Low burn-up pellet adhesives and preparation method thereof

A binder and fuel consumption technology, applied in the field of low fuel consumption pellet binder and its preparation, can solve the difficulty in meeting the requirements of iron ore raw material moisture and pelletizing moisture, increase blast furnace ironmaking smelting fuel consumption, reduce Iron grade of pellets and other issues, to reduce investment costs and energy consumption in the drying process, increase the appropriate upper limit, and improve the quality of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of pellet binder with low burn-up

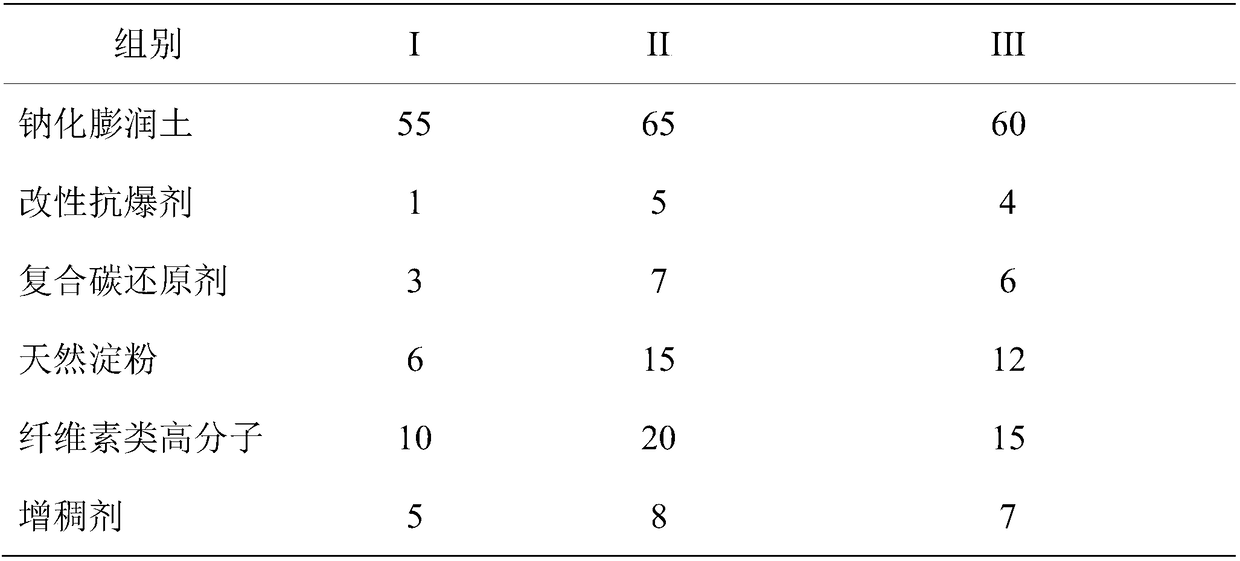

[0026] The raw materials in the low-burn-up pellet binder were mixed according to the parts by mass described in Table 1 to obtain three groups of low-burn-up pellet binders I to III with different mixing ratios.

[0027] Table 1 Low-burn-up pellet binders with different mixing ratios (parts by mass)

[0028]

Embodiment 2

[0029] Example 2: Preparation of low burn-up pellet binder

[0030] Step 1. Preparation of sodium bentonite: Dissolving sodium alginate and sodium carbonate in water and stirring evenly to obtain a compound sodium modified solution; then adding the compound sodium modified solution to the ground natural calcium-based bentonite , the grinding particle size of the calcium-based bentonite is less than 0.5mm, mixed evenly to obtain a mixed slurry; adding dimethyl dioctadecyl ammonium chloride to the resulting mixed slurry, adjusting the pH value to 5-7, and then heating up to 70 -100°C, at this temperature, vinyl alcohol is added while stirring, and the reaction is stirred for 2-4 hours. After the reaction is completed, the reaction product is sequentially dried, crushed and ground to obtain the sodium bentonite; wherein, sodium alginate, The mass ratio of sodium carbonate to calcium-based bentonite is 3:1:100.

[0031] Preparation of modified antiknock agent: put polyacrylamide ...

Embodiment 3

[0037] Example 3: Preparation of low burn-up pellet binder

[0038] Step 1. Preparation of sodium bentonite: Dissolving sodium alginate and sodium carbonate in water and stirring evenly to obtain a compound sodium modified solution; then adding the compound sodium modified solution to the ground natural calcium-based bentonite , the grinding particle size of the calcium-based bentonite is less than 0.5mm, mixed evenly to obtain a mixed slurry; adding dimethyl dioctadecyl ammonium chloride to the resulting mixed slurry, adjusting the pH value to 5-7, and then heating up to 70 -100°C, at this temperature, vinyl alcohol is added while stirring, and the reaction is stirred for 2-4 hours. After the reaction is completed, the reaction product is sequentially dried, crushed and ground to obtain the sodium bentonite; wherein, sodium alginate, The mass ratio of sodium carbonate to calcium-based bentonite is 25:8:100.

[0039] Preparation of modified antiknock agent: put polyacrylamide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com