Polypropylene silencing pipe master batch, preparation method and use method therefor

A polypropylene and polypropylene resin technology, applied in the field of polypropylene material and its preparation, can solve the problems of low mechanical properties, low tensile strength, poor impact strength, etc., achieve uniform texture, improve mechanical properties and impact strength , to achieve a balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

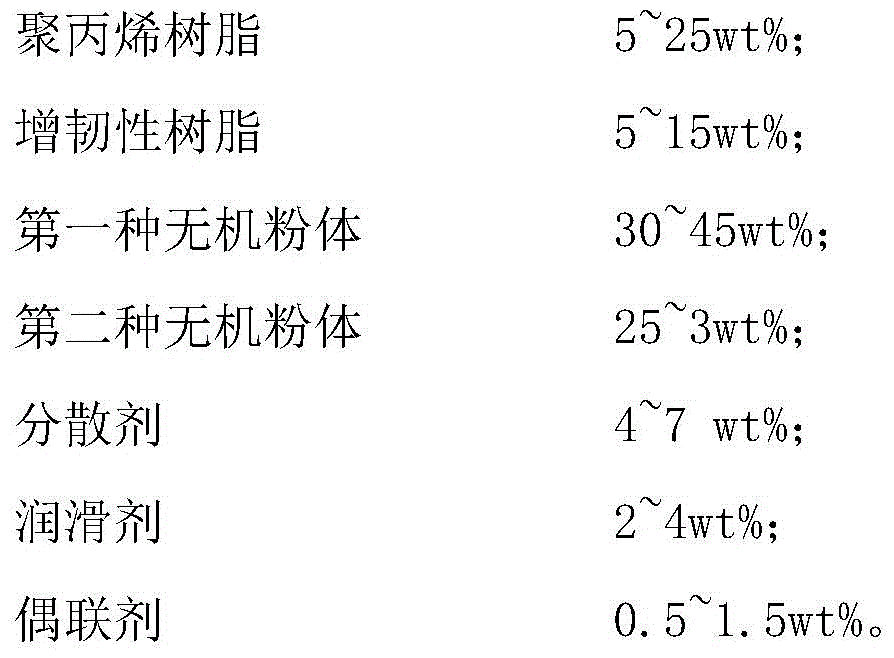

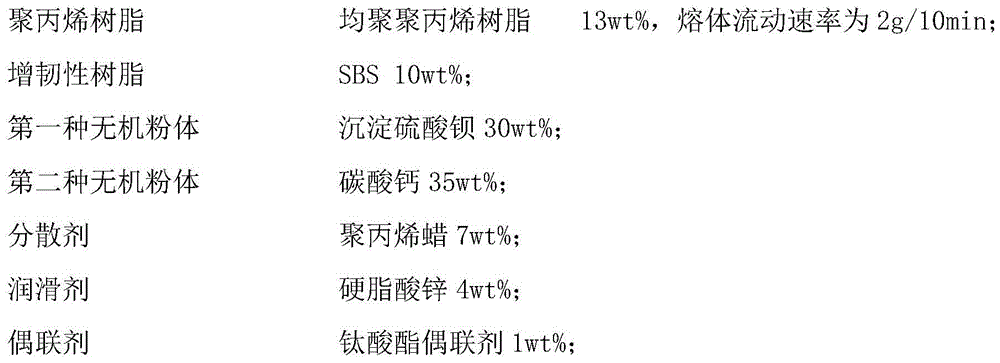

[0025] (1) Weigh raw materials according to the following mass fractions

[0026]

[0027] (2) Homopolypropylene resin, SBS and zinc stearate are dropped into a high-speed mixer, and mixed evenly at a high speed;

[0028] (3) Put the precipitated barium sulfate, calcium carbonate and titanate coupling agent into the high-speed mixer, and mix evenly at high speed;

[0029] (4) The mixed powder obtained in step (3) is added to the powder obtained in step (1), and polypropylene wax is added simultaneously, and mixed uniformly in a high-speed mixer;

[0030] (5) Extrude and knead with a twin-screw extruder, cut into pellets on the die surface, and then undergo air cooling and sieving to obtain the finished product 1-1.

Embodiment 2

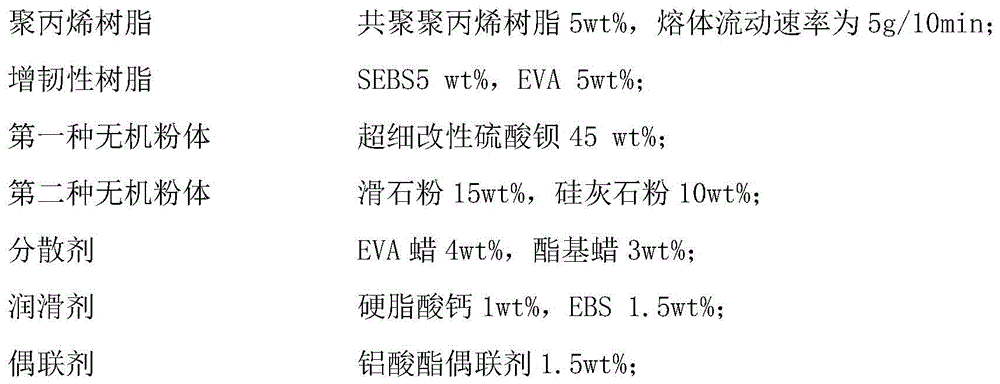

[0032] (1) Weigh raw materials according to the following mass fractions

[0033]

[0034] (2) Put copolymerized polypropylene resin, SEBS, EVA and calcium stearate, EBS into high-speed mixer, and mix evenly at high speed;

[0035] (3) Put super modified barium sulfate, talc powder, wollastonite powder and aluminate coupling agent into the high-speed mixer, and mix evenly at high speed;

[0036] (4) join the mixed powder that step (3) obtains in the powder that step (1) obtains, add EVA wax, ester-based wax simultaneously, mix in high-speed mixer;

[0037] (5) Extrude and knead with a twin-screw extruder, cut into pellets on the die surface, and then undergo air cooling and sieving to obtain the finished product 1-2.

Embodiment 3

[0039] (1) Weigh raw materials according to the following mass fractions

[0040]

[0041] (2) Homopolypropylene resin, EPDM, EPM, magnesium stearate, and erucamide are put into a high-speed mixer, and mixed evenly at high speed;

[0042] (3) Put barite powder, talcum powder and silane coupling agent into the high-speed mixer, and mix evenly at high speed;

[0043] (4) The mixed powder obtained in step (3) is added to the powder obtained in step (1), and polypropylene wax and EVA wax are added simultaneously, and mixed uniformly in a high-speed mixer;

[0044] (5) Extrude and knead with a twin-screw extruder, cut into pellets on the die surface, and then undergo air cooling and sieving to obtain finished products 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com