Efficient cement ball mill internal structure

A cement mill and internal structure technology, applied in the field of mill equipment, can solve problems such as not much improvement in grinding effect, increase in mill load, and insufficient lifting height, so as to avoid over-grinding, increase throwing height, good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

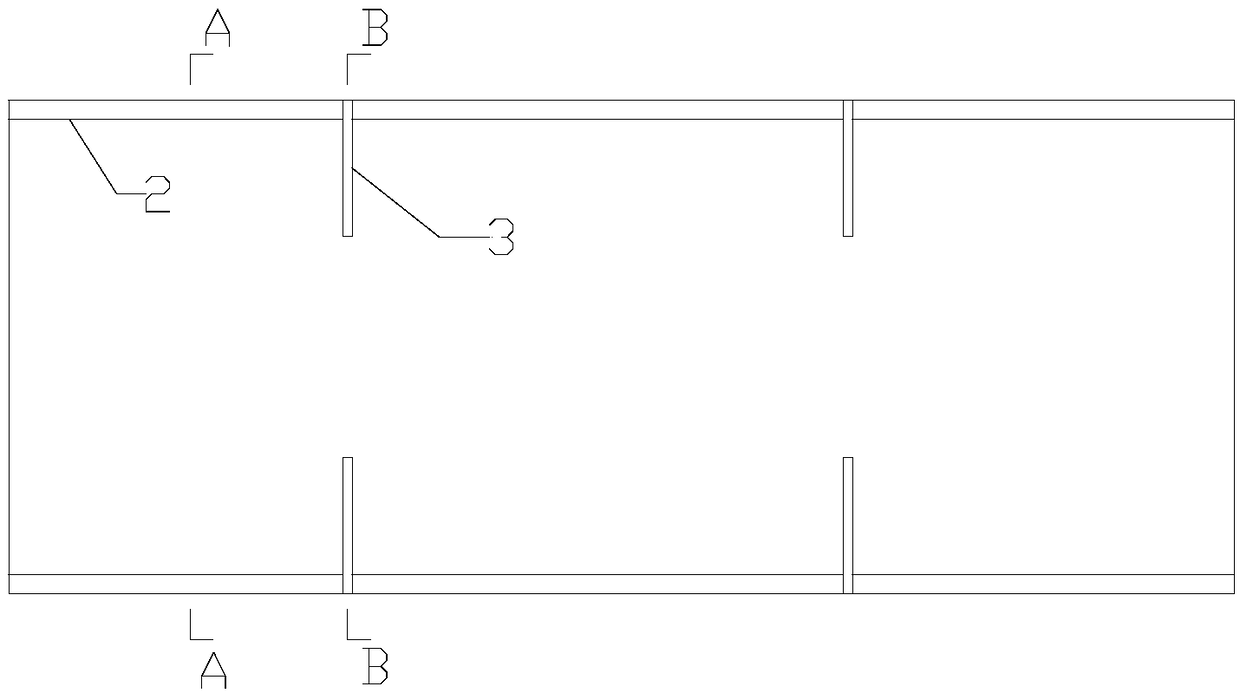

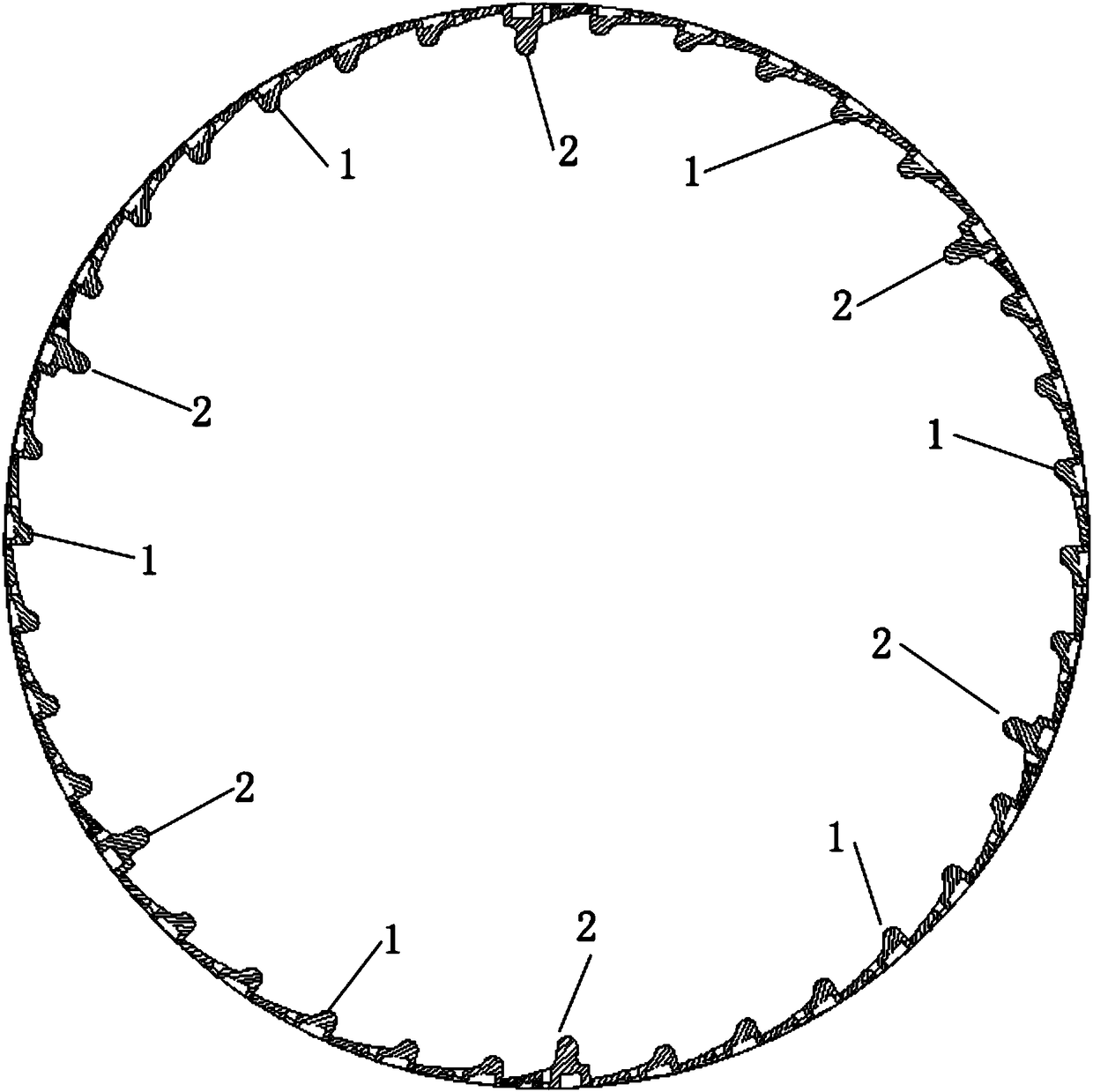

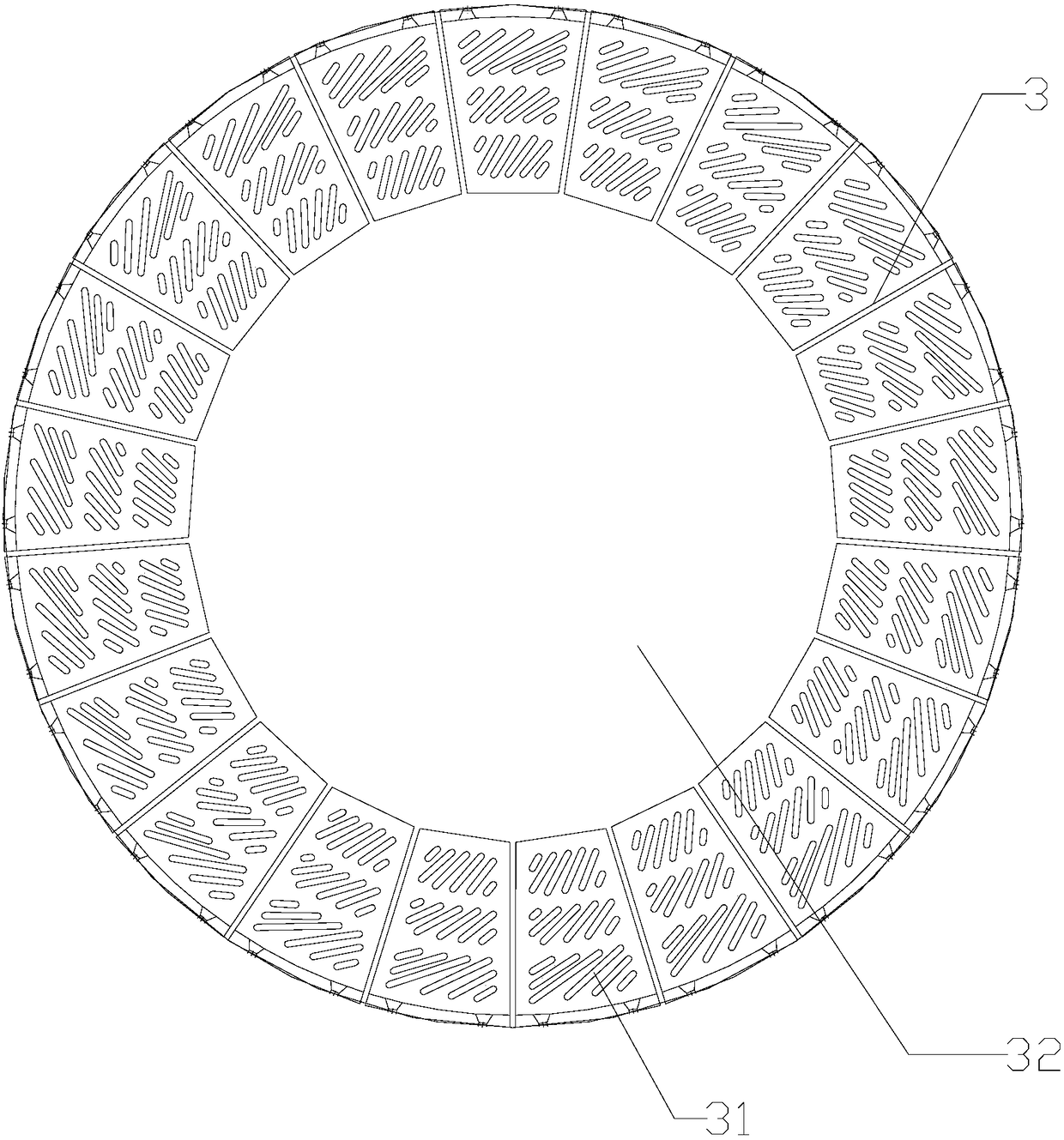

[0033] see Figure 1 to Figure 3 , the present invention provides a cement mill liner structure, which includes a lifting liner 1 installed on the inner wall of the cement mill cylinder, a lifting force distance changing device 2 and a compartment material control plate 3; the lifting liner 1 Install longitudinally along the axial direction of the cement mill cylinder, and transversely install sequentially along the circumferential direction of the cement mill cylinder. Between the adjacent lifting liners in the circumferential direction, the parabolic lug end of one lifting liner is connected to the non-parabolic end of the other lifting liner. The bump end is in contact; the lifting distance variable device 2 is installed longitudinally along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com