Chemical mechanical polishing method

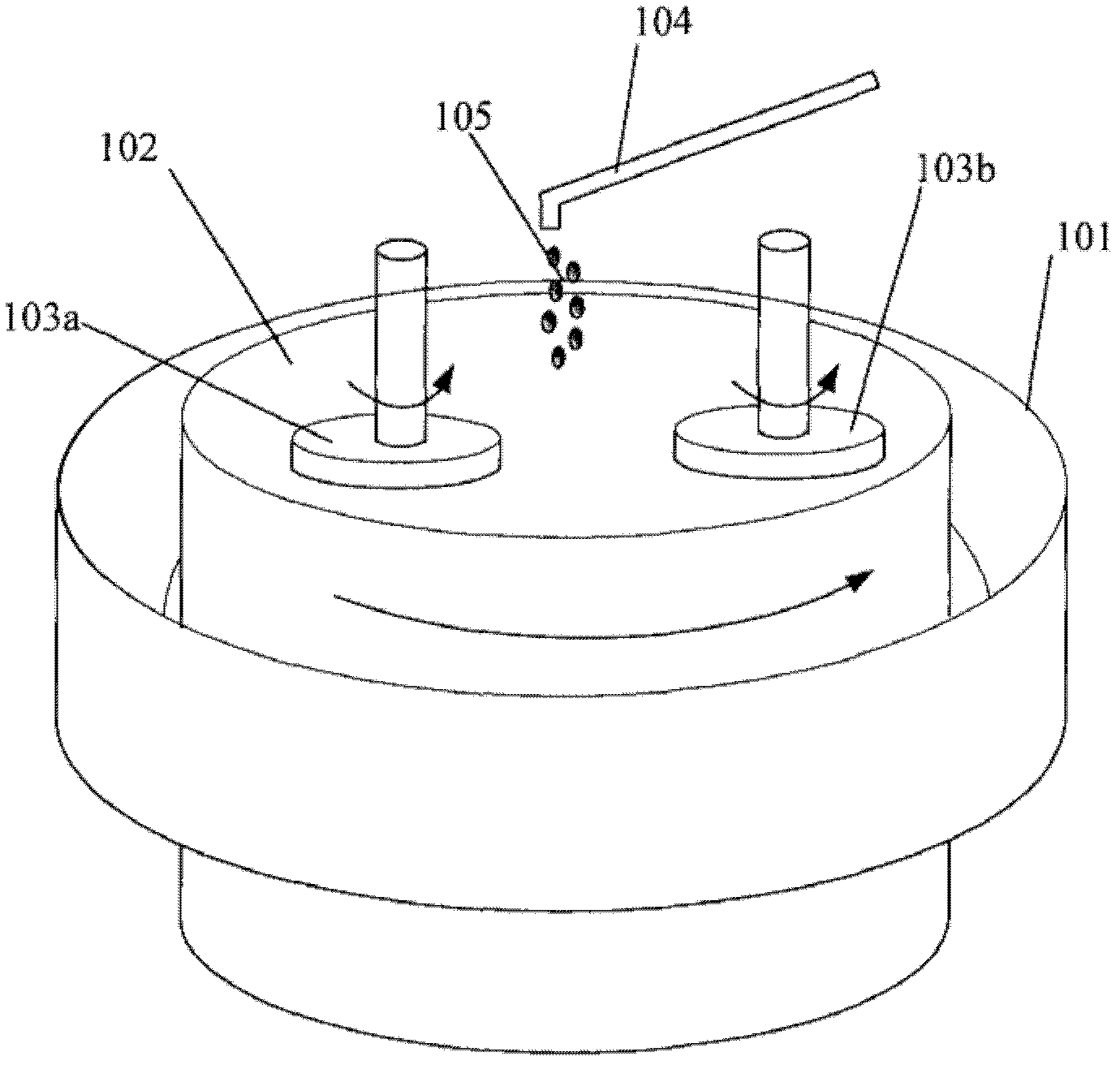

A grinding method and chemical-mechanical technology, used in grinding devices, grinding machine tools, electrical components, etc., can solve the problems of insufficient grinding, no way to effectively grind, over-grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

