Titanium alloy part grinding equipment and grinding method

A technology of parts and titanium alloys, which is applied in the field of grinding equipment for titanium alloy parts, can solve the problems of poor consistency of grinding effects, no mature available, no targeted grinding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Such as figure 1 , Figure 6 As shown, a cooling water circulation system 800 is also included. The cooling water circulation system is mainly used to provide coolant or cutting fluid to the grinding work platform 200. In a specific embodiment, the cooling water circulation system 800 includes a water tank 802, and the bottom of the water tank 802 is also equipped with a second drain. The valve 807 and the second drain valve 807 are used to drain the coolant when replacing the coolant. The pumping motor 806 drives the pump to pump the cooling water in the water tank 802 to the primary filter 805 and the secondary filter 804 in turn, and then transports it to the polishing tank 202, which is connected to the water tank 802 through the return pipe 803. The filter mesh of the filter element in the primary filter 805 should be smaller than that of the second stage filter, and the second stage filter precision of titanium alloy parts grinding should not be lower than 10 μm....

Embodiment 2

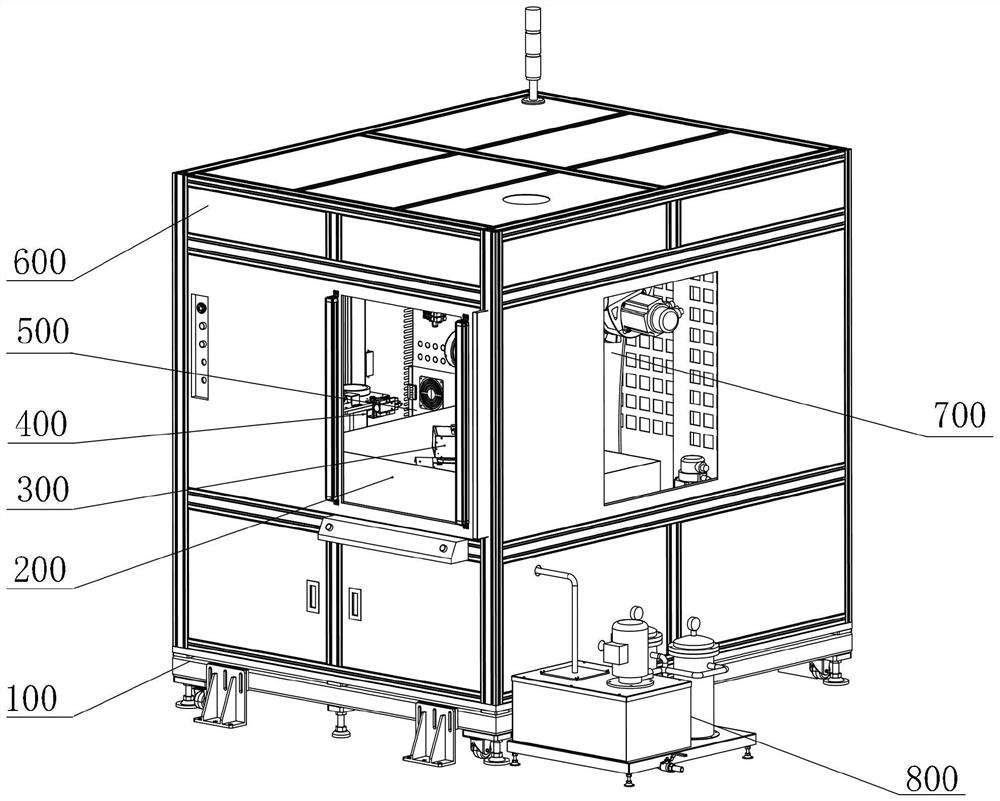

[0084] Such as figure 1 , Figure 7 As shown, it also includes a frame 600, the frame 600 includes a plurality of profile frames 609 fixedly connected to form a frame, a partition is installed on the frame, and the side wall of the frame 600 is provided with an emergency stop switch 606, which is used to quickly turn off the equipment in an emergency. STOP to prevent further injury. The external control button 604 is convenient for the operator to operate outside the frame. The loading window 605 and the retrieving window 610, the loading window 605 uses a rodless cylinder with a linear slide rail as the guide and power. After the grinding is completed, the loading window 605 is automatically opened. After the workpiece is manually clamped, when starting the grinding, The loading window 605 is automatically closed. A safety grating 601 and a control box 602 are installed on the material retrieving window 610, and a three-color light 607 and a heat dissipation vent 608 are a...

Embodiment 3

[0086] Such as figure 1 , Figure 8 As shown, a support module 100 is also installed in the frame 600. Specifically, the support module 100 includes a load-bearing base plate 103 installed on the load-bearing beam 104. The load-bearing base plate 103 can be made of high-strength steel plates to increase the weight of the bottom and prevent the industrial robot 700 from The position of the device is shifted during movement.

[0087] The bottom of the load-bearing beam 104 is also equipped with a foot support seat 102, a heavy-duty foot cup 101 and a heavy-duty roller 105. The foot support seat 102 and the heavy-duty foot cup 101 are convenient to adjust the height of the support module 100. Fuma wheel is loaded, and the heavy-duty roller 105 is convenient to move the grinding equipment as a whole. In order to further reduce the shaking of the support module, the foundation support base 102 can be fixed by foundation bolts.

[0088] Such as Figure 9 Shown, a kind of grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com