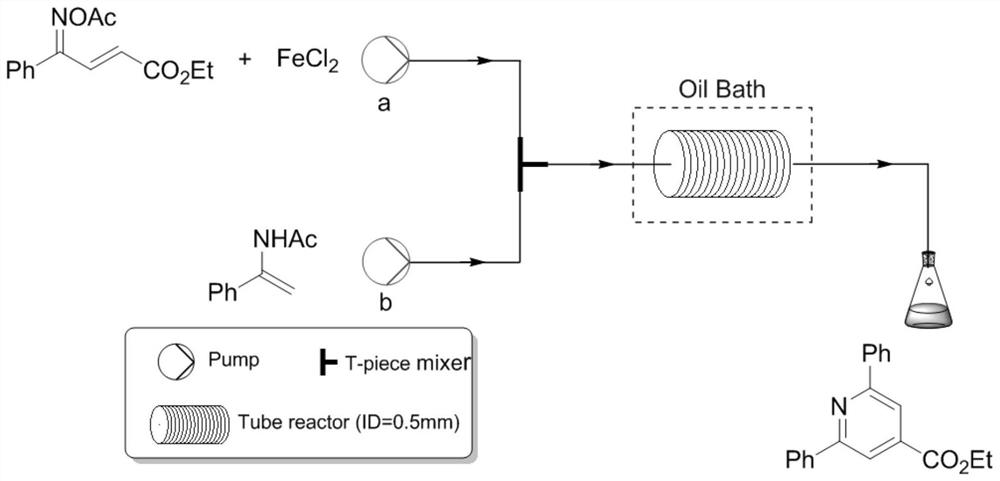

Method for synthesizing pyridine compound by using microchannel reaction device

A microchannel reaction and ester compound technology, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problems of low reaction efficiency, long reaction time, and complicated reaction steps. Achieve the effect of speeding up the reaction rate, green reaction conditions, and easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

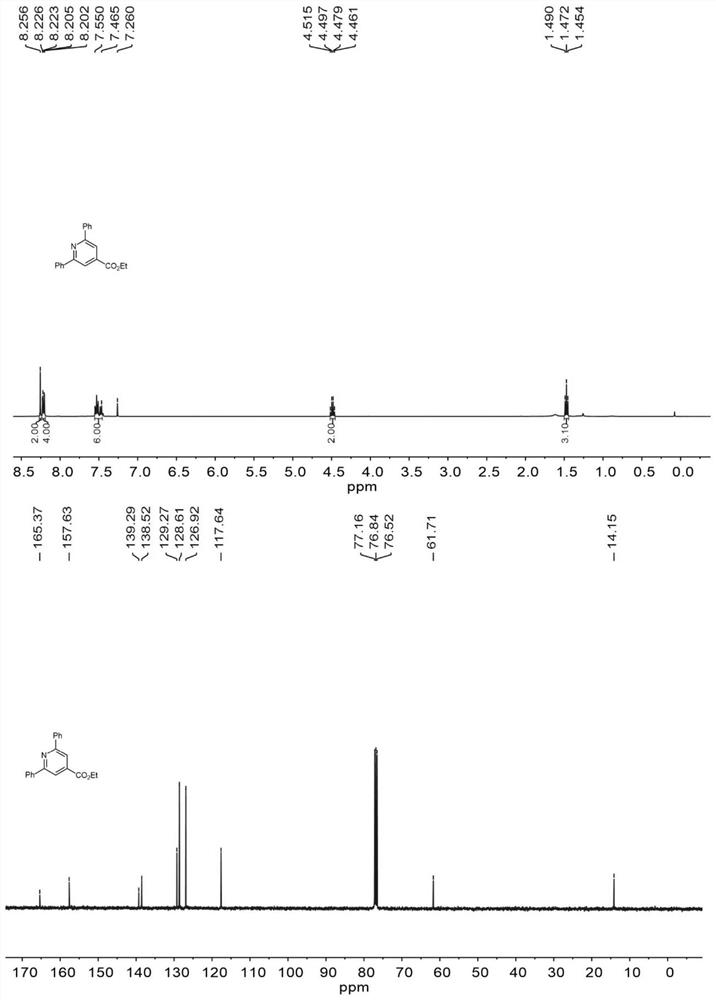

Embodiment 1

[0048] Dissolve 1mmol (0.261g) of (2E,4E)-4-(acetoxyimino)-4-phenylbut-2-enoic acid ethyl ester, 0.1mmol (0.0125g) of ferrous chloride in 10mL In 1,2-dichloroethane, the resulting mixed solution is recorded as solution A; 2mmol (0.322g) of N-(1-phenylvinyl)acetamide was dissolved in 10mL of 1,2-dichloroethane , the resulting mixed solution is recorded as solution B, and then solution A and solution B are pumped into the microchannel reaction device according to the flow volume ratio of 1:1, the flow rate is 0.5mL / min, and they enter the microchannel reaction after being mixed by a Y-type mixer. React at 120° C. for 8 minutes in a microreactor (the inner diameter of the polytetrafluoroethylene tube of the microreactor is 0.5 mm, and the volume of the polytetrafluoroethylene tube is 4 mL). The organic phase was obtained from the discharge of the microreactor, and concentrated in vacuo to obtain the crude product, which was separated by developer column chromatography with a rati...