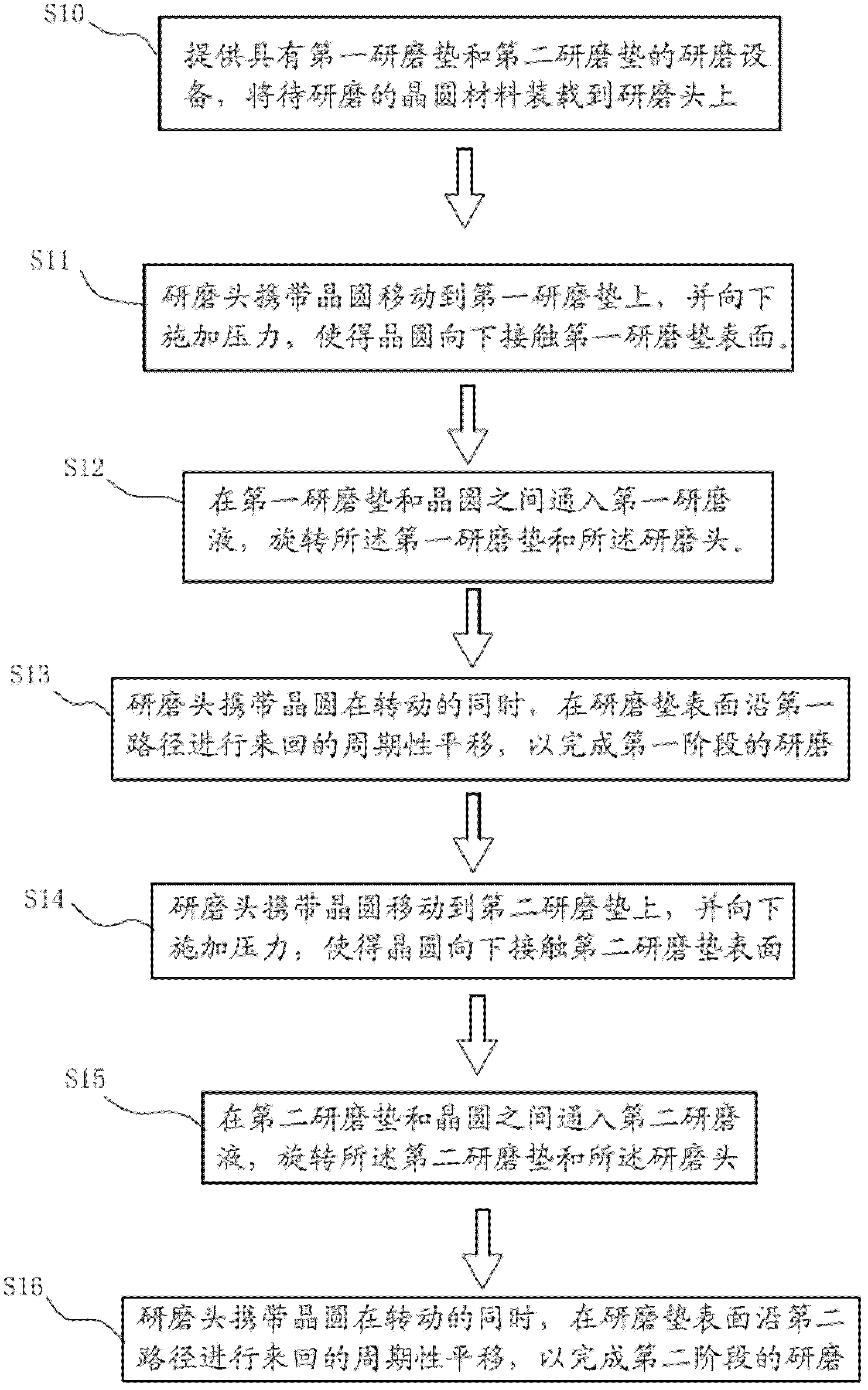

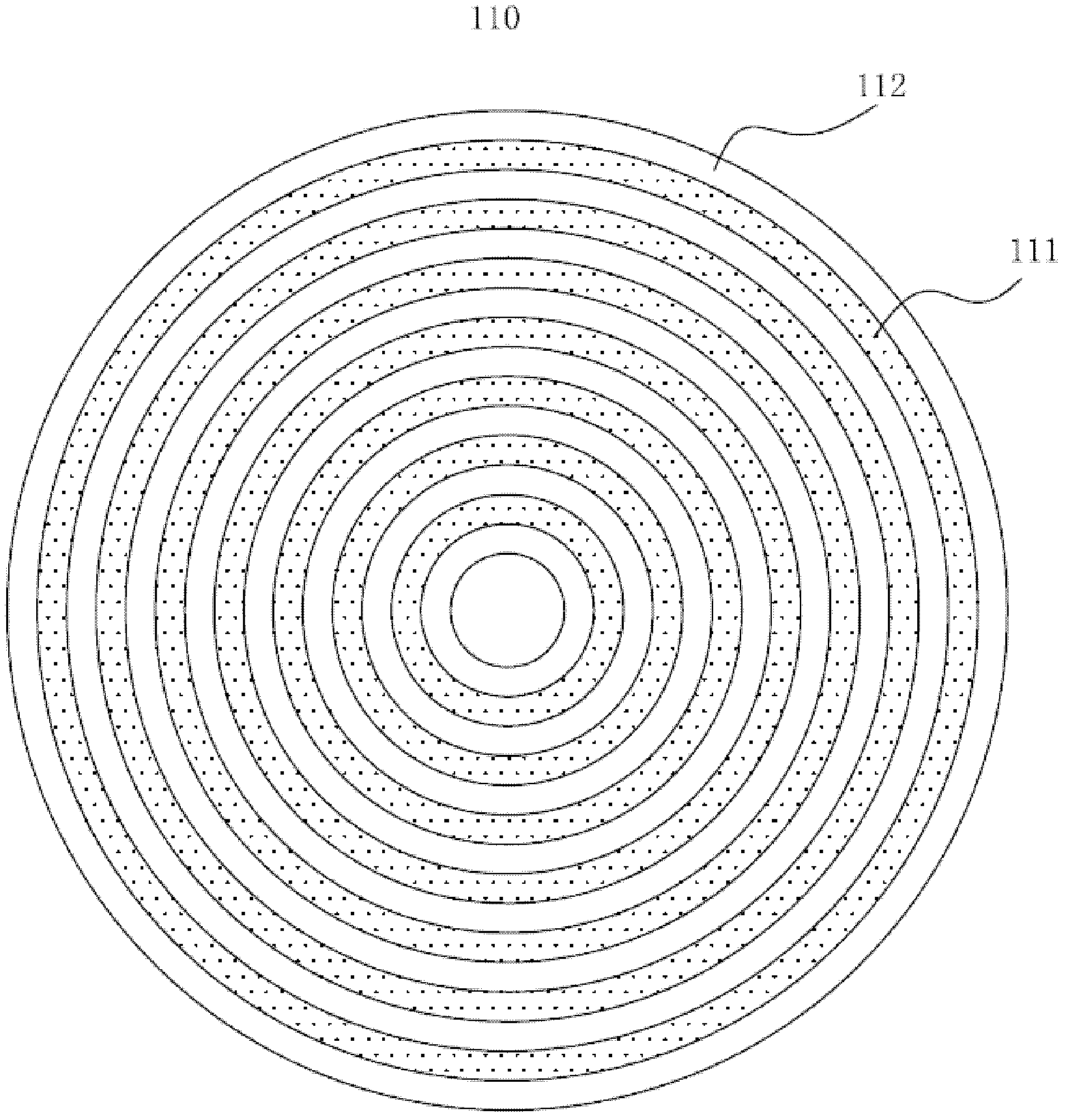

[0051] Embodiment 1 illustrates the chemical mechanical polishing method of the present invention using the same polishing pad and different polishing paths. The polishing pad used is a polishing pad with a concentric circle structure.

[0052] Please refer to Figure 3A-3B , Figure 3A-3B It is an existing concentric circle structure polishing pad. As shown in the figure, a plurality of concentric grooves 111 and convex islands 112 are arranged on the surface of the polishing pad 110 , and the grooves 111 and the convex islands 112 are arranged on the polishing pad 110 at intervals. Through these grooves 111, the distribution of the grinding liquid on the grinding pad 110, the flow of fresh grinding liquid in the grinding area, the flow of used grinding liquid out of the grinding area and the substantially unused grinding liquid flowing through the grinding area can be improved. The specific gravity of the grinding liquid, etc.

[0053] Specifically, taking grinding an 8-i...

Embodiment 2

[0065] Embodiment 2 is a chemical mechanical polishing method using two different polishing pads and the same or different polishing paths. The second embodiment is essentially a modification of the first embodiment. That is, the distribution of grooves and convex islands in the first grinding pad 210 and the second grinding pad 210' is just opposite. On the first grinding pad 210, it is the position of the grooves, and on the second grinding pad 210', it happens to be convex islands. On the first polishing pad 210 are convex islands, and on the second polishing pad 210' are exactly grooves. Such as Figure 8 as shown, Figure 8 It is a comparison diagram of polishing pads with two different surface structures in Example 2. In this case, even if the trajectories of the first grinding path and the second grinding path are not changed, the resulting grinding effect can play a complementary role.

[0066] Further, if the changes of grooves and convex islands are not only diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com