equiv) and add it to 5% v / v acetic acid aqueous solution to prepare a 20mL solution as material I; weigh 2.76g of NaNO 2 (40mmol, 2.0equiv) was added to water to prepare a 10mL solution as material II; 2.76g of hydroxylamine hydrochloride (40mmol, 2.0equiv) was weighed and added to water to prepare a 10mL solution as material III; 1.6mL 25mol / L of sodium hydroxide (40mmol, 2.0equiv) solution, as material IV. Material I and material II are simultaneously transported to the microchannel reactor for mixing, and then transported to the low-temperature module for reaction after mixing. Among them, the flow rate of material I is 5.0mL / min, the flow rate of material II is 2.5mL / min, the inner diameter of the low temperature module microchannel reactor is 1.5mm, the length is 20m, and the volume is 35.3mL. The reaction temperature was 10°C, and the residence time of the reaction was 4.7 minutes. Then pump in material III and material ...

Embodiment 3

[0040] Weigh 1.32g of malononitrile (20mmol, 1.0equiv) and add it to 5% v / v acetic acid aqueous solution to prepare a 20mL solution as material I; weigh 2.76g of NaNO 2 (40mmol, 2.0equiv) was added to water to prepare a 10mL solution as material II; 2.76g of hydroxylamine hydrochloride (40mmol, 2.0equiv) was weighed and added to water to prepare a 10mL solution as material III; 1.6mL 25mol / L of sodium hydroxide (40mmol, 2.0equiv) solution, as material IV. Material I and material II are simultaneously transported to the microchannel reactor for mixing, and then transported to the low-temperature module for reaction after mixing. Among them, the flow rate of material I is 5.0mL / min, the flow rate of material II is 2.5mL / min, the inner diameter of the low temperature module microchannel reactor is 0.8mm, the length is 20m, and the volume is 10.0mL. The reaction temperature was 10°C, and the residence time of the reaction was 1.3 minutes. Then pump in material III and material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com