Novel double-interval barrel of ball milling machine

A dual-section, ball mill technology, applied in grain processing, etc., can solve the problem of slow material pushing, and achieve the effects of improving efficiency, reducing wear and tear, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] For the sake of accurate understanding, the following are the precise definitions of the technical terms that will appear in the following text:

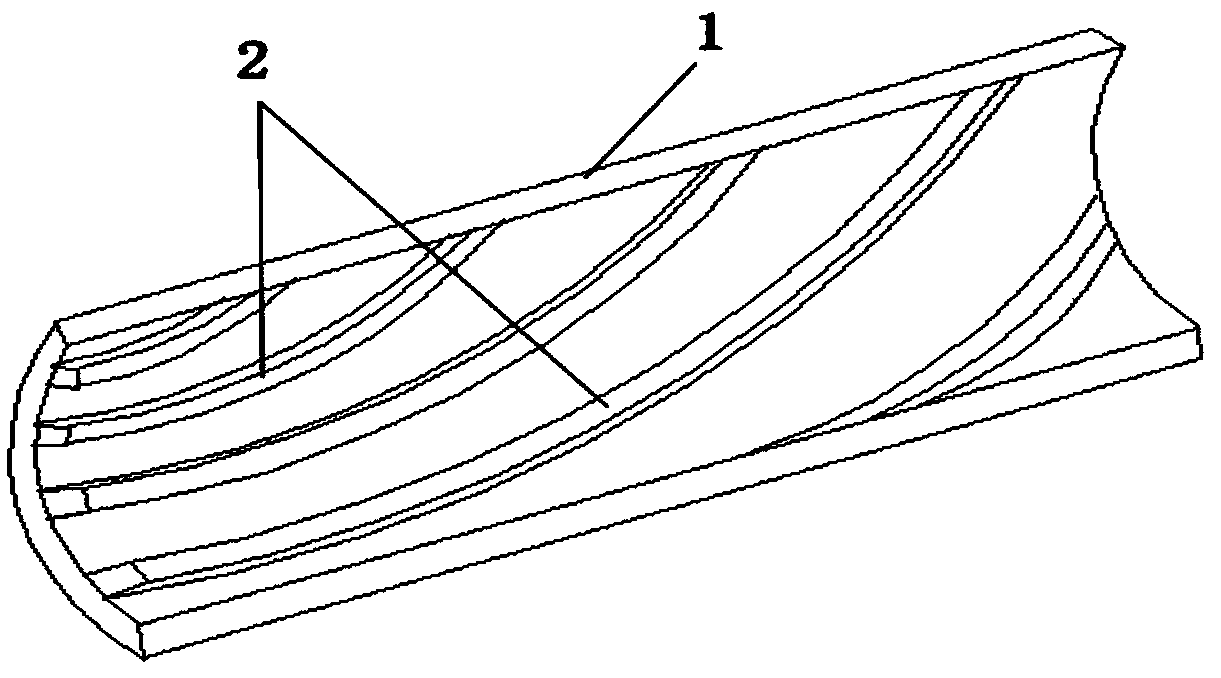

[0020] "Rifle line" refers to: the gun barrel and the spiral concave-convex line inside the gun barrel. The sunken hollow is called the Yin line or the Yin chamber, and the raised one is called the Yang line or Yang chamber.

[0021] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0022] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

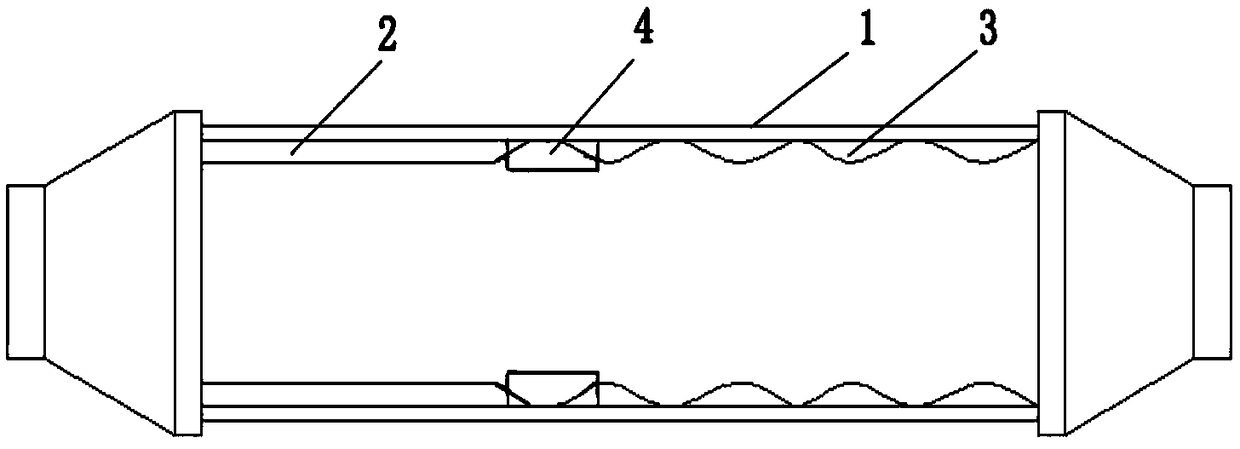

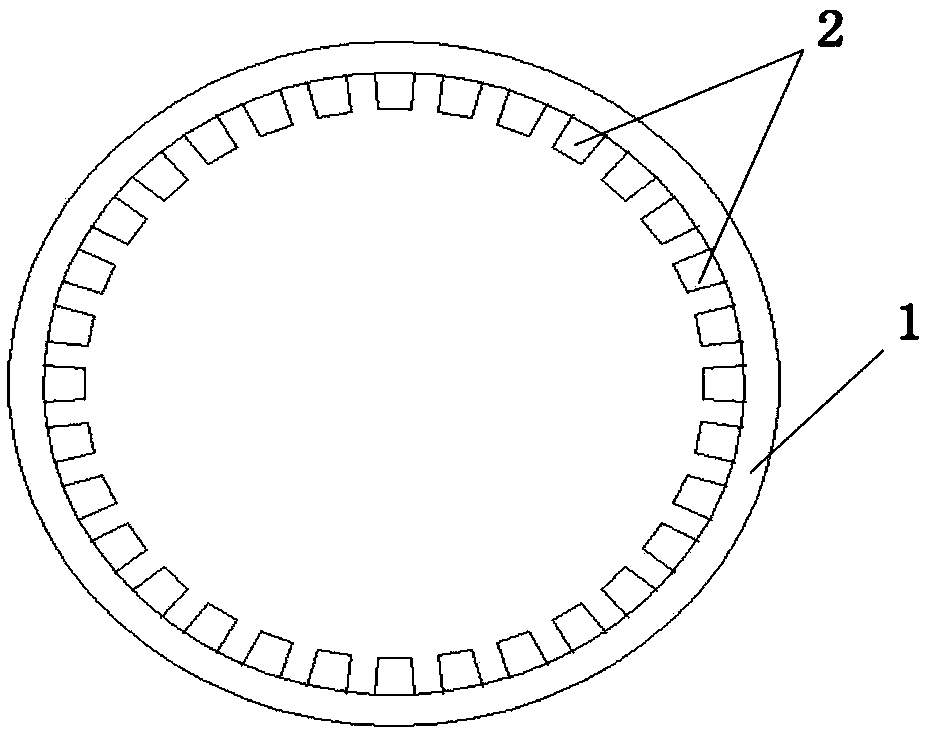

[0023] Such as Figure 1-3 The new double-section barrel of the ball mill shown includes a barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com