Graphitic brush, and motor having graphitic brush

A graphite and motor technology, applied in circuits, current collectors, electrical components, etc., can solve the problems of easy wear and tear of graphite brushes, shortened motor life, and increased wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

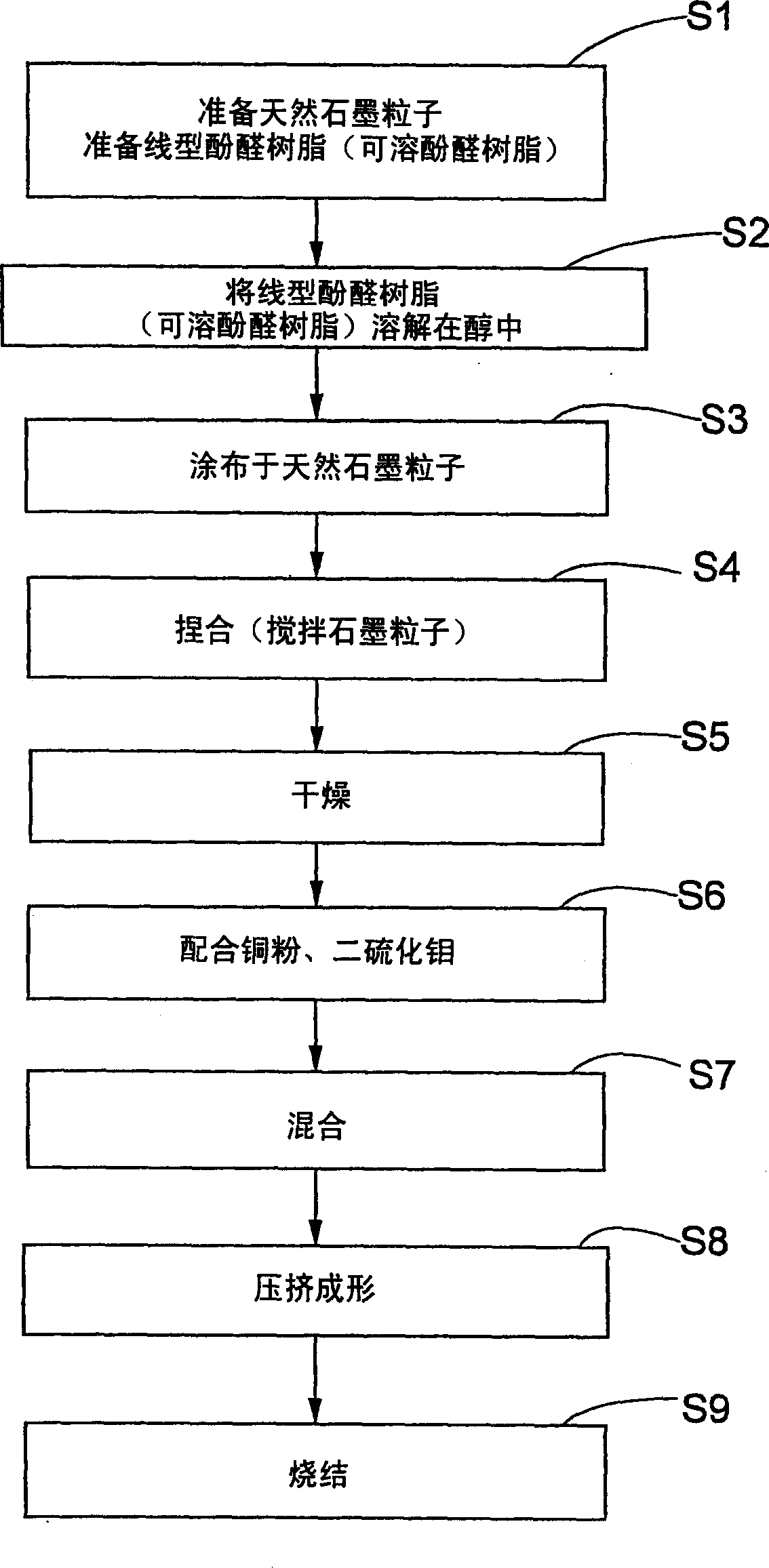

Method used

Image

Examples

Embodiment 1

[0085] A continuous operation test of the motor 10 was performed using a graphite brush 1 impregnated with ethylene glycol having a boiling point of about 198° C. as the liquid 21 . Also, for ethylene glycol, the temperature at which the vapor pressure reaches 18mmHg is 105°C, and the temperature at which the vapor pressure reaches 355mmHg is 175°C. The result is as Figure 8 It can be seen that the amount of wear can be reduced up to about 180°C, and the amount of wear increases as the temperature rises at an operating temperature above that. That is, up to about 100°C is the effect of moisture absorbed from the atmosphere, and up to 180°C is the effect of ethylene glycol. In addition, when the temperature exceeds 180° C., the vapor pressure of ethylene glycol further increases, and the time until it is exhausted is shortened, so the operating temperature increases, and the amount of abrasion of the graphite brush 1 increases. Therefore, the motor 10 using the graphite brus...

Embodiment 2

[0087]Using the graphite brush 1 impregnated with glycerin having a boiling point of about 290° C. as the liquid 21 , a continuous operation test of the motor 10 was carried out in the same manner as in Example 1. FIG. Also, glycerin has a vapor pressure of 180 °C at 18 mmHg and a temperature of 355 mmHg at 260 °C. The result is as Figure 9 As shown, the amount of wear can be reduced up to about 100°C and 200 to 250°C, and the amount of wear increases at operating temperatures in between. Similar to Example 1, up to 100°C is the effect of moisture absorbed from the atmosphere, and at 200 to 250°C is the effect of glycerin. However, at the temperature in between, the moisture evaporates before reaching 100 hours, and the evaporation temperature of glycerin is still low. Therefore, if the temperature becomes higher between 100 and 200°C, the time until the moisture is exhausted will be shortened, so the amount of wear will increase. . Therefore, the motor 10 using the graphi...

Embodiment 3

[0091] As a liquid 21, make a Figure 11 A graphite brush 1 is impregnated with a mixture of three glycol ethers having vapor pressure characteristics shown. Diethylene glycol dimethyl ether has a vapor pressure of 18mmHg to 355mmHg and a wide temperature range of about 55°C to 135°C. In addition, both terminal groups have methyl groups and are diethers, so they are the most thermally stable diethyl ethers. A kind of alcohol ether. Furthermore, it has hygroscopicity, and its molecular weight is 134.17, which is about 50% larger than that of glycerin, which is 92.09.

[0092] Triethylene glycol dimethyl ether has a vapor pressure of 18mmHg to 355mmHg and a temperature range of about 115°C to 190°C. In addition, both terminal groups are methyl groups and are triethers, so it is the most thermally stable dimethicone. A kind of alcohol ether. Like ethylene glycol dimethyl ether, it has hygroscopicity, and its molecular weight is 178.22, which is nearly twice as large as glyceri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com