Ore dressing process for reducing content of silicon dioxide in iron ore concentrate

A silica and iron concentrate technology, applied in solid separation and other directions, can solve the problems of high SiO2 content, low recovery rate of iron concentrate, high content, reduce impurity content, avoid high iron grade in tailings, improve The effect of concentrate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]A kind of beneficiation process of reducing silicon dioxide content in the iron concentrate of the present embodiment, the steps are:

[0042] Step 1. Crushing: For low-grade magnetite ore, the grade of iron ore raw ore is 15-20%, the occupancy rate of magnetic iron in the ore is 75-90%, and the gangue minerals are mainly albite, epidote, and green clay Stone, actinolite, etc., are crushed to -20mm particles, and then wet pre-selected to -3mm coarse concentrate by high-pressure roller mill ultra-fine crushing and screening fully closed-circuit process;

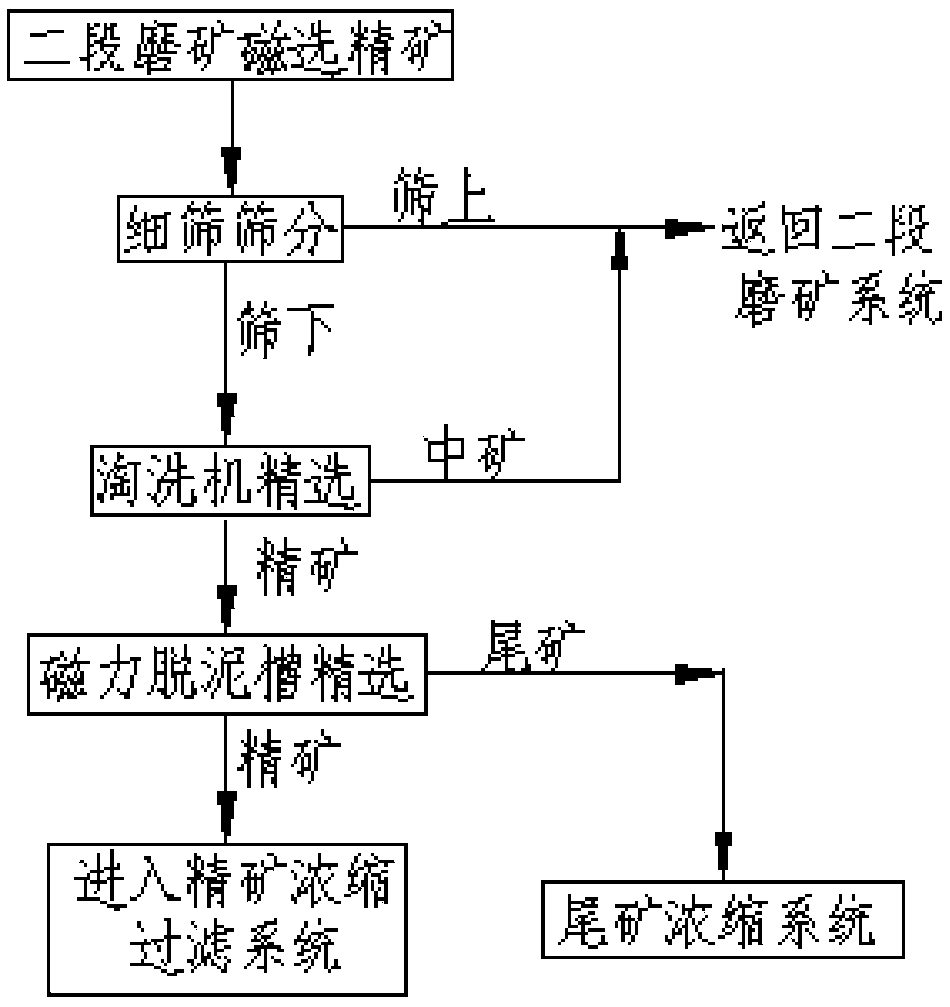

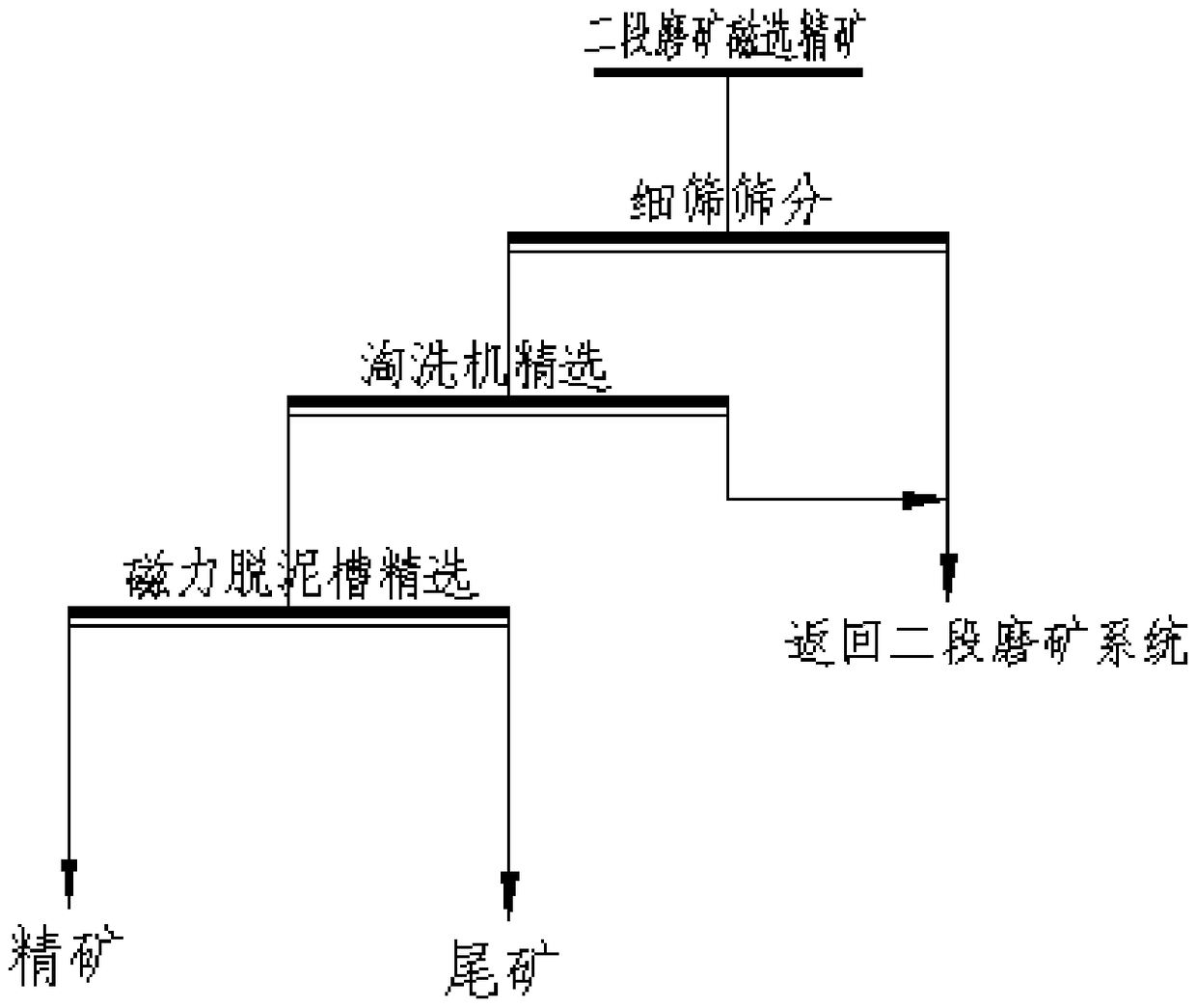

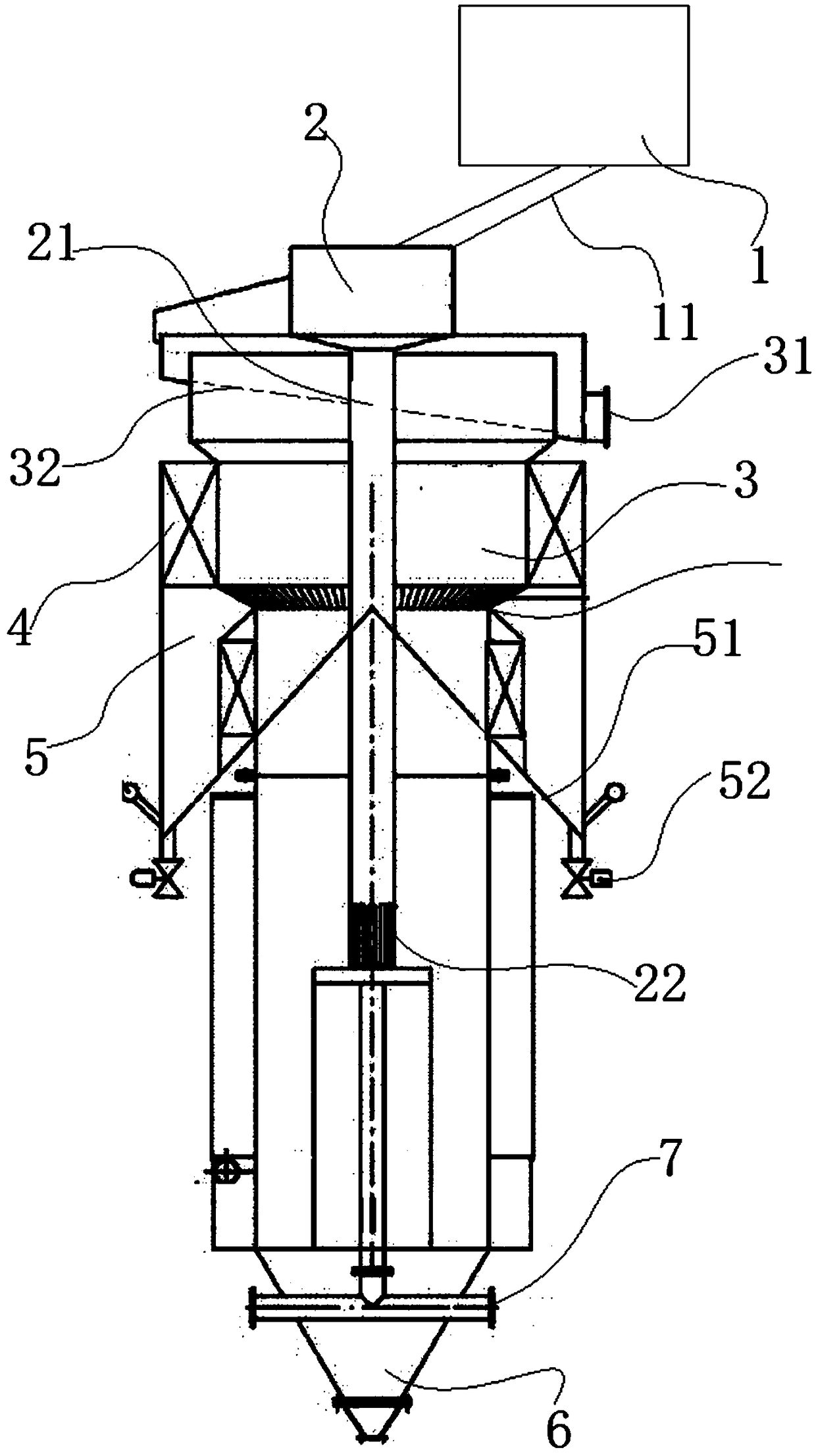

[0043] Step 2, ore grinding: carry out second stage grinding-classification-weak magnetic separation (ie figure 1 The second-stage grinding and magnetic separation concentrate at the top of the middle), specifically:

[0044] (1) Perform one-stage grinding-classification-one-stage weak magnetic separation on the wet pre-selection coarse concentrate to obtain a one-stage weak magnetic separation coarse concentrate and th...

Embodiment 2

[0053] A kind of beneficiation process of reducing the silicon dioxide content in the iron concentrate of the present embodiment, the basic steps are the same as embodiment 1: the steps are:

[0054] Step 1. Crushing: For low-grade magnetite ore, the grade of iron ore raw ore is 19.51%, the occupancy rate of magnetic iron in the ore is 75-90%, and SiO 2 The content is 6.80%. The gangue minerals are mainly albite, epidote, chlorite, actinolite, etc., crushed to 20-0mm particles, and then subjected to high-pressure roller mill ultra-fine crushing and full-closed wet pre-selection to -3mm rough concentrate;

[0055] Step 2, ore grinding: carry out the second stage of ore grinding-classification-weak magnetic separation, specifically:

[0056] (1) Perform one-stage grinding-classification-one-stage weak magnetic separation on the wet pre-selection coarse concentrate to obtain a one-stage weak magnetic separation coarse concentrate and throw out the tailings;

[0057] (2) The fir...

Embodiment 3

[0065] A kind of beneficiation process of reducing the silicon dioxide content in the iron ore concentrate of the present embodiment, the basic steps are the same as embodiment 2, the difference and improvement are: the steps are:

[0066] Step 1. Crushing: For low-grade magnetite ore, the grade of iron ore raw ore is 18.51%, the occupancy rate of magnetic iron in the ore is 75-90%, and SiO 2 The content of gangue minerals is 6.2%. The gangue minerals are mainly albite, epidote, chlorite, actinolite, etc., crushed to 20-0mm particles, and then carry out high-pressure roller mill ultra-fine crushing and screening full-closed wet pre-selection process to- 3mm rough concentrate;

[0067] Step 2, ore grinding: carry out the second stage of ore grinding-classification-weak magnetic separation, specifically:

[0068] (1) Perform one-stage grinding-classification-one-stage weak magnetic separation on the wet pre-selection coarse concentrate to obtain a one-stage weak magnetic separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com