Cooling device capable of cooling multiple forged pieces

A cooling device and forging technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as insufficient cooling efficiency, and achieve the effect of ensuring cooling efficiency and quality, ensuring safety and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

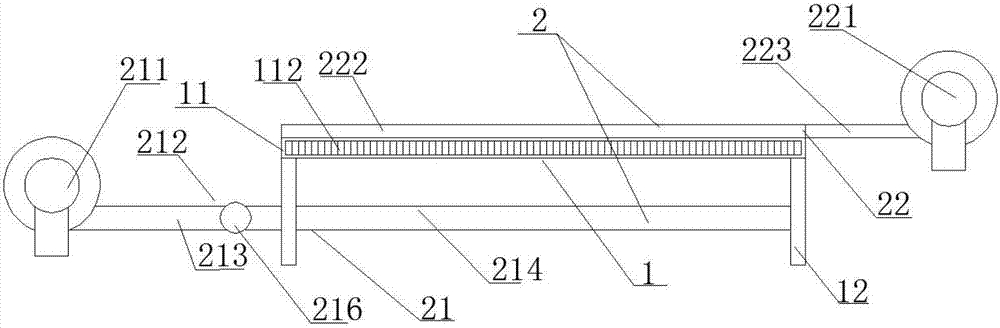

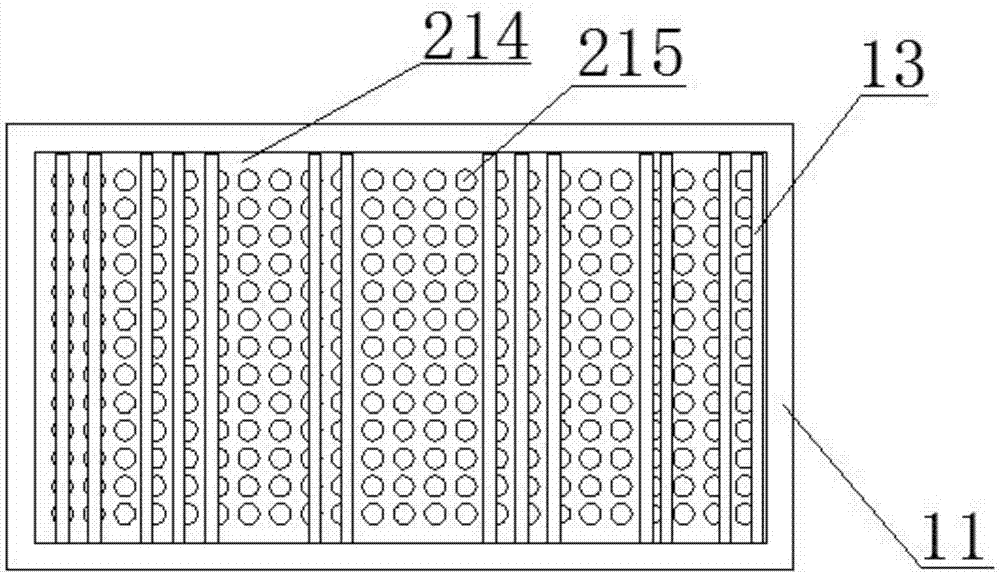

[0023] Such as figure 1 As shown, a cooling device that can cool various forgings includes a cooling frame 1 and a ventilation device 2, and is characterized in that: the cooling frame 1 includes a frame 11, supporting legs 12 and beams 13, and the frame 11 is square, The beam 13 is slidably connected in the frame 11, the support leg 12 is connected to the bottom of the frame 11, the ventilation device 2 includes a lower ventilation device 21 and a side ventilation device 22, and the lower ventilation device 21 is arranged below the frame 11, The side ventilation devices 22 are evenly distributed around the frame 11 .

Embodiment 2

[0025] On the basis of Example 1, such as figure 1 figure 2 As shown, the lower ventilation device 21 includes a blower 211 and a ventilation pipe 212, the ventilation pipe 212 is divided into an air inlet section 213 and an air outlet section 214, the air inlet section 213 is connected to the air outlet of the blower 21, and the air outlet The section 214 is a square pipe with the same size as the frame 11 , and several air outlet holes 215 are evenly opened on the air outlet pipe 214 , and the air inlet section 213 and the air outlet section 214 are connected by a spherical air collecting pipe 216 .

Embodiment 3

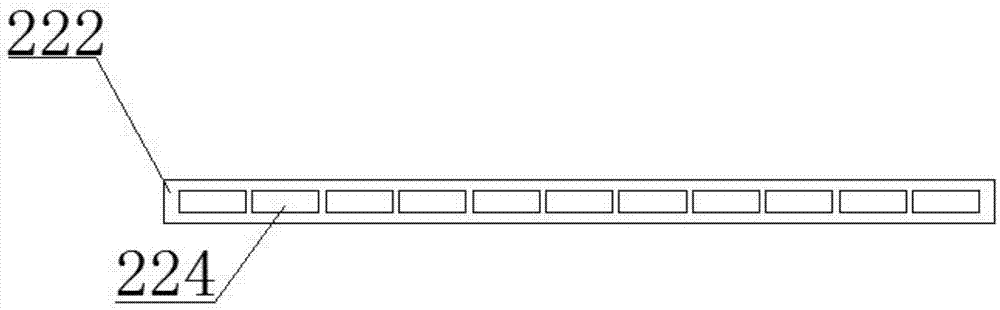

[0027] On the basis of embodiment 1 or embodiment 2, such as Figure 1-Figure 3 As shown, the side ventilation device 22 includes a side fan 221 and a side outlet pipe 222, the side outlet pipe 222 is arranged on the frame 11, and the side fan 221 is connected to the side outlet pipe 222 through a guide pipe 223, Side air outlets 224 are uniformly opened on the side air outlet pipe 222 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com