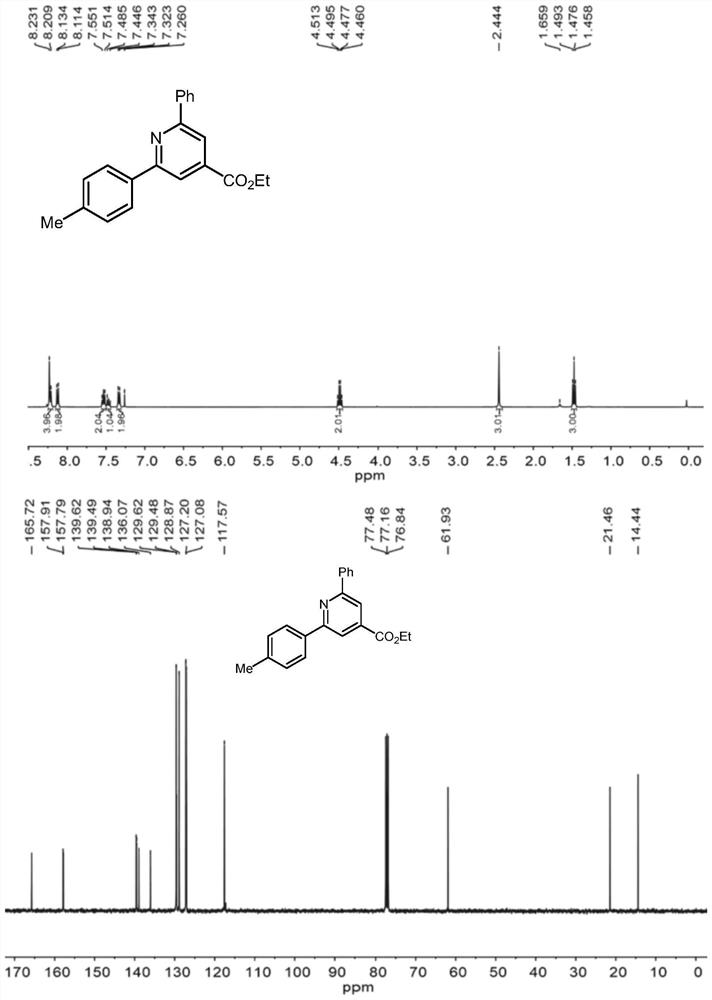

Embodiment 2

[0050] 1mmol (0.275g) of (2E,4E)-4-(acetoxyimino)-4-(p-tolyl)but-2-enoic acid ethyl ester, 0.1mmol (0.0125g) of ferrous chloride Dissolve in 10mL of 1,2-dichloroethane, and the resulting mixed solution is recorded as solution A; 2mmol (0.322g) of N-(1-phenylvinyl)acetamide is dissolved in 10mL of In ethyl chloride, the resulting mixed solution is recorded as solution B, and then solution A and solution B are pumped into the microchannel reaction device according to the flow volume ratio of 1:1, and the flow rate is 0.5mL / min respectively. React at 120° C. for 8 minutes in a microchannel reactor (the inner diameter of the polytetrafluoroethylene tube of the microreactor is 0.5 mm, and the volume of the polytetrafluoroethylene tube is 4 mL). The organic phase was obtained from the discharge of the microreactor, concentrated in vacuo to obtain the crude product, and separated by column chromatography with a developing agent with a ratio of petroleum ether to ethyl acetate of 5:1 ...

Embodiment 3

[0052] Add 1mmol (0.295g) of (2E,4E)-4-(acetoxyimino)-4-(p-chlorophenyl)but-2-enoic acid ethyl ester, 0.1mmol (0.0125g) of ethylene chloride Iron was dissolved in 10mL of 1,2-dichloroethane, and the resulting mixed solution was recorded as solution A; 2mmol (0.322g) of N-(1-phenylvinyl)acetamide was dissolved in 10mL of 1,2- In dichloroethane, the resulting mixed solution is recorded as solution B, and then solution A and solution B are pumped into the microchannel reaction device according to the flow volume ratio of 1:1, and the flow rate is 0.5mL / min respectively, after being mixed by a Y-type mixer Enter the microchannel reactor (the inner diameter of the polytetrafluoroethylene tube of the microreactor is 0.5mm, and the volume of the polytetrafluoroethylene tube is 4mL) and react at 120°C for 8min. The organic phase was obtained from the discharge of the microreactor, concentrated in vacuo to obtain the crude product, and separated by column chromatography with a developi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com