Bearing frame or cylinder head cover for a combustion engine

A technology for supporting the frame and cylinder head cover, applied to the rigid support of bearing parts, bearings for rotational motion, bearings, etc., which can solve the problems of obstructing the cylinder head cover, small available space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

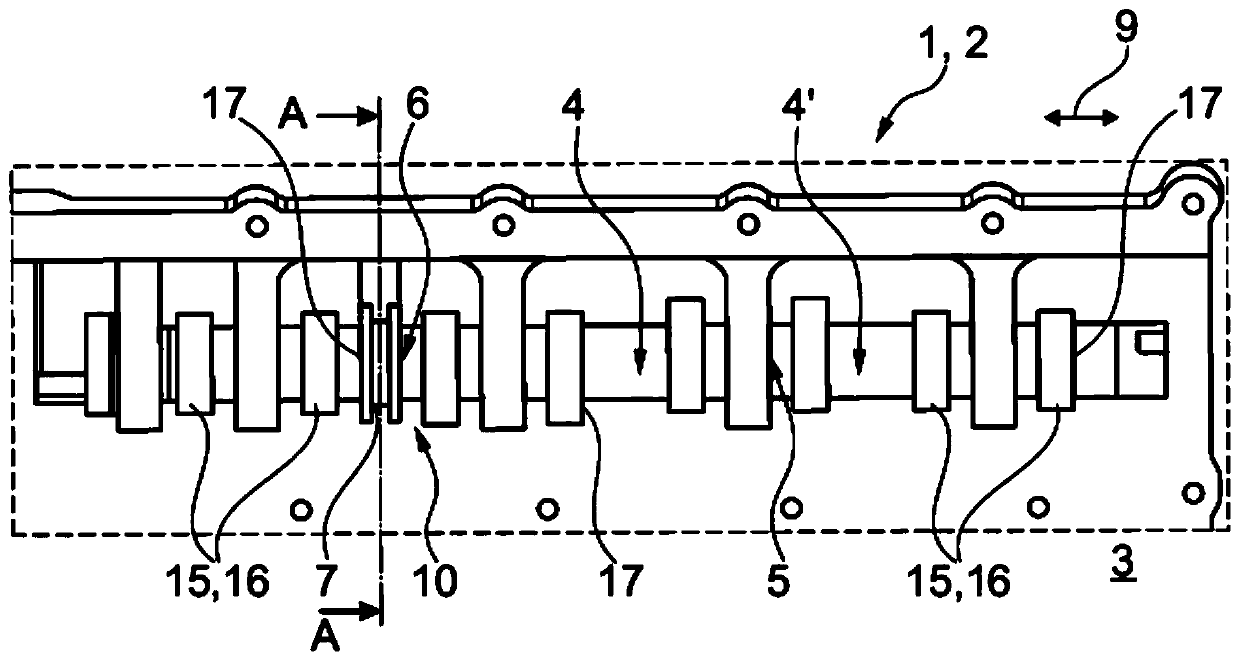

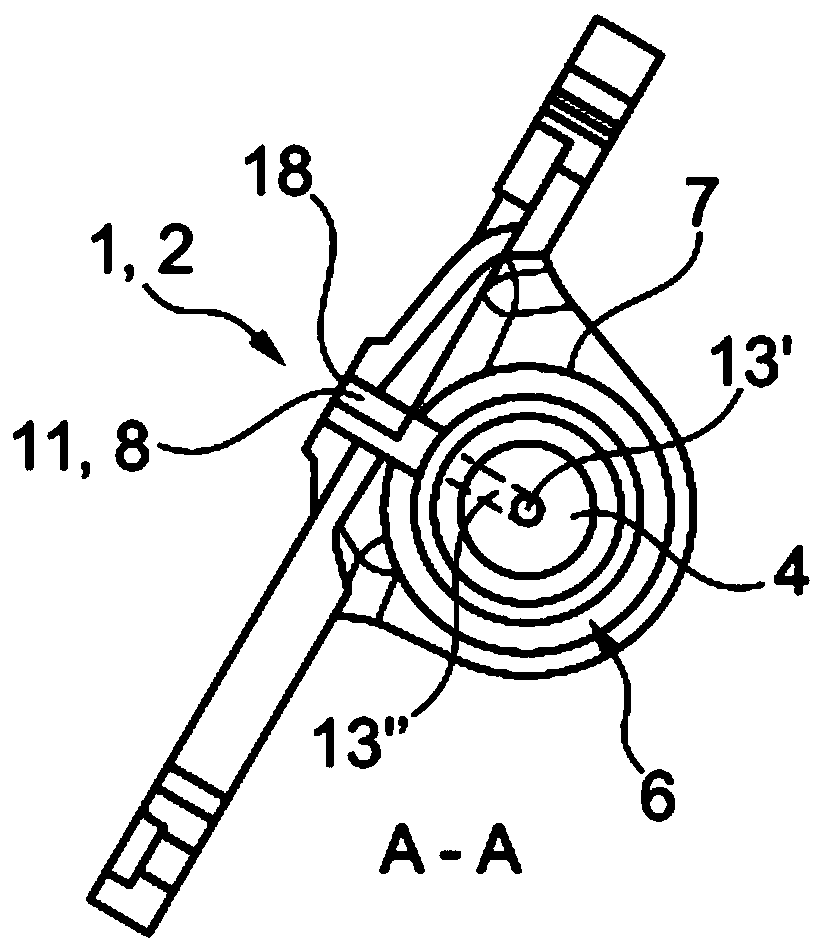

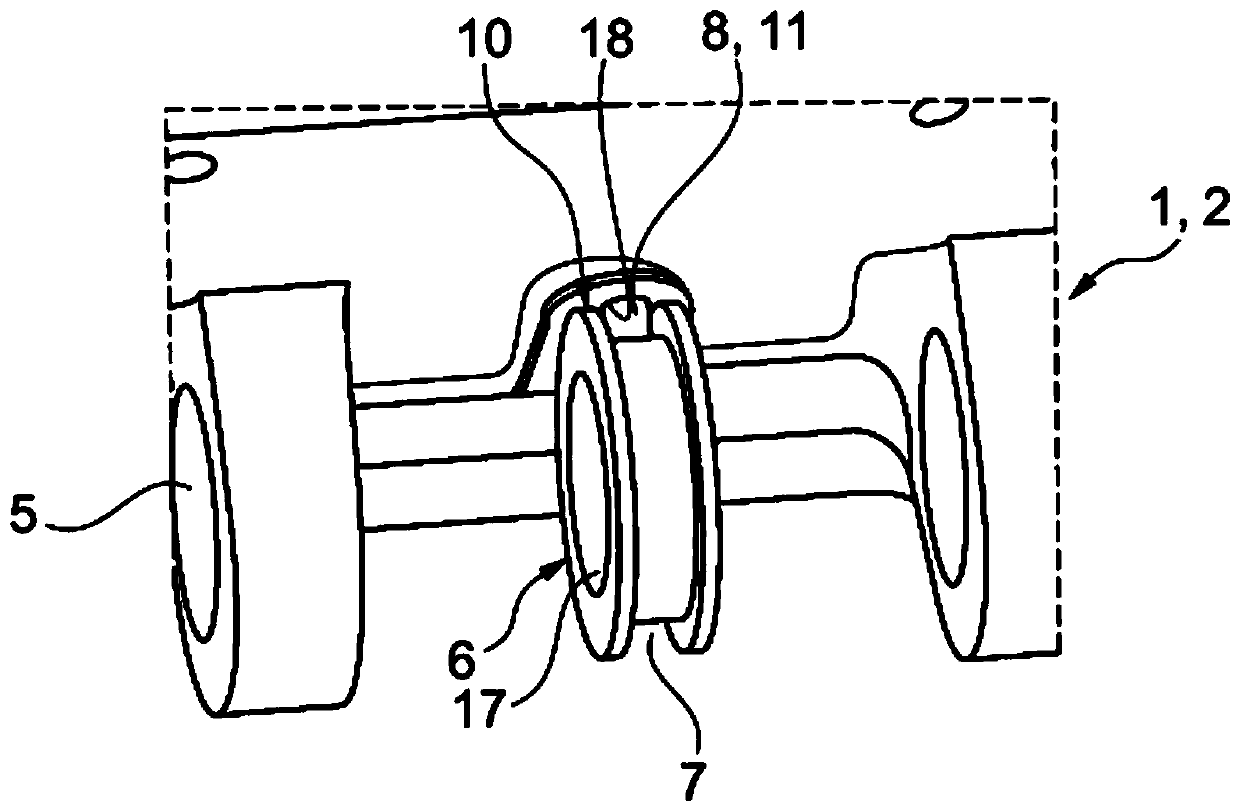

[0029] according to Figure 1 to Figure 5 , the bearing frame 1 of the internal combustion engine 3 according to the invention or the cylinder head cover 2 of the internal combustion engine 3 according to the invention has at least one camshaft body 4 mounted therein (cf. figure 1 and figure 2 ), the camshaft body 4 is mounted in at least two bearing openings 5 arranged along the bearing channel in the tunnel bearing. Here, the bearing opening 5 completely closes off the camshaft body 4 . According to the invention, at least one axial shaft support ring 6 (see, inter alia, figure 2 and image 3 ) is then arranged on the camshaft body 4 , the axial shaft body bearing ring 6 has an annular groove 7 which is open towards the bearing frame 1 or towards the cylinder head cover 2 . At least one associated engagement element 8 is arranged on the support frame 1 or on the cylinder head cover 2 , which engagement element 8 engages to the annular groove 7 and, as a result, forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com