Integral cooling system and LED illumination device with the same

A heat dissipation system and integrated technology, applied in lighting devices, cooling/heating devices for lighting devices, lighting and heating equipment, etc., can solve problems such as shortened service life, component burnout, integrated circuit damage, etc. The effect of improving the efficiency of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

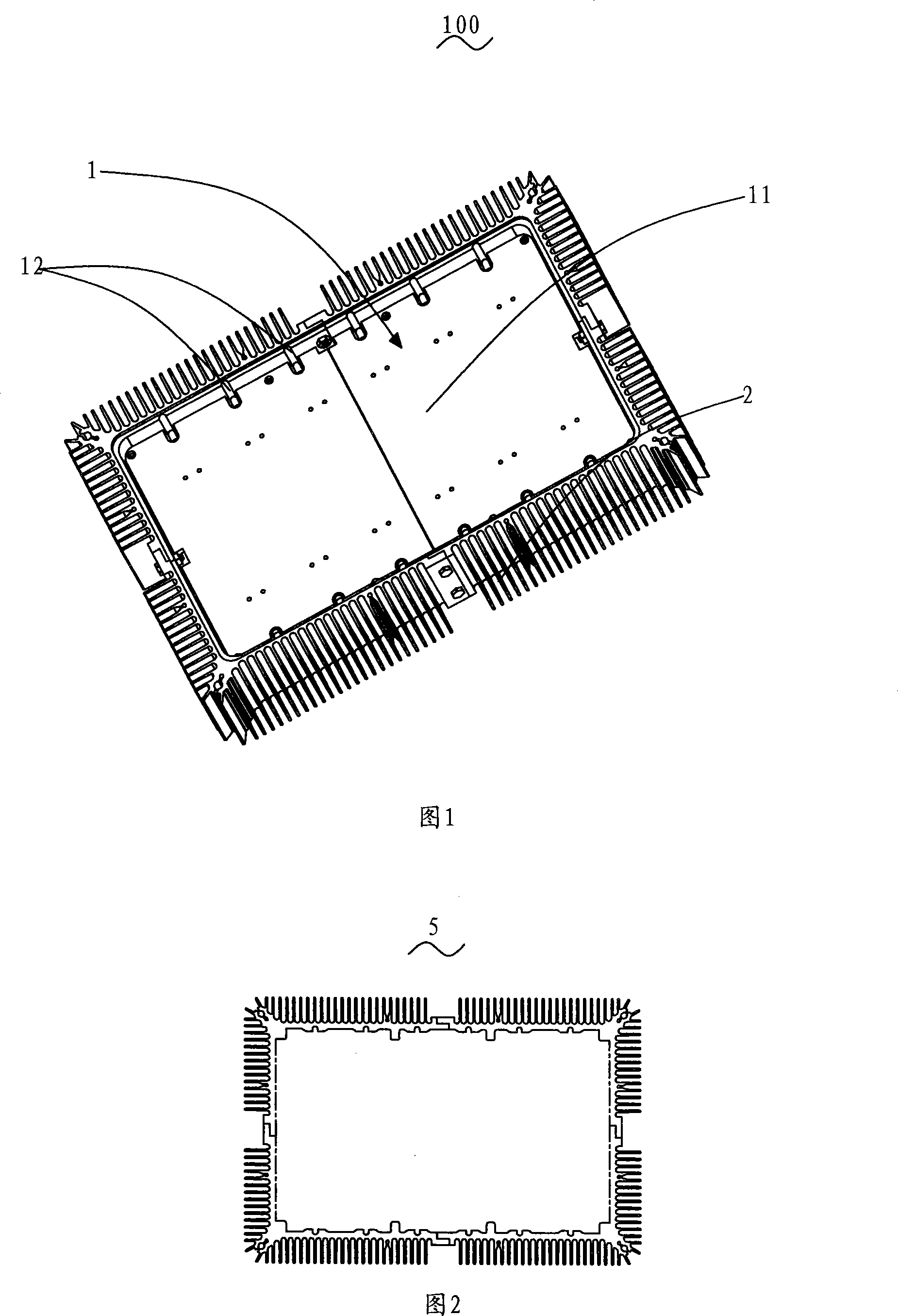

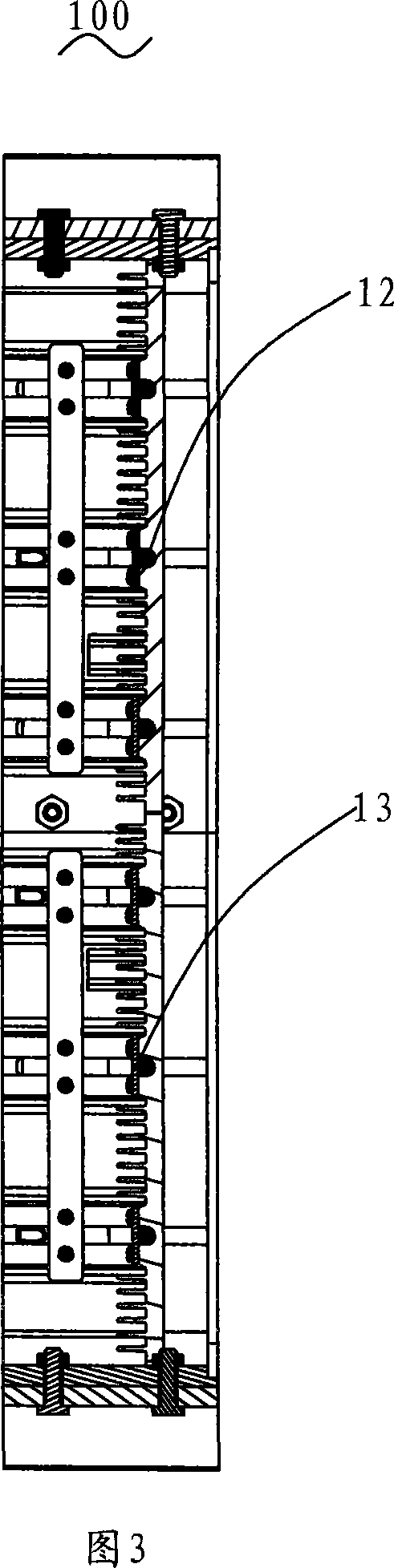

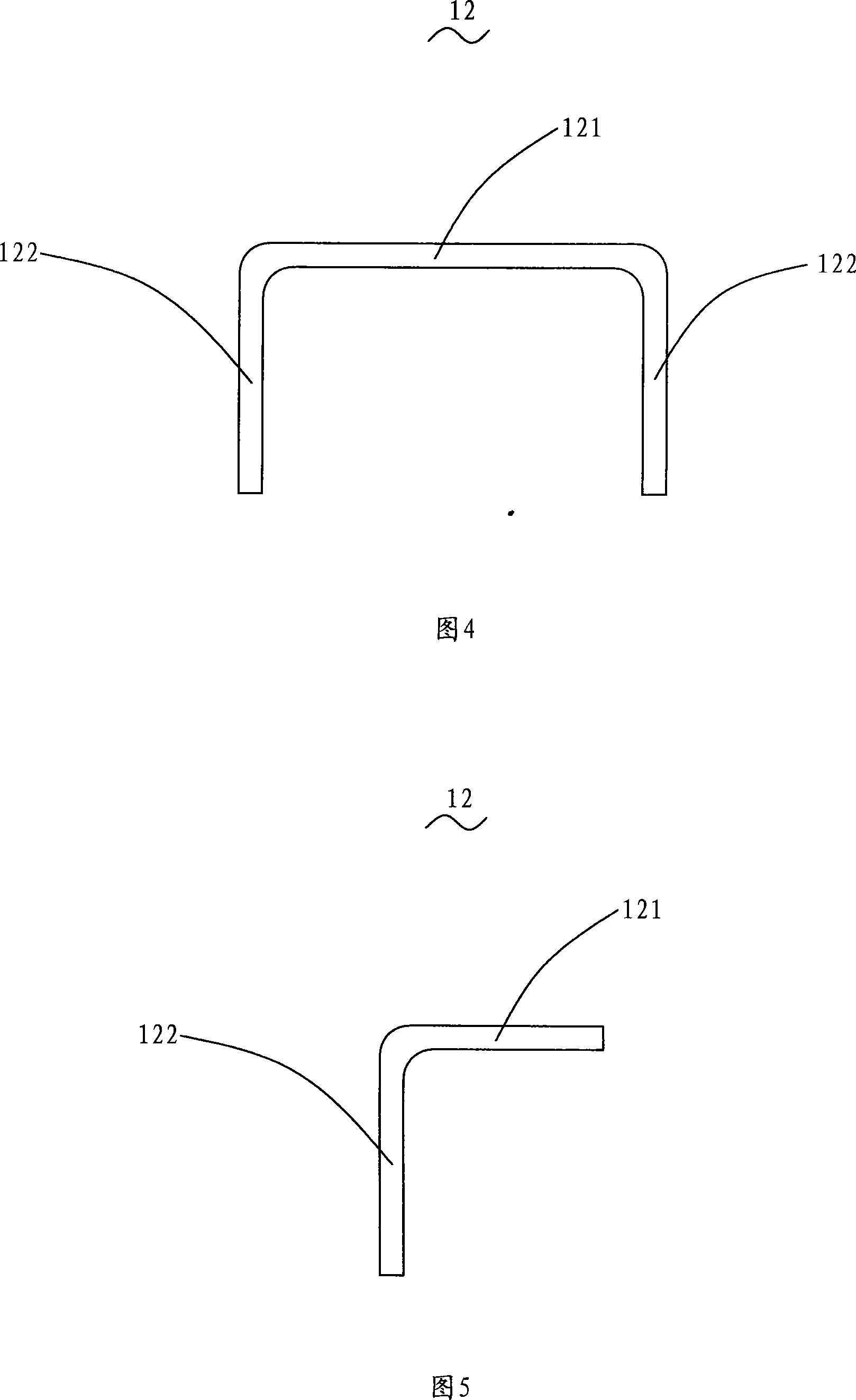

[0020] As shown in Figure 1. The present invention provides an integral heat dissipation system, which includes a heat conduction mechanism 1 and a heat dissipation mechanism (including 2). There is a heat pipe 12 with a heat absorbing portion 121 and a condensing portion 122, the bottom plate 11 has a mounting surface for installing a heat source and other heat dissipation surfaces for heat dissipation; the heat dissipation mechanism is a heat dissipation casing 2, and the heat dissipation casing 2 can be formed by Extruded pure aluminum; contact heat transfer between the heat dissipation surface of the bottom plate 11 , the condensation part 122 of the heat pipe 12 and the inner wall of the heat dissipation housing 2 . The heat absorbing portion 121 of the heat pipe 12 is located near the installation surface of the bottom plate, and the condensation portion 122 of the heat pipe 12 is located on a side adjacent to the installation surface of the bottom plate 11 .

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com