Patents

Literature

114results about How to "Balance of Mechanical Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing low-temperature flexible random copolymerization polypropylene product

The invention discloses a method for preparing a low-temperature flexible random copolymerization polypropylene product, which comprises the following steps of: melting and blending 100 parts of random copolymerization polypropylene resin containing less than 4 percent of ethylene monomers and 5 parts of beta nucleating agent to prepare a beta nucleating agent master batch; melting and blending 2 to 10 parts of beta nucleating agent master batch, 100 parts of random copolymerization polypropylene resin containing less than 4 percent of ethylene monomers and 0.1 to 0.5 part of antioxidant to prepare random copolymerization polypropylene modified aggregates, and performing injection molding on the aggregates to form a product; and finally, annealing the product at the temperature of 90 and 120 DEG C for 1 to 12 hours, and placing at the room temperature for over 48 hours. The product prepared by the method has the balanced mechanical property and can maintain excellent rigidity while improving low-temperature toughness substantially, so the method provides the new technology for the preparation of copolymerization polypropylene products of products such as tubular products, electrical and electronic equipment, home appliances, automobiles and the like which have the excellent low-temperature toughness.

Owner:SICHUAN UNIV

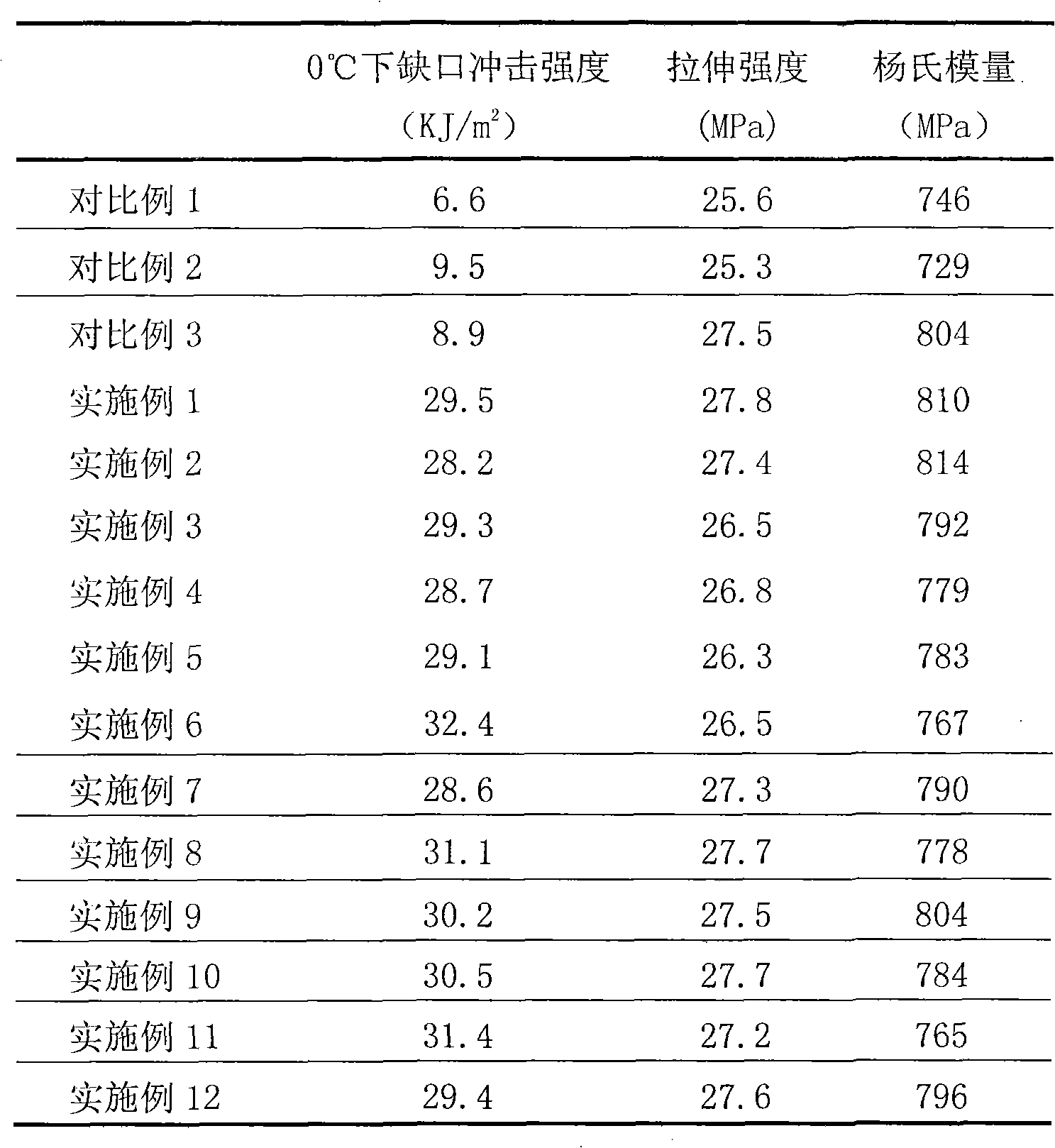

High flow polyolefin composition with high stiffness and toughness

The present invention relates to a polyolefin composition comprising two heterophasic propylene copolymers which differ in the intrinsic viscosity of their xylene soluble fractions.

Owner:BOREALIS AG

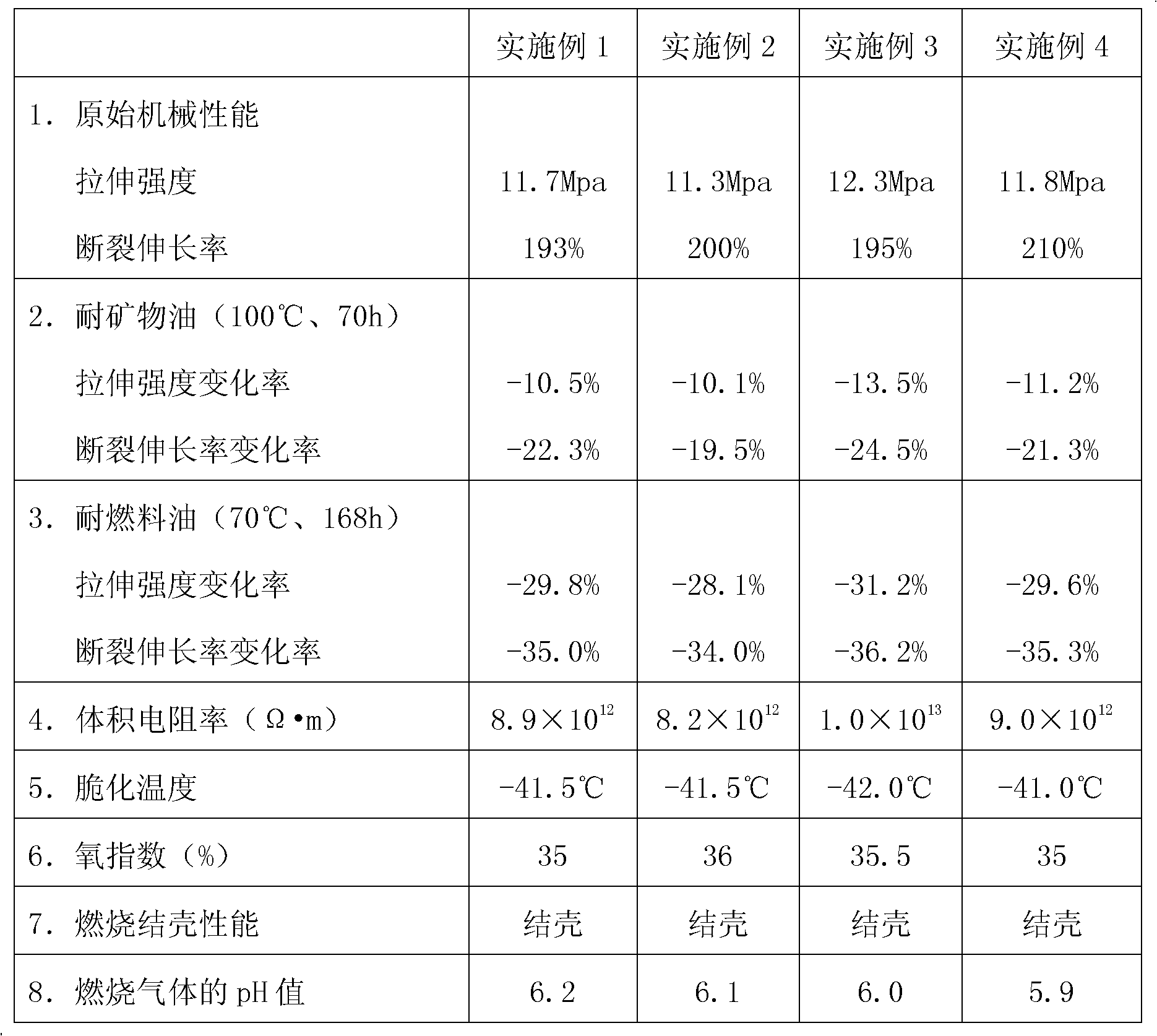

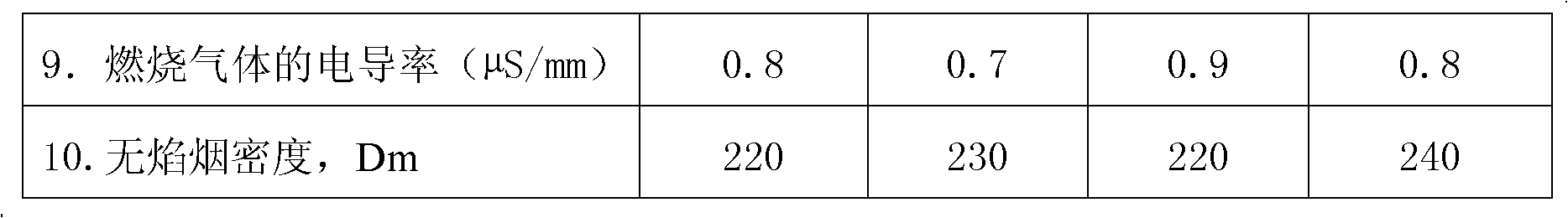

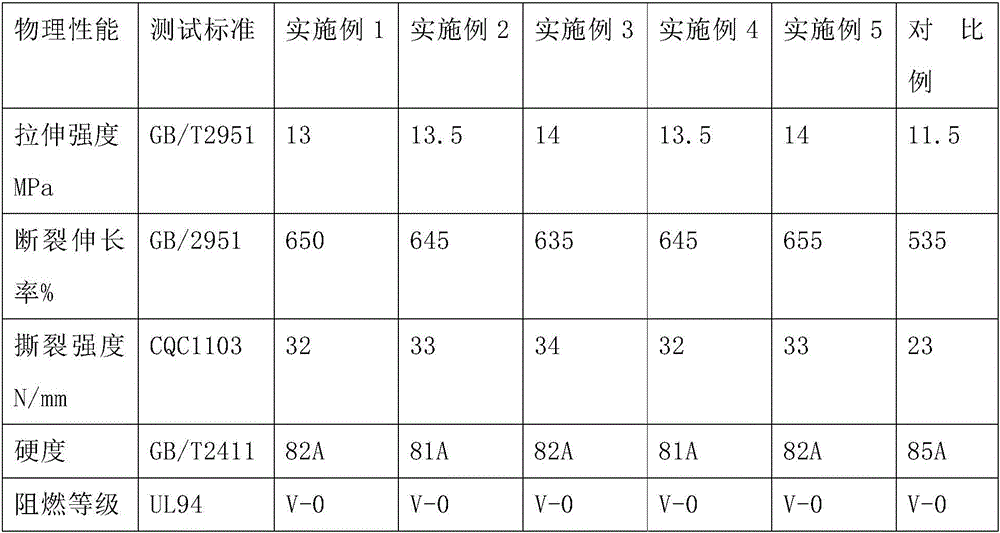

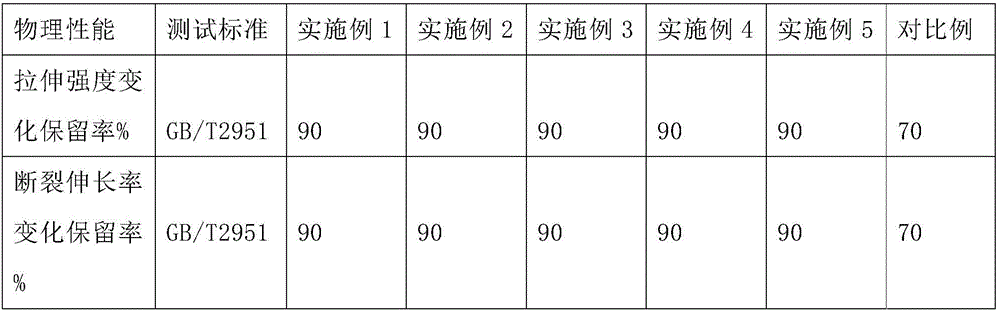

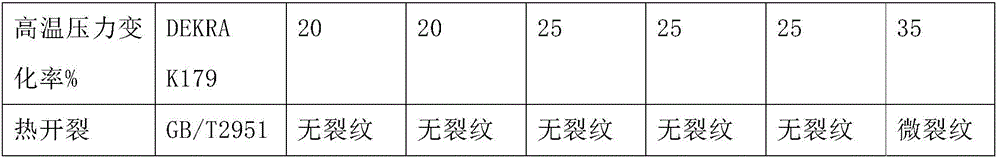

Crosslinked, oil-resistant, low temperature-resistant, low-smoke, halogen-free and flame-retardant cable material and its preparation method

InactiveCN102485782AGood oil resistanceImprove low temperature resistanceInsulated cablesInsulated conductorsPolyolefinCarvacryl acetate

The invention belongs to the wire and cable material field, and relates to a crosslinked, oil-resistant, low temperature-resistant, low-smoke, halogen-free and flame-retardant cable material and its preparation method. The crosslinked, oil-resistant, low temperature-resistant, low-smoke, halogen-free and flame-retardant cable material comprises the following raw materials by weight percentage: 10-20% of ethane-vinyl acetate copolymer with low VA content, 10-20% of ethane-vinyl acetate copolymer with high VA content, 10-30% of graft polyolefin, 40-60% of fire retardant, 1-10% of crustization agent, 2-5% of plasticizer, 1-3% of crosslinking sensitizing agent, 0.5-3% of anti-oxidant, 0.5-2% of processing auxiliary agent and 0-3% of colouring agent. The obtained cable material has the advantages of relative balance and excellent mechanical property, oil resistant performance, low temperature resistance performance, flame resistance and the like. The crosslinked, oil-resistant, low temperature-resistant, low-smoke, halogen-free and flame-retardant cable material of the present invention can be widely used in the track traffic vehicle cable field.

Owner:SHANGHAI SPECIAL CABLE ELECTROTECHN

Flame retardant acrylonitrile butadiene styrene (ABS) composition with high heat resistance and high toughness and preparation method and application thereof

InactiveCN102827452ABalance of Mechanical PropertiesSimple manufacturing methodPolymer scienceMicrowave oven

The invention discloses a flame retardant acrylonitrile butadiene styrene (ABS) composition with high heat resistance and high toughness and a preparation method and the application of the composition; the flame retardant ABS composition comprises the components in parts by weight: 100 parts of high temperature resistant ABS masterbatches, 10-25 parts of environment-friendly brominated flame retardant, 5-10 parts of flame retardant synergist, 0.5-2 parts of maleic anhydride grafting styrene block copolymer (SEBS), 5-15 parts of flexibilizer and 0.5-5 parts of processing agent. The preparation method of the flame retardant ABS composition comprises two steps of: firstly, preparing the high temperature resistant ABS masterbatches; and secondly, mixing the temperature resistant ABS masterbatches, the environment-friendly brominated flame retardant, the flame retardant synergist, the maleic anhydride grafting SEBS, the flexibilizer and the processing agent, adding the mixture into a twin-screw extruder and then carrying out extruding and pelleting to obtain the flame retardant ABS plastic particles with high heat resistance and high toughness. The flame retardant ABS composition with high heat resistance and high toughness has high heat resistance, impact resistance and flame retardant effect as well as excellent stability and mechanical property, thus being widely applied to the fields such as a motor, a blower, a power supply box, a microwave oven, an electric cooker, an extension socket, an automobile instrument, a heat-resistant storage battery and the like.

