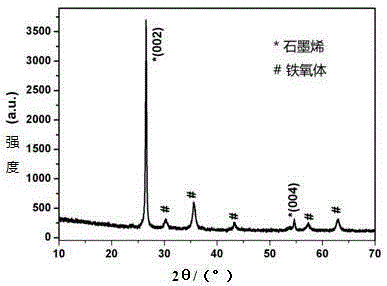

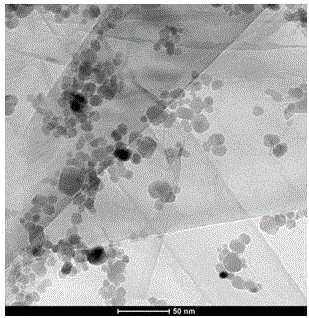

Continuous synthesis method of graphene/ferrite nanocomposite

A technology of nanocomposite materials and synthesis methods, applied in the field of continuous synthesis of graphene/ferrite nanocomposite materials, can solve the problems of continuous and rapid synthesis without breakthroughs, and achieve light weight, low synthesis temperature, and good wave absorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

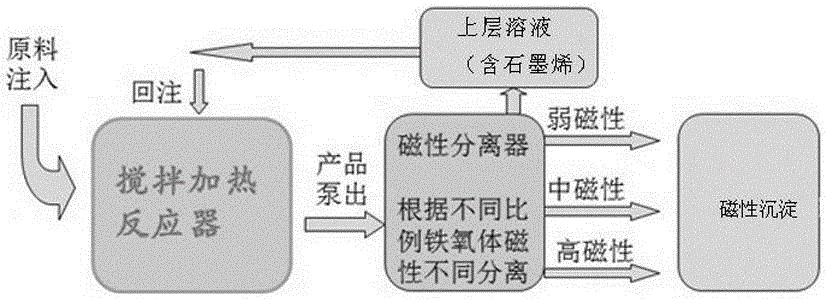

[0027] combine image 3 , a continuous synthesis method of graphene / ferrite nanocomposite material, comprises the steps:

[0028] Step 1, weighing 20g of graphene according to the stoichiometric ratio and dispersing it in 1000ml of deionized water, then adding 16.5g of sodium hydroxide to the solution, at this time the pH value of the solution was greater than 11, stirred and ultrasonically oscillated to obtain a graphene solution;

[0029] Step 2, take 200ml of the graphene solution of step 1 and add it to the heating stirrer, the reaction temperature is 60°C, under electric stirring, add 50ml of the mixed solution of ferrous sulfate and ferric chloride to the solution at a speed of 50ml / min, and keep warm for 5 Minutes, wherein, the concentration of ferrous sulfate is 0.4mol / L, and the concentration of ferric chloride is 0.4mol / L;

[0030] Step 3, pump the reaction solution in step 2 into the container with NdFeB magnets at the bottom, let it stand for 1 minute, tilt the co...

Embodiment 2

[0036] combine image 3 , a continuous synthesis method of graphene / ferrite nanocomposite material, comprises the steps:

[0037] Step 1, weighing 20g of graphene according to the stoichiometric ratio and dispersing it in 1000ml of deionized water, then adding 16.5g of sodium hydroxide to the solution, at this time the pH value of the solution was greater than 11, stirred and ultrasonically oscillated to obtain a graphene solution;

[0038] Step 2, take 200ml of the graphene solution of step 1 and add it to the heating stirrer, the reaction temperature is 95°C, under electric stirring, add 50ml of ferrous sulfate, ferric chloride, zinc nitrate and chloride to the solution at a speed of 50ml / min The mixed solution of nickel is kept warm for 5 minutes, wherein the concentration of ferrous sulfate is 0.3mol / L, the concentration of ferric chloride is 0.3mol / L, the concentration of zinc nitrate is 0.15mol / L, and the concentration of nickel chloride is 0.15 mol / L; adding the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com