Method for synthesizing 2,4-difluorobenzaldehyde by using micro-channel reactor

A microchannel reactor, the technology of difluorobenzaldehyde, is applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, preparation of organic compounds, etc., and can solve the problems of low production efficiency, harsh reaction conditions and high production costs. problems, to achieve the effect of improving production efficiency and yield, continuous reaction process, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

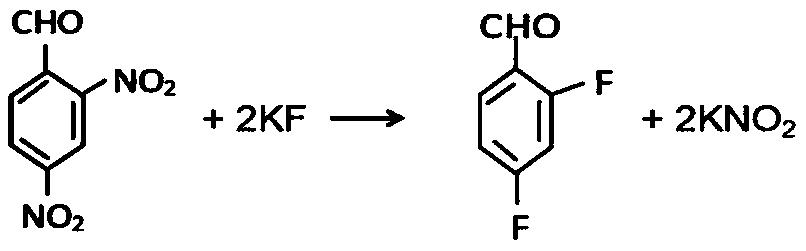

[0031] A method for synthesizing 2,4-difluorobenzaldehyde with a microchannel reactor, comprising the following steps: a certain amount of 2,4-dinitrobenzaldehyde is dissolved in a sulfolane solvent under stirring to form a solution A; A certain amount of potassium fluoride was dissolved in sulfolane under stirring to form solution B; use a peristaltic pump to mix solution A and solution B at a molar ratio of 1:4, and add an appropriate amount of tetramethylammonium bromide as a phase transfer catalyst, inject micro Intense mixing of the two solutions is realized in the channel reactor. After the reaction solution flows out of the microchannel reactor, it is introduced into the purification tank with a catheter, and the mixture of 2,4-difluorobenzaldehyde and sulfolane in the purification tank is rectified and purified. Sulfolane is reused in the system to obtain 2,4-difluorobenzaldehyde fine product with a purity of ≥99%.

[0032] Specifically, the pore diameter of the microc...

Embodiment 2

[0036] Dissolve 20g of 2,4-dinitrobenzaldehyde in 300ml of sulfolane solvent with stirring to form solution A; dissolve 30g of potassium fluoride in 300ml of sulfolane with stirring to form solution B; use a peristaltic pump to simultaneously dissolve solution A and solution B, and add 0.8g tetramethylammonium bromide as a phase transfer catalyst, inject into the microchannel reactor to realize the strong mixing of the two solutions, and keep it at 200-210°C, and control the reaction time at 50-55 seconds, After the reaction solution flows out of the microchannel reactor, it is introduced into the purification tank with a catheter, and the mixture of 2,4-difluorobenzaldehyde and sulfolane in the purification tank is rectified and purified, and the sulfolane is distilled out, and then returned to the system for repeated use to obtain a purity of ≥ 99% 2,4-difluorobenzaldehyde essence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com