Owner:WUHAN JINFA TECH CO LTD

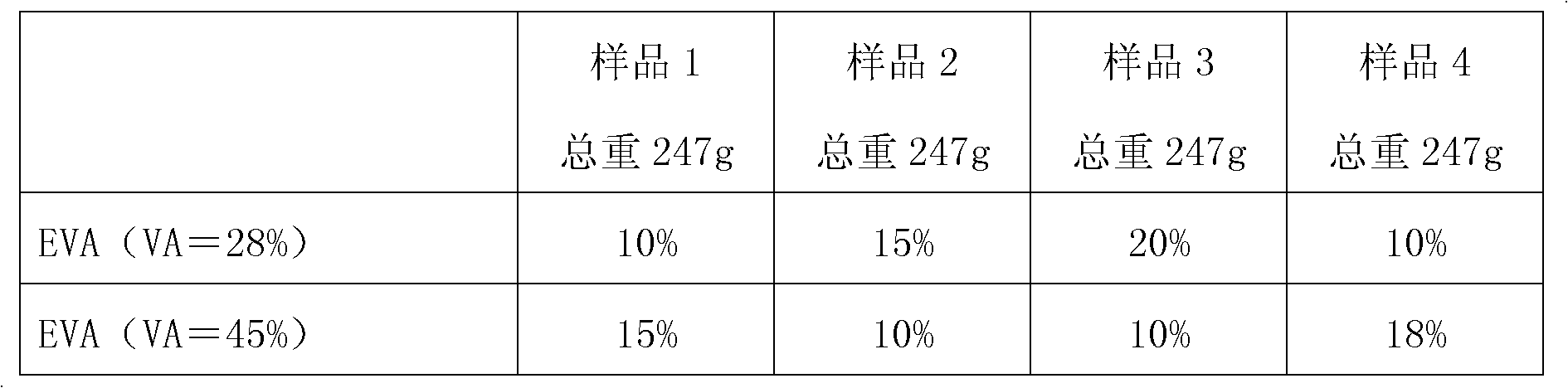

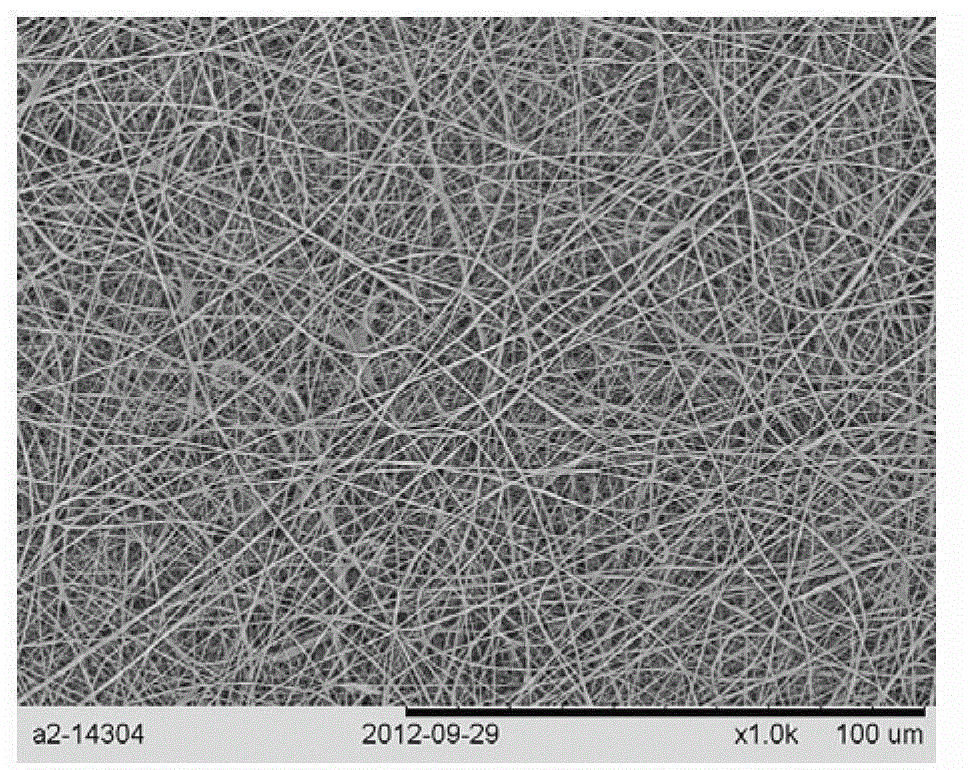

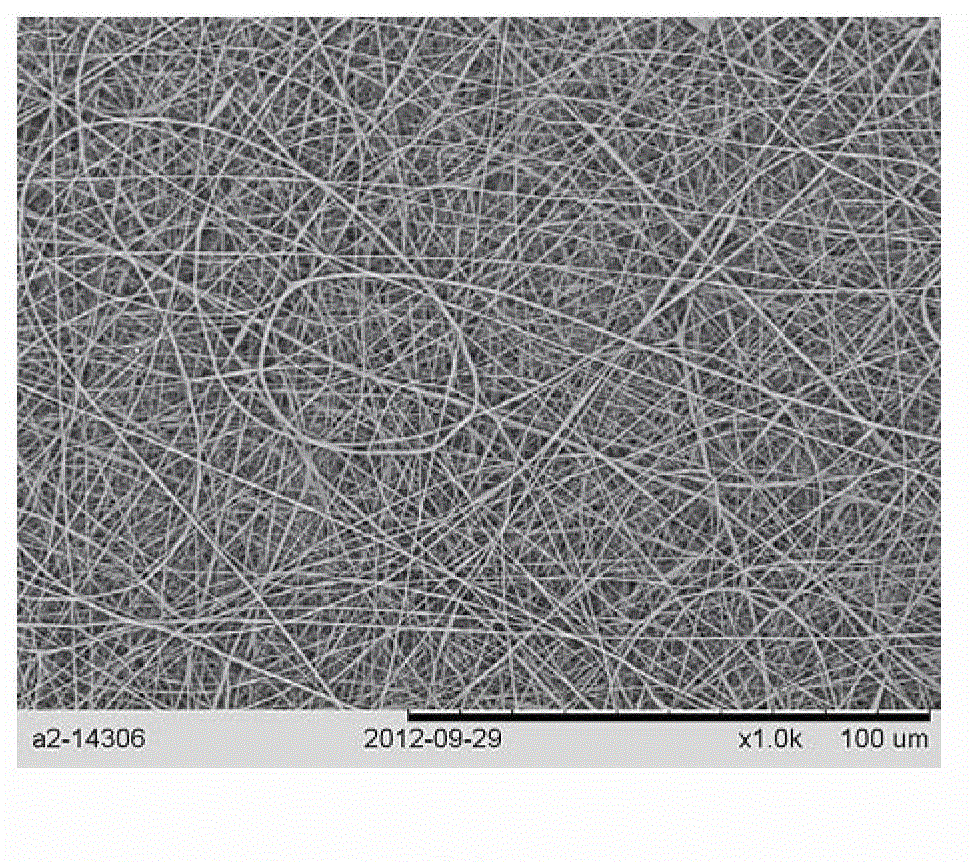

Preparation method for protein-polyose-polylactic acid polycaprolactone vascular stent

InactiveCN103147225AGood balance mechanicsWell balanced biocompatibilityNon-woven fabricsProsthesisBiocompatibility TestingVascular tissue engineering

The invention relates to a preparation method for a protein-polyose-polylactic acid polycaprolactone vascular stent. The method comprises the following steps: (1) completely dissolving chitosan into a hexafluoroisopropanol and trifluoroacetic acid mixed solution to obtain a chitosan solution; (2) completely dissolving collagen into hexafluoroisopropanol to obtain a collagen solution; (3) completely dissolving polylactic acid polycaprolactone into hexafluoroisopropanol to obtain a polylactic acid polycaprolactone solution; and (4) mixing and stirring the chitosan solution, the collagen solution and the polylactic acid polycaprolactone solution to obtain a protein-polyose-polylactic acid polycaprolactone spinning solution, and then achieving static spinning to obtain the protein-polyose-polylactic acid polycaprolactone vascular stent. The prepparation materials have superior biocompatibility and mechanical property; and the designed multi-component composite biological material has a broad application prospect, and the preparation method is simple and feasible and is mainly used in small-caliber vascular tissue engineering.

Owner:DONGHUA UNIV

High flow polyolefin composition with high stiffness and toughness

The present invention relates to a polyolefin composition comprising two heterophasic propylene copolymers which differ in the intrinsic viscosity of their xylene soluble fractions.

Owner:BOREALIS AG

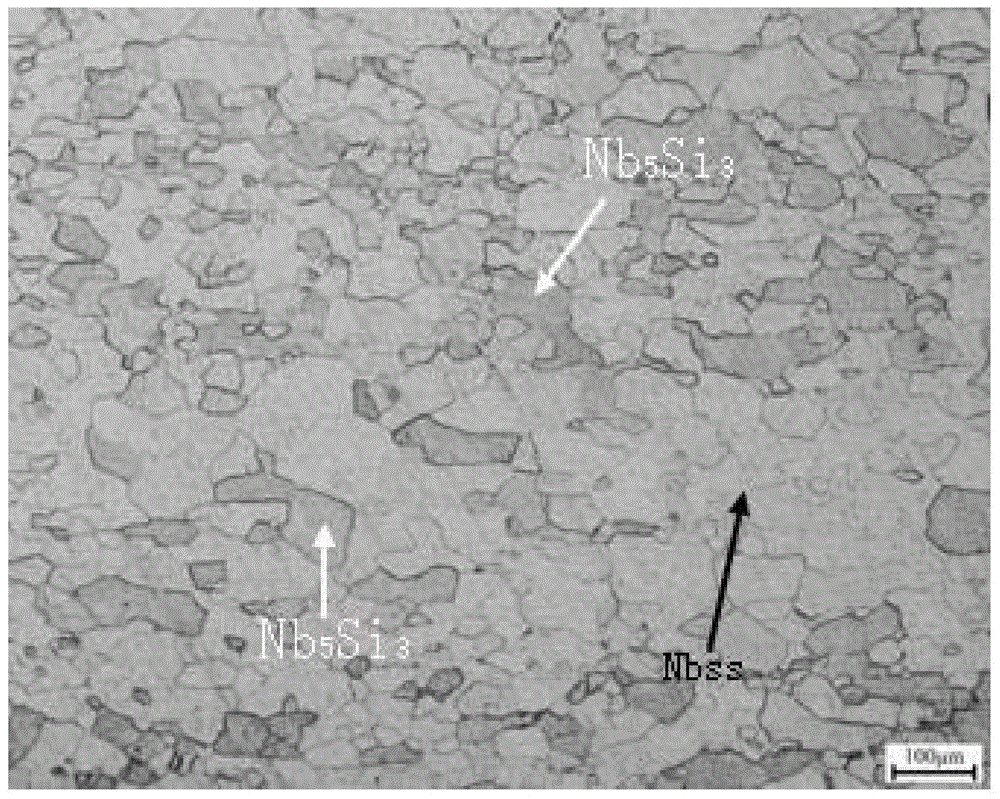

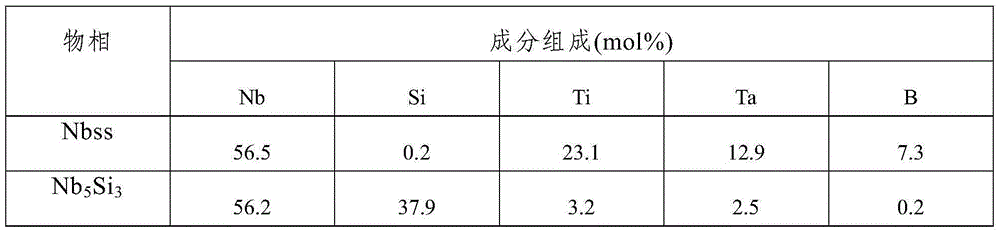

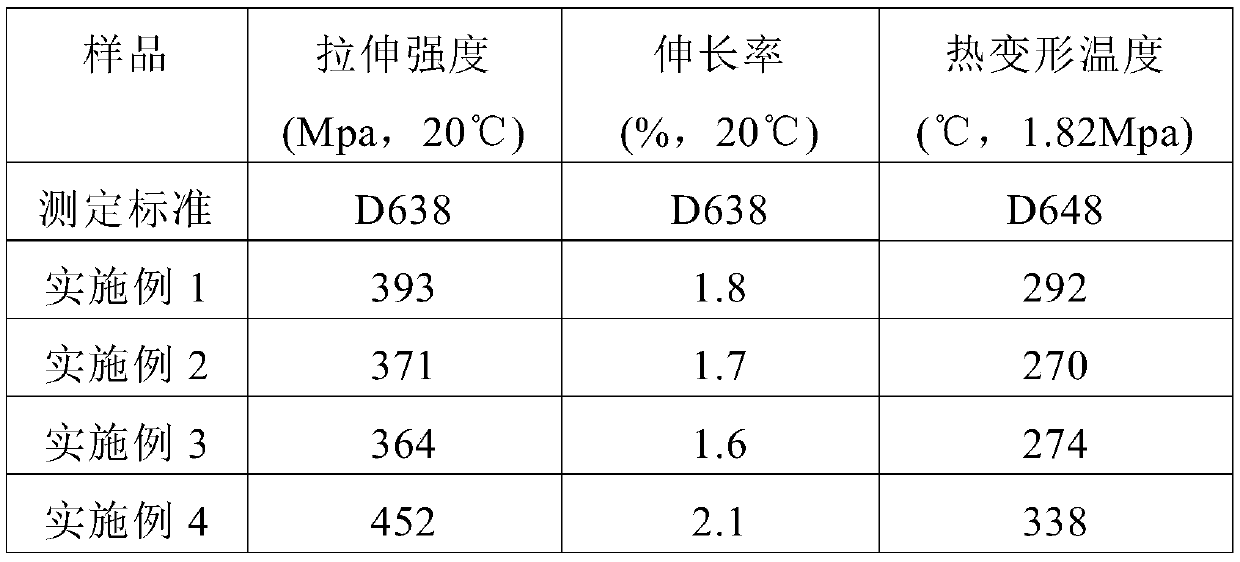

Nb-Si-Ti-Ta-B alloy material and preparation method thereof

ActiveCN105200295ARoom temperature ductility balanceBalance of Mechanical PropertiesNiobiumMechanical property

The invention discloses an Nb-Si-Ti-Ta-B alloy material which is prepared from the following raw materials according to the following atom percentage: 6-20% of Si, 16-30% of Ti, 5-15% of Ta, 2-8% of B and the rest of Nb and unavoidable impurities. In addition, the invention also discloses a method for preparing the Nb-Si-Ti-Ta-B alloy material. The method comprises the following steps: 1, silicon powder, titanium powder, tantalum powder, boron powder and niobium powder are uniformly mixed and the mixture is compacted to form an electrode, and electric arc melting is carried out to obtain an alloy ingot; and 2, the alloy ingot undergoes extrusion so as to obtain the Nb-Si-Ti-Ta-B alloy material. Tensile strength of the Nb-Si-Ti-Ta-B alloy material under the condition of 1300 DEG C is 267MPa-425MPa. Ductility and toughness at room temperature, room-temperature mechanical property and high temperature tensile strength of the Nb-Si-Ti-Ta-B alloy material are well balanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-performance heat conduction material and preparation method thereof

ActiveCN102702742ABalance of Mechanical PropertiesImprove performanceTemperature controlPolyetherimide

The invention relates to the technical field of high polymer materials, and discloses a high-performance heat conduction material. The high-performance heat conduction material consists of the following components in part by weight: 25 to 50 parts of polyetherimide (PEI), 5 to 10 parts of polyamide (PA), 30 to 60 parts of heat conduction filler, 5 to 15 parts of reinforcing material, 0 to 2 parts of compatilizer, 0 to 5 parts of lubricating agent, and 0 to 5 parts of other aid; and a nine-section temperature control twin-screw extrusion process is used as a preparation method. The characteristic of heat conduction and the mechanical property of the heat conduction high polymer material are balanced. By adding the heat conduction filler, the heat-conducting property of the material is improved; by adding PA, the processing performance of the material is improved, and cost is reduced; and compatilizer, the lubricating agent, and other aids are added selectively, so that the performance of the material can be improved further according to using requirements.

Owner:昆山聚威工程塑料有限公司

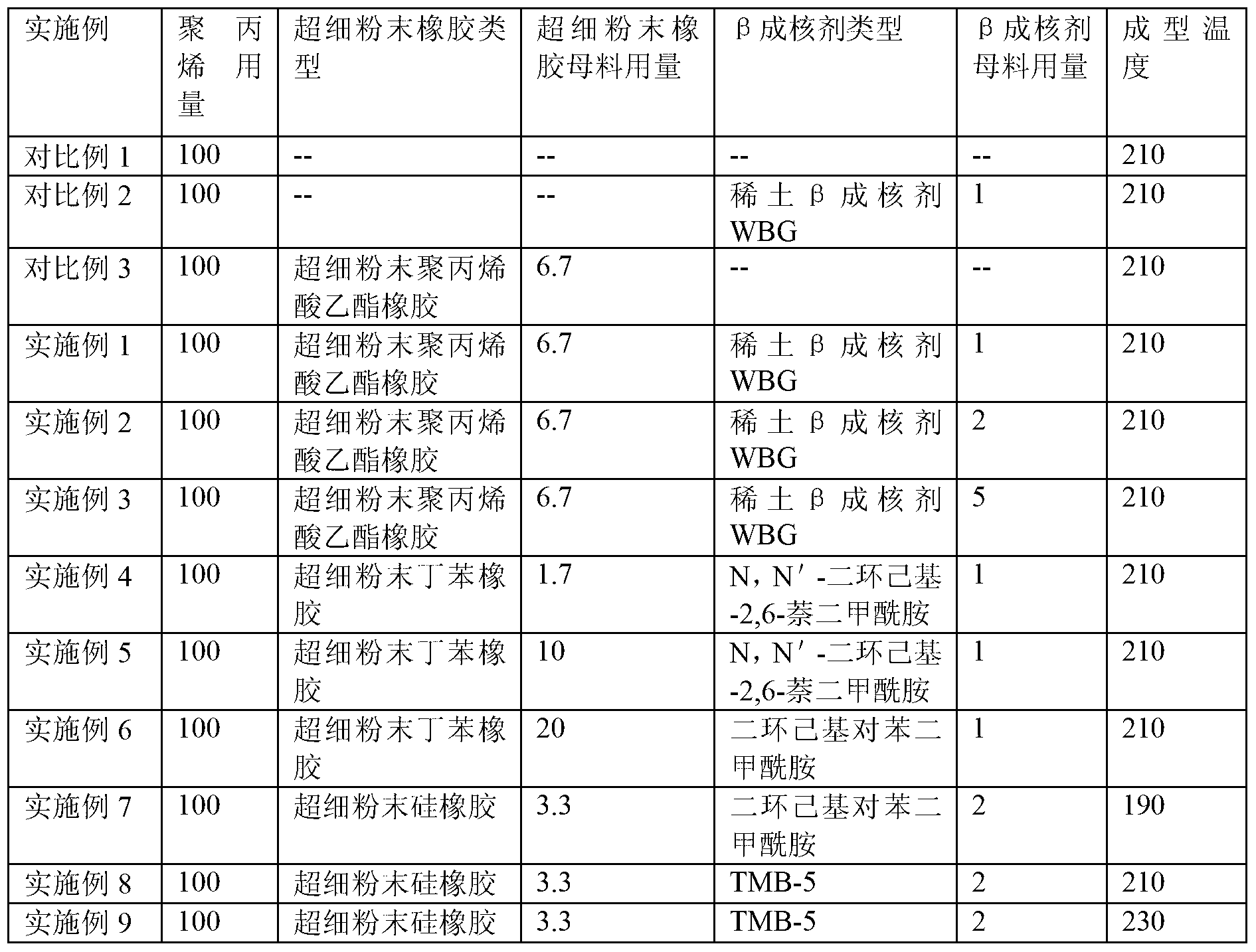

Preparation method for low temperature toughness isotatic polypropylene product

ActiveCN103265758ALower glass transition temperatureGood low temperature performancePolypropyleneRubber technology

The invention discloses a preparation method for a low temperature toughness isotatic polypropylene product. The preparation method comprises the following steps of (1) pre-mixing 100 parts of isotatic polypropylene resin and 5 parts of beta nucleating agent to obtain a mixture and then putting the mixture into a twin-screw extruder, and carrying out melt blending and extruding to obtain beta nucleating agent master batch; (2) pre-mixing 100 parts of isotatic polypropylene resin and 30 parts of superfine powder rubber to obtain a mixture and then putting the mixture into the twin-screw extruder, and carrying out melt blending and extruding to obtain superfine powder rubber master batch; (3) pre-mixing 100 parts of isotatic polypropylene resin, 1-5 parts of beta nucleating agent master batch, 1.7-20 parts of superfine powder rubber master batch and 0.1-0.2 part of antioxygen to obtain a mixture and then putting the mixture into the twin-screw extruder, and carrying out melt blending and extruding to obtain isotatic polypropylene modified granules; and (4) carrying out injection moulding on the isotatic polypropylene modified granules, so as to obtain the low temperature toughness isotatic polypropylene product. According to the method, the technical measures of adding both the beta nucleating agent and the superfine powder rubber are adopted, so that the properties, especially the low temperature impact toughness of the product are greatly improved.

Owner:SICHUAN UNIV

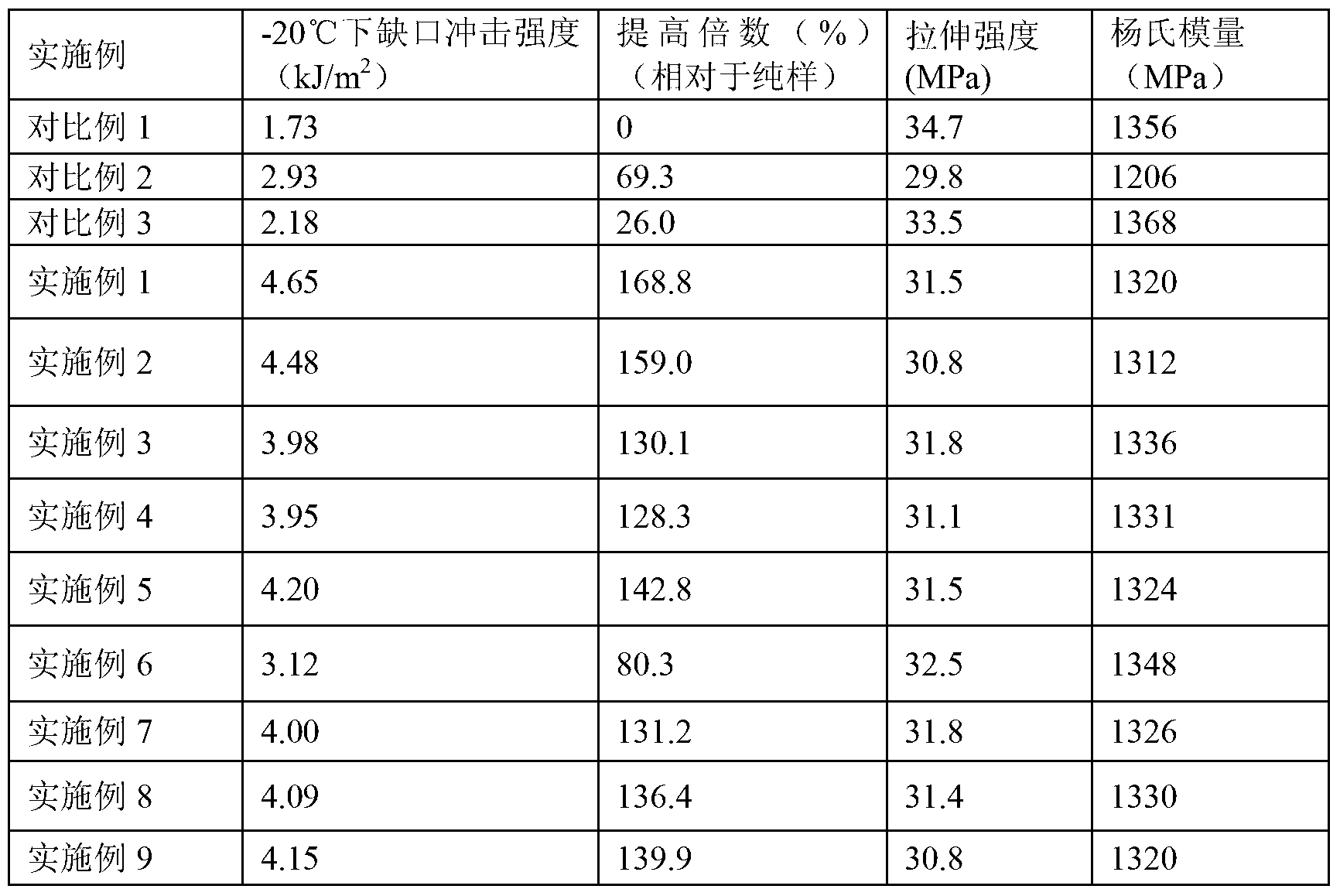

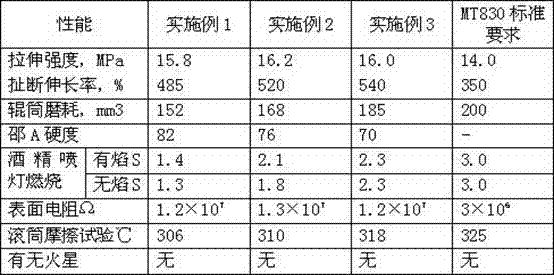

Elastomer for covering layer of fiber laminated flame-retardant conveyor belt used for coal mine and preparation method thereof

The invention discloses an elastomer for a covering layer of a fiber laminated flame-retardant conveyor belt used for a coal mine and a preparation method thereof. The elastomer comprises the following components in parts by weight: 50 to 70 parts of base rubber material natural rubber, 20 to 40 parts of thermoplastic styrene-butadiene rubber SEBS, 5 to 10 parts of modified chlorosulfonated polyethylene MCSM, 40 to 60 parts of a reinforcing agent, 1.5 to 3 parts of a silane coupling agent, 45 to 100 parts of a flame retardant, 5 to 15 parts of an activator, 1.5 to 3 parts of an anti-aging agent, 6 to 15 parts of a flame-retardant plasticizer, 1.0 to 2.5 parts of an accelerator and 1.5 to 3.5 parts of a vulcanizing agent. The elastomer prepared by using the method provided by the invention has good mechanical properties and elasticity, can meet the requirements of underground conveying in the coal mine, is convenient for production and processing, and facilitates reduction of production cost.

Owner:ANHUI OUNAI RUBBER & PLASTIC IND

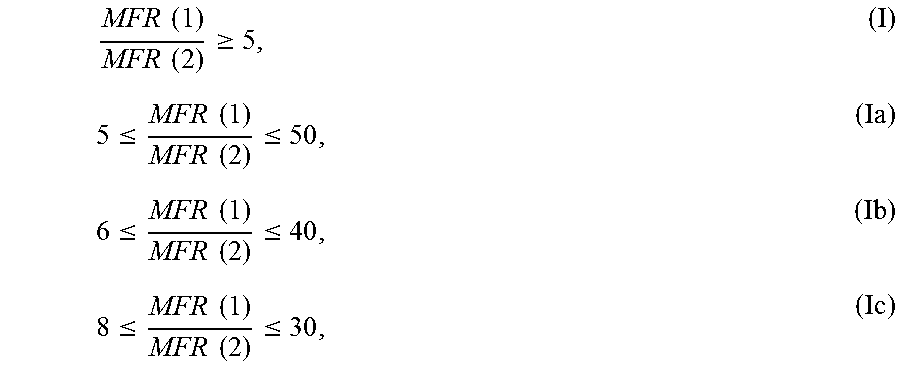

High flow polyolefin composition with high stiffness and toughness

The present invention relates to a polyolefin composition comprising two heterophasic propylene copolymers which differ in the melt flow rate.

Owner:BOREALIS AG

Composition for finishing polish of silicon wafer and preparation method of composition

InactiveCN104530987AEnhance the firmness of the packageAchieve near-limit polishingSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesDispersityCompound (substance)

The invention relates to a composition for finishing polish of a silicon wafer and a preparation method of the composition and relates to the field of chemical mechanical polishing. The composition comprises silicon dioxide sol, a hydroxyl nitrogen-containing alkaline compound, a hydroxyl carboxyl acidic compound, an alkaline compound, a high-molecular compound, a surfactant and deionized water, wherein the particle size of grinding particles in the silicon dioxide sol is 0.1nm to 10nm. According to the composition disclosed by the invention, polishing particles of which the particle size is reduced to a plurality of nanometers are adopted, the hydroxyl nitrogen-containing alkaline compound and the hydroxyl carboxyl acidic compound for stabilizing the polishing particles are also adopted, and the components have the function of effectively maintaining the stability and dispersity of particles, so that the precision and quality of the polished surface of the silicon wafer are improved.

Owner:SHENZHEN LEAGUER MATERIAL +2

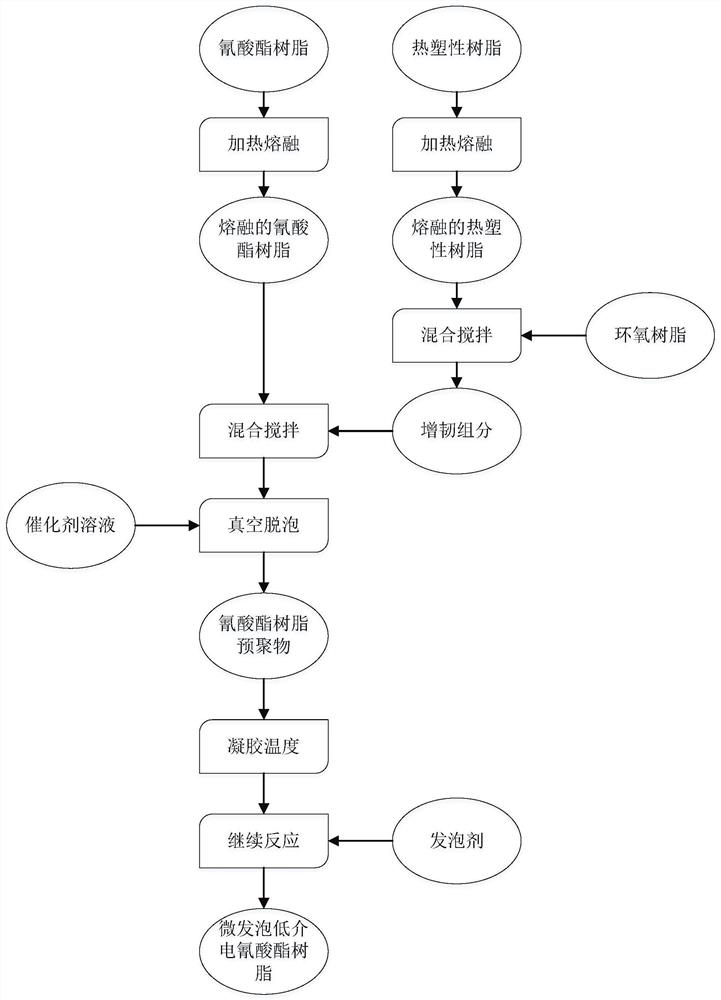

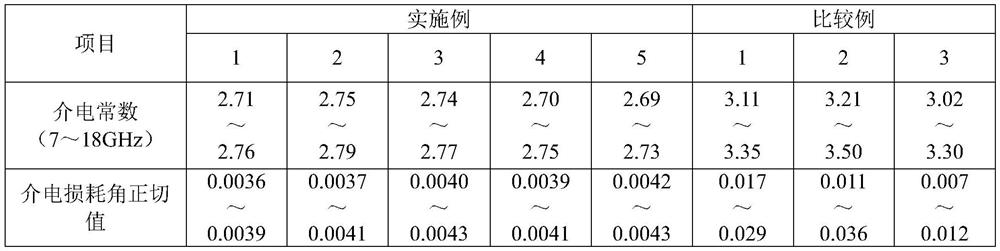

Micro-foaming low-dielectric cyanate ester resin and preparation method thereof

The invention discloses micro-foaming low-dielectric cyanate ester resin and a preparation method thereof, and belongs to the technical field of materials, the micro-foaming low-dielectric cyanate ester resin comprises the following components in parts by mass: 75-95 parts of cyanate ester resin, 5-25 parts of epoxy resin, 5-20 parts of thermoplastic resin, 0.25-5 parts of foaming agent and 0.5-3 parts of catalyst, wherein the thermoplastic resin contains a terminal hydroxyl group, and the foaming agent is an azo monomer containing two formamide reaction groups. The micro-foaming low-dielectric cyanate ester resin has micron-scale pores, so that air is introduced into the resin to reduce interface loss, the resin has a relatively low dielectric constant and loss tangent, the dielectric property has small fluctuation along with frequency change, and meanwhile, the resin has relatively good thermal conductivity, and the mechanical property and dielectric property of the resin are balanced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

ABS resin with high dimensional stability and preparation method thereof

The invention relates to ABS resin with high dimensional stability and a preparation method thereof. The ABS resin is prepared from the following components in parts by weight: 40 to 60 parts of ABS resin, 10 to 18 parts of ABS high rubber powder, 25 to 45 parts of highly branched styrene-acrylonitrile copolymer, 0 to 2 parts of a heat-resisting agent, 10 to 20 parts of a toughening agent and 0.5to 5 parts of an auxiliary agent. Compared with the prior art, the ABS resin with a high precision shrinkage rate is obtained by controlling the content of the high rubber powder ABS and introducing the highly branched SAN and the toughening agent, so that the ABS can be used in structural parts with high requirements on the shrinkage rate, such as automobiles, household appliances and the like, and has a wide market application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

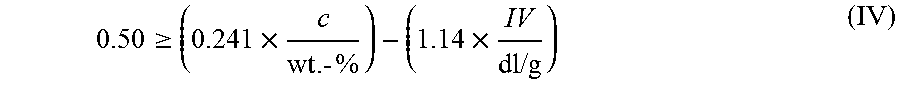

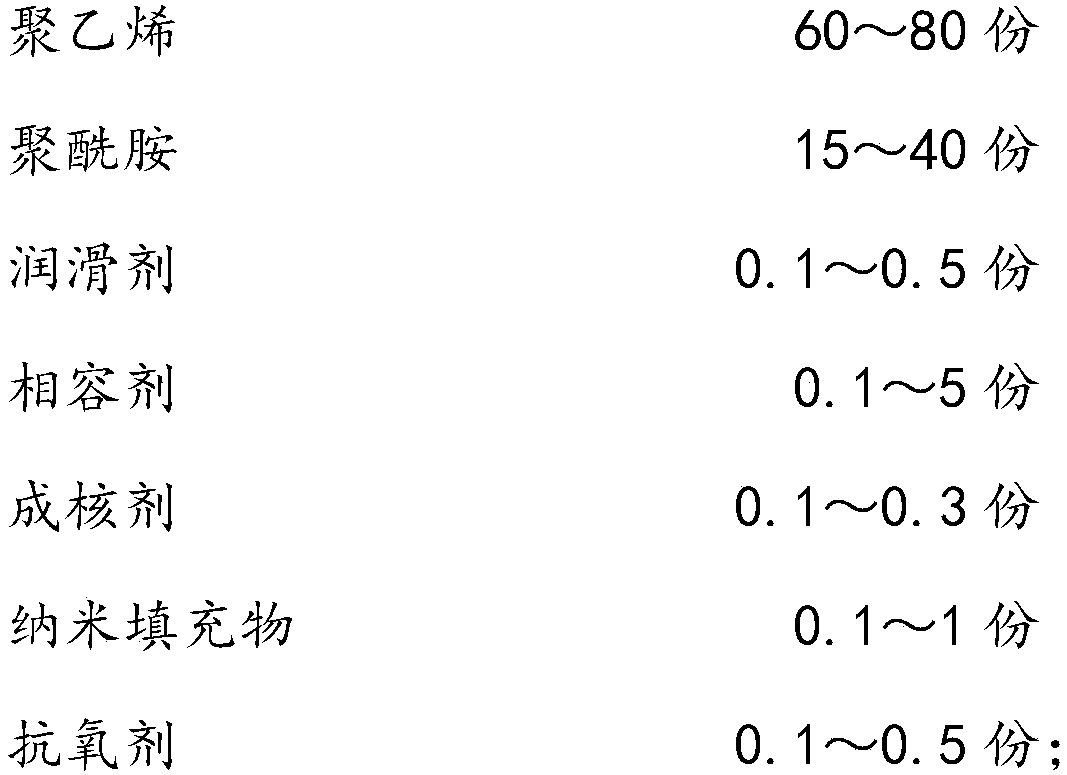

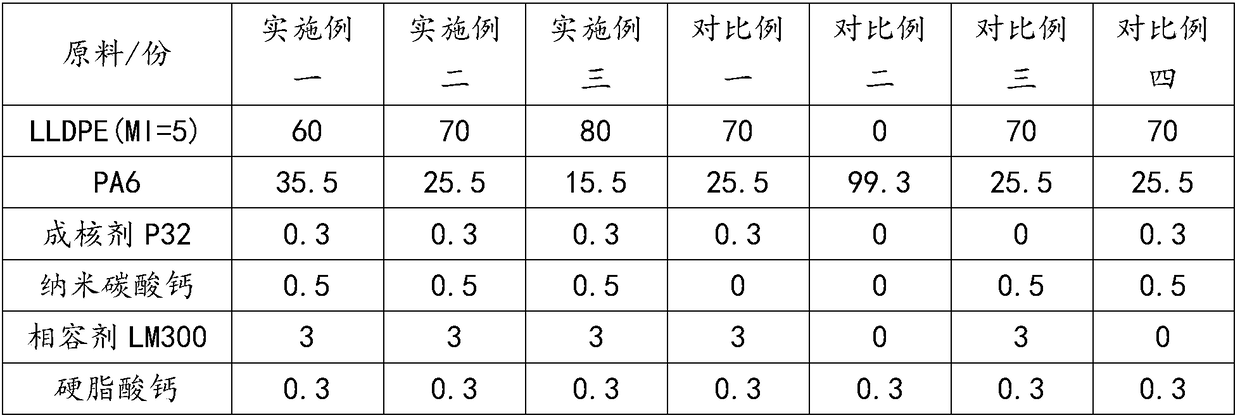

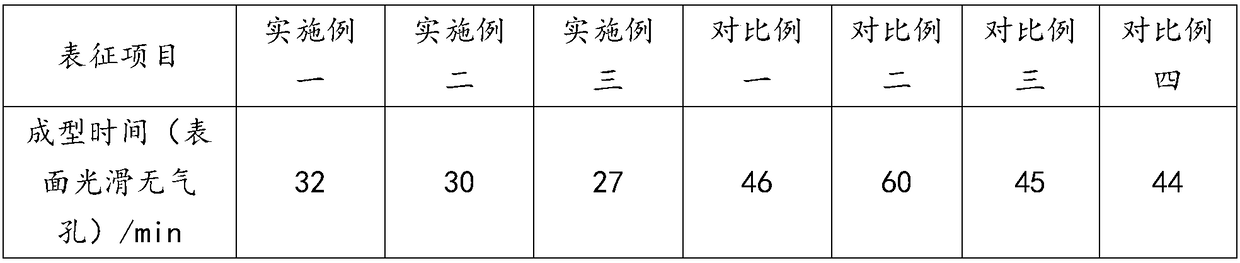

Rapidly-formable composite rotomolding material and power preparation method thereof

InactiveCN109438824APromote aggregation and disappearAvoid degradationAntioxidantWorking temperature

The invention relates to the technical field of rotomolding material modification, in particular to a rapidly-formable composite rotomolding material and a power preparation method thereof. The composite rotomolding material comprises, by mass,, 60-80 parts of polyethylene, 15-40 parts of polyamide, 0.1-0.5 part of lubricants, 0.1-5 parts of compatibilizers, 0.1-0.3 part of nucleating agent, 0.1-1part of nano-filler and 0.1-0.5 part of antioxidant. The rapidly-formable composite rotomolding material has the advantages that gas accumulation and disappearance on the surface of molten resin arepromoted through a certain proportion of nano-fillers, the rotomolding time is shortened, resin degradation is avoided, and polyethylene / polyamide rotomolding products with smooth and pore-free surfaces are obtained; the prepared composite rotomolding material can be grinded at the normal temperature, the high cost of existing refrigerating and grinding techniques is avoided, and the polyethylene / polyamide rotomolding products, with the smooth and pore-free surfaces, high working temperatures and balanced mechanical properties, applicable to rotomolding are obtained.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

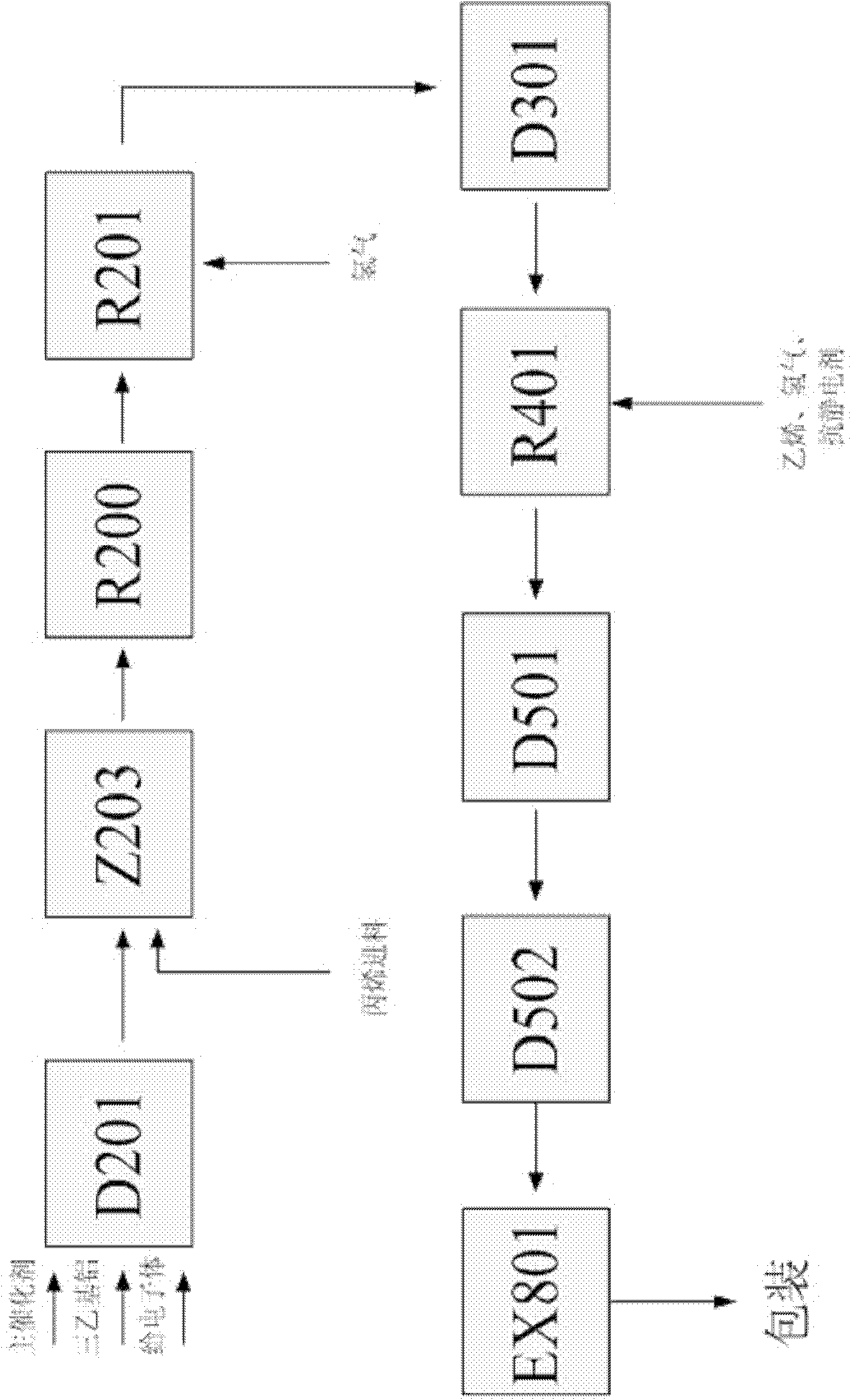

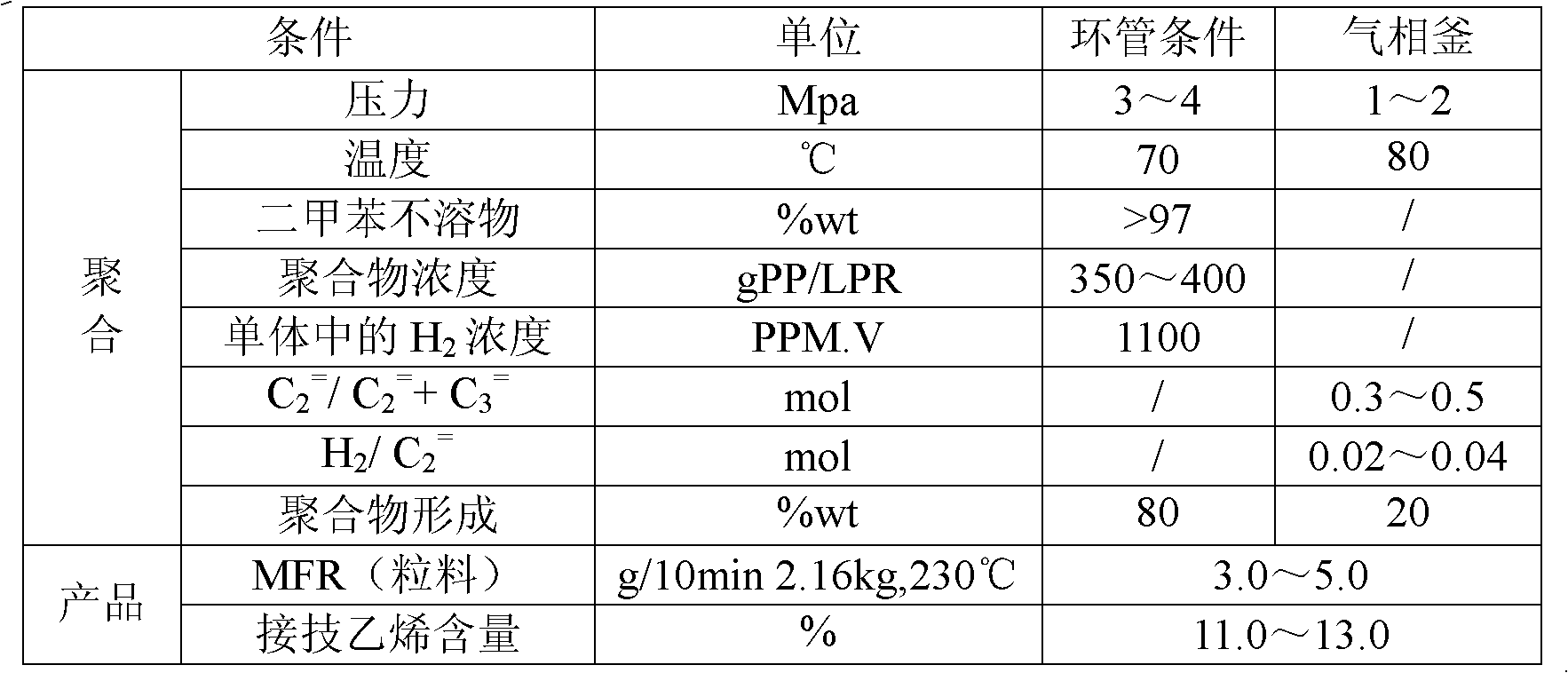

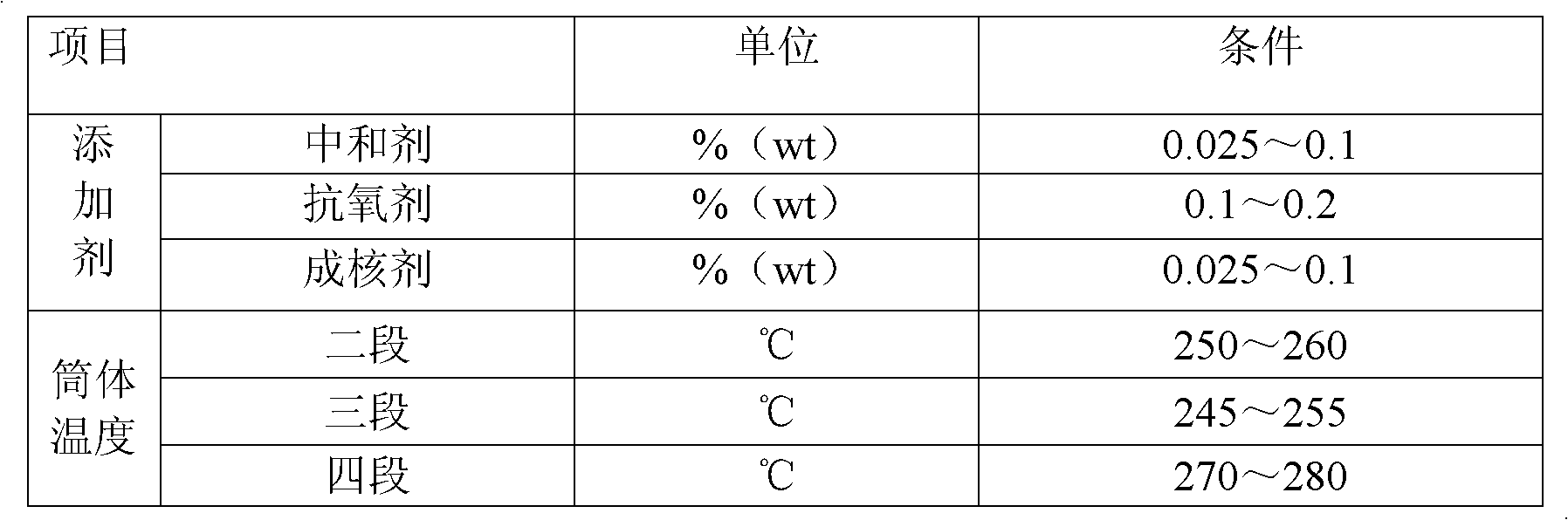

Synthesizing method of high-ethylene-content polypropylene injection molding tank special-purposed resin

ActiveCN102827450ARealize industrial stable scale productionBalance of Mechanical PropertiesPolypropyleneAntioxidant

The invention relates to a synthesizing method of high-ethylene-content polypropylene injection molding tank special-purposed resin. The resin is synthesized by using a Spheripol loop polypropylene apparatus. According to the invention, a CS-II catalyst is adopted; propylene and hydrogen are added into a loop reactor; and propylene homo-polymerization is carried out with a liquid bulk polymerization manner; an obtained homo-polymer, ethylene, propylene and hydrogen are added into a gas-phase reactor, and are subjected to gas-phase copolymerization; ethylene partial pressure ratio is regulated to 40-45%, and copolymer powder with an ethylene content of 11-13% and a relatively high ethylene-propylene rubber-phase content is obtained; the powder is mixed with an antioxidant and a neutralizing agent according to a formulation ratio; a nucleating agent is adopted in auxiliary for improving a product quality; and extrusion granulation and homogenization are carried out, such that the special-purposed material is obtained. A melt flow rate of the special-purposed particle material is 3-5g / 10min.

Owner:PETROCHINA CO LTD

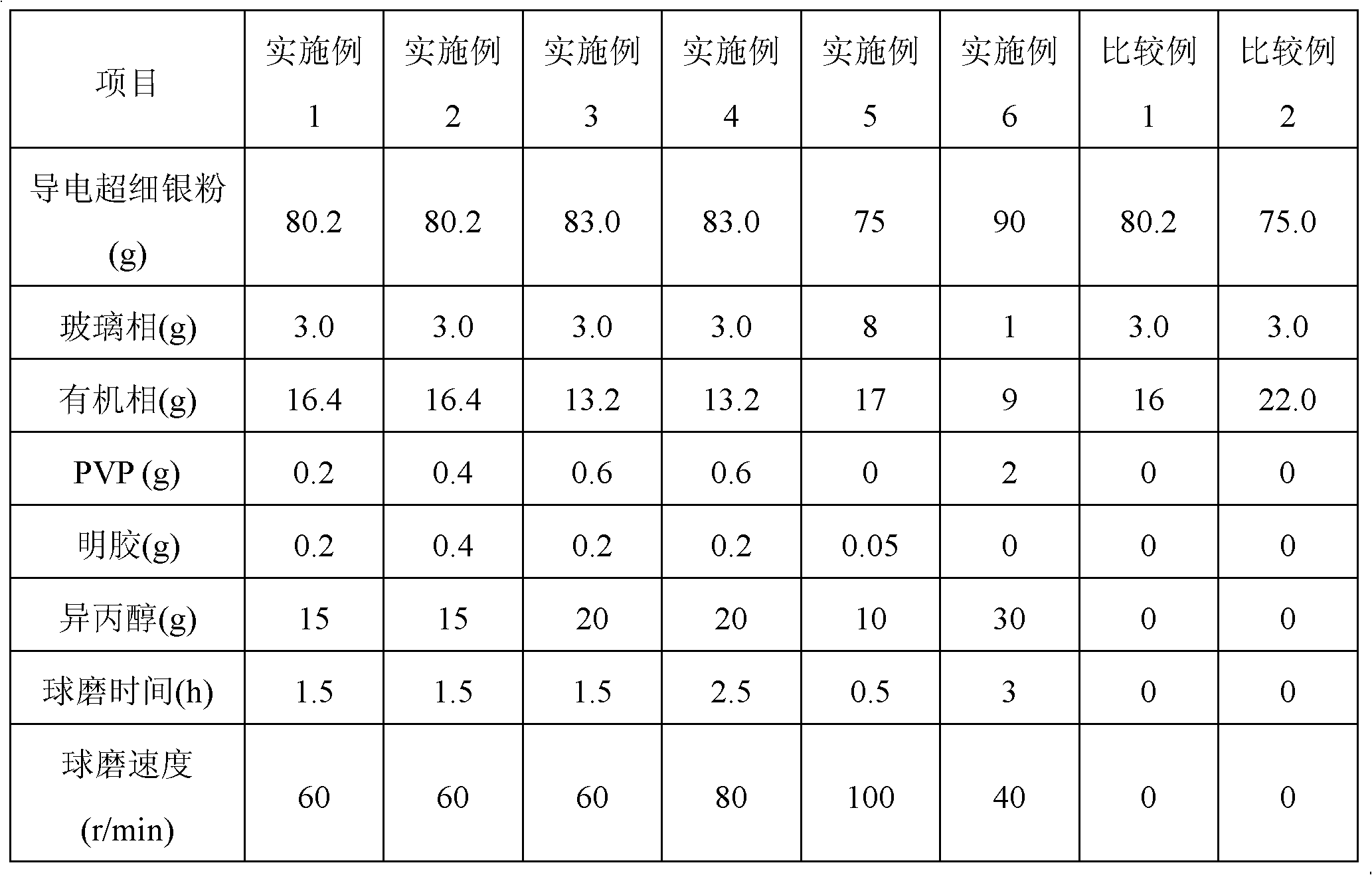

Modified silver thick film sizing agent for crystalline silicon solar cell and preparation method thereof

ActiveCN102543257AImprove the reunion situationImprove electrical performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureElectricityFill factor

The invention discloses a modified silver thick film sizing agent for a crystalline silicon solar cell and a preparation method thereof. The modified silver thick film sizing agent comprises the following ingredients by weight percentage: conductive superfine silver powders accounting for 75 to 90 percent, glass powders accounting for 1 to 8 percent, and organic phases accounting for 9 to 17 percent; in addition, the modified silver thick film sizing agent also comprises surface active agents accounting for 0.05 to 2 percent of the total weight of the conductive superfine silver powders and the glass powders. According to the invention, the surfaces of the powders are coated with a layer of surface active agents, so that the aggregation condition of the powders can be improved, the powders can be dispersed in the organic phases better so as to form a more stable sizing agent system, at the same time, the scraper fineness of the sizing agent can be reduced, and the service life of the sizing agent can be prolonged. An electrode printed through the modified silver thick film sizing agent achieves great height, low body resistance and higher mechanical strength after being sintered. Therefore, not only the modified silver thick film sizing agent disclosed by the invention improves the mechanical strength of the electrode of the cell, but also fill factors (FF) of the cell are increased, the series resistance is reduced, the optical conversion efficiency is improved, and the cell can be enabled to achieve good balance of comprehensive electrical property and mechanical performance.

Owner:上海太阳能工程技术研究中心有限公司

Polymerization preparation method of similar nano inorganic powder material modified styrene resin

The invention provides a polymerization preparation method of similar nano inorganic powder material modified styrene resin. The polymerization preparation method is characterized in that a similar nano inorganic powder material for modification is added after phase transformation in the polymerization process of the styrene monomer.

Owner:GUANGDONG RASTAR SYNTHETIC MATERIAL COMPANY

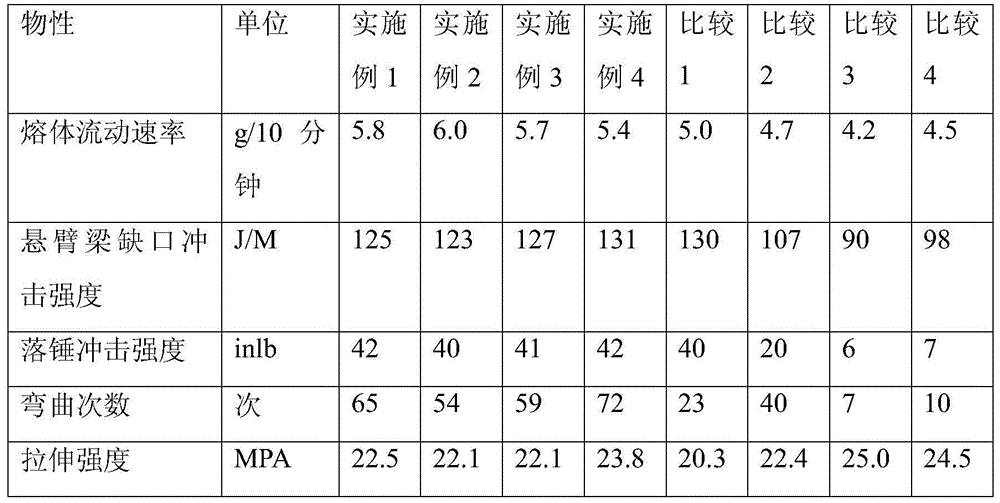

Polypropylene material suitable for manufacturing automobile interior decorations, preparation method and use thereof

The invention discloses a polypropylene material suitable for manufacturing automobile interior decorations, a preparation method and a use thereof. The polypropylene material suitable for manufacturing automobile interior decorations is prepared from the following raw materials in parts by weight: 1-3 parts of lubricant, 0.5-2.5 parts of dispersant, 1-5 parts of antioxidant, 2-6 parts of inorganic filler, 3-8 parts of glass fiber and 30-80 parts of polypropylene. The preparation method is simple, the cost is low, the rigidity, stability, formability, mechanical property, anti-aging property and the like of the polypropylene material are improved by the mutual cooperation of the components; at the same time, it also has good yellowing resistance, and the obtained polypropylene material suitable for manufacturing automobile interior decorations can be used for preparing automobile bumpers, rear-view mirrors, lamps, automobile roofs, glove boxes, automobile seat back plates, door platesand other automobile decorations, and the balance between impact strength and mechanical properties can be obtained.

Owner:湖北瀚氏汽车零部件有限公司

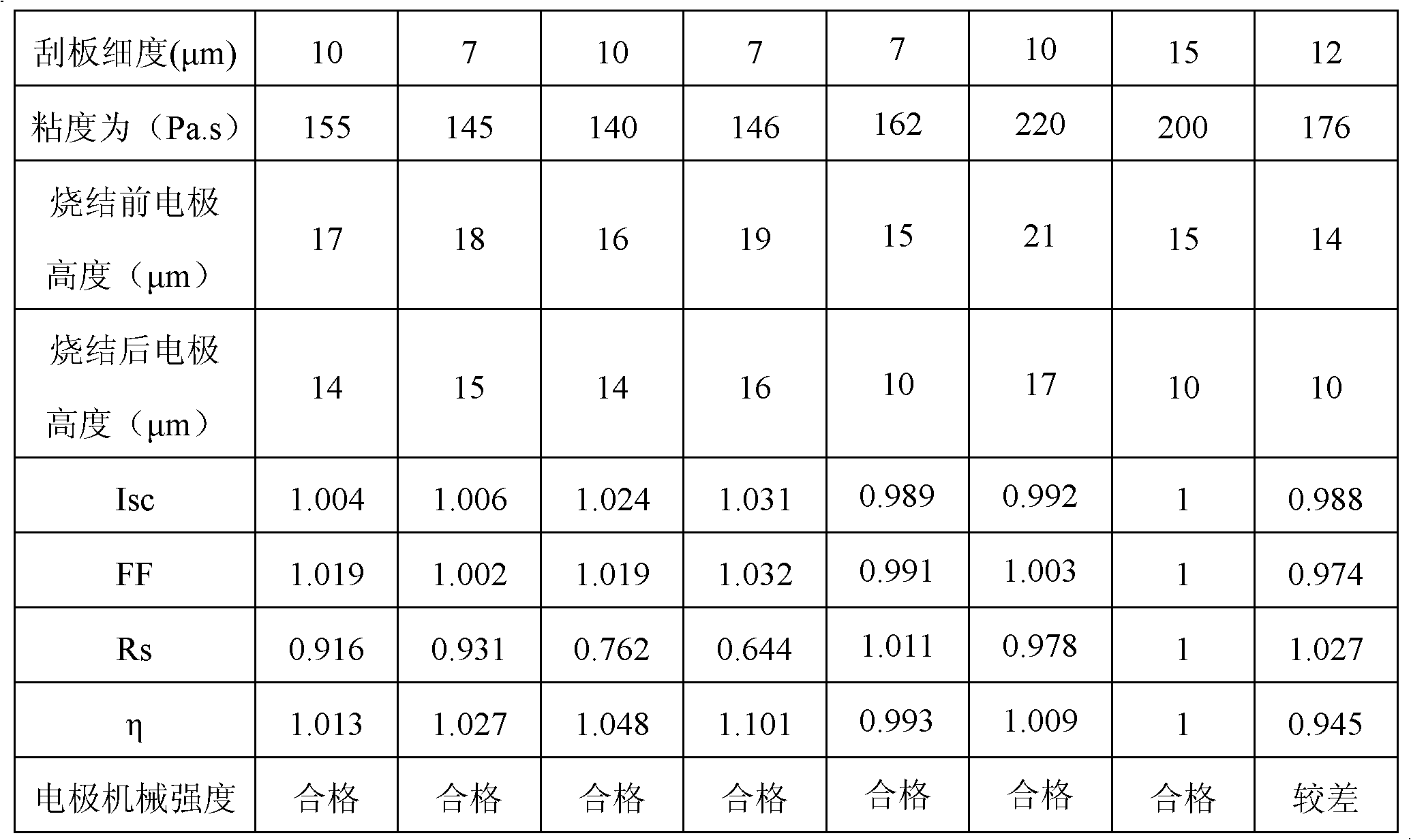

Thermoplastic elastomer material for 125-DEG C new energy automobile cable and preparation method thereof

InactiveCN106675041AImprove heat resistanceBalance of Mechanical PropertiesPlastic/resin/waxes insulatorsLiquid organic insulatorsChemistryEpoxidized soybean oil

The invention discloses a thermoplastic elastomer material for a 125-DEG C new energy automobile cable. The thermoplastic elastomer material comprises the following raw materials in parts by weight: 20-45 parts of SEBS resin, 10-30 parts of epoxidized soybean oil, 15-50 parts of polyolefin, 25-50 parts of halogen-free flame retardant, 0.5-2.5 parts of antioxidant, 0.5-3 parts of lubricating agent, 5-10 parts of compatibilizer and 0.5-1 part of peroxide, wherein the halogen-free flame retardant includes a main fire retardant and an auxiliary fire retardant; the main fire retardant is composed of organic phosphate and melamine pyrophosphate; and polyphosphoester is served as the auxiliary fire retardant. The invention also discloses a preparation method for the thermoplastic elastomer material for the 125-DEG C new energy automobile cable. The thermoplastic elastomer material prepared according to the invention has excellent comprehensive performances, such as, ageing resistance, excellent machinability, excellent mechanical property, tearing resistance, low-smoke zero-halogen flame resistance and environmental protection.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

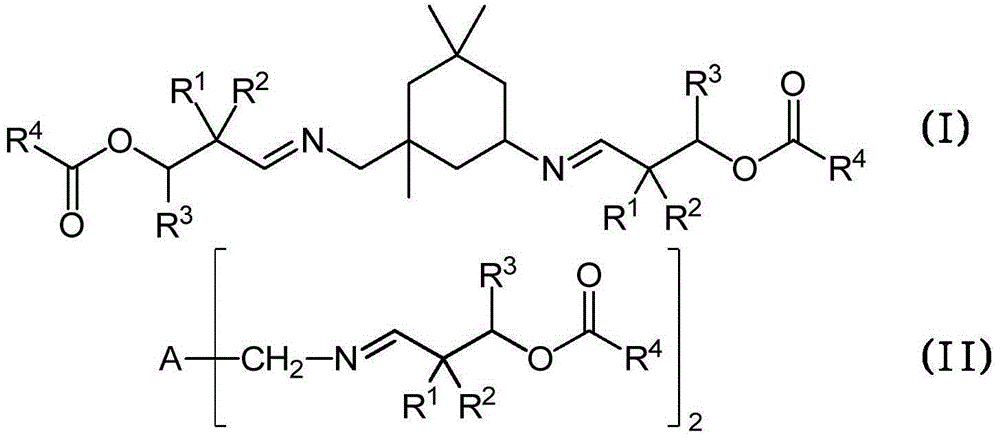

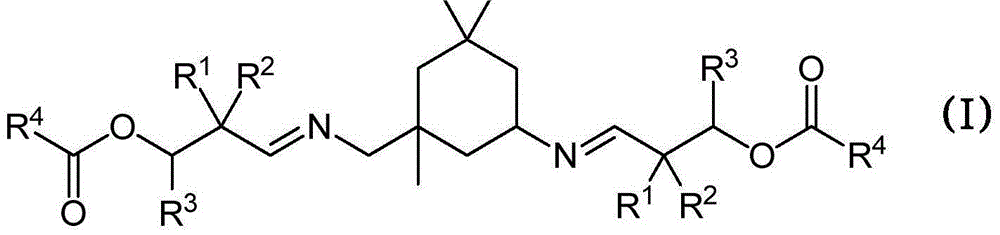

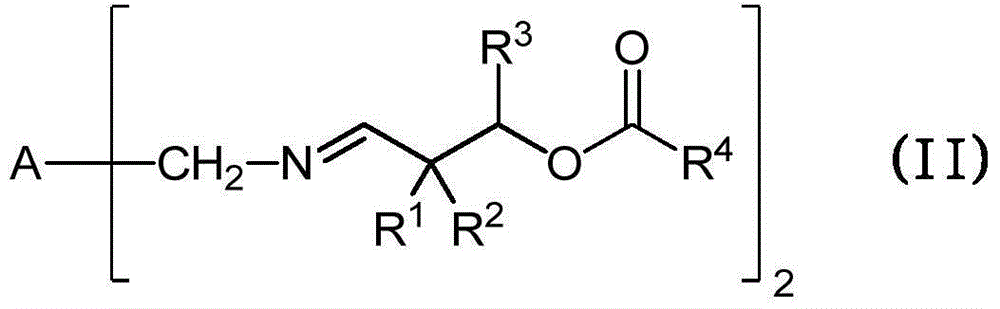

Bio-based reactive flame retardant, flame-retardant waterborne polyurethane emulsion and preparation methods of bio-based reactive flame retardant and flame-retardant waterborne polyurethane emulsion

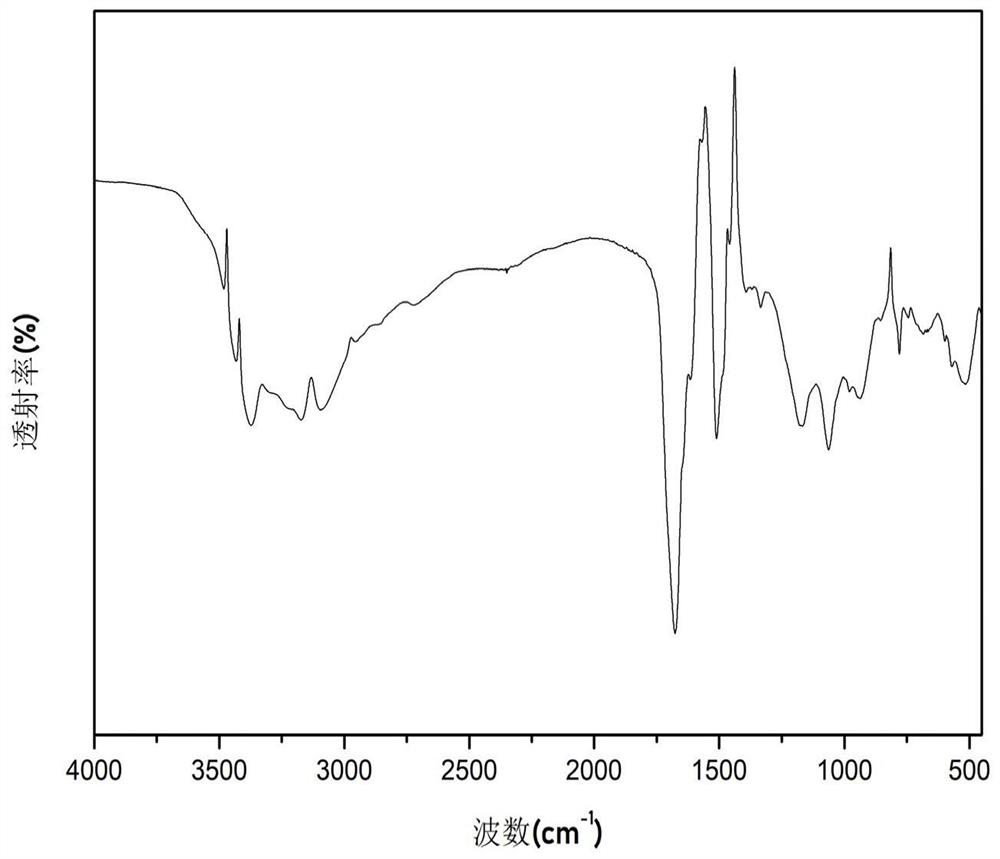

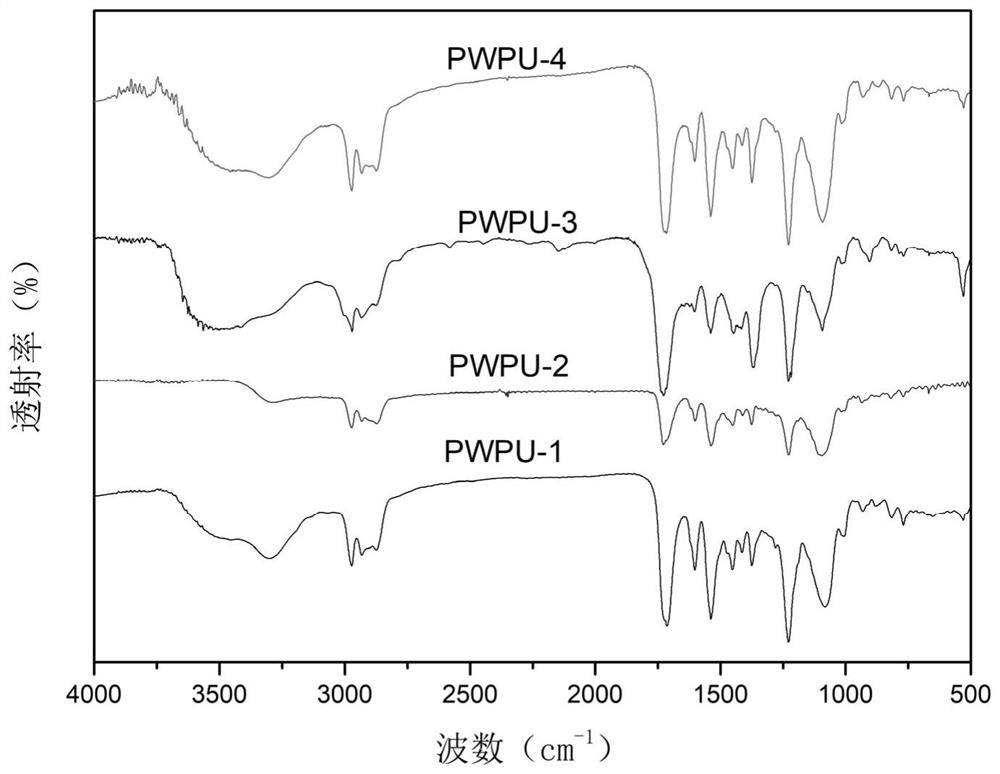

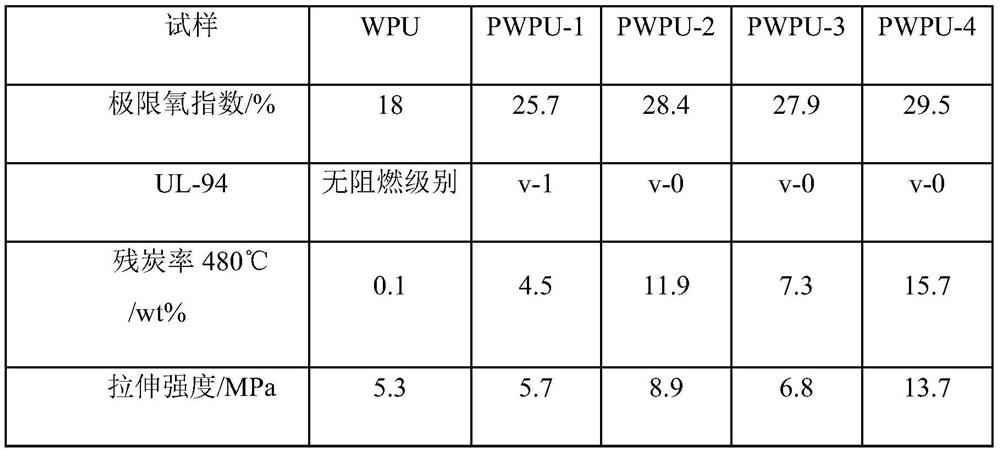

ActiveCN113354680AExcellent intrinsic flame retardant propertiesLittle impact on mechanical propertiesOrganic compound preparationGroup 5/15 element organic compoundsPolymer sciencePropanoic acid

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

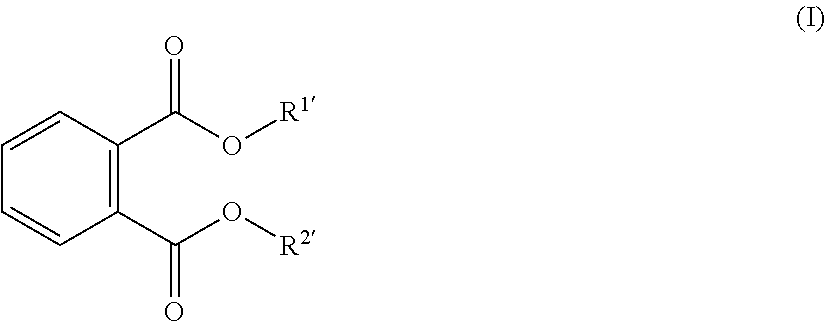

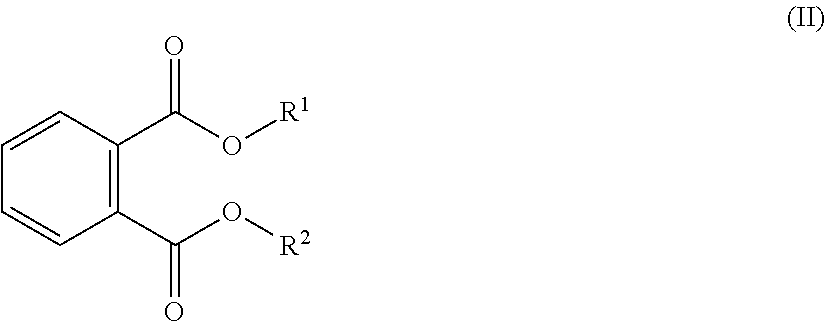

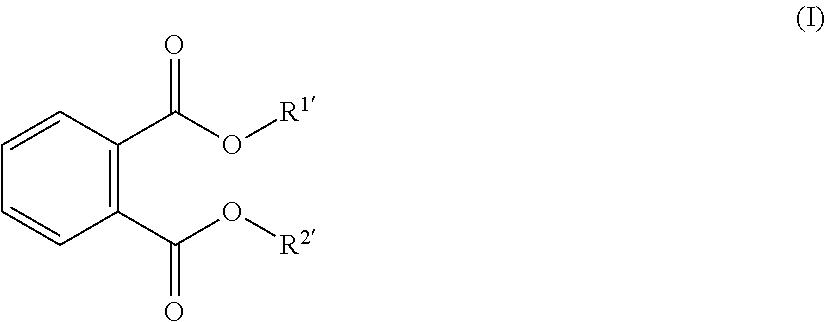

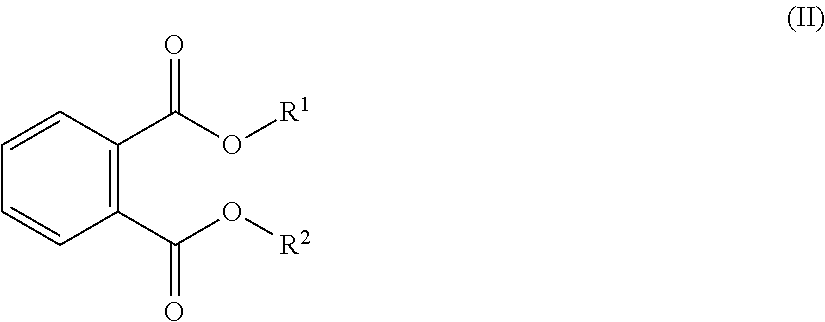

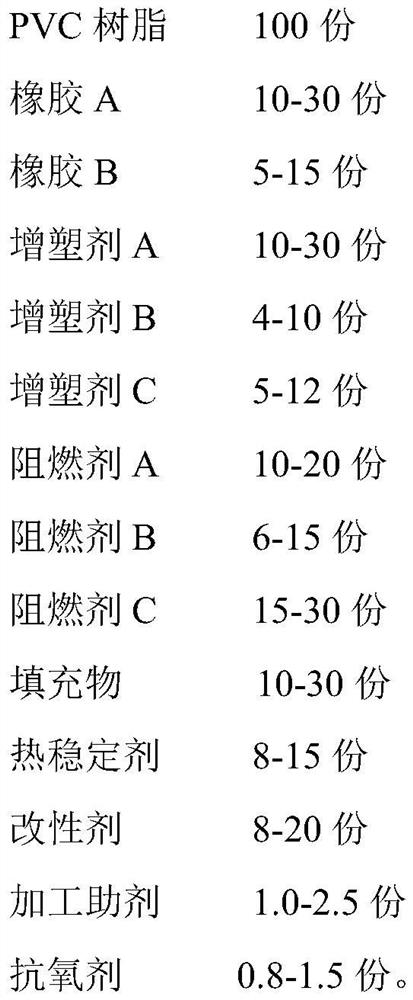

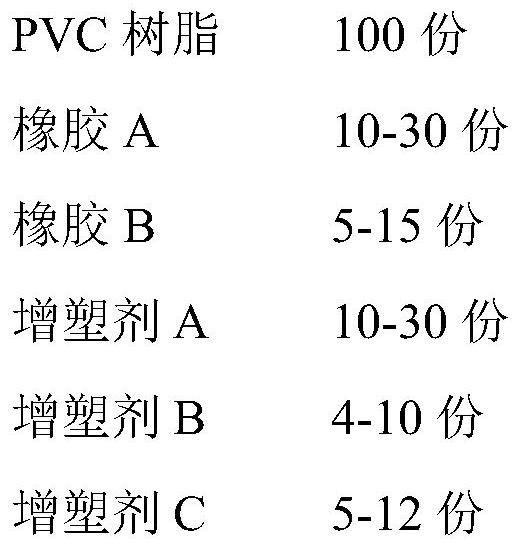

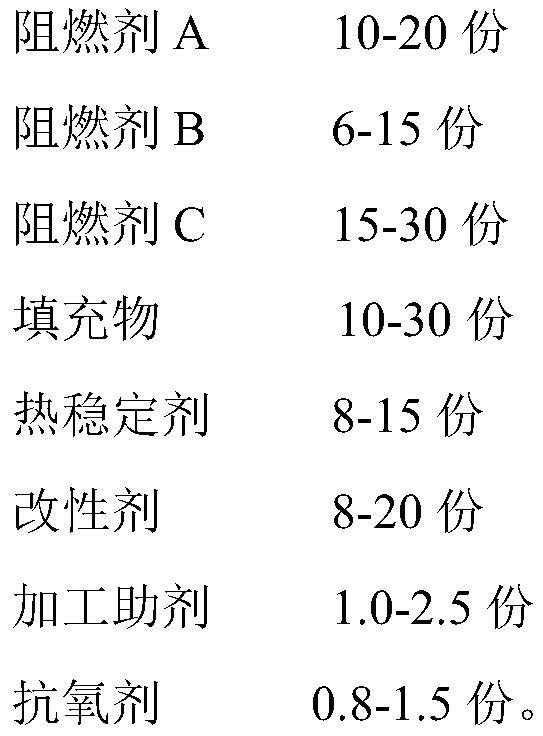

Soft oil-resistant flame-retardant polyvinyl chloride material and preparation method thereof

PendingCN112143131AGood processing performanceGood mechanical propertiesPlastic/resin/waxes insulatorsFlame resistancePolymer chemistry

The invention provides a soft oil-resistant flame-retardant polyvinyl chloride material and a preparation method thereof. The material is prepared from the following components in parts by weight: 100parts of PVC resin, 10-30 parts of rubber A, 5-15 parts of rubber B, 10-30 parts of a plasticizer A, 4-10 parts of a plasticizer B, 5-12 parts of a plasticizer C, 10-20 parts of a flame retardant A,6-15 parts of a flame retardant B, 15-30 parts of a flame retardant C, 10-30 parts of a filler, 8-15 parts of a heat stabilizer, 8-20 parts of a modifier, 1.0-2.5 parts of a processing aid and 0.8-1.5parts of an antioxidant. The polyvinyl chloride material obtained in the invention considers the balance of softness, oil resistance and flame retardance, can meet the requirements that the oxygen index reaches 36 or above, the shore hardness is 78 + / - 3 A, and IRM902# oil resistance is achieved at 90 DEG C for 168 h, and can be used for cables with the requirements for softness, high oil resistance and high flame retardance.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

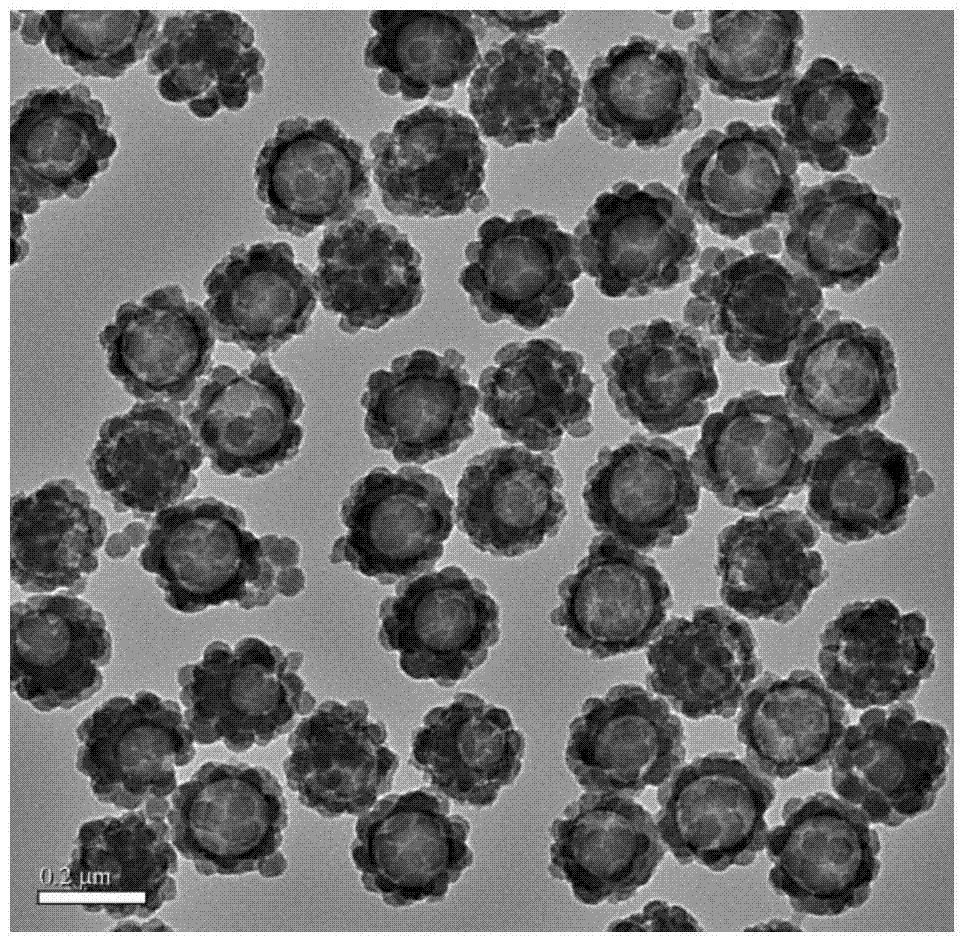

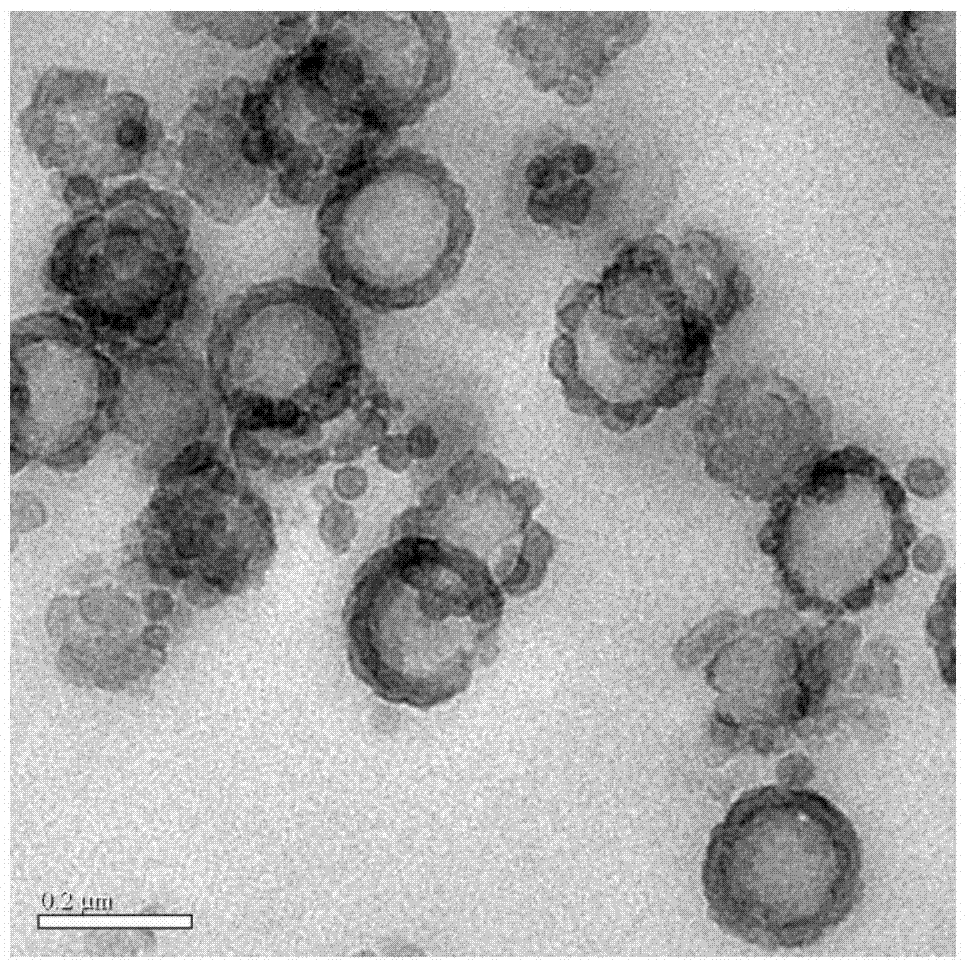

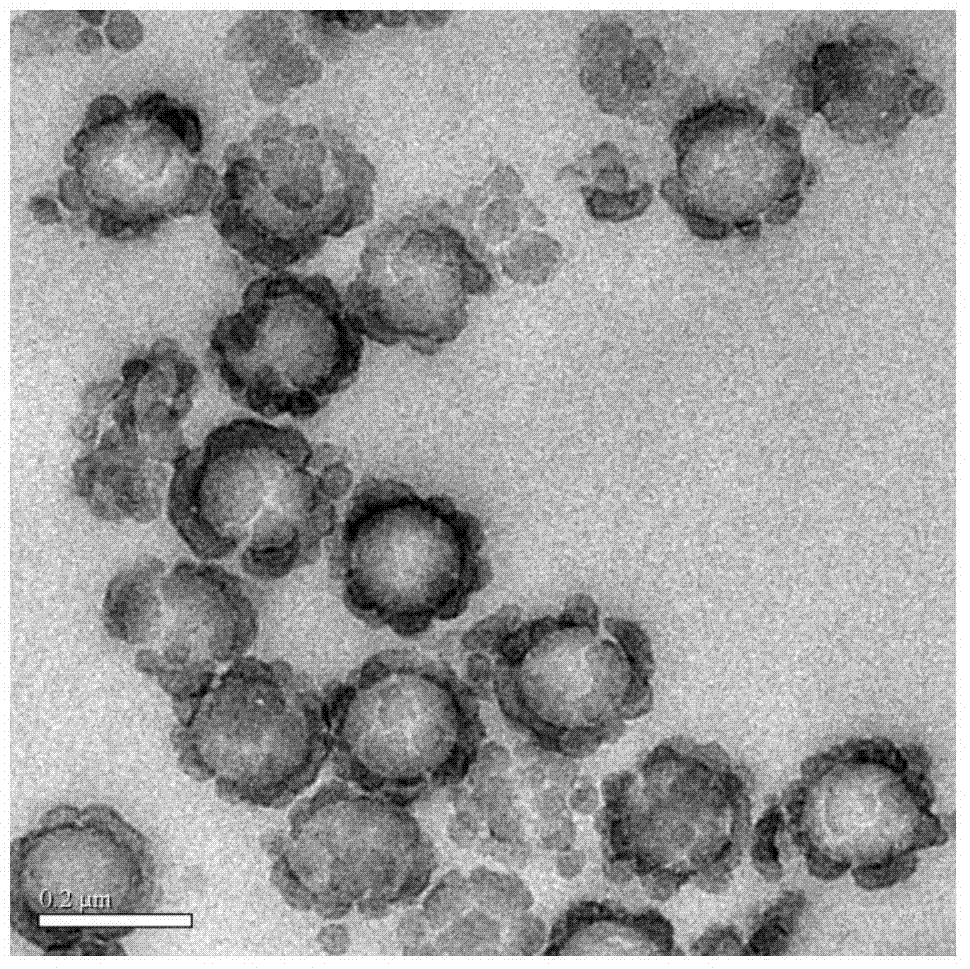

Polymer-matrix composite material and preparation method thereof

The invention discloses a polymer-matrix composite material and a preparation method thereof. The composite material comprises silicon dioxide hollow nanospheres and a polymer-matrix material, wherein the silicon dioxide hollow nanospheres are dispersed into the polymer-matrix material; the adding amount of the silicon dioxide hollow nanospheres is 0.1wt.% to 10wt.%; the preparation method of the composite material comprises the following steps: (1) preparing the silicon dioxide hollow nanospheres by a sol-gel method; (2) dispersing the silicon dioxide hollow nanospheres prepared from the step (1) into the polymer-matrix material, and forming a polymer-matrix material-silicon dioxide hollow nanosphere uniform dispersion system; (3) adding a curing agent, and solidifying the polymer-matrix material obtained from the step (2). The polymer-matrix material-silicon dioxide hollow nanosphere composite material disclosed by the invention has excellent mechanical property and acoustic damping property, and is simple in preparation method and mild in reaction condition.

Owner:HUAZHONG UNIV OF SCI & TECH

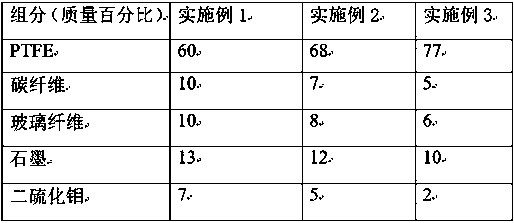

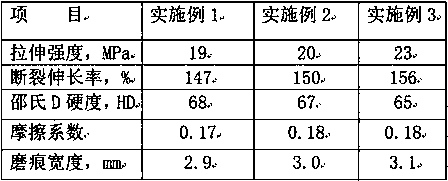

Wear-resistant PTFE composite material and preparation method thereof

InactiveCN109486069AReduce coefficient of frictionBalance of Mechanical PropertiesReciprocating motionGraphite

The invention discloses a wear-resistant PTFE composite material. The wear-resistant PTFE composite material is characterized by being prepared from the following components in percent by mass: 60-77%of PTFE, 5-10% of carbon fibers, 6-10% of glass fibers, 10-13% of graphite and 2-7% of molybdenum disulfide. The design balances the mechanical properties and friction property of the material, improves the wear resistance of the material to the maximum extent while reducing the tensile performance to the minimum extent, reduces the sliding friction coefficient of the product and improves the dimensional stability of the product effectively and prolongs the service life effectively. The formula is suitable for a sealing part which is good in wear resistance and bearing capacity or a frictionstructural part needing to reciprocate, so that the friction noise can be reduced, the grinding amount entering a circulating region is reduced, and the risk of strain breakage in assembly and use isreduced.

Owner:NANJING COMPTECH COMPOSITES CORP +1

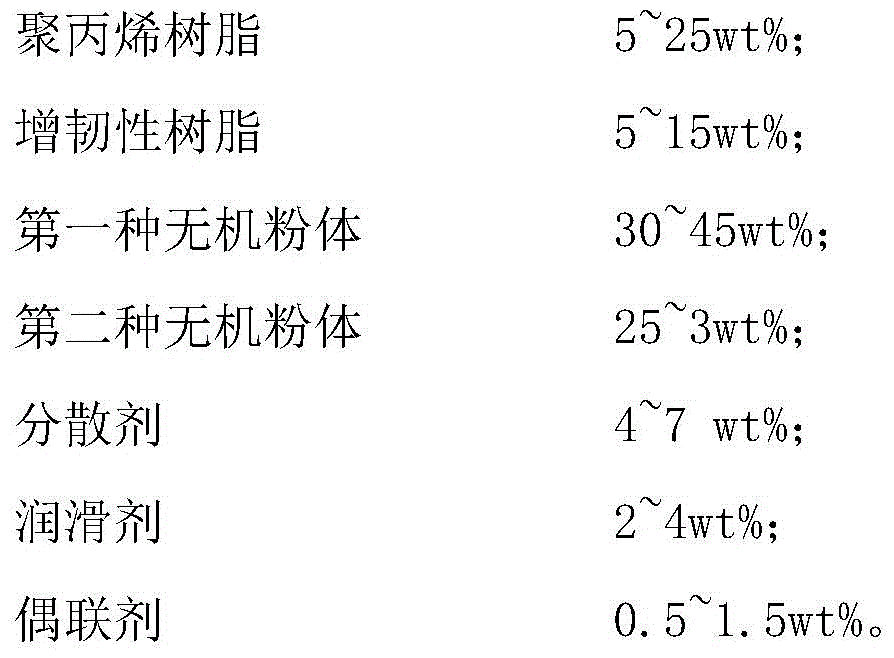

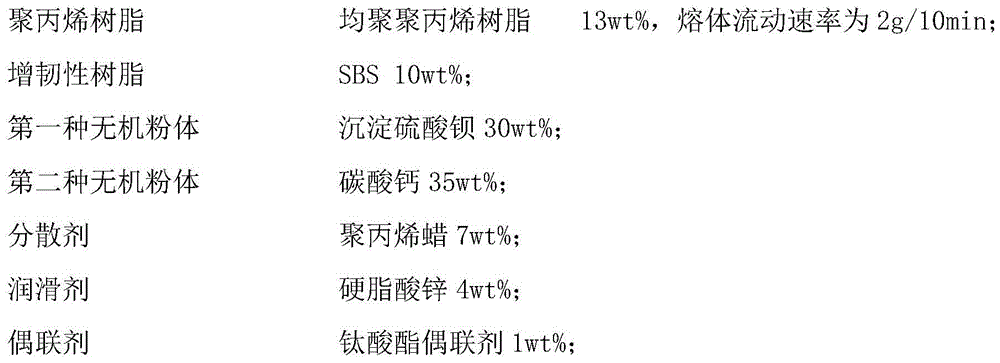

Polypropylene silencing pipe master batch, preparation method and use method therefor

InactiveCN105670110AImprove mechanical propertiesHigh impact strengthNoise reductionInjection moulding

The invention provides a polypropylene silencing pipe master batch, a preparation method and a use method therefor. The polypropylene silencing pipe master batch includes, by weight, 5-25% of polypropylene resin, 5-15% of a toughening resin, 30-45% of a first inorganic powder, 25-35% of a second inorganic powder, 4-7% of a dispersing agent, 2-4% of a lubricant and 0.5-1.5% of a coupling agent. The preparation method includes the steps of mixing and stirring the polypropylene resin, the toughening resin and the lubricant uniformly, adding the mixed components to a uniformly-stirred mixture of the two inorganic powders and the coupling agent, and adding the dispersing agent with uniform stirring, and performing extrusion and mixing, performing mould surface granule cutting, and air-cooling and sieving granules to obtain the master batch. A product, which is prepared from the polypropylene noise reduction pipe master batch and homo-polypropylene in a mixed injection moulding manner, is low in cost, is excellent in mechanical performance and high in anti-impact strength, and can adapt harsh weather conditions and complex environment demands.

Owner:CHANGZHOU HONGMEI PLASTIC MASTERBATCH

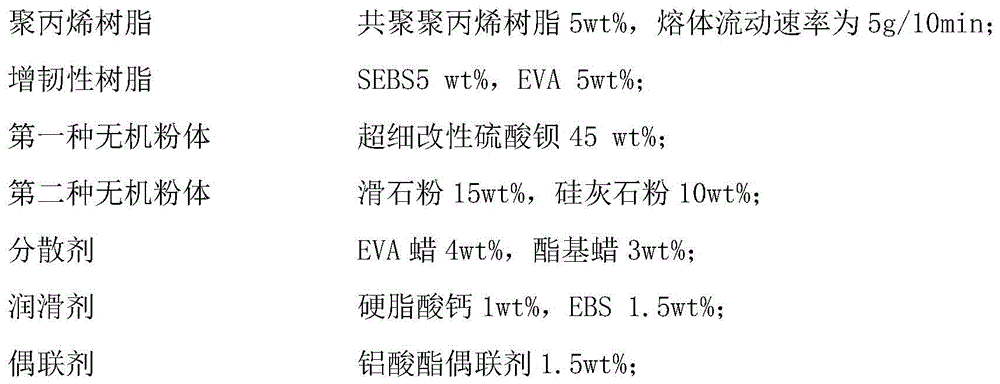

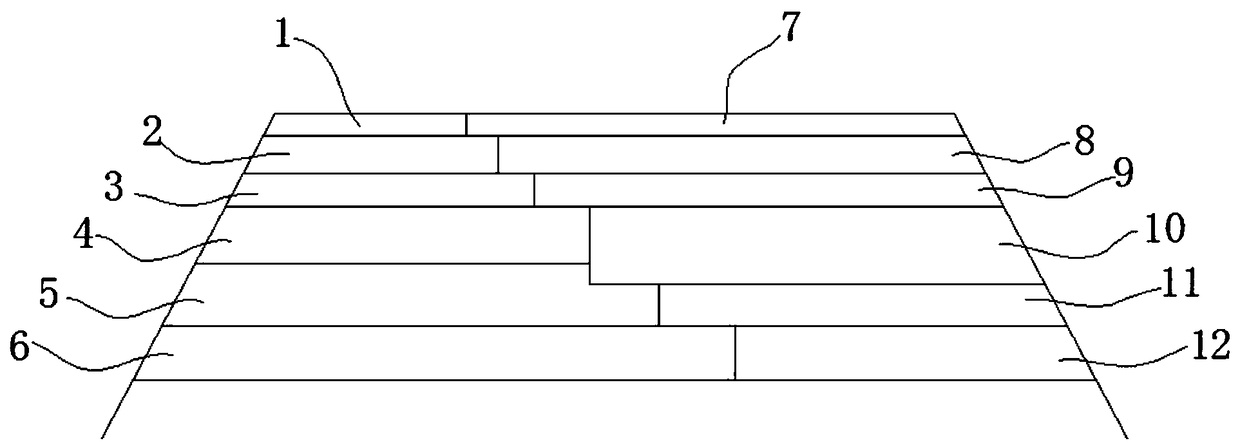

Highway widened roadbed structure and construction method thereof

The invention discloses a highway widened roadbed structure and a construction method thereof and belongs to the technical field of road engineering. From top to bottom, structural layers, corresponding to a semi-rigid old highway, of a widened new highway are an asphalt surface course, an asphalt middle surface course, an asphalt lower surface course, a graded broken stone course, a lower semi-rigid material base course and a bottom semi-rigid material base course in sequence, wherein frameworks are laid in the graded broken stone course; the frameworks are of circular ring-shaped or polygonal frame body structures; multiple layers of frameworks are laid; and the framework in each layer and the framework in an adjacent layer are partially staggered from each other. According to the highway widened roadbed structure, the mechanical property of the graded broken stone course can be effectively improved so that damages, such as reflection cracks, of the widened roadbed in service are reduced; and moreover, the highway widened roadbed structure has the advantages that the making is simple, the production cost is lower, the highway widened roadbed structure is suitable for large-scalepopularization and so on.

Owner:广东云津工程建设有限公司

Liquid-applied waterproofing membrane for roofs

InactiveCN104995226ASmall shrinkageLow odor profileRoof covering using sealantsOther chemical processesPolymer chemistryAldimine

The present invention describes a one-part moisture-curing liquid applied waterproofing membrane comprising an MDI-based polyurethane polymer and two different aldimines as blocked amine hardeners in a specific ratio range. The membrane has a low odour, a long shelf life stability, a low viscosity at low solvent content, a sufficiently long open time to allow hand application and cures fast to a solid elastic material. The liquid-applied waterproofing membrane is particularly suitable for roofing applications, possessing high strength, high elongation and good durability under outdoor wheathering conditions in a broad temperature range.

Owner:SIKA TECH AG

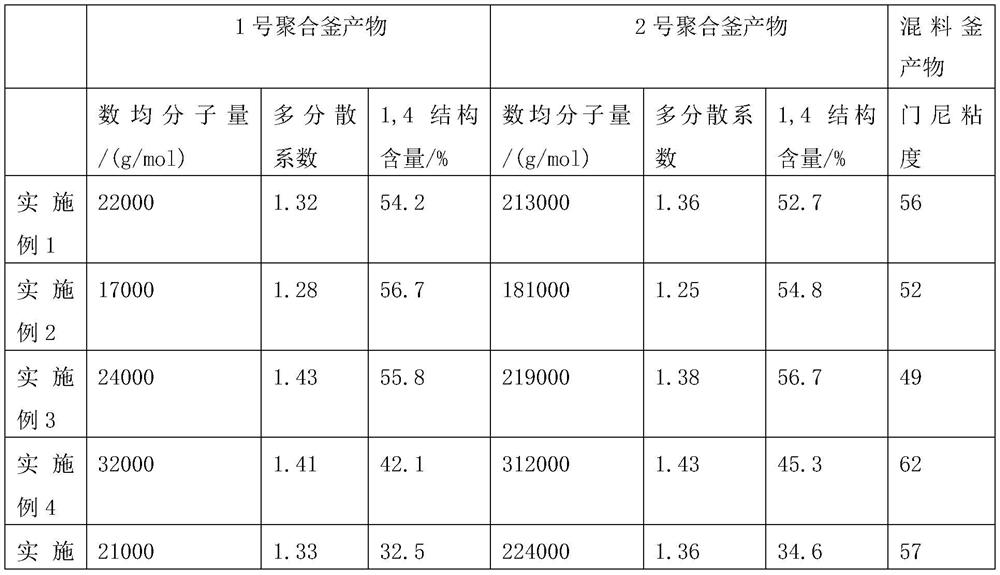

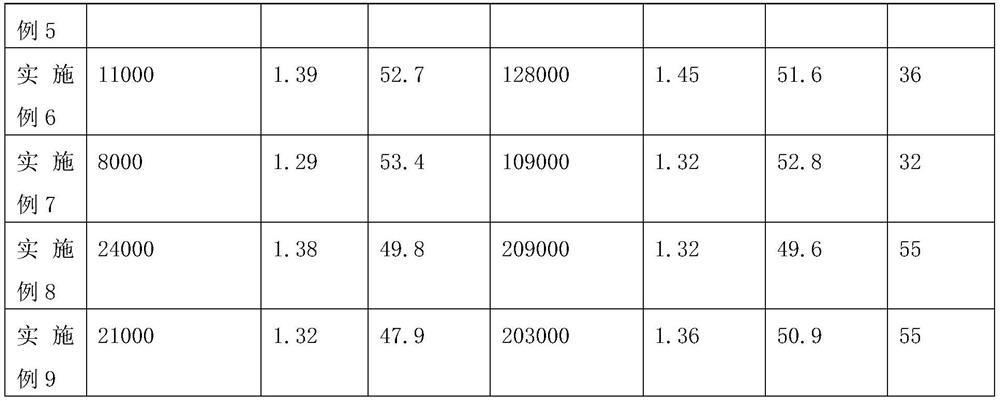

Preparation method of integrated rubber

InactiveCN112142915ALittle impact on mechanical propertiesBalance of Mechanical PropertiesButadiene DioxideN-Butyllithium

The invention discloses a preparation method of integrated rubber. The method comprises the following steps: respectively adding isoprene, styrene, butadiene, cyclohexane and a structure modifier intoa first polymerization kettle, uniformly stirring, and heating to 40-70 DEG C; respectively adding isoprene, styrene, butadiene, cyclohexane and a structure regulator into a polymerization kettle, uniformly stirring, and heating to 40-70 DEG C; respectively adding a catalyst diluents of n-butyllithium into the first polymerization kettle and a second polymerization kettle, and respectively addingisopropanol into the first polymerization kettle and the second polymerization kettle to terminate the reaction after the reaction time is up; respectively obtaining a low-molecular-weight glue solution and a high-molecular-weight glue solution in the first polymerization kettle and the second polymerization kettle; transferring the glue solutions in the first polymerization kettle and the secondpolymerization kettle to a mixing kettle according to a mass ratio of 0.05-0.2:1, heating to 40 DEG C, and stirring for 20 min; and pouring the glue solution in the mixing kettle into absolute ethylalcohol, carrying out flocculation, and then drying to obtain the filling liquid glue type integrated rubber. The integrated rubber prepared by the method has relatively low Mooney viscosity.

Owner:北京戍光科技有限公司

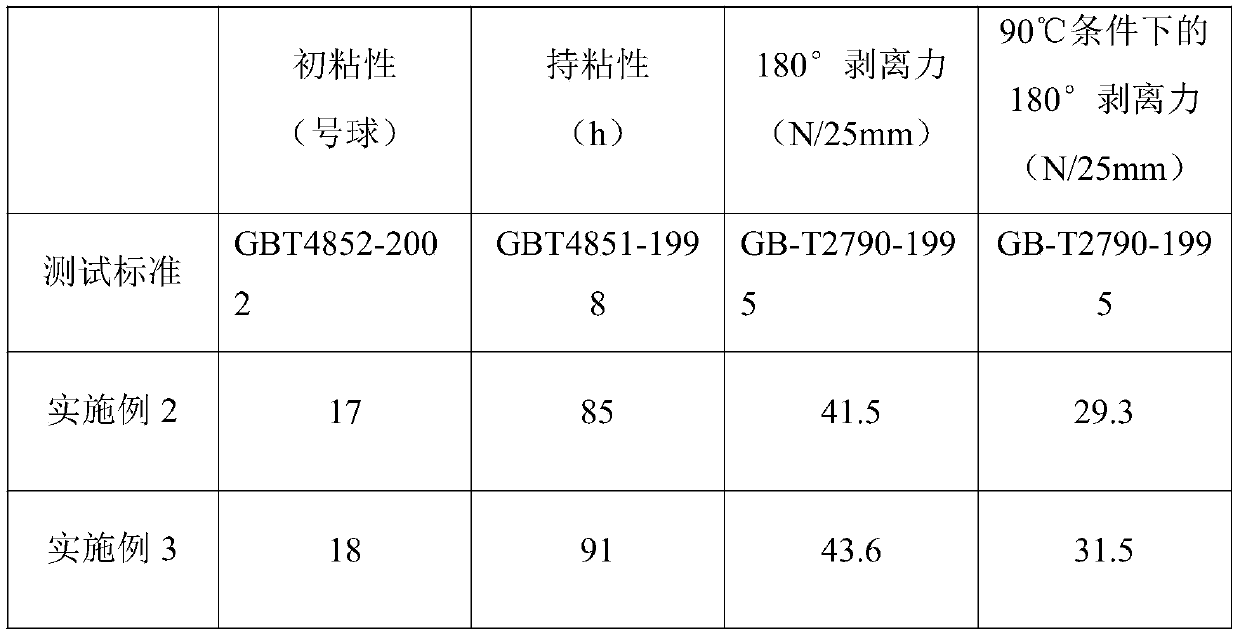

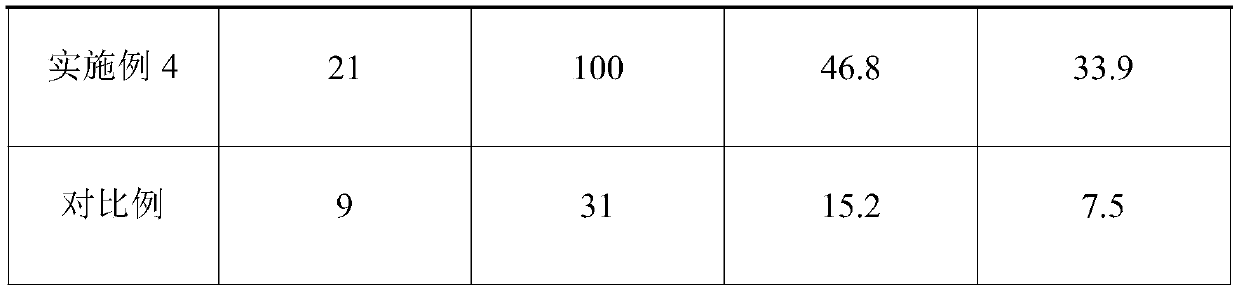

Pressure sensitive adhesive with high stripping force and preparation method thereof

ActiveCN110041860AImprove peel forceGood initial adhesionEster polymer adhesivesRosin adhesivesIsooctyl acrylate1-dodecanethiol

The invention discloses a pressure sensitive adhesive with the high stripping force. The pressure sensitive adhesive is prepared from the following raw materials, in parts by weight: 45-55 parts of 2-ethylhexyl acrylate, 4-9 parts of acrylamide, 40-50 parts of butyl acrylate, 7-12 parts of hydroxypropyl acrylate, 3-7 parts of methyl acrylate, 70-90 parts of ethyl acetate and butanone with the massratio being 1 to 1, 1.3-2.2 parts of azodiisobutyronitrile, 0.6-1 part of 1-dodecanethiol and 3-5 parts of tuluene diisocynate. The pressure sensitive adhesive with the high stripping force has the good initial adhesion and persistent adhesion, the 180-degree stripping force is high and can be held at the temperature of 90 DEG C, and the pressure sensitive adhesive can adhere firmly, and has thegood anti-plasticizer property and temperature resistance. No benzene and methylbenzene serves as solvents in the synthesis process of the pressure sensitive adhesive, and the pressure sensitive adhesion is low in toxicity, environmentally friendly, and wide in application range.

Owner:浙江铂淳新材料股份有限公司

Solvent-free silicon-based ablation-resistant material

The invention provides a solvent-free silicon-based ablation-resistant material. The solvent-free silicon-based ablation-resistant material comprises 100 parts of liquid silicone resin, 0 to 20 parts of carbon fibers, 0 to 100 parts of silicon carbide, 0 to 10 parts of silica, 0 to 50 parts of metal oxide or silicate and 1 to 5 parts of a curing agent. The invention overcomes the problem that conventional silicone resin containing benzene solvents poses harm to human beings and pollutes environment when used as a matrix material for ablation of a solid rocket engine, the solvents need to be removed in the process of material molding and the period of material preparation is long; and the ablation-resistant material provided by the invention has high heat stability, good antioxidation performance and good ablation resistance, can realize casting or compression molding at normal temperature and is applicable to structural protection of aircrafts with complex structures and severe ablation.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com