Preparation method and application of a superabsorbent composite binder for iron ore pellets

A technology of high water absorption and binder, which is applied in the field of metallurgical engineering materials, can solve the problems of reducing the iron grade of pellet ore, and the binder is difficult to adapt to the requirements of iron ore raw material moisture and pelletizing moisture, etc., to reach the total iron grade The effect of improving and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

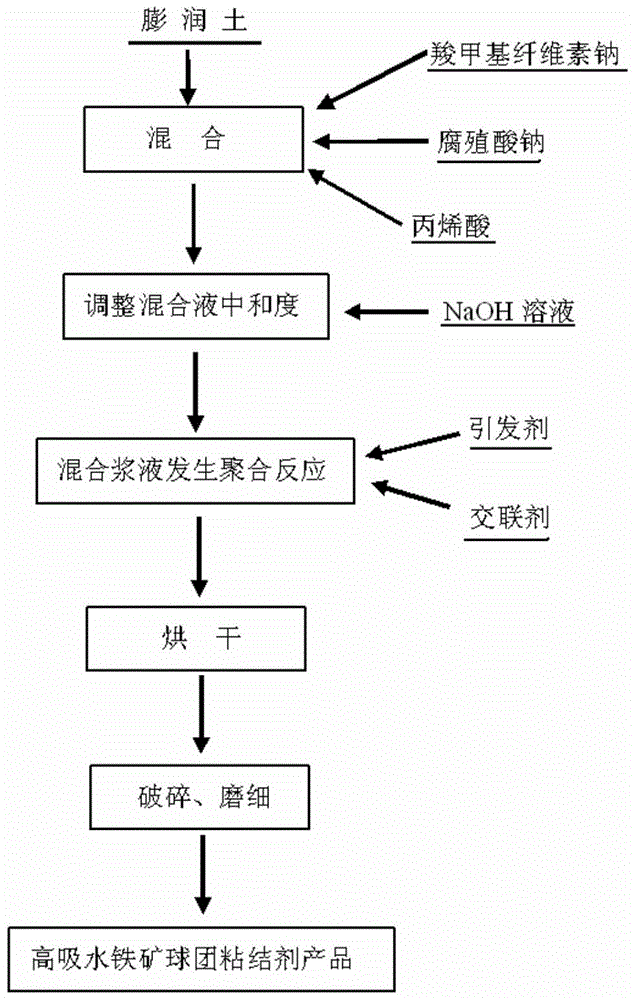

[0042] Mix sodium carboxymethylcellulose: sodium humate: bentonite: acrylic acid according to the mass percentage of 0.01:5:100:10, add water to make a mixed slurry; then use NaOH solution to adjust the neutralization degree of the mixed slurry to 70%; Add 0.1% of the initiator and 0.1% of the cross-linking agent in sequence, then place the mixed slurry at a temperature of 50°C and stir for 1 hour, then dry it at a temperature of 80°C, and break the dried sample And grind until the particle size of -0.074mm accounts for 99% by mass, thus obtaining a superabsorbent composite binder, and its 2h water absorption rate reaches 820%.

[0043] During application, the composite binder is added to the magnetite concentrate at a ratio of 0.5% of the dry mass of the magnetite concentrate and mixed evenly. The moisture content of the mixture is 9.0%, and the suitable moisture content of the obtained green balls is 9.6%. The drop strength is 4.2 times / 0.5m, the compressive strength is 14.2...

Embodiment 2

[0045] Sodium carboxymethyl cellulose: sodium humate: bentonite: acrylic acid is mixed evenly according to the mass percentage of 0.03:15:100:10, and water is added to make a mixed slurry; then NaOH solution is used to adjust the neutralization degree of the mixed slurry to 75%; Add 0.5% of the initiator and 1.0% of the cross-linking agent in sequence, place the mixed slurry at a temperature of 65°C and stir for 2 hours, then dry it at a temperature of 80°C, and break the dried sample And grind until the particle size of -0.074mm accounts for 99% by mass, thus obtaining a superabsorbent composite binder, and its 2h water absorption rate reaches 1260%.

[0046] In application, the composite binder is added to the magnetite concentrate according to the ratio of 0.75% of the dry mass of the magnetite concentrate and mixed evenly. The moisture content of the mixture is 9.7%, and the suitable moisture content of the obtained green balls is 10.4%. The drop strength is 7.5 times / 0.5m...

Embodiment 3

[0048] Sodium carboxymethyl cellulose: sodium humate: bentonite: acrylic acid is mixed evenly according to the mass percentage of 0.05:30:100:10, and water is added to make a mixed slurry; then NaOH solution is used to adjust the neutralization degree of the mixed slurry to 80%; Add 1.0% of the initiator and 2.0% of the crosslinking agent in sequence, and place the mixed slurry at 80°C for 3 hours, then dry it at 80°C, and break the dried sample And grind until the particle size of -0.074mm accounts for 99% by mass, thus obtaining a superabsorbent composite binder, and its 2h water absorption rate reaches 1830%.

[0049] In application, the composite binder is added to the magnetite concentrate according to the proportion of 1.0% of the dry mass of the magnetite concentrate and mixed evenly. The moisture content of the mixture is 10.3%, and the suitable moisture content of the green ball obtained is 10.9%. The drop strength is 9.6 times / 0.5m, the compressive strength is 11.6N / